Stress transfer control technology for fracturing weak structural bodies in subgrade dynamic pressure roadways

-

摘要:

为了满足煤矿安全生产的需要,许多巷道都会布置在煤层底板中,如部分运输大巷、排水巷道、瓦斯抽采巷道等。采动应力容易造成底板巷道围岩应力升高,加剧底板巷道围岩变形,造成支护永久失效、顶板下沉、巷道底鼓、两帮收敛等破坏。针对此,提出了在应力传递路径上实施水力压裂,在指定的区域制造出一定空间形态的水压裂缝网,形成压裂弱结构体,实现区域范围内的应力转移,从而降低巷道区域范围内的应力,控制巷道的围岩稳定性的控制技术,并通过理论分析及现场工程验证等方式,揭示了底板动压巷道压裂弱结构体应力转移的力学机制,建立了相应的力学模型,对压裂弱结构体的合理位置、范围等影响因素进行了求解。得出:①压裂弱结构体使局部应力场发生明显变化,出现应力升高区和应力降低区,应力降低区主要分布在弱结构体与采动应力连线的方向上,主要集中在一个拱形的范围内;由于膨胀效应,在与应力来源垂直的方向上产生应力集中,出现应力升高区。②最大主应力变化幅度与压裂弱结构体的长轴长L、短轴长H、到巷道的距离P、与巷道连线的水平夹角β、压裂层的强度C及内摩擦角α、压裂的损伤变量D等有关。其中到巷道的距离P对卸压效果影响最大,损伤变量D对卸压效果影响最小。③采用提出的计算方法设计了淮北矿业集团袁店一矿的103运输集中巷的卸压方案,工程应用结果表明,底板动压巷道变形速率明显减缓,验证了底板强动压巷道压裂弱结构体应力转移模型的合理性。

Abstract:In order to meet the needs of safe production in coal mines, many roadways are arranged in the bottom plate of coal seams, such as part of transportation alleys, drainage roadways, and gas extraction roadways. The mining stress generated by the working face causes the stress increase of the surrounding rock of the floor roadway through the transmission of the floor rock strata. It exacerbates the deformation of the surrounding rock of the floor roadway, which is easy to cause permanent support failure, roof sinking, dropsy at the bottom of the roadway, convergence of the two gangs, and other damages. In response to this, a control technology is proposed to implement hydraulic fracturing in the stress transfer path, creating a network of hydraulic fractures with a certain spatial pattern in the designated area, forming a fractured weak structural body, realizing stress transfer within the area, thus reducing the stress within the area of the roadway, and controlling the stability of the perimeter rock of the roadway, and through theoretical analysis and field engineering verification, the mechanical mechanism of stress transfer of weak structures in floor dynamic pressure roadway fracturing is revealed, the corresponding mechanical model is established, and the influence factors such as reasonable location and range of weak structures are solved. The results show that: ① Fracturing weak structure causes obvious changes in local stress field, and there are stress increasing zone and stress decreasing zone, and the stress decreasing zone is mainly distributed in the direction of the connection between weak structure and mining stress, mainly concentrated in an arch range; Due to the expansion effect, the stress concentration occurs in the vertical direction of the stress source, and the stress rise area appears. ② The magnitude of maximum principal stress change is related to the long axis L, short axis H, distance P to the roadway, horizontal angle β to the roadway line, strength C and internal friction angle α of the fractured layer, and damage variable D of the fracture in the weak structural body of the fracture. ③ The proposed method is used to design the pressure relief scheme of 103 belt concentrated roadway in Yuandian No. 1 Mine of Huaibei Mining Group. The engineering application results show that the deformation rate of roadway under dynamic pressure of floor is significantly reduced, and the rationality of the stress transfer model of fractured weak structure in roadway under strong dynamic pressure of floor is verified.

-

0. 引 言

随着煤炭开采深度的增加,地应力水平逐渐增加,开采扰动所处的深部环境进一步加剧了采动影响,造成巷道围岩普遍出现难以控制的大变形,严重制约矿井的安全生产[1-3]。目前我国常用的人工卸压措施有钻孔、爆破、水力压裂等方法[4-5]。钻孔卸压方法具有工艺简单、施工方便的优点,但是存在工程量大、卸压深度受限、密集钻孔破坏支护的整体性等缺点[6-7]。爆破卸压法曾广泛用于矿山岩体维护,具有工艺简单、可控范围较大等特点,但是由于爆破易产生有毒有害气体,对生产工序影响较大,尤其是在高瓦斯矿井使用限制较多[8-10]。水力压裂通过大量高压水压裂软化岩体,弱化岩体的强度,改变其完整性。相比爆破卸压,水力压裂具有扰动小、工程量少、安全性高等特点,近些年逐渐开始应用于围岩控制方面[11-12]。

国内外学者对水力压裂在围岩控制方面的应用进行了广泛的研究:CHANG等[13]发现水力压裂切顶卸压使巷道围岩变形破坏程度减小,围岩完整性提高。ZHANG等[14]对沿空留巷水力压裂切顶的力学模型和卸压机制进行了研究,发现通过水力压裂的方法可有效改善工作面端头的受力环境。CHEN等[15]分析了坚硬顶板条件下孤岛煤柱承压区和塑性断裂区的演化机理,提出了主动切顶改变煤柱应力集中的技术。杨欢等[16]通过分段水力压裂超前弱化关键岩层的方法有效破坏岩体的完整性,转移应力传递路径均布集中应力。程利兴[17]针对千米深井高应力巷道围岩大变形水力压裂应力转移机理进行了研究。刘江伟等[18-19]提出利用悬顶弯曲变形产生的附加水平拉应力进行顶板切割和应力消除。吴拥政[20]提出了通过定向水力压裂技术转移护巷煤柱高采动应力。刘长友等[21-22]阐释了人工裂化煤岩体的弱结构体特征,提出了弱结构体应力转移理论框架。

但目前多以水力裂缝扩展切断坚硬顶板的机制卸压,水力压裂弱化岩层强度进行应力转移卸压尚处于起步阶段,卸压机理尚未完全明确,卸压方案与参数设计主要依靠经验,没有形成卸压法的科学性、合理性和准确性[23–28]。基于此,以淮北矿业股份有限公司袁点一井煤矿为工程背景,结合动压巷道卸压原理及人工压裂弱结构体的理论[18,29-30],提出以人工压裂的方式在应力传递途径上形成压裂弱结构体,通过调整定量参数改变局部应力场的分布,使底板巷道处于应力降低区中,实现底板巷道卸压护巷的目的,可为类似条件下深部巷道围岩稳定控制提供理论支撑。

1. 底板动压巷道变形特征和失稳机制

1.1 工程概况

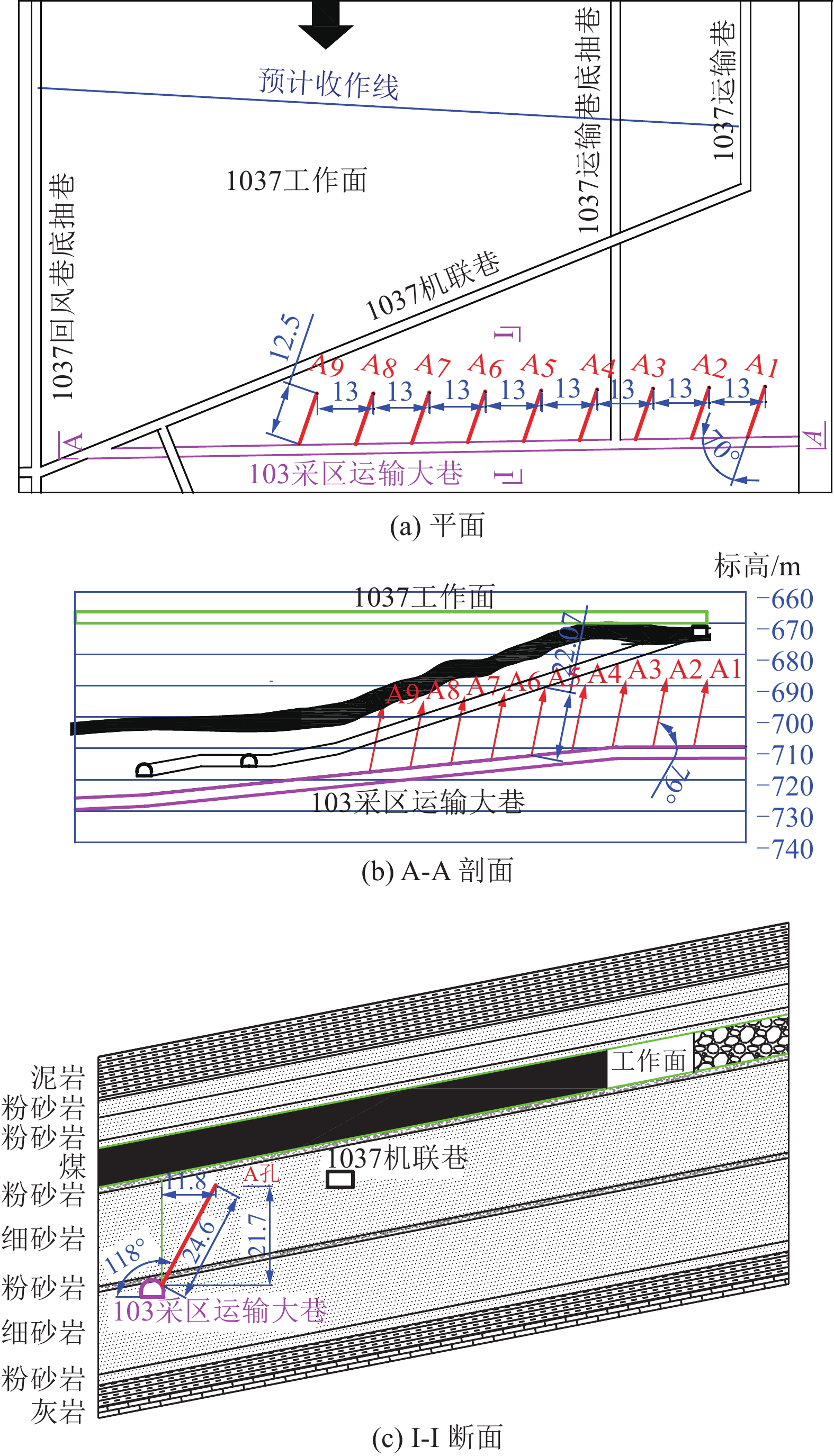

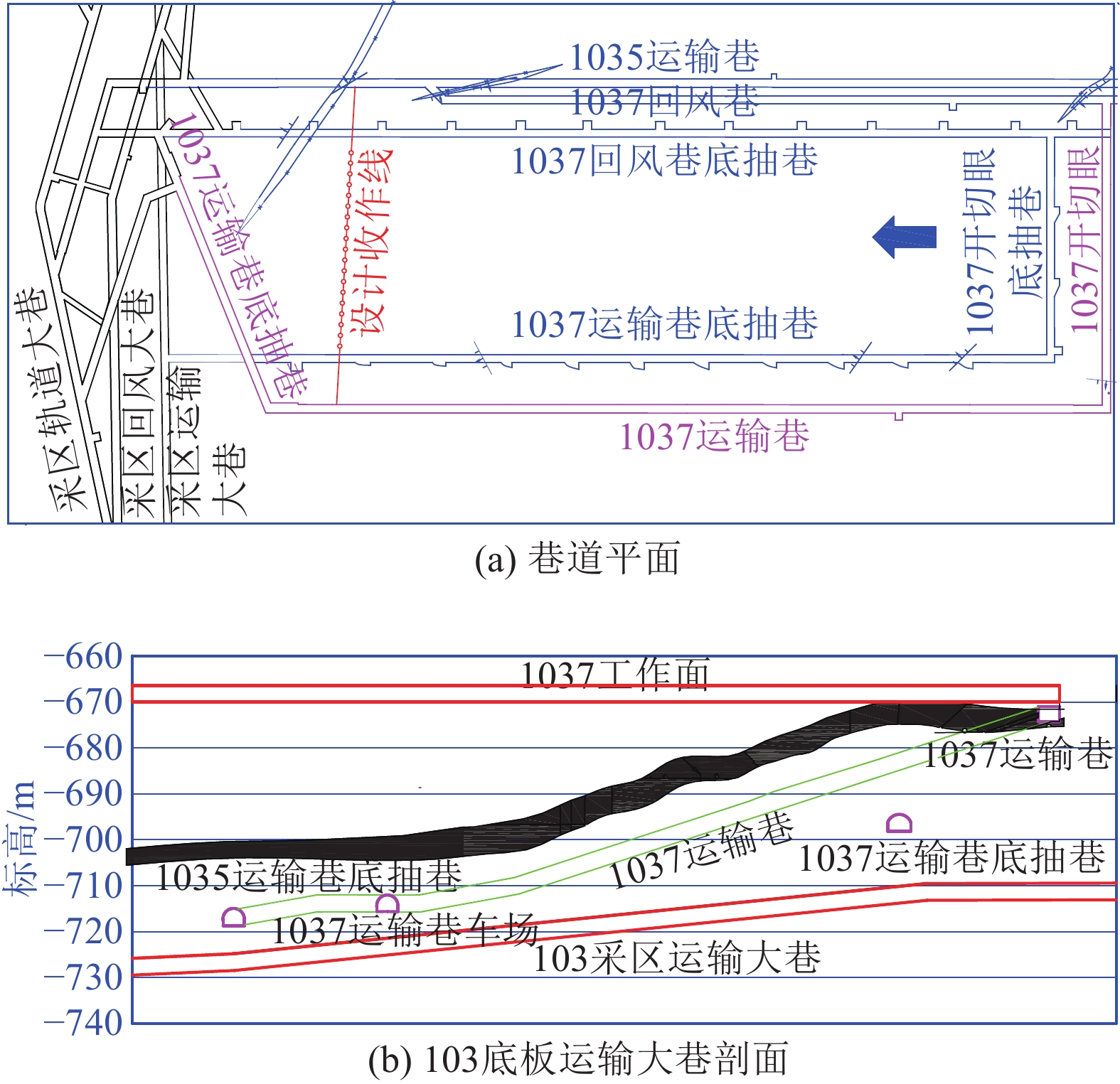

淮北矿业股份有限公司袁店一矿设计产量为1.8 Mt/a。如图1所示,1037工作面位于一水平103采区,地面标高+25.9~+27.9 m;工作面标高−635.6~−722.8 m,平均埋深为707 m;井下位置南与1035工作面相邻;北靠近aF1(∠55°~70° H=260~310 m)断层;西至aF12(∠50°~60° H=0~8 m)和NF155(∠50°~60° H=0~5 m)断层;东接103采区3条大巷。

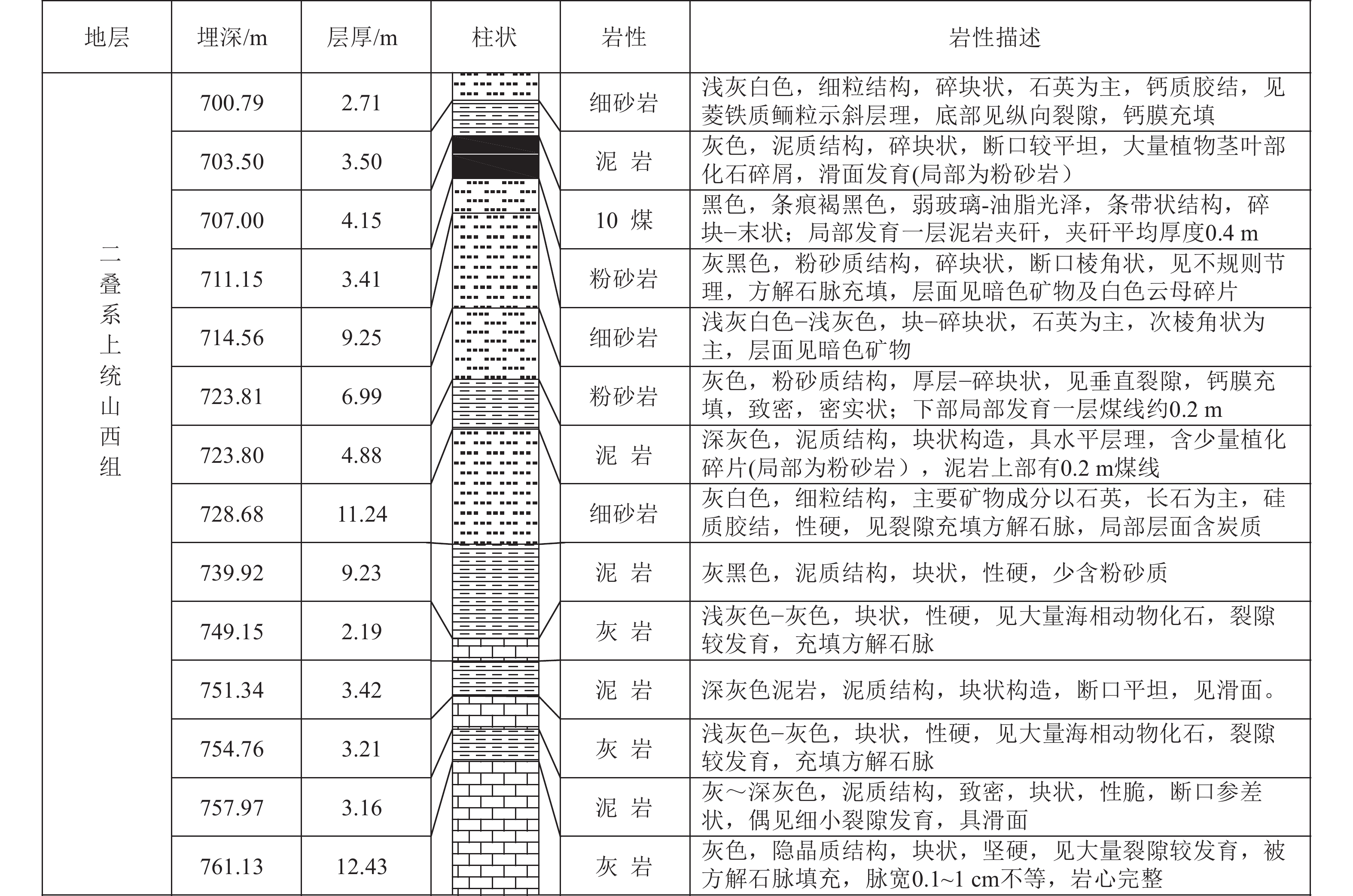

工作面综合柱状如图2所示,1037工作面10号煤层赋存较稳定,煤层平均厚度4.15 m。工作面煤层倾角为2°~19°,平均10°。煤层结构简单,工作面局部发育1~2层夹矸,夹矸为泥岩或碳质泥岩,总厚度为0.49~1.12 m,平均0.76 m。

1.2 开采技术条件

1037工作面设计走向长度458~500 m,平均479.3 m,倾向长度184 m。采用倾向长壁综合机械化采煤法,工作面采用ZY10000/26/56液压支架。根据测定,工作面超前应力影响范围为煤壁前20 m,距离煤壁5 m时应力最高,应力升高系数为2.5,正常应力为18 MPa。1037工作面设计终采线到103采区运输大巷的水平距离96~104 m,平均100 m;垂直距离为40~60 m,平均距离50 m。103集中运输大巷净宽×净高=4.6 m×3.6 m,采用29U钢+锚网索喷支护;锚杆使用ø22 mm×2 800 mm左旋螺纹钢锚杆,间排距800 mm×800 mm;锚索使用ø22 mm×6 200 mm钢绞线,间排距1 600 mm×1 600 mm。

1.3 深部底板巷道群变形特征和失稳机制

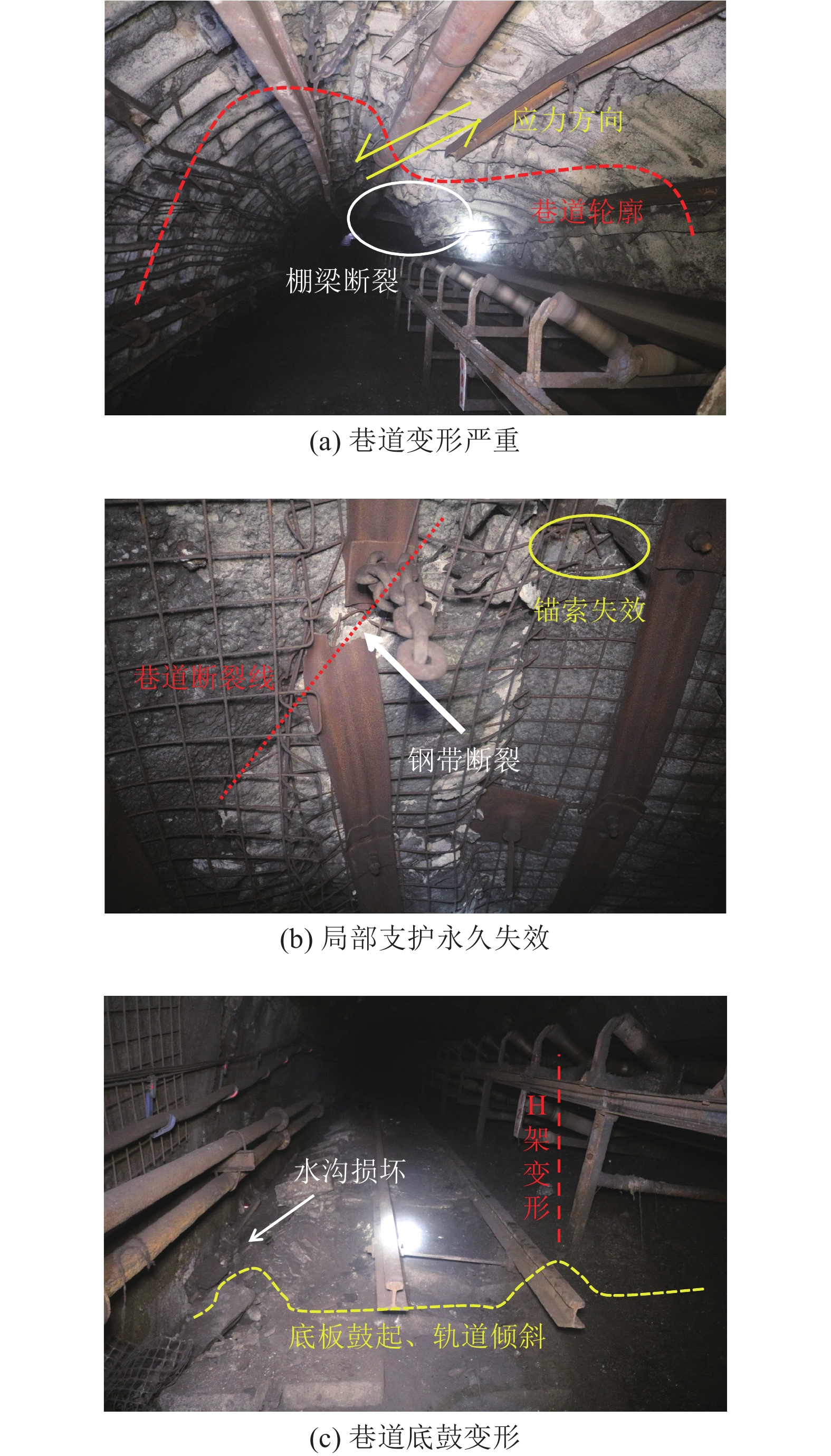

随着1037工作面推进,工作面的超前支承应力及底板的高应力影响范围随之前移,通过底板岩层作用到巷道上,包括:底板1037运输联络巷、103采区运输大巷、103采区回风大巷,表现出典型的深部底板巷道变形特征:如图3所示,巷道下沉速度快,顶底板移近量大,巷道轮廓变形严重,29U型钢棚断裂,受到的应力比较集中。如图3b所示,巷道出现锚杆索支护失效,W型钢带受压折断,钢筋网片连接点开裂等情况,局部支护永久失效,巷道顶板出现明显的开裂线。如图3c所示,巷道底板臌起,沿线水沟受压变形破坏,轨枕、H架等弯曲变形。

由图3a可知,巷道右侧与工作面的距离更近,巷道先于左侧变形,且变形更加剧烈。这说明采动应力传递路径由远及近、由上向下。结合图2分析可知,103底板巷道变形失稳的原因一方面是随着1037工作面的推进,采动造成的超前支撑力逐渐前移,另外一方面是底板岩层中含有2层较厚的细砂岩层,由于细砂岩硬度高、弹性模量大,作为似弹性体将采动应力极大的传递到底板巷道上,使巷道围岩受高应力挤压断裂、失稳。

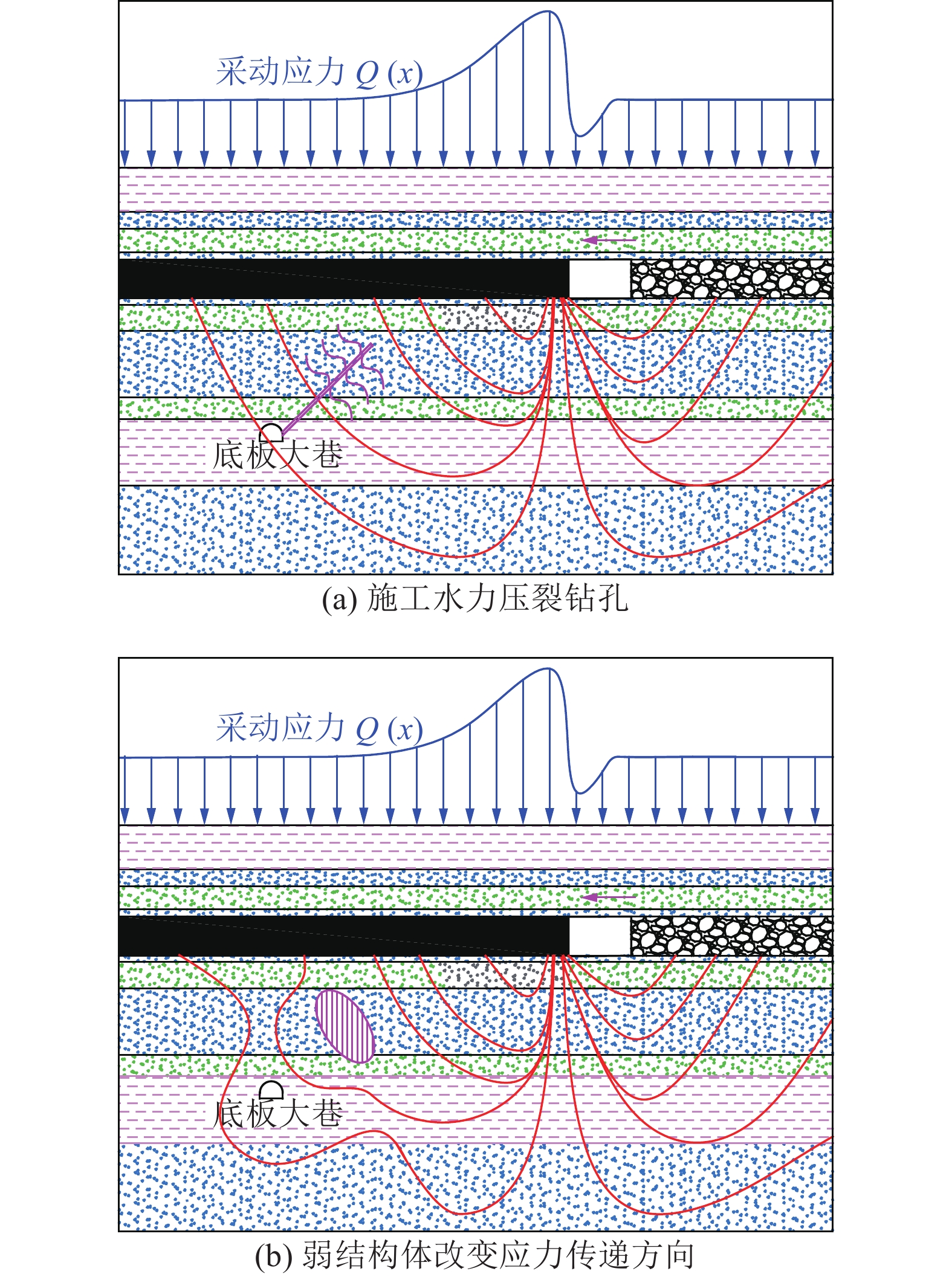

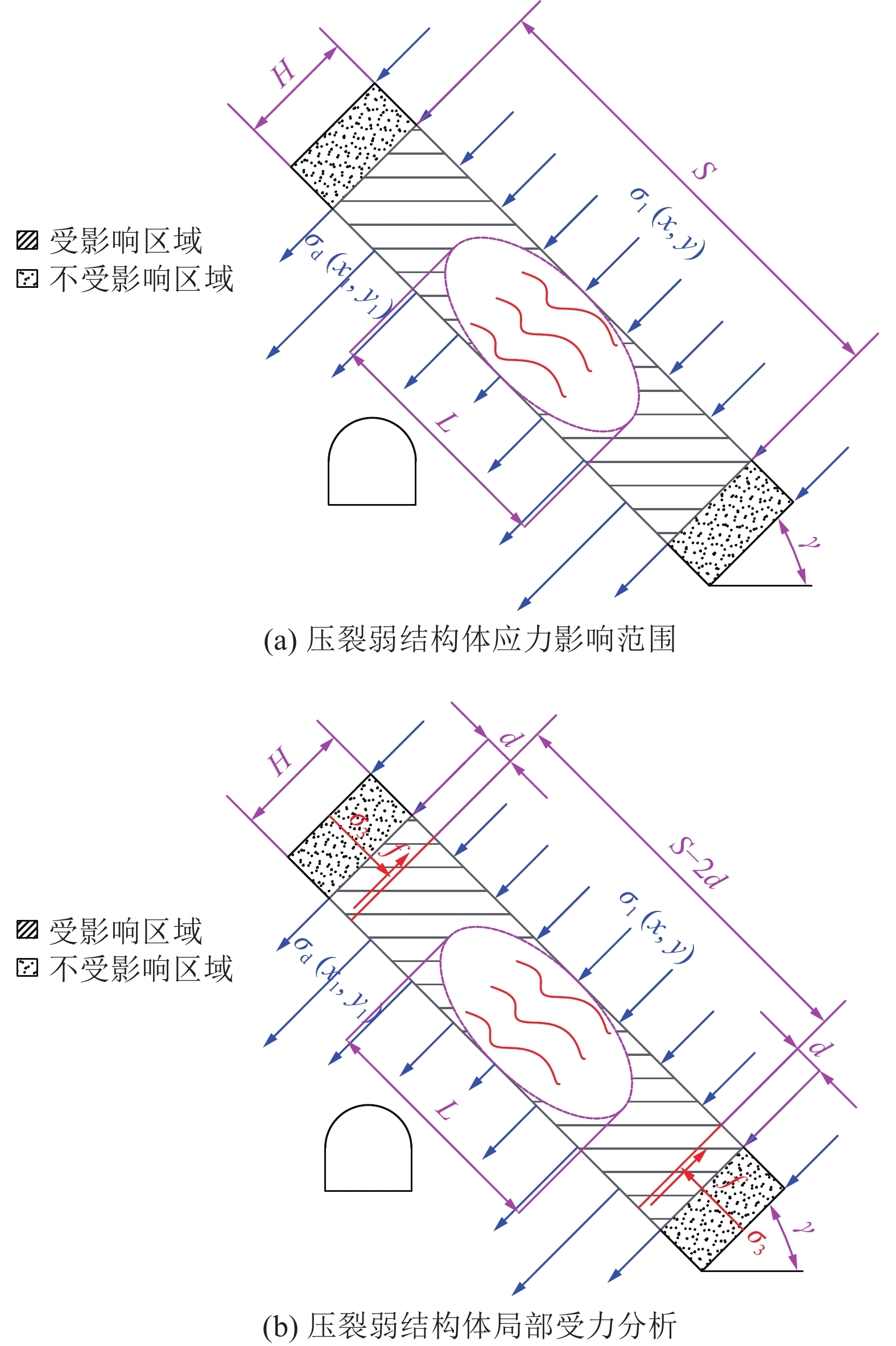

2. 深井底板动压巷道人工压裂应力转移控制原理

如图4a所示,采动应力是引起底板岩层应力变化的应力源之一,随着工作面的推进,采动应力在底板中的分布逐渐增加,强度高、弹性模量大的底板岩层将大部分应力传递到下一层。由于底板巷道围岩承载能力较弱,底板应力场发生变化时,底板巷道会先于其他岩层受压变形。通过水力压裂等方式压裂采动应力传递的关键岩层,形成裂缝。研究表明[18-19,21,29],含有预制裂缝的岩体受压后,裂缝会优先发生起裂,相比完整岩体,抗压强度、弹性模量等均明显降低,形成较为均质的近似于椭球形的似弹性体,称之为压裂弱结构体。如图4b所示,由于采动应力的传递,水压裂缝受压形成压裂弱结构体。压裂弱结构体强度降低,其能传递的应力随之降低;同时由于其弹性模量相对减小,通过对邻近的完整体作用,使其传递的应力升高,改变局部应力场的分布状态,发生应力转移。底板强动压巷道人工压裂应力转移控制技术就是通过调整人工压裂的参数,使底板巷道围岩受到的应力降低,达到卸压护巷的目的。

3. 深井底板动压巷道人工压裂应力转移的力学模型

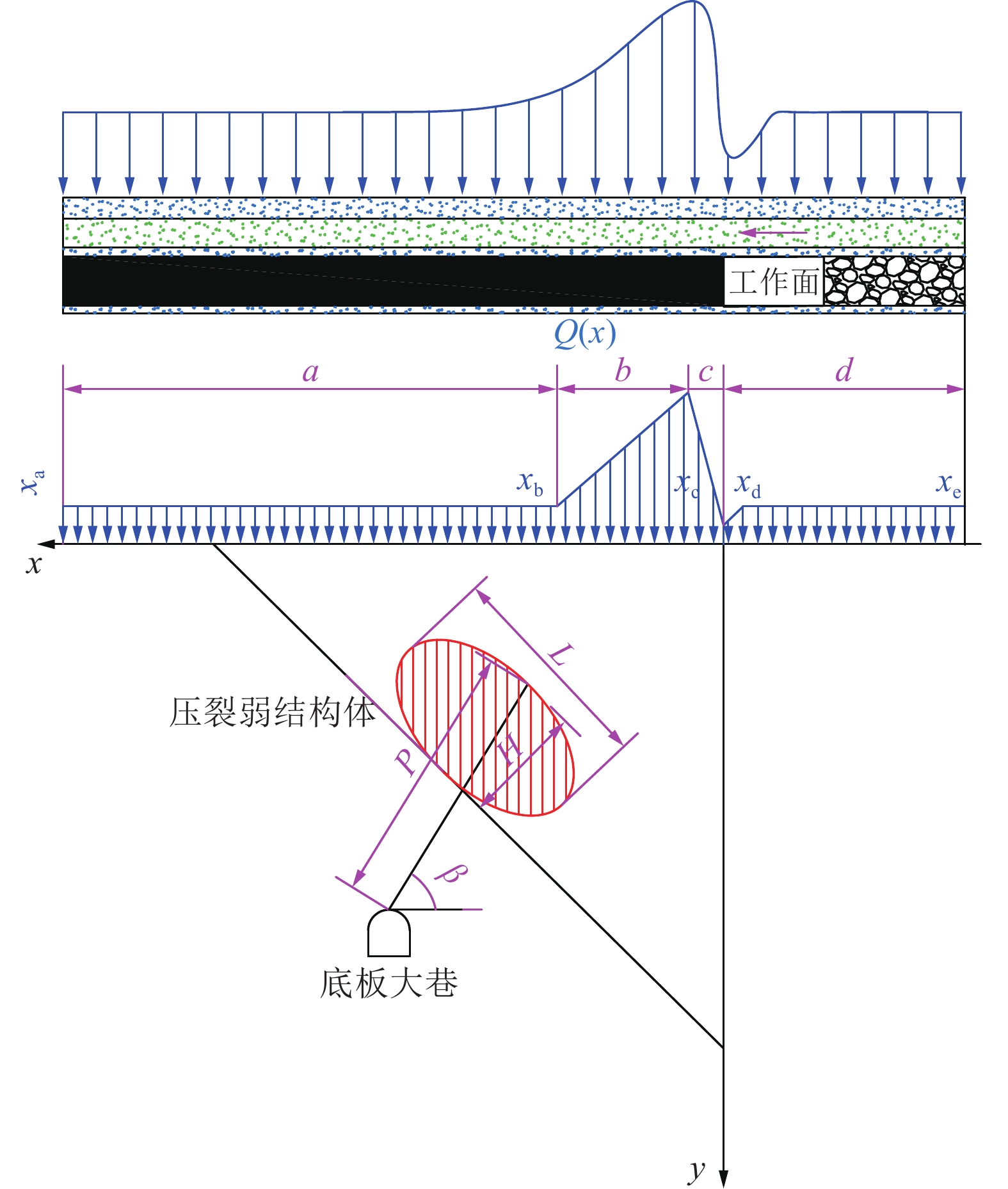

以工作面煤壁为原点,工作面推进方向为x正方向,垂直向下方向为y正方向建立坐标系,如图5所示。工作面采动应力近似于函数Q(x),作用范围为(−b, 0)到(a, 0)。压裂弱结构体到巷道的距离为P,与巷道连线的水平夹角为β;假设压裂弱结构体为椭球体,长轴长为L、短轴长为H。

$$ Q\left( x \right) = \left\{ {\begin{array}{*{20}{l}} {{q_1}}&{\left( {{x_{\rm{a}}} \leqslant x < {x_{\rm{b}}}} \right)}\\ {{k_1}\left( {x - {x_{\rm{b}}}} \right) + {q_1}}&{\left( {{x_{\rm{b}}} \leqslant x < {x_{\rm{c}}}} \right)}\\ {{k_2}\left( {x - {x_{\rm{d}}}} \right) + {q_1}}&{\left( {{x_{\rm{c}}} \leqslant x < {x_{\rm{d}}}} \right)}\\ {{q_1}}&{\left( {{x_{\rm{d}}} \leqslant x \leqslant {x_{\rm{e}}}} \right)} \end{array}} \right.$$ (1) 式中:$ Q(x) $为采动应力的近似函数;$ {q_1} $为应力稳定区的均布载荷;$ {k_1} $为xb与xc之间应力变化函数的斜率;$ {k_2} $为xc与xd之间应力变化函数的斜率;$ a $为xa与xb的距离;$ b $为xb与xc的距离;$ {{c}} $为xc与xd的距离;$ {{d}} $为xd与xe的距离。

在人工压裂前,底板中任一点(x, y),该微小集中力在M点表现出的应力状态[31–33]为

$$ \left\{ \begin{gathered} {\sigma _x} = \frac{2}{\pi }\int_{{x_{{e}}}}^{{x_{{a}}}} {\frac{{Q(\varepsilon ){{\left( {x - \varepsilon } \right)}^2}y}}{{{{\left[ {{{\left( {x - \varepsilon } \right)}^2} + {y^2}} \right]}^2}}}} {\mathrm{d}}\varepsilon \\ {\sigma _y} = \frac{2}{\pi }\int_{{x_{{e}}}}^{{x_{{a}}}} {\frac{{Q(\varepsilon ){y^3}}}{{{{\left[ {{{\left( {x - \varepsilon } \right)}^2} + {y^2}} \right]}^2}}}} {\mathrm{d}}\varepsilon \\ {\tau _{xy}} = \frac{2}{\pi }\int_{{x_{{e}}}}^{{x_{{a}}}} {\frac{{Q(\varepsilon )\left( {x - \varepsilon } \right){y^2}}}{{{{\left[ {{{\left( {x - \varepsilon } \right)}^2} + {y^2}} \right]}^2}}}} {\mathrm{d}}\varepsilon \\ \end{gathered} \right.$$ (2) 式中:$ x_{{{a}}} $为点a的x坐标;$ x_{{{e}}} $为点e的x坐标;$ \sigma_{x} $为受到的水平主应力;$ \sigma_{y} $为受到的垂直主应力;$ \tau_{x y} $为受到的剪应力。

$$ \sigma_{1}(x, y)=\frac{\sigma_{x}+\sigma_{y}}{2}+\sqrt{\left(\frac{\sigma_{x}-\sigma_{y}}{2}\right)^{2}+\tau_{x y}^{2}} $$ (3) $$ C_{1}=(1-D) C $$ (4) 式中:$ \sigma_{1}(x, y) $为受到的最大主应力;$ C_{1} $为压裂弱结构体的单轴抗压强度;$ C $为压裂层位的单轴抗压强度;$ D $为损伤变量。

如图6a所示,可以通过式(5)计算出应力场改变的岩体长度S

$$ \left\{\begin{array}{l} \eta=\dfrac{\pi L}{4 S} \\ f(\eta) S=\displaystyle\int_{x_0-\tfrac{S}{2} \cos \;\gamma}^{x_0+\tfrac{S}{2} \cos\; \gamma} \sigma_1(x, y){\mathrm{d}}x \end{array}\right. $$ (5) 式中:$ \eta $为压裂弱结构体所占比例;$ f(\eta) $为比例为$ \eta $时岩体强度;$ L $为压裂弱结构体的长轴长度;$ S $为压裂弱结构体的应力影响长度;$ x_{0} $为压裂弱结构体的上部中点横坐标;$ \gamma $为压裂弱结构体的水平夹角。

如图6b所示,对$ (s-2 d) $长的岩体进行受力分析得:

$$\begin{aligned} & \qquad\qquad \int_{x_0-\tfrac{(S-2 d)}{2} \cos \;\gamma}^{x_0+\tfrac{(S-2 d)}{2} \cos \;\gamma} \sigma_1(x, y){\mathrm{d}}x= \\ & {\left[\sigma_3 \frac{1+\sin \;\alpha}{1-\sin \;\alpha}+f\left(\frac{\pi L}{4(S-2 d)}\right)\right](S-2 d)+2 \sigma_3 H v} \end{aligned}$$ (6) $$\begin{aligned} &\qquad\qquad\qquad\qquad \sigma_3= \\ & \frac{\int_{x_0-\tfrac{(S-2 d)}{2} \cos\; \gamma}^{x_1+\tfrac{(S-2 d)}{2} \cos\;\; \gamma} \sigma_1(x, y)-f\left(\dfrac{\pi L}{4(S-2 d)}\right)(S-2 d){\mathrm{d}}x}{\left(\dfrac{1+\sin\; \alpha}{1-\sin \;\alpha}\right)(S-2 d)+2 H v} \end{aligned} $$ (7) 式中:$ H $为压裂弱结构体的短轴长度。

$$ C_{\mathrm{d}}=\left\{\begin{array}{l} C \qquad\quad\left(d \leqslant\dfrac{S-L}{2}\right) \\ f(\psi)\qquad\left(\dfrac{S-L}{2}<d \leqslant\dfrac{S}{2}\right) \end{array}\right. $$ (8) $$ \sigma_{{\mathrm{d}}}\left(x_{1}, y_{1}\right)=\max \left(\sigma_{1}+\sigma_{3} H \upsilon , C_{{\mathrm{d}}}\right) $$ (9) 式中:$ \alpha $为岩体的内摩擦角;$ t $为岩体的摩擦系数;$ C_{{\mathrm{d}}} $为点(x1, y1)处的强度;$ \psi $为点(x1, y1)处弱结构体的比例;$ \sigma_{{\mathrm{d}}}\left(x_{1}, y_{1}\right) $为点(x1, y1)处的最大主应力。

人工压裂前,底板大巷(x2, y2)处受S段上的应力传递的应力为

$$ \left\{\begin{aligned} & q \sigma_{x_2}=\frac{2}{\pi} \int_{x_0-\tfrac{S}{2}}^{x_0+\tfrac{S}{2}} \begin{aligned} & \sigma_1\left[\varepsilon, \cot \;\gamma\left(\varepsilon-x_0\right)+y_0\right]\left(x_2-\varepsilon-x_0\right)^2 {\left(y_2-y_0-H\right)}/{\left[\left(x_2-\varepsilon-x_0\right)^2+\left(y_2-y_0-H\right)^2\right]^2} {\mathrm{d}} \varepsilon \\ \end{aligned} \\ & q \sigma_{y_2}=\frac{2}{\pi} \int_{x_0-\tfrac{S}{2}}^{x_0+\tfrac{S}{2}} {\sigma_1\left[\varepsilon, \cot \;\gamma\left(\varepsilon-x_0\right)+y_0\right] y_0^3}/{\left[\left(x_2-\varepsilon-x_0\right)^2+\left(y_2-y_0-H\right)^2\right]^2} {\mathrm{d}} \varepsilon \\ & q \tau_{x_2 y_2}=\frac{2}{\pi} \int_{x_0-\tfrac{S}{2}}^{x_0+\tfrac{S}{2}} \begin{aligned} & \sigma_1\left[\varepsilon, \cot\; \gamma\left(\varepsilon-x_0\right)+y_0\right]\left(x_2-\varepsilon-x_0\right) {\left(y_2-y_0-H\right)^2}/{\left[\left(x_2-\varepsilon-x_0\right)^2+\left(y_2-y_0-H\right)^2\right]^2} {\mathrm{d}} \varepsilon \end{aligned} \\ & q \sigma\left(x_2, y_2\right)=\frac{q \sigma_{x_2}+q \sigma_{y_2}}{2}+\sqrt{\left(\frac{q \sigma_{x_2}-q \sigma_{y_2}}{2}\right)^2+q \tau_{x_2 y_2}{ }^2} \end{aligned} \right.$$ (10) 式中:$ q{\sigma _{{x_2}}} $为底板大巷(x2, y2)处受S段上的应力传递的水平应力;$ q{\sigma _{{{{y}}_2}}} $为底板大巷(x2, y2)处受S段上的应力传递的垂直应力;$ q{\tau _{{x_2}{y_2}}} $为底板大巷(x2, y2)处受S段上的应力传递的剪应力;$ q\sigma ({x_2},{y_2}) $为底板大巷(x2, y2)处受S段上的应力传递的最大主应力;$y_1 $为压裂弱结构体的上部中点纵坐标;y0为压裂弱结构体的上部中点纵坐标;人工压裂后,底板大巷(x2, y2)处受S段上的应力传递的应力为

$$ \left\{\begin{aligned} & h \sigma_{x_2}=\frac{2}{\pi} \int_{x_0-\tfrac{S}{2}}^{x_0+\tfrac{S}{2}} \begin{aligned} & \sigma_{\mathrm{d}}\left[\varepsilon, \cot \;\gamma\left(\varepsilon-x_0\right)+y_0\right]{\left(x_2-\varepsilon-x_0\right)^2\left(y_2-y_0-H\right)}/{\left[\begin{array}{l} \left(x_2-\varepsilon-x_0\right)^2 \left(y_2-y_0-H\right)^2 \end{array}\right]^2} {\mathrm{d }}\varepsilon \\ \end{aligned} \\ & h \sigma_{y_2}=\frac{2}{\pi} \int_{x_0-\tfrac{S}{2}}^{x_0+\tfrac{S}{2}} {\sigma_{\mathrm{d}}\left[\varepsilon, \cot \;\gamma\left(\varepsilon-x_0\right)+y_0\right] y_0{ }^3}/{\left[\begin{array}{l} \left(x_2-\varepsilon-x_0\right)^2 +\left(y_2-y_0-H\right)^2 \end{array}\right]^2} {\mathrm{d}} \varepsilon \\ & h \tau_{x_2 y_2}=\frac{2}{\pi} \int_{x_0-\tfrac{S}{2}}^{x_0+\tfrac{S}{2}} \begin{aligned} & \sigma_{\mathrm{d}}\left[\varepsilon, \cot \;\gamma\left(\varepsilon-x_0\right)+y_0\right] {\left(x_2-\varepsilon-x_0\right)\left(y_2-y_0-H\right)^2}/{\left[\begin{array}{l} \left(x_2-\varepsilon-x_0\right)^2 +\left(y_2-y_0-H\right)^2 \end{array}\right]^2} {\mathrm{d}} \varepsilon \end{aligned} \\ & h \sigma\left(x_2, y_2\right)=\frac{h \sigma_{x_2}+h \sigma_{y_2}}{2}+\sqrt{\left(\frac{h \sigma_{x_2}-h \sigma_{y_2}}{2}\right)^2+h \tau_{x_2 y_2}^2} \\ \end{aligned} \right.$$ (11) 式中:$ {{h}}{\sigma _{{x_2}}} $为底板大巷(x2, y2)处受S段上的应力传递的水平应力;$ h{\sigma _{{{{y}}_2}}} $为底板大巷(x2, y2)处受S段上的应力传递的垂直应力;$ {{h}}{\tau _{{x_2}{y_2}}} $为底板大巷(x2, y2)处受S段上的应力传递的剪应力;$ h\sigma ({x_2},{y_2}) $为底板大巷(x2, y2)处受S段上的应力传递的最大主应力;压裂后,底板大巷(x2, y2)处受到的最大主应力为

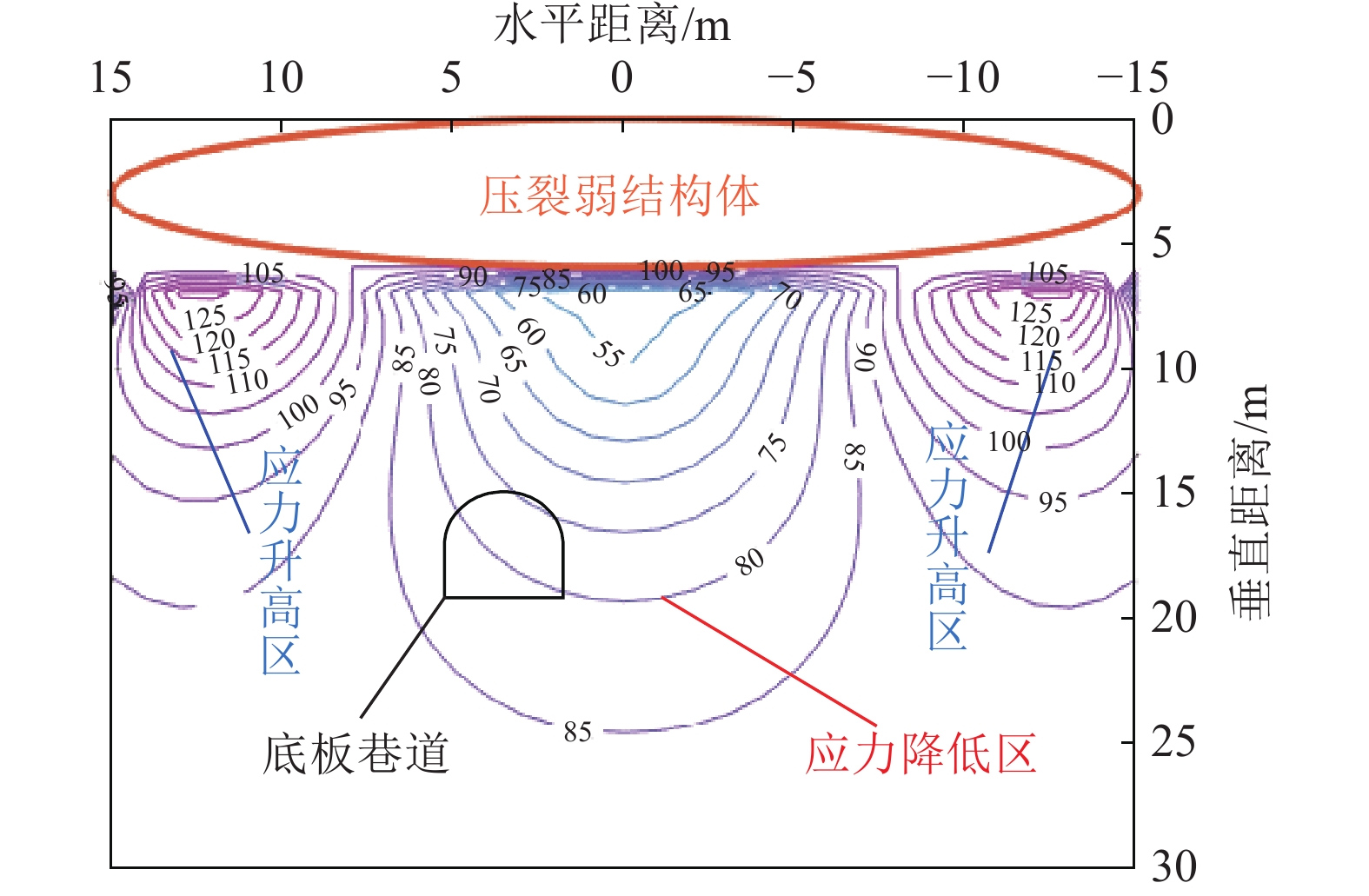

$$ F({x_2},{y_2}) = {\sigma _1}({x_2},{y_2}) - q\sigma ({x_2},{y_2}) + h\sigma ({x_2},{y_2}) $$ (12) 在垂直方向0 m,水平方向−15~15 m范围内受18 MPa的均布承载应力,通过Matlab软件计算压裂后与压裂前的最大主应力变化幅度(压裂前与压裂后最大主应力的百分比)、主应力方向与不同水平距离、垂直距离的关系如图7所示。应力场发生明显变化,形成3个区域:应力升高区、应力降低区、应力升高区。应力降低区主要分布在弱结构体与采动应力连线的方向上,主要集中在一个拱形的范围内;由于膨胀效应,在与应力来源垂直的方向上产生应力集中,出现应力升高区。

4. 底板强动压巷道压裂弱结构体应力转移影响因素

由3节与图7分析可知,结合袁店一矿的工程背景,底板巷道至工作面的水平距离x2=100 m,垂直距离y2=50 m。则确定影响最大主应力的可控参数为:压裂弱结构体的长轴长L=30 m、压裂弱结构体的短轴长H=12 m、到巷道的距离P=30 m、与巷道连线的水平夹角β=60°、压裂层的内摩擦角α=30°、压裂层的强度C=40 MPa、压裂的损伤变量D=0.8等。

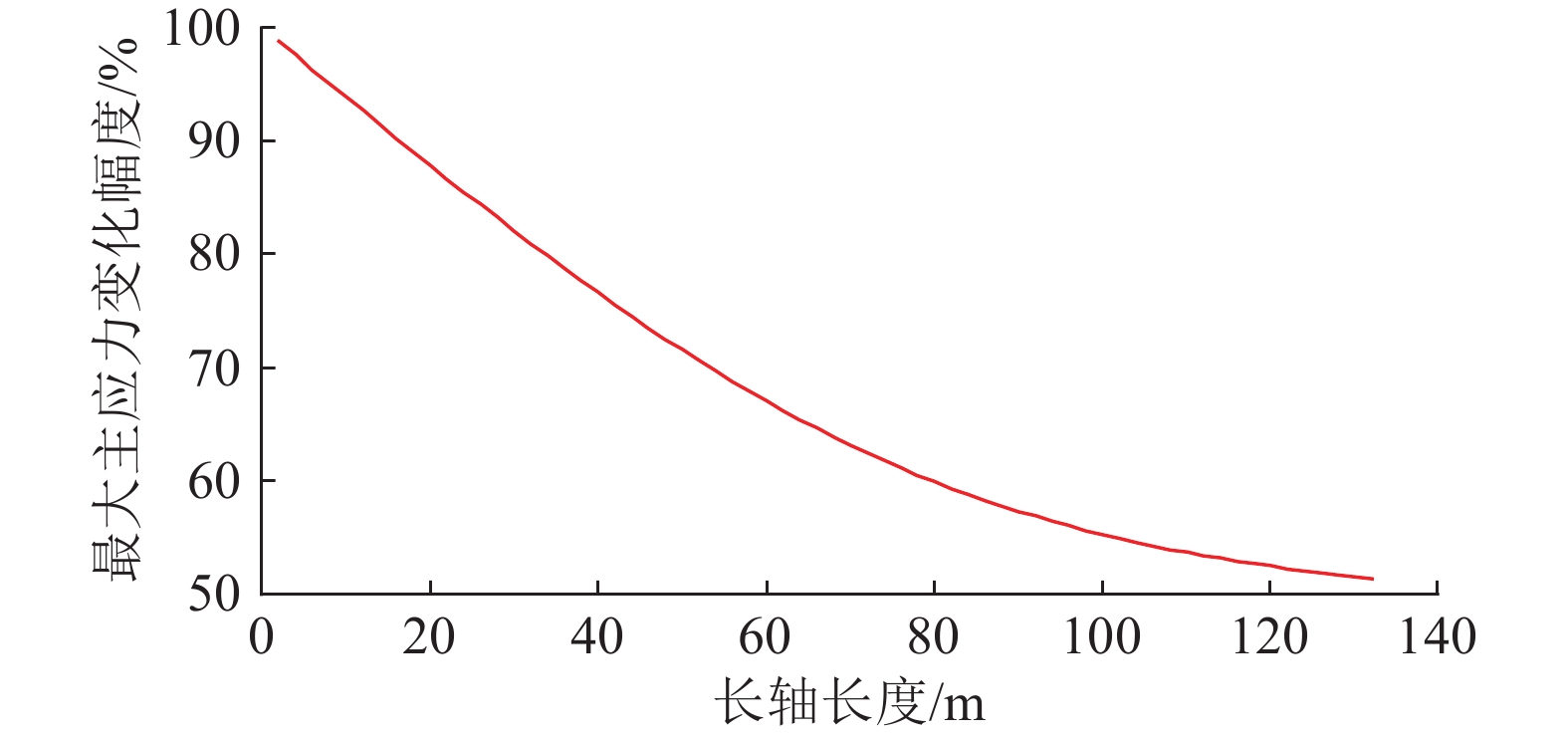

4.1 压裂弱结构体长轴长度

压裂弱结构体长轴长度L对最大主应力变化幅度的影响如图8所示,随着压裂弱结构体的长轴长度L的增加,压裂后底板巷道受到的最大主应力逐渐减小,当L大于60 m时,最大主应力变化的幅度逐渐减缓。这是因为压裂弱结构体的长轴长度越长,卸压的范围不断增加,底板巷道处的卸压程度也不断增加,当长度增加到一定值时,卸压效果逐渐变缓,最终趋于不变。

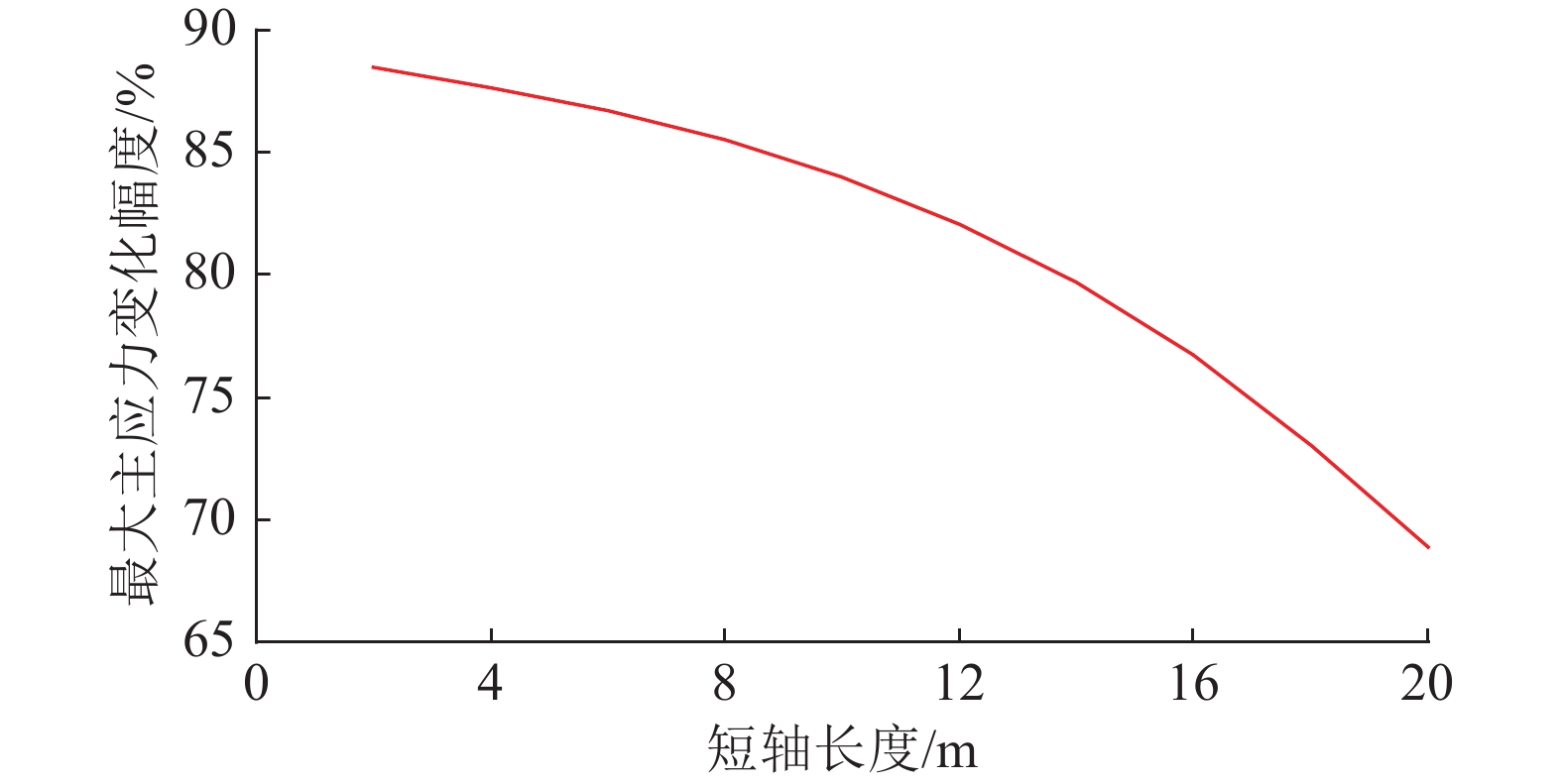

4.2 压裂弱结构体短轴长度

压裂弱结构体短轴长度H对最大主应力变化幅度的影响如图9所示,随着短轴长度H的增加,底板巷道受到的最大主应力逐渐减小。这是因为短轴长度H越大,底板巷道距离弱结构体的底部越近,巷道受到的最大主应力越小,卸压效果越好。

4.3 至巷道的距离

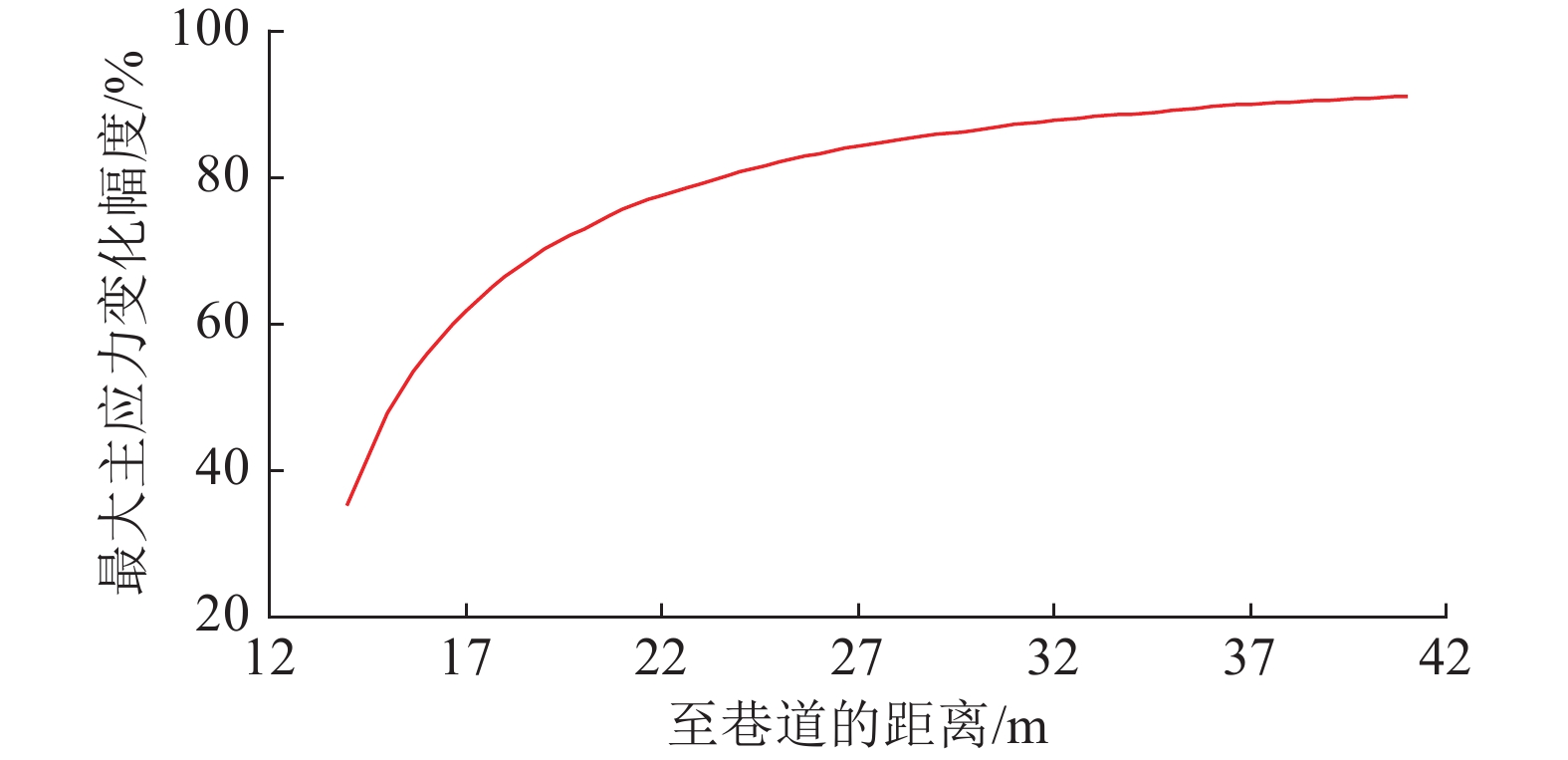

至巷道的距离P对最大主应力变化幅度的影响如图10所示。由图10可知,随着至巷道的距离的增加,压裂后底板巷道受到的最大主应力逐渐增大,当P大于25 m时,最大主应力的变化幅度逐渐变缓。这是因为巷道距离压裂弱结构体越远,受到压裂弱结构体的影响越小,最大主应力变化越小。

4.4 与巷道连线的水平夹角

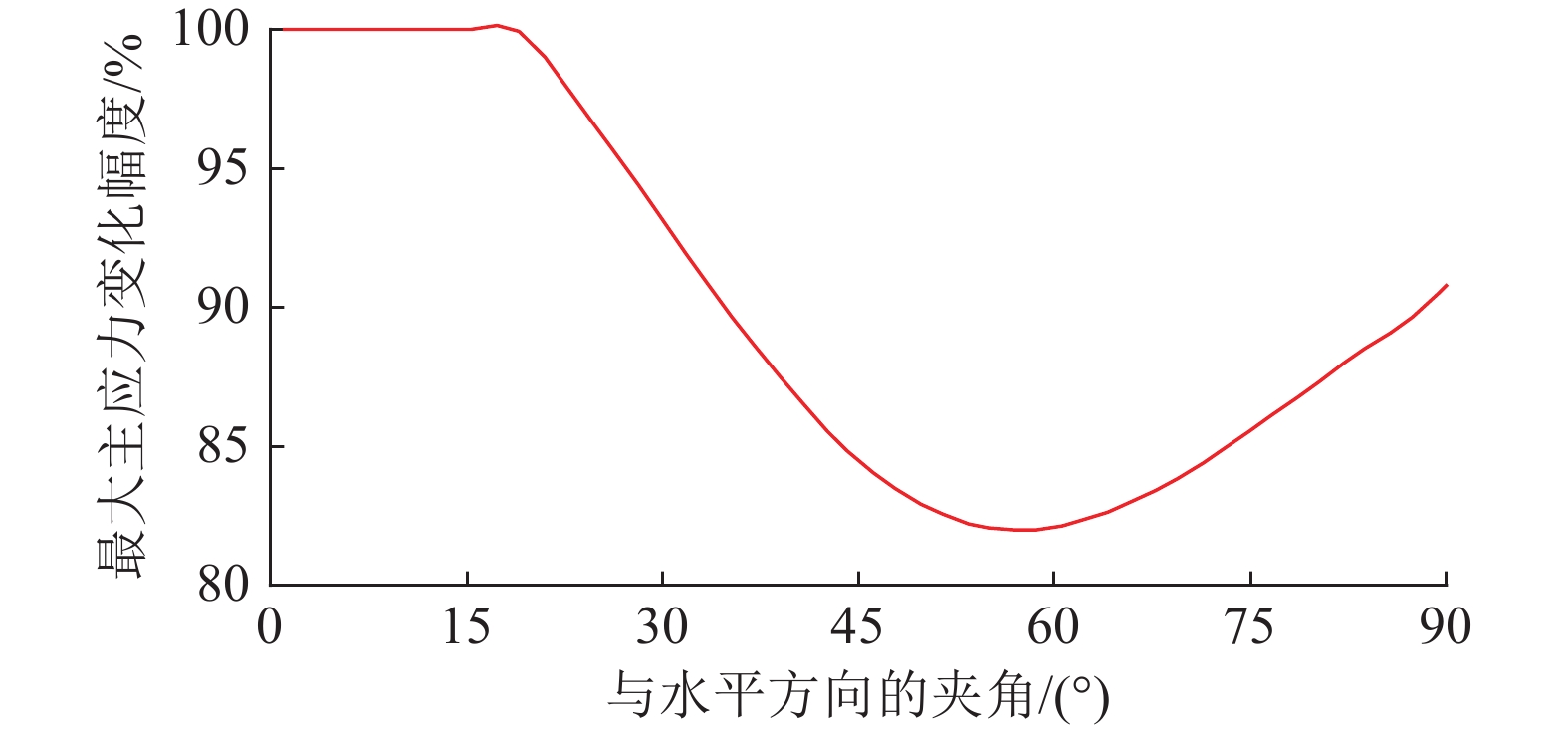

与巷道连线的水平夹角β对最大主应力变化幅度的影响如图11所示。随着与巷道连线的水平夹角的增加,压裂后底板巷道受到的最大主应力整体呈先减小再增大的趋势,在β趋近于60°,最大主应力最小;β小于20°时,最大主应力几乎不变。这是因为β小于20°时,压裂弱结构体对底板巷道的影响较小,β大于20°时,压裂弱结构体开始逐渐影响底板巷道所处的最大主应力。

4.5 压裂弱结构体内摩擦角

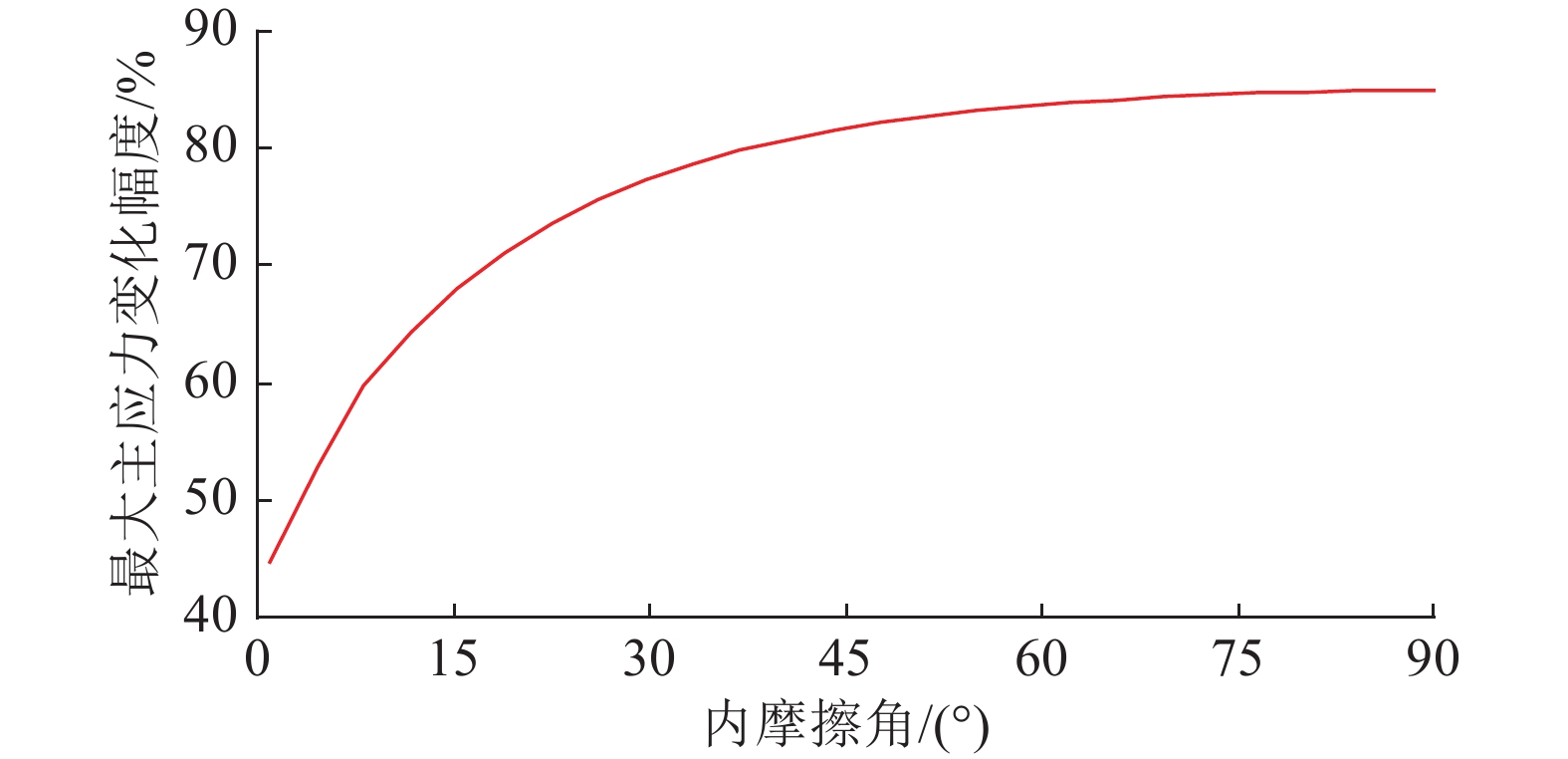

压裂弱结构体内摩擦角α对最大主应力变化幅度的影响如图12所示。随着压裂弱结构体内摩擦角的增加,压裂后底板巷道受到的最大主应力逐渐增大,最后趋于稳定。这是随着内摩擦角度的增加,压裂弱结构体下部传递的支承应力增大,底板巷道受到的最大主应力越大,最后趋于稳定。

4.6 压裂层位强度

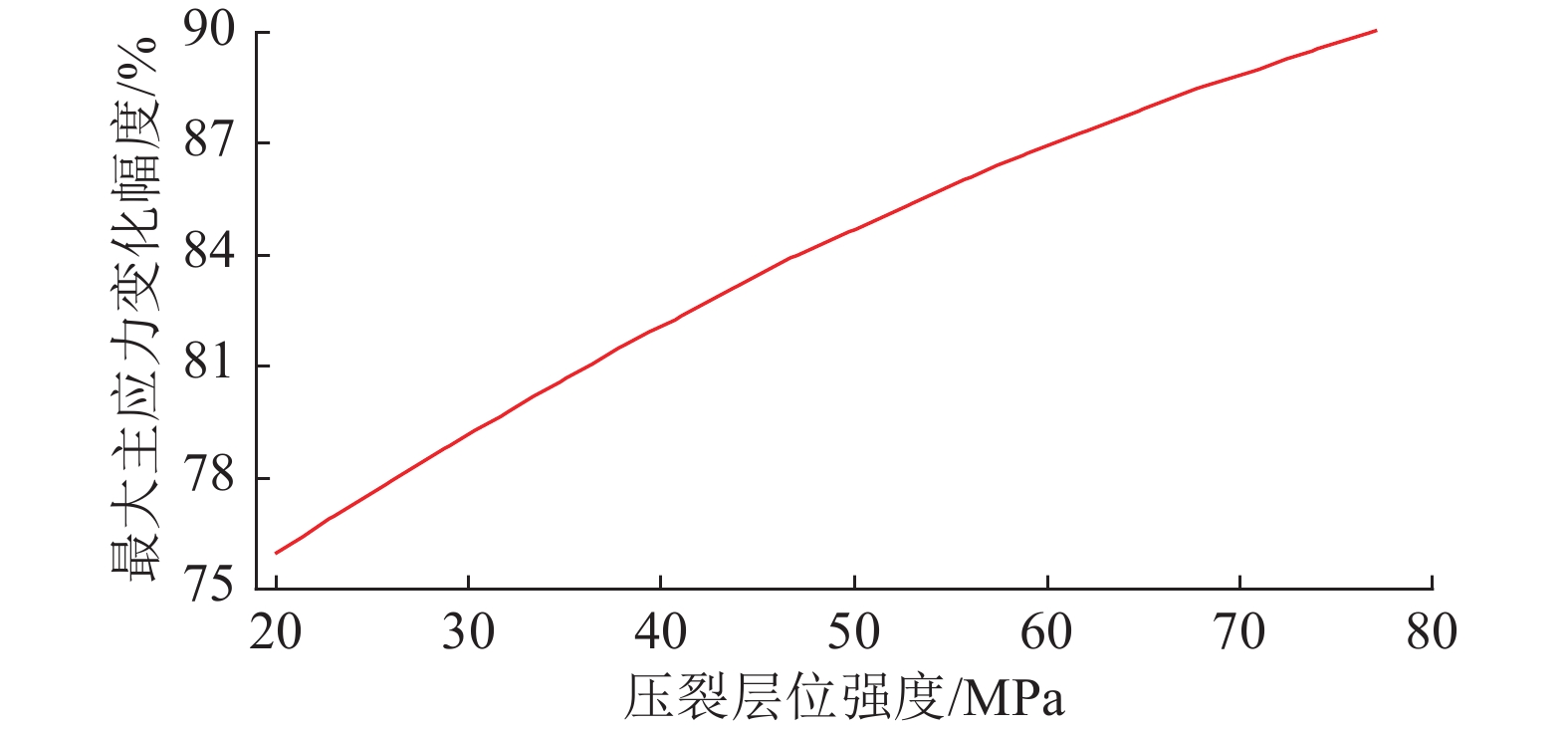

压裂层位强度C对最大主应力的影响如图13所示。随着压裂层位强度C的增加,压裂后底板巷道受到的最大主应力逐渐增大。这是因为压裂层位的强度影响着压裂弱结构体下部传递的支承压力,压裂层位强度越小,压裂弱结构体传递的支承压力越小,巷道受到的主应力越小。

4.7 损伤变量

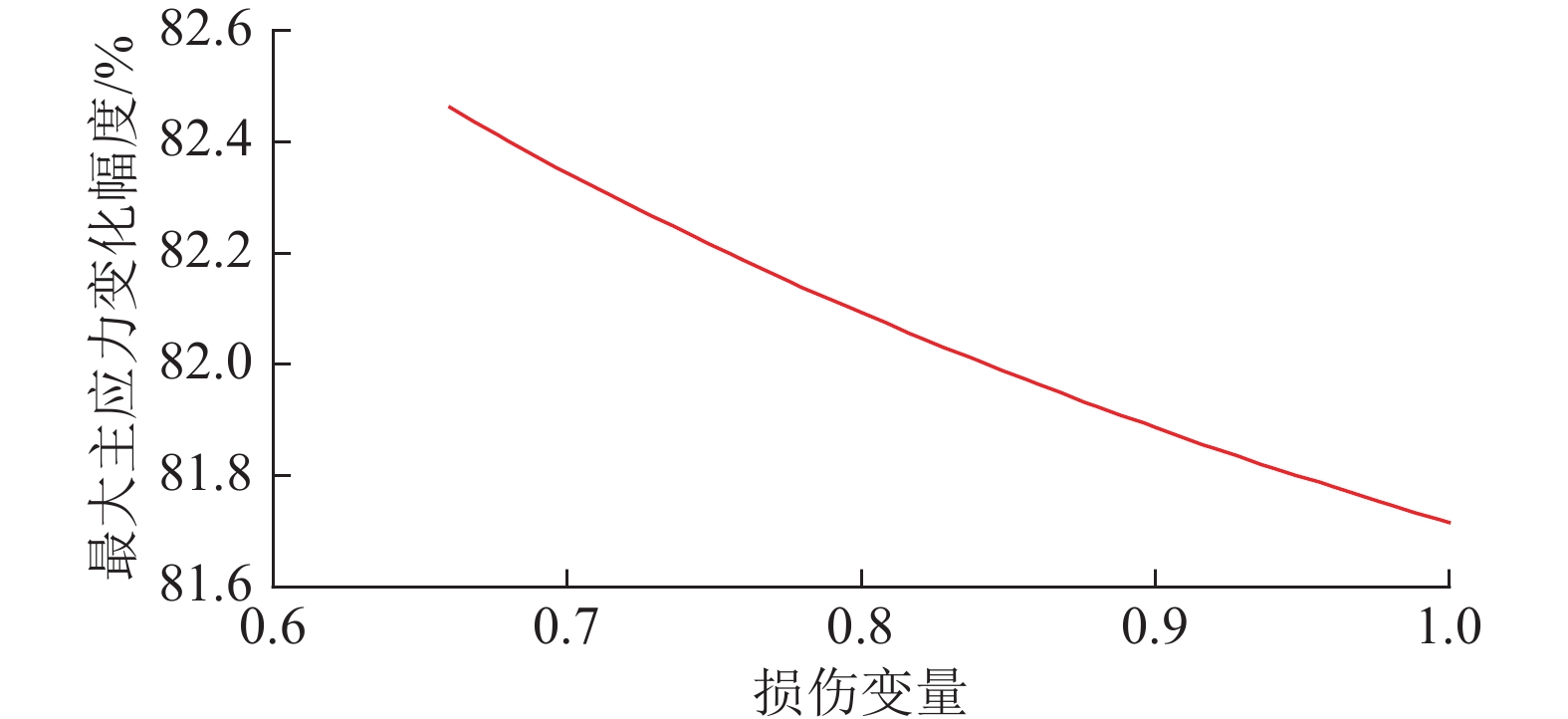

损伤变量D对最大主应力的影响如图14所示。随着损伤变量的增加,压裂后底板巷道受到的最大主应力与压裂前的比值逐渐减小。这是因为损伤变量越大,压裂弱结构体的强度越低,压裂弱结构体传递的应力越小,底板巷道受到的最大主应力越小。

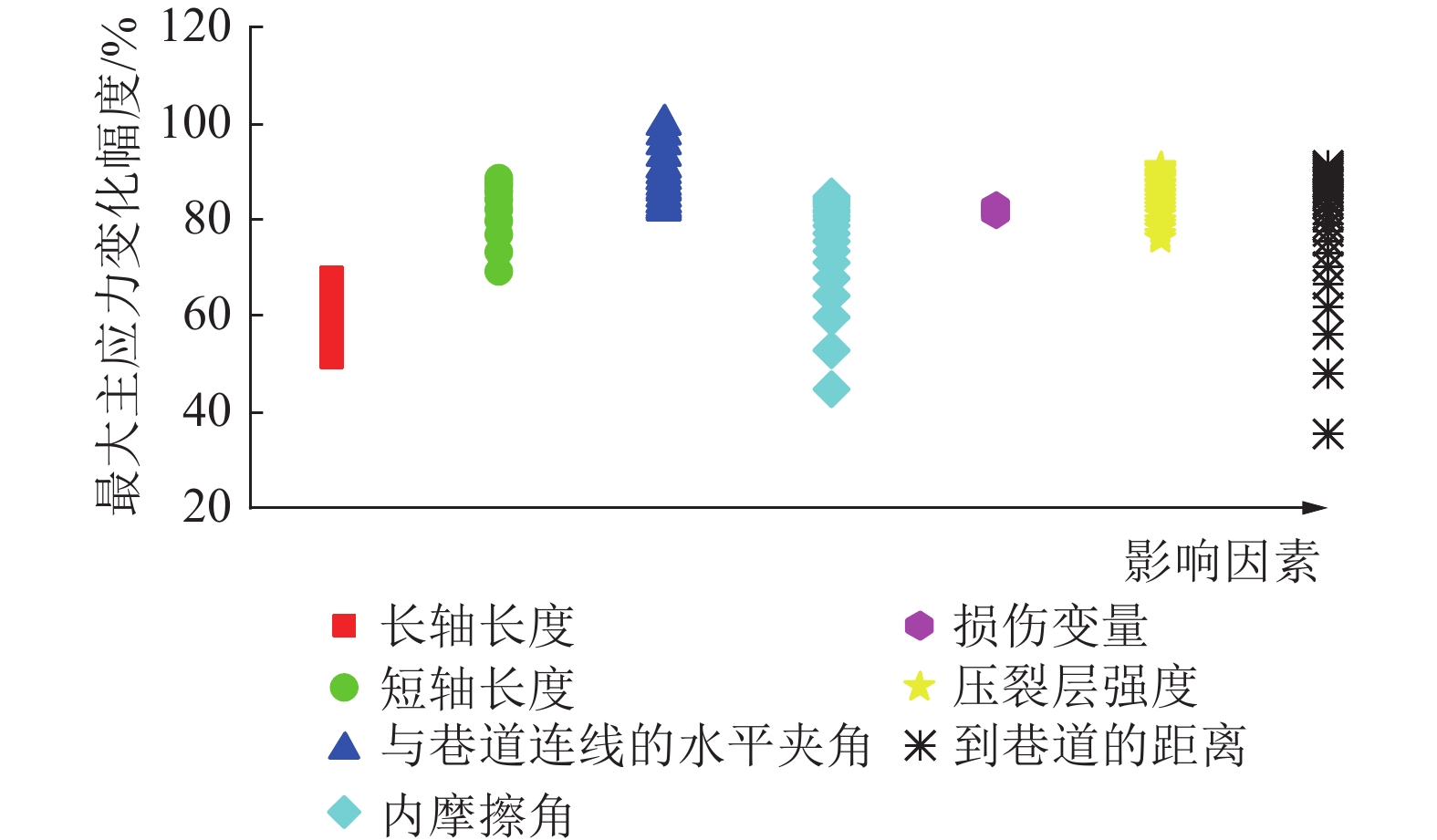

4.8 影响参数的敏感性分析

不同因素对压裂后底板巷道受到的最大主应力影响的敏感性如图15所示,图15表明,对于不同影响因素,最大主应力变化比的变化区间由大到小依次为至巷道的距离、内摩擦角、短轴长度、与巷道连线的水平夹角、长轴长度、压裂层强度、损伤变量。可见,到巷道的距离对卸压效果影响最大,损伤变量对卸压效果影响最小。

4.9 水力压裂控制参数的计算方法

水力压裂应力转移控制技术的施工参数计算方法如下:

1)已知采动应力Q(x)、底板巷道的位置(x2, y2)。估算压裂层强度C和压裂层摩擦因数f。

2)考虑底板巷道支护条件,计算压裂弱结构体满足安全条件的参数要求。

3)计算压裂弱结构体长轴长度L、短轴长度H、至巷道的距离P、与巷道连线的水平夹角β、压裂弱结构体的内摩擦角α、损伤变量D。通过计算结果调整各项参数,直至底板巷道围岩受到的最大主应力达到最优。

4)通过压裂位置计算出钻孔长度、钻孔角度及钻孔排布方式。

5. 水力压裂卸压方案及效果分析

5.1 理论计算

根据4节计算结果,结合袁店一矿的工程背景,底板巷道至工作面的水平距离x2=100 m,垂直距离y2=50 m,选去细砂岩为压裂层,内摩擦角α=30°,单轴抗压强度C=40 MPa,损伤变量D=0.8。将上述数据代入式(10)。

计算得出当压裂弱结构体的长轴长度L取最大值、短轴长度H=12 m、到巷道的距离P=25 m、与巷道连线的水平夹角β=60°时,卸压效果最好。将以上数据转化为水力压裂方案如下。

5.2 水力压裂卸压方案

压裂钻孔布置如图16所示,在103采区运输大巷段朝向工作面方向施工钻孔A,共计施工9个钻孔。具体参数如下:

钻孔A1—A9,朝着1037工作面施工,钻孔与巷道夹角70°,钻孔与水平方向的夹角为40°,钻孔长度25 m。所有的钻孔直径为94 mm,钻孔间距为13 m。采用后退式压裂。

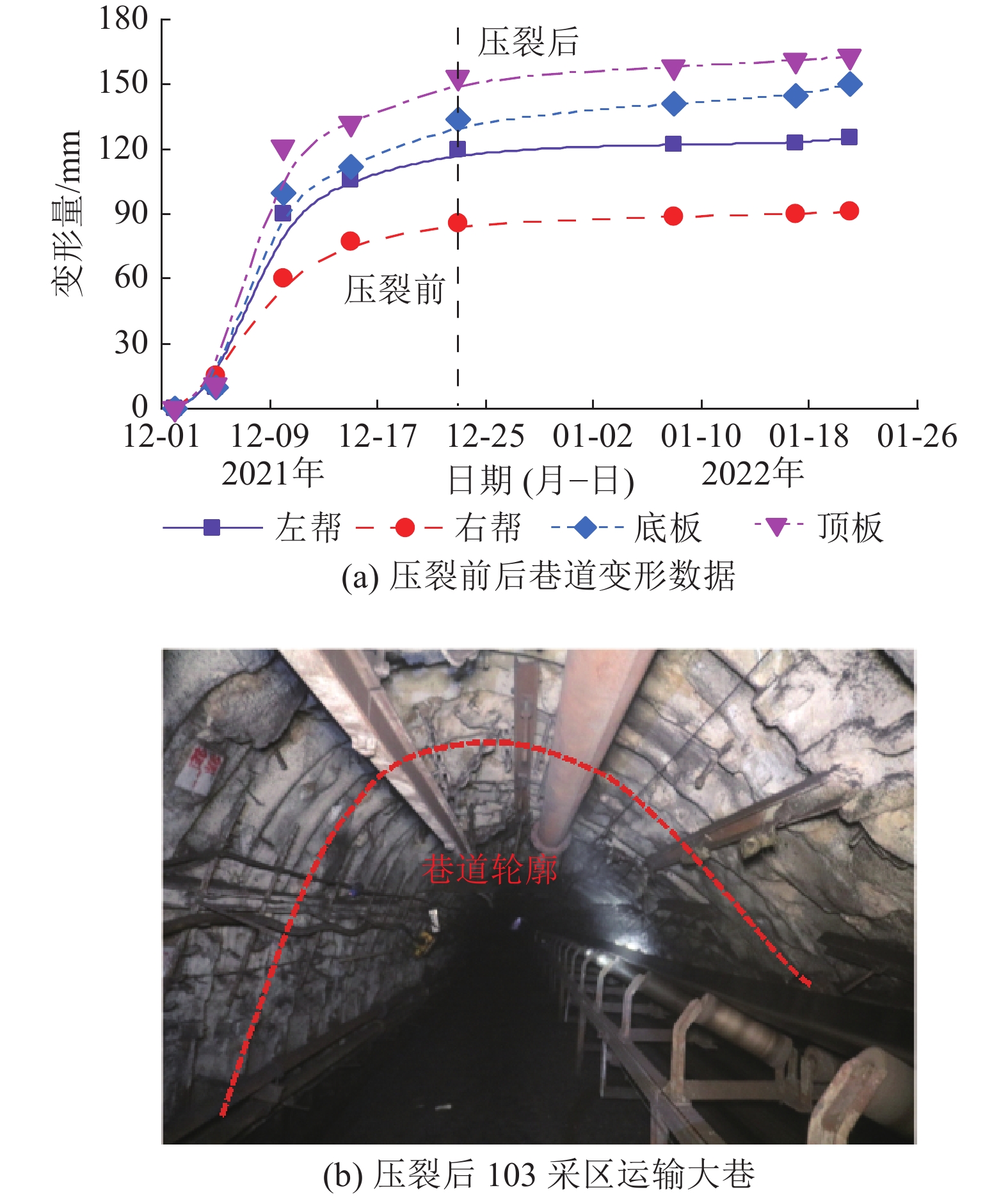

5.3 观测结果对比及分析

2021年12月23日开始在袁店一矿实施水力压裂,根据103采区运输大巷建立的巷道围岩变形监测站压裂前后的巷道变形量如图17a所示。压裂前后的左帮变形量分别为5.7、0.18 mm/d;压裂前后的右帮变形量分别为4.1、0.17 mm/d;压裂前后的底板变形量分别为6.4、0.57 mm/d;压裂前后的顶板变形量分别为7.28、0.36 mm/d。压裂前后变形速率明显降低。由图17b可知,水压压裂卸压前后巷道围岩受力情况得到改善,巷道变形情况得到缓解,水力压裂卸压护巷效果明显。

6. 结 论

1)压裂弱结构体使应力场发生明显变化,出现应力升高区和应力降低区,应力降低区主要分布在压裂弱结构体的正下方,随着垂直距离的增加,最大主应力比值等值线逐渐增大。应力升高区主要分布在上覆应力降低区域的两侧。

2)最大主应力变化幅度主要与压裂弱结构体的长轴长L、压裂弱结构体的短轴长H、到巷道的距离P、与巷道连线的水平夹角β、压裂层的强度C、损伤变量D、压裂层的内摩擦角α等有关,其中,至巷道的距离P对卸压效果影响最大,损伤变量D对卸压效果影响最小。

3)采用提出的计算方法设计了淮北矿业集团袁店一矿的103采区运输大巷的卸压方案,工程应用结果表明,底板动压巷道变形速率明显减缓,验证了底板强动压巷道压裂弱结构体应力转移模型的合理性。

-

-

[1] 袁 亮. 深部采动响应与灾害防控研究进展[J]. 煤炭学报,2021,46(3):716−725. doi: 10.13225/j.cnki.jccs.YT21.0158 YUAN Liang. Research progress of mining response and disaster prevention and control in deep coal mines[J]. Journal of China Coal Society,2021,46(3):716−725. doi: 10.13225/j.cnki.jccs.YT21.0158

[2] 陈绍杰,张鑫源,石瑞明,等. 煤系逆断层形成过程及其对采动灾害的影响规律[J]. 煤炭学报,2023,48(8):2995−3008. CHEN Shaojie,ZHANG Xinyuan,SHI Ruiming et al. Formation process of coal-bearing series reverse fault and its influence on mining disaster[J]. Journal of China Coal Society,2023,48(8):2995−3008.

[3] LI H,GUO K,GUO G. Strata and surface influence range of deep coal mining for mine land reuse[J]. Environmental Earth Sciences,2022,81(3):68. doi: 10.1007/s12665-022-10174-6

[4] 康红普,王国法,姜鹏飞,等. 煤矿千米深井围岩控制及智能开采技术构想[J]. 煤炭学报,2018,43(7):1789−1800. KANG Hongpu,WANG Guofa,JIANG Pengfei,et al. Conception for strata control and intelligent mining technology in deep coal mines with depth more than 1 000 m[J]. Journal of China Coal Society,2018,43(7):1789−1800.

[5] 康红普,姜鹏飞,黄炳香,等. 煤矿千米深井巷道围岩支护-改性-卸压协同控制技术[J]. 煤炭学报,2020,45(3):845−864. KANG Hongpu,JIANG Pengfei,HUANG Bingxiang,et al. Roadway strata control technology by means of bolting-modi-fication-destressing in synergy in 1 000 m deep coal mines[J]. Journal of China Coal Society,2020,45(3):845−864.

[6] ZHANG L,HUANG P,LIU S,et al. Relief mechanism of segmented hole reaming and stress distribution characteristics of drilling holes in deep coal mine[J]. Processes,2022,10(8):1566. doi: 10.3390/pr10081566

[7] 张星宇. 高应力巷道聚能切缝卸压技术与原理[D]. 北京:中国矿业大学(北京),2021. ZHANG Xinyu. Pressure relief technique and its principle based on cutting seam by energy-focusing blast for high-stress roadway[D]. Beijing :China University of Mining & Technology-Beijing,2021.

[8] 杨敬轩,于 斌,匡铁军,等. 基于煤岩深孔爆破问题的液体炸药研发与技术[J]. 煤炭学报,2021,46(6):1874−1887. YANG Jingxuan,YU Bin,KUANG Tiejun,et al. Development and technical practice of liquid explosive based on deep-hole blasting problem[J]. Journal of China Coal Society,2021,46(6):1874−1887.

[9] 程敬义,魏泽捷,白纪成,等. 基于爆破卸压的深部构造应力富水软岩巷道底鼓控制技术研究[J]. 煤炭科学技术,2022,50(7):117−126. CHENG Jingyi,WEI Zejie,BAI Jicheng,et al. Study floor heave control technology of deep tectonic stress water-rich soft rock roadway based on blasting pressure relief[J]. Coal Science and Technology,2022,50(7):117−126.

[10] 刘志刚,曹安业,井广成. 煤体卸压爆破参数正交试验优化设计研究[J]. 采矿与安全工程学报,2018,35(5):931−939. LIU Zhigang,CAO Anye,JING Guangcheng. Research on parameters optimization of stress relief blasting in coal roadway using orthogonal experiment[J]. Journal of Mining & Safety Engineering,2018,35(5):931−939.

[11] 林 健,郭 凯,孙志勇,等. 强烈动压巷道水力压裂切顶卸压压裂时机研究[J]. 煤炭学报,2021,46(S1):140−148. LIN Jian,GUO Kai,SUN Zhiyong,et al. Study on fracturing timing of hydraulic fracturing top-cutting and pressure relief in roadway with strong dynamic pressure[J]. Journal of China Coal Society,2021,46(S1):140−148.

[12] 康红普,张 晓,王东攀,等. 无煤柱开采围岩控制技术及应用[J]. 煤炭学报,2022,47(1):16−44. KANG Hongpu,ZHANG Xiao,WANG Dongpan,et al. Strata control technology and applications of non-pillar coal mining[J]. Journal of China Coal Society,2022,47(1):16−44.

[13] CHANG Q,YAO X,WANG X,et al. Investigation on hydraulic fracturing and cutting roof pressure relief technology for underground mines:a case study[J]. Lithosphere,2021,2021:4277645. doi: 10.2113/2021/4277645

[14] XIAO Z,HONGPU K. Pressure relief mechanism of directional hydraulic fracturing for gob-side entry retaining and its application[J]. Shock and Vibration,2021,2021:6690654. doi: 10.1155/2021/6690654

[15] CHEN D,WANG X,ZHANG F,et al. Research on directional controllability of cracking in hydraulic fracturing of hard overburden based on local stress field intervention[J]. Energies,2022,15(12):4252. doi: 10.3390/en15124252

[16] 杨 欢,郑凯歌,李彬刚,等. 工作面过上覆遗留煤柱致灾机理及超前区域防治技术研究[J]. 煤炭科学技术,2023,51(9):46−54. YANG Huan,ZHENG Kaige,LI Bingang,et al. Disaster mechanism of overlying coal pillar in working face and advanced regional prevention technology [J]. Coal Science and Technology,2023,51(9):46−54.

[17] 程利兴. 千米深井巷道围岩水力压裂应力转移机理研究及应用[D]. 北京:中国矿业大学(北京),2021. CHENG Lixing. Research and application of hydraulic fracturing stresstransfer mechanism in surrounding rock of kilometer deep mine roadway[D]. Beijing:China University of Mining & Technology-Beijing,2021.

[18] LIU J,LIU C,YAO Q,et al. The position of hydraulic fracturing to initiate vertical fractures in hard hanging roof for stress relief[J]. International Journal of Rock Mechanics and Mining Sciences,2020,132:104328. doi: 10.1016/j.ijrmms.2020.104328

[19] LIU J,LIU C,LI X. Determination of fracture location of double-sided directional fracturing pressure relief for hard roof of large upper goaf-side coal pillars[J]. Energy Exploration & Exploitation,2020,38(1):111−136. doi: 10.1177/0144598719884701

[20] 吴拥政. 回采工作面双巷布置留巷定向水力压裂卸压机理研究及应用[D]. 北京:煤炭科学研究总院,2018. WU Yongzheng. Study on de-stressing mechanism of directional hydraulic fracturing to control deformation of reused roadway in longwall mining with two gateroad layout and its onsite practices[D]. Beijing:China Coal Research Institute,2018.

[21] 刘长友,刘江伟. 煤岩体裂化的弱结构体应力转移原理及应用[J]. 采矿与安全工程学报,2022,39(2):359−369. LIU Changyou,LIU Jiangwei. principle and applicaition of stress transfer of weak structure body in coal-rock mass cracking[J]. Journal of Mining & Safety Engineering,2022,39(2):359−369.

[22] 杜贝举,刘长友,吴锋锋,等. 深井高应力软弱围岩巷道变形机理及控制研究[J]. 采矿与安全工程学报,2020,37(6):1123−1132. DU Beiju,LIU Changyou,WU Fengfeng et al. Deformation mechanism and control technology of roadway in deep mine with high stress and weak surrounding rock[J]. Journal of Mining & Safety Engineering,2020,37(6):1123−1132.

[23] 康红普,姜鹏飞,冯彦军,等. 煤矿巷道围岩卸压技术及应用[J]. 煤炭科学技术,2022,50(6):1−15. KANG Hongpu, JIANG Pengfei, FENG Yanjun et al. Destressing techlogy for rock around coal mine raodways and its applications[J]. Coal Science and Technology,2022,50(6):1−15.

[24] 康红普. 我国煤矿巷道围岩控制技术发展70年及展望[J]. 岩石力学与工程学报,2021,40(1):1−30. KANG Hongpu. Seventy years development and prospects of strata control technologies for coal mine roadways in China[J]. Chinese Journal of Rock Mechanies and Engineerings,2021,40(1):1−30.

[25] ZHAI W,GUO Y,MA X,et al. Research on hydraulic fracturing pressure relief technology in the deep high-stress roadway for surrounding rock control[J]. Advances in Civil Engineering,2021,2021:1217895. doi: 10.1155/2021/1217895

[26] LU Y,YANG Z,LI X,et al. Problems and methods for optimization of hydraulic fracturing of deep coal beds in China[J]. Chemistry and Technology of Fuels and Oils,2015,51(1):41−48. doi: 10.1007/s10553-015-0573-1

[27] HE Q,SUORINENI F T,MA T,et al. Parametric study and dimensional analysis on prescribed hydraulic fractures in cave mining[J]. Tunnelling and Underground Space Technology,2018,78:47−63. doi: 10.1016/j.tust.2018.04.012

[28] 康红普,冯彦军. 定向水力压裂工作面煤体应力监测及其演化规律[J]. 煤炭学报,2012,37(12):1953−1959. KANG Hongpu,FENG Yanjun. Monitoring of stress change in coal seam caused by directional hydraulicfracturing in working face with strong roof and its evolution[J]. Journal of China Coal Society,2012,37(12):1953−1959.

[29] 刘江伟. 人工裂化煤岩体的应力场改变机制及控制研究[D]. 徐州:中国矿业大学,2020. LIU Jiangwei. Research on mechanism and control of stress field change of artificial cracking coal and rock mass[D],Xuzhou:China University of Mining & Technology,2020.

[30] LIU J,WU N,SI G,et al. Experimental study on mechanical properties and failure behaviour of the pre-cracked coal-rock combination[J]. Bulletin of Engineering Geology and the Environment,2021,80(3):2307−2321. doi: 10.1007/s10064-020-02049-6

[31] 李 杨. 煤层群开采围岩应力壳时空演化特征研究[D]. 北京:中国矿业大学(北京),2017. LI Yang. The study on temporal and spatial evolution characteristics ofsurrounding rock stress shell for coal seam group mining[D]. Beijing:China University of Mining & Technology-Beijing,2017.

[32] 李家卓. 采场底板围岩应力壳力学特征研究[D]. 淮南:安徽理工大学,2015. LI Jiazhuo. Study on mechanical characteristics on surrounding rock of stope floor stresss shell[D]. Huainan:Anhui University of Science & Technology,2015.

[33] 张 旋. 采动应力场对坚硬顶板水力裂缝形态的影响规律研究[D]. 重庆:重庆大学,2018. ZHANG Xuan. Study on the law of hydraulic fracture morphology in hard roof under the influence of mining activities[D]. Chongqing:Chongqing University,2018.

-

期刊类型引用(8)

1. 陈泽民,李振雷,钟涛平,宋大钊,刘旭东,胡旭聪. 急倾斜特厚煤层防冲开采方法数值模拟研究. 煤矿安全. 2025(01): 117-127 .  百度学术

百度学术

2. 侯挺,聂谦,薛兴伟. 弱化转移高水平应力技术在巷道修护中的研究与应用. 山东煤炭科技. 2025(01): 12-16 .  百度学术

百度学术

3. 陈学亚,张宁波,刘立明,陈宝宝,付世雄. 遗留煤柱扰动下薄间距动压巷道压裂卸压护巷技术研究. 煤炭工程. 2025(01): 42-51 .  百度学术

百度学术

4. 郭争利,杨真. 水力压裂防治强矿压机理及卸压护巷技术研究. 山西冶金. 2025(01): 204-206 .  百度学术

百度学术

5. 龚惠春,夏广宁,杨生龙,刘鹏,杨龙. 深埋工作面回采巷道复合顶板水压致裂技术应用. 陕西煤炭. 2024(08): 90-94+140 .  百度学术

百度学术

6. 赵会波. 水力压裂裂缝开裂压力影响因素分析及应用. 煤炭工程. 2024(09): 127-135 .  百度学术

百度学术

7. 聂嘉汾,张海东. 不同切顶角度下临空巷道围岩力学响应特征及控制效果. 山西煤炭. 2024(04): 120-127 .  百度学术

百度学术

8. 曹沛沛. 水力切顶卸压在动压巷道围岩控制中应用. 内蒙古煤炭经济. 2024(24): 160-162 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: