0 引 言

煤层气是国家大力提倡开发的一种清洁能源。根据成因,煤层气可分为生物成因和热成因2种类型[1-4]。基于煤层气的生物成因理论,煤的微生物增产技术得以发展,该技术不仅具有增加能源储备的作用,而且具有增渗效应[5-6]。

截至2016年,我国煤层气产量为45.0亿m3,其中山西省是我国煤层气资源最为丰富的省份,煤层气产量达43.2亿m3,占全国产量的96.0%。龙泉井田作为山西省中阶煤代表井田,井田面积35.2 km2 。龙泉井田的煤层气品质好,甲烷含量自上而下有逐渐增大的趋势。生物成气技术会为该地区煤层气开发开辟新的道路,作为重要的补充技术增产煤层气,为国家和地方的发展带来很大的经济和社会效益[7]。

目前,国内外关于生物成气的研究主要集中在原位微生物群落结构[8-9],生物成气影响因素[10-11],实验室模拟产气和产气机理等方面[12-13]。如:产甲烷菌群中细菌以变形菌门为主,古菌以甲烷杆菌属和甲烷微菌属为主,产甲烷途径以氢营养型和乙酸发酵型居多,且不同产气环境中微生物群落组成存在较大差异[14];沁水盆地煤层微生物通过富集后产甲烷群落结构发生了显著的变化,尤其是古菌优势菌群如甲烷八叠球菌丰度增加。培养基组分及煤量在成气过程中扮演重要角色[15]。ZHANG等[16]的研究表明煤炭生物成气过程中产生的气体及中间产物对持续产气并无抑制作用,而缺乏酵母粉、蛋白碱等类似成分的营养物质,会显著影响煤炭生物成气的持续性。林海等[17]和郭红光等[18]发现原位环境产甲烷菌群经驯化后能大幅提升菌群的产甲烷能力。UNAL等[19]的研究表明微量元素对产甲烷菌功能基因表达水平及菌群结构有一定的影响。杨秀清等[20]发现无烟煤生物发酵(160 L)产气具有可行性,发酵过程中菌群结构较原始煤层水有显著变化。此外,有研究通过比较不同培养条件下微生物菌群降解煤产甲烷情况,优化产甲烷条件[21-22]。

以上研究多侧重于研究影响生物产气能力的客观条件或产气不同时期厌氧菌群结构的变化,鲜见在菌群降解煤产甲烷过程中,通过实时监测发酵产气趋势、营养消耗情况等,即时干预发酵过程,活化功能菌群,从而调控菌群降解煤产甲烷过程,提高菌群降解煤产甲烷能力的研究。基于该方向研究工作的缺陷,笔者从龙泉地区煤层水样中富集培养产甲烷功能菌群,对菌群进行驯化,提高其产气能力。利用该菌群及龙泉矿烟煤在厌氧发酵罐中进行中试产气试验,发酵后期向罐内添加营养物,对发酵过程进行调控,活化功能菌群,改善成气效果,为后期现场生物煤层气的开采提供基础数据。

1 试验材料与方法

1.1 样品采集及物化性质分析

煤层排出水样品取自山西龙泉矿,样品采集过程参照文献[23]操作;煤样采自龙泉矿4号煤层。根据国家标准进行煤样的工业分析(GB/T 30732—2014《煤的工业分析方法》)和元素分析(GB/T 31391—2015《煤的元素分析》),结果见表1。为了便于试验,煤样经破碎过筛得到0.850~0.425 mm(20~40目)样品干燥保藏备用。

表1 龙泉煤样工业分析和元素分析结果

Table 1 Coal sample industry analysis and element analysis results in Longquan Mine

工业分析/%发热量/ (MJ·kg-1) 元素分析/%MadAadVadVdafFCadw(C)w(H)w(O)w(S)w(N)1.431.2624.0232.7242.029.2780.134.5212.420.851.18

注:ad为空气干燥基;daf为干燥无灰基。

1.2 产甲烷菌群富集和驯化产气试验

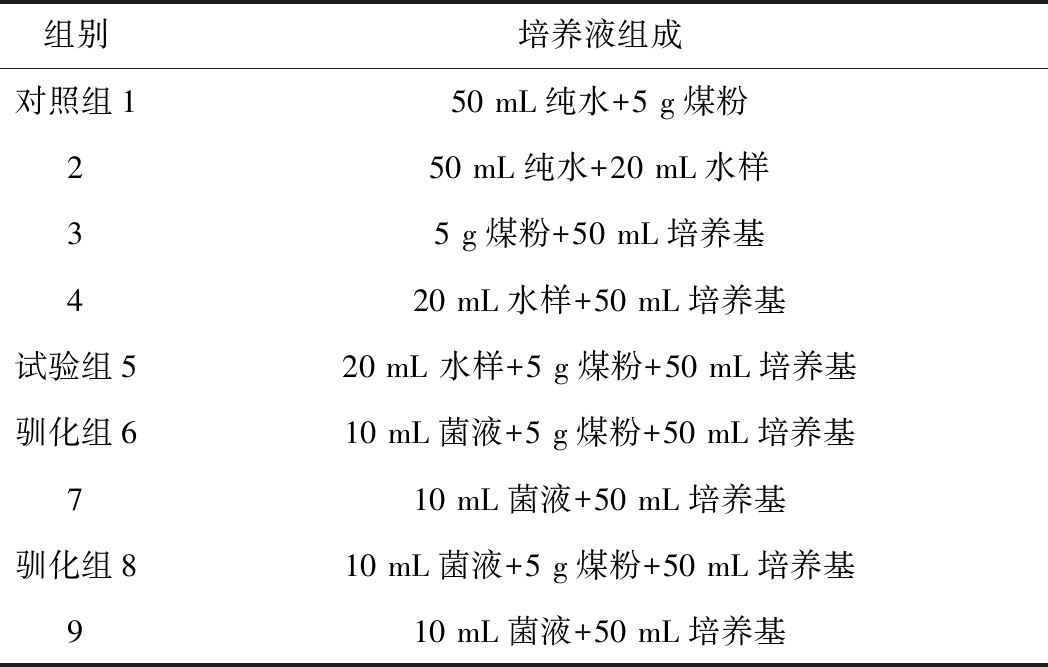

产甲烷菌群富集采用的基本培养基、微量元素和维生素组分等参照文献[24]配置。微生物接种操作在厌氧工作站(DG1000,英国DWS)中完成,具体富集试验方案见表2,操作流程如下:250 mL灭菌厌氧瓶内分别加入各培养液组分,用一次性注射器经无菌过滤器向瓶内加入维生素100 μg/L和半胱氨酸0.25 g/L后封口取出。为了提高富集培养物的产气量,以富集试验组培养至45 d的菌液为菌源,对产甲烷菌群进行驯化产气试验,驯化试验方案见表2。接种好的富集和驯化样品均放入25 ℃恒温培养箱内培养,所有试验均设置3组平行。采用气相色谱仪(7890A,美国安捷伦)定期分析厌氧培养过程中产生的气体成分。

表2 产甲烷菌群富集试验和产气驯化试验

Table 2 Microbiological enrichment test of methane production and domestication test of gas production

组别培养液组成对照组123450 mL纯水+5 g煤粉50 mL纯水+20 mL水样5 g煤粉+50 mL培养基20 mL水样+50 mL培养基试验组520 mL 水样+5 g煤粉+50 mL培养基驯化组6710 mL菌液+5 g煤粉+50 mL培养基10 mL菌液+50 mL培养基驯化组8910 mL菌液+5 g煤粉+50 mL培养基10 mL菌液+50 mL培养基

1.3 产甲烷微生物厌氧发酵产气中试试验

氮气保护下向自制厌氧发酵罐(200 L)内加入10 kg煤样、100 L培养基,通入氮气30 min,接种驯化培养45 d的菌液(接种量10%), 封罐压力1 kPa,35 ℃恒温培养。另以原煤样进行吸附气解吸对照试验,解吸罐装煤样量为10 kg,温度35 ℃,解吸时间45 d。

分别在第25、26和32 d进行放气和补料操作:第25 d,放气至罐压为12 kPa;第26 d,放气至0,充入10 L CO2,放出发酵料液20 L,补入20 L培养液(NH4Cl∶0.6 g/L,K2HPO4∶0.9 g/L,KH2PO4∶0.6 g/L,MgCl2∶0.3 g/L,Ye∶1.5 g/L);第32 d,补入1.5 L培养液(NH4Cl∶24 g,K2HPO4∶40 g,KH2PO4∶18 g,MgCl2∶2 g,Ye∶10 g,微量元素:100 mL,维生素:100 mL)。

定期记录发酵罐(图1)内压力变化,采用气相色谱仪分析培养过程中产生的气体组分及浓度变化。采用离子色谱仪(ICS-300)分析反应初始体系及产气高峰期发酵液中离子种类和浓度[25] 。

图1 中试厌氧发酵罐(200 L)

Fig.1 Anaerobic fermentation for pilot test (200 L)

2 结果与讨论

2.1 龙泉产甲烷菌群富集产气

富集培养龙泉气田产甲烷菌群,成气效果及趋势如图2所示,其中1、 3组结果表明原煤吸附气甲烷含量分别为5.38%和4.98%,2、4组几乎无CH4生成,但4组CO2含量较2组有所提高,推测是水样中发酵菌和腐生菌被激活,消耗培养基中有机底物生成CO2。5组最高CH4量达8.3%,产气率为1.24 mL/g,明显高于对照组,说明样品中有重要内源产气功能菌群,通过增加营养物可被激活 [23]。综上,龙泉产甲烷菌群有一定成气能力,但效果不佳,为改善成气效果,需增加培养基中营养物浓度,并进行菌源驯化试验。

图2 富集产气试验气体组分和含量变化曲线

Fig.2 Variation curves for gas components and concentration of enrichment gas production test

2.2 龙泉产甲烷菌群驯化试验

驯化后各试验组气体含量随时间变化曲线如图3所示,6组和8组的驯化结果优于7组和9组,甲烷体积分数达19%。可见驯化过程中煤粉起重要作用。该结果也说明通过驯化,菌群降解煤的产气量显著提高(由8.3%上升至19%),初始产气点提前,到达产气稳定期的周期缩短。陈浩等[26]研究表明:本源菌可以降解煤产甲烷,通过人为干预可大幅提高产量,如添加外源菌种,产气量可达1.68 m3/t,增产比例达115%,而添加营养物质产气量达1.9 m3/t,增产比例达144%。林海等[27]研究表明,产甲烷菌群经7次驯化后,适应期由15 d缩短到6 d,产气量由30 mL增至260 mL,每100 mL培养基中添加1.0 g乙酸钠,产气量可增加80 mL。

图3 驯化试验气体组分和含量变化曲线

Fig.3 Variation curves for gas components and concentration of domestication gas production experiments

2.3 龙泉产甲烷微生物厌氧发酵中试产气

龙泉中试产气总的产气量和气体组分及含量变化如图4所示。产气周期约为25 d,0~11 d为延滞期,11~21 d为指数期, 21 d之后为稳定期,截至第38 d,总产气量达84.32 L(H2:0.14 L, CH4:60.55 L, CO2:23.63 L)。产甲烷浓度最高达 27.06%。产气速率为0.221 mL/(g·d),产甲烷速率为0.159 mL/(g·d)。原煤解吸气试验结果表明解吸气平均值为0.187 5 L/kg,中试发酵试验解吸气贡献0.18 L/kg,仅占总产气量2.0%左右。

图4 龙泉井田产甲烷菌群厌氧发酵气体体积变化和含量变化

Fig.4 Volume and components variation of gas in anaerobic fermentation with methanogens obtained from Longquan Minefiled

龙泉地区生物成气与国内外其他地区报道相比周期较短,初始产甲烷时间较晚,氢气消耗量较多。甲烷含量停止增长后,煤仍然具有继续成气的潜力。补入CO2或补充20%与原营养液浓度相同的新营养液,对维持产气效果并不理想。但是通过提高营养液中各组分浓度,增加微量元素和维生素,能有效恢复发酵产气,出现第2个产气高峰点,但甲烷含量并未达到第1次产气高峰的甲烷含量水平。可见如何通过补料维持产气,还有许多问题有待进一步研究,如营养液替换比例、替换时间、替换组分等。

有研究结果表明,微量元素和维生素在维持产气稳定性方面发挥重要作用[28]。酵母粉在成气过程中的作用不同学者各执己见。有的认为酵母粉含维生素、氨基酸和微量矿物质,可作为激活剂刺激煤的生物气化[29],有的认为酵母粉能够增加煤的溶解度和生物降解[30]。然而,文献[31]研究表明,酵母粉对甲烷生成产生抑制作用。

龙泉煤层水,厌氧产气初期和高峰期溶液中离子浓度结果见表3。由表中结果可知发酵初期中钠、钾、镁、氨、氯和磷均明显增加,这和培养基添加有关。相比之下,发酵高峰期溶液中磷酸根离子、钾离子和镁离子浓度较初始液体中浓度降低。磷脂是细胞膜系统的重要组成部分,是维持微生物的生命活动的细胞基础,发酵过程中菌群代谢传代,都离不开磷元素的参与,因此磷元素的降低可能与微生物的生长有关。钾离子作为细胞内外渗透泵作用的重要元素,在细胞能量代谢,电子传递过程中发挥着举足轻重的作用,因此推测钾离子浓度降低可能与细胞的摄入有关。镁离子参与产甲烷菌系重要辅酶的活性发挥。氨盐浓度也降低,作为氮源参与微生物厌氧发酵。硫酸根离子和硝酸根离子浓度有所上升,有研究表明硫酸还原菌与厌氧发酵菌底物对产气有抑制作用,也有研究提出硫酸根离子会抑制产甲烷菌的活性,甚至影响了产甲烷代谢途径碳的流向与分配[32]。还有报道称互营代谢是生物厌氧发酵过程中的核心代谢途径,硫酸盐还原菌与互营烃降解菌之间是合作或竞争关系尚待证实[33]。

发酵液中硫酸根离子的增长表征了硫酸还原菌系在厌氧发酵过程中起到一定负作用,未来可能需添加针对其的诱导或抑制剂[34]。有报道称ε-变形菌纲是煤层水中的第一大类群。其中螺杆菌属(Sulfuricurvum kujiense)细菌是化能无机营养菌,在严格厌氧的环境中以硝酸盐为电子受体,靠氧化硫化物、元素硫和氢获得能量[35]。在地下油藏中靠氧化原油中的硫进行代谢,也有研究表明反硝化菌系参与了厌氧生物成气,为甲烷菌群生长繁殖提供厌氧环境[36]。中试厌氧发酵过程中硝酸根离子的上升支持了报道结果。

表3 龙泉井田产甲烷菌群中试厌氧发酵前后离子浓度变化

Table 3 Changes of ion concentration before and after anaerobic pilot anaerobic fermentation in Longquan Minefield

检测项目矿井水量/(mg·L-1)离子浓度/(mg·L-1)反应初期产气量后期pH值8.037.007.03氟化物0.190.2111.75氯化物167.901 394.50665.20亚硝酸盐未检出未检出未检出可溶性磷酸盐30.101 765.8026.69硝酸盐321.80336.10463.50溴盐0.150.230.15硫酸盐10.5711.64575.90碳酸盐未检出未检出未检出重碳酸盐未检出未检出未检出氨盐未检出1 800448.40钠828.10842.30449.60钾27.482 432.351 464.00镁9.23325.168.93钙17.9417.9021.94硬度82.74∗82.74∗82.74∗

注:*以CaO计。

3 结 论

1)以龙泉地区水样和煤样为研究对象,进行了微生物菌群富集驯化和中试厌氧发酵调控等研究。

2)龙泉煤层产甲烷菌群经富集驯化后,降解烟煤产甲烷的浓度由8.2%上升至19%,且产气周期缩短。中试试验中,产甲烷浓度最高达27.06%,产甲烷速率达0.159 mL/(g·d)。

3)在煤炭生物成气厌氧发酵衰退期添加酵母粉、氮源、磷盐、镁盐、维生素、微量元素,可重新激活产甲烷菌群的活性,使其降解烟煤产甲烷浓度回升至16.75%。

4)硫酸还原菌和反硝化菌可能在煤炭生物成气厌氧发酵代谢途径中发挥重要作用。

[1] WELTE C U.A microbial route from coal to gas[J].Science,2016,354:184-184.

[2] 陈 润,王优阳,王琳琳,等.煤层生物气组成特征及其影响因素研究进展[J].煤炭科学技术,2016,44(11):167-172.

CHEN Run,WANG Youyang,WANG Linlin,et al.Research progress on characteristics of biogenic coal bed gases and its influence factors[J].Coal Science and Technology,2016,44(11):167-172.

[3] STRAPO D,MASTALERZ M,DAWSON K,et al.Biogeochemistry of microbial coal-bed methane[J].Annual Review of Earth and Planetary Sciences,2011,39 :617-656.

D,MASTALERZ M,DAWSON K,et al.Biogeochemistry of microbial coal-bed methane[J].Annual Review of Earth and Planetary Sciences,2011,39 :617-656.

[4] ROMEO M F,CYNTHA A R,GARY D S,et al.Methanogenic pathways of coal-bed gas in the Power River Basin,United States:the geologic factors[J].Int J Coal Geol,2008,76:52-75

[5] ZHENG Hang,CHEN Tianyu,VICTOR Rudolph,et al.Biogenic methane production from Bowen Basin coal waste materials[J].International Journal of Coal Geology,2017,169:22-27.

[6] 郭红光,王 飞,李志刚.微生物增产煤层气技术研究进展[J].微生物学报,2015,42(3):584-590.

GUO Hongguang,WANG Fei,LI Zhigang.Research progress of microbially enhanced coalbed methane[J].Microbiology China,2015,42(3):584-590.

[7] FALLGREN P H,JIN S,ZENG C,et al.Comparison of coal rank for enhanced biogenic natural gas production[J].Int J Coal Geol,2013,115:92-96.

[8] GUO Hongguang,YU Zhisheng,ZHANG Hongxun.Phylogenetic diversity of microbial communities associated with coalbed methane gas from Eastern Ordos Basin,China[J].International Journal of Coal Geology,2015(150/151):120-126.

[9] GUO Hongguang,YU Zhisheng,IAN P Thompson,et al.A contribution of hydrogenotrophic methanogenesis to the biogenic coal bed methane reserves of Southern Qinshui Basin,China[J].Environmental Biotechnology,2014,98:9083-9093.

[10] 李亚平,郭红光,韩 青,等.水稻秸秆与煤共降解增产煤层生物甲烷试验研究[J].煤炭科学技术,2018,46(4):215-221.

LI Yaping,GUO Hongguang,HAN Qing,et al.Experimental research on enhancing biogenic methane production in coal seam by co-degradation of rice straw and coal[J].Coal Science and Technology,2018,46(4):215-221.

[11] 王保玉,陈林勇,邰 超,等.外源菌群煤生物气化初步研究:菌群结构、煤种及煤孔(裂)隙[J].煤炭学报,2014,39(9):1797-1801.

WANG Baoyu,CHEN Linyong,TAI Chao,et al.A preliminary study of biological coal gasification by exogenous bacteria:microbiome composition,coal type,pore and seam fracture[J].Journal of China Coal Society,2014,39(9):1797-1801.

[12] LIU Jianmin,WANG Baoyu,TAI Chao,et al.An effective method to detect volatile intermediates generated in the bioconversion of coal to methane by gas chromatography-mass spectrometry after in-situextraction using headspace solid-phase micro-extraction under strict anaerobic conditions[J].Plos One,2016,11(10):e016394910.

[13] 陈林勇,王保玉,邰 超,等.无烟煤微生物成气中间代谢产物组成及其转化[J].煤炭学报, 2016,41(9):2305-2311

CHEN Linyong,WANG Baoyu,TAI Chao,et al.Composition and conversion of intermediate products in the process of anthracite gasification by microorganism[J].Journal of China Coal Society,2016,41(9):2305-2311.

[14] STEPHEN Y Park,LIANG Yanna.Biogenic methane production from coal:a review on recent research and development on microbially enhanced coalbed methane(MECBM)[J].Fuel,2016,166:258-267.

[15] 杨秀清,吴瑞薇,韩作颖,等.基于mcrA基因的沁水盆地煤层气田产甲烷菌群与途径分析[J].微生物学通报,2017,44(4):795-806.

YANG Xiuqing,WU Ruiwei,HAN Zuoying,et al.Analysis of methanogenic community and pathway of coalbed methane fileds in the Qinshui basin based on mcrA gene[J].Microbiology China,2017,44(4):795-806.

[16] ZHANG Ji,LIANG Yanna.Evaluating approaches for sustaining methane production from coal through biogasification[J].Fuel,2017,102:233-240.

[17] 汪 涵,林 海,董颖博,等.外源产甲烷菌降解褐煤产气实验[J].石油勘探与开发,2012,39(6):764-768.

WANG Han,LIN Hai,DONG Yingbo,et al.Experiments on the gas production of brown coal degraded byexogenous methanogens[J].Petroleum Exploration and Development,2012,39(6):764-768.

[18] GUO Hongguang,LIU Ruyin,YU Zhisheng,et al.Pyrosequencing reveals the dominance of methylotrophic methanogenesis in a coal bed methane reservoir associated with Eastern Ordos Basin in China[J].International Journal of Coal Geoloy,2012,93(1):56-61.

[19] UNAL B,PERRY V R,Shcth M,et al.Trace elements affect methanogenic activity and diversity in enrichments from subsurface coal bed produced water[J].Frontiers in Microbiology,2012(3):175-180.

[20] YANG Xiuqing,CHEN Yanmei,WU Ruiwei,et al.Potential of biogenic methane for pilot-scale fermentation ex situ with lump anthracite and the changes of methanogenic consortia[J].Journal of Industrial Microbiology & Biotechnology,2018,45(4):229-237.

[21] RITTER D,VINSON D,BARNHART E,et al.Enhanced microbial coalbed methane generation:a review of research,commercial activity,and remaining challenges[J].Int J Coal Geol,2015,146:28-41.

[22] 徐 鑫,梁 萌.提高煤层气采收率的方法和技术进展[J].中国煤层气,2016,13(3):3-6.

XU Xin,LIANG Meng.Method of improving CBM recovery rate and technologies research progress[J].China Coalbed Methane,2016,13(3):3-6.

[23] MAYUMI D,MOCHIMARU H,TAMAKI H,et al.Methane production from coal by a single methanogen[J].Science,2016,354:222-225.

[24] ZHANG Ji,LIANG Yanna,PANDEY R,et al.Characterizing microbial communities dedicated for conversion of coal to methane in situ[J].Int J Coal Geol,2015,146:145-154.

[25] WU Yuting,GE Xiaoguang,ZHOU Ni.Analysis on coal bed methane corresponding to groundwater chemical types in some northern China Plain coal fields[J].World Scientific,2017(2):243-250.

[26] 陈 浩,李贵中,陈振宏,等.微生物提高煤层气产量模拟实验研究[J].煤田地质与勘探,2016,44(4):64-68.

CHEN Hao,LI Guizhong,CHEN Zhenhong,et al.Simulation experiment on enhancing coalbed methane production by microbes[J].Coal Geology&Exploration,2016,44(4):64-68.

[27] 林 海,隋梦琪,汪 涵.微生物增产煤层气菌种的驯化[J].煤炭学报,2012,37(8):1359-1363.

LIN Hai,SUI Mengqi,WANG Han.Domestication of microbially enhanced coalbed methane microorganism[J].Journal of China Coal Society,2012,37(8):1359-1363.

[28] THAKER N,KHARDEAVIS A,PUROHIT H J.Recent advances in factors and method for stimulation of biomethane production[J].Recent Advances in Dna & Gene Sequences,2015,9(1):3-13.

[29] RITTER D,VINSON D,BARNHART E,et al.Enhanced microbial coaled methane generation:a review of research,commercial activity,and remaining challenges[J].Int J Coal Geol,2015,146:28-41.

[30] FAKOUSSA R,HOFRICHTER M.Biotechnology and microbiology of coal degradation[J].Appl Microbiol Biotechnol,1999,52:25-40.

[31] HARRIS S H,SMITH R L,BARKER C E.Microbial and chemical factors influencing methane production in laboratory incubations of low-rank subsurface coals[j].Int J Coal Geol,2008,76:46-51.

[32] ZHANG Ji,PARK S Y,LIANG Y,et al.Finding cost-effective nutrient solutions and evaluating mental conditions for biogasifying bituminous coal to methane in situ[J].Appl Energy,2016,165:559-568.

[33] ROHIT P,SATYA H,FENG R M,et al.Changes in gas storage and transport properties of coal as a result of enhanced microbial methane generation[J].Fuel,2016,179:114-123.

[34] JONE E P J,VOYTEK M A,CORUM M D,et al.Stimulation of methane generation from nonproductive coal by addition of nutrients or a microbial consortium[J].Applied and Environmental Microbiology,2010,76(21):7013-7022.

[35] 吴 鹏,魏国琴,韩作颖,等.沁水盆地寺河地区煤层水细菌多样性分析[J].生物技术,2017,27(2):161-166.

WU Peng,WEI Guoqin,HAN Zuoying,et al.Bacteria diversity in coalbed water at Sihe area of Qinshui Basin[J].Biotechnology,2017,27(2):161-166.

[36] XIAO D,PENG S P,WANG E Y.Fermentation enhancement of methanogenic archaea consortia from an illinois basin coalbed via DOL emulsion nutrition[J].Plos One,2015,10(4):124-128.