移动扫码阅读

地球科学与测绘

移动扫码阅读

我国多煤层发育区煤系非常规天然气(煤层气、煤系页岩气、煤系致密砂岩气简称“煤系气”或煤系“三气”)开发潜力巨大[1-3]。将煤层、煤系泥质岩、煤系砂岩互层段作为统一目标层段进行综合评价与勘探开发,可实现煤系气资源综合利用和效益最大化[4-6],基于煤系气储层优化组合的分段射孔、分层压裂、合层排采是实现煤系气共探共采的关键技术手段[7-9]。优化合采产层组合,确定射孔位置,优化压裂工艺与施工参数,均衡改造多类型煤系气储层,对煤系气勘探开发至关重要,甚至决定煤系气合采成败。

我国煤系气共探共采尚处于探索阶段,目前已取得1 000 m以浅多煤层合采或以煤层为主要目的层的煤系气合采勘探突破[1,10],但射孔位置优化多限于煤系泥页岩与煤系砂岩的叠置组合[11];鲜有1 000 m以深的煤系气勘探开发,仅在鄂尔多斯盆地东缘开展了较为系统的煤层气和煤系砂岩气合采[12-14],鸡西盆地煤系“三气”共探共采取得点上突破[15]。由于具有工业开采价值的煤系气藏赋存及共采的有利深度一般大于1 000 m[16],因此深部煤系气共探合采关键技术有待于进一步探索。选择中国地质调查局在鸡西盆地梨树井田实施的煤系气地质调查井HJD1井,以下白垩统城子河组埋深1 000~1 430 m的煤层、煤系致密砂岩层、煤系泥质岩层互层发育段为目标,系统研究了煤系气储层地质特征,优选了煤系气有利层段,优化组合了合采产层,探索了与煤系多类型储层特征相匹配的分段射孔、水力压裂工艺,优化了压裂施工流程与工艺参数,实现了煤系气储层的均衡改造,对相似地质条件区煤系气高效勘探开发具有借鉴意义。

鸡西盆地主要含煤地层为中生界下白垩统城子河组。城子河组为一套断陷期沉积的以陆相三角洲前缘相和滨浅湖-半深湖相为主的砂泥岩互层夹煤层、煤线沉积,地层总厚度580~830 m,含煤20余层,单层厚度0.40~2.75 m,煤层累计厚度23.4~33.2 m,瓦斯相对涌出量5.0~13.0 m3/t;煤系泥页岩、碳质粉砂岩、碳质泥岩等暗色地层约占地层总厚度的37%~43%,单层厚度0.35~5.70 m,有机质含量0.47%~5.19%,具有典型的煤系烃源岩特征。煤系烃源岩与储层互层状接触,源-储匹配关系好,煤层、煤系碳质泥岩、致密砂岩中均见到活跃气测显示[17-18]。

HJD1井位于黑龙江省东部鸡西盆地梨树镇坳陷梨树井田。梨树井田位于梨树沟向斜南翼,为一构造复杂程度中等、轴向近东西向的背斜向斜褶曲,褶曲幅度小,两翼对称,地层倾角20°左右(图1)。HJD1井钻遇城子河组上煤组12煤、14煤,中-下煤组22煤、23煤、28煤、29煤等区域主力煤层,煤层结构简单,单层厚度0.60~2.75 m。该井为具有二开结构的小角度定向斜井,二开592.58~1 488.09 m为稳斜段,井斜7.46°~11.12°,方位142.7°~151.1°(图1)。

图1 鸡西盆地HJD1井位置与井身结构(鸡西盆地构造纲要图据文献[18-19])

Fig.1 Location and wellbore structure of Well HJD1 in Jixi Basin(Structural outline of Jixi Basin according to literature [18-19])

上煤组宏观煤岩类型以半亮煤、半暗煤为主,煤体结构以原生结构为主,裂隙较为发育,渗透率为(0.386~0.67)×10-3 μm2;中-下煤组宏观煤岩类型以半暗煤、暗淡煤为主,煤体结构多为碎裂结构和碎粒结构,渗透率为(0.158~0.195)×10-3 μm2;为中等渗透性煤储层。孔隙类型有群带状分布、较少连通的有机质气孔、单条-网状张性裂隙、黏土矿物晶间孔及溶蚀孔等[19-21];压汞法测定煤岩孔隙度为2.24%~7.02%,平均为4.46%,煤孔隙度偏低。

煤系泥岩以灰黑-深灰色泥岩、粉砂质泥岩和黑色碳质泥岩为主,矿物成分以伊利石和石英为主;孔隙类型以微孔、微裂缝为主,孔隙度0.13%~5.99%,平均1.28%,渗透率普遍低于1.00 ×10-3 μm2,为特低孔特低渗储层。煤系砂岩以灰色细砂岩、粉砂岩、泥质粉砂岩、中砂岩为主,矿物成分以碳酸盐岩类、石英等脆性矿物为主,脆性矿物指数为30~73,多为45~70,利于压裂改造;孔隙类型以粒间溶蚀孔为主,样品测试孔隙度为0.62%~8.10%,渗透率为(0.000 1~4.02)×10-3 μm2,为低孔低渗砂岩储层。主力煤层顶底板具有较好的隔水性与封盖性。

可采煤层现场解吸瓦斯相对涌出量为3.36~7.88 m3/t,平均5.35 m3/t;兰氏体积为9.98~25.64 m3/t,平均为18.13 m3/t;兰氏压力为1.87~4.54 MPa,平均2.95 MPa。根据注入/压降试井获得的煤层压力,计算其理论含气饱和度为22.16%~60.21%,平均33.93%;临界解吸压力为0.90~2.51 MPa,平均1.46 MPa;临储比为0.04~0.23,平均0.12。煤储层具有临界解吸压力低、临储比低、欠饱和的特征,决定了煤层气井见套压前排水降压时间相对较长。

煤系泥岩气测全烃峰值一般为5.04%~13.88%,峰基比为4.23~12.87;空气干燥基瓦斯相对涌出量为0.28~0.81 m3/t,平均0.55 m3/t。煤系砂岩气测全烃峰值一般为1.5%~24.0%,峰基比为3.36~14.99;空气干燥基含气量为1.76~3.46 m3/t,平均2.70 m3/t;含气饱和度为13.20%~25.30%,平均19.88%。

煤岩有机质质量分数为82.90%~91.10%,平均87.00%,生烃潜量S1+S2质量分数为151.5~176.2 mg/g,有机质丰度较高,生烃潜量好。煤岩中有机显微组分占53.17%~88.94%,其中镜质组占91.03%~97.56%,惰质组占2.44%~8.97%,不含壳质组。煤的镜质组最大反射率(Ro,max)为1.04%~1.46%,平均1.30%,为中等变质程度的肥煤和焦煤。煤工业分析水分、灰分、挥发分平均值分别为0.68%、25.16% 和26.78%,属于特低水、低-中灰、中挥发分煤。总体上有利于煤层气生成、吸附与富集。

煤系暗色泥岩有机质类型以Ⅲ型为主、少量Ⅱ2型,属于生气型源岩,有机质质量分数为0.46%~7.81%,氯仿沥青“A”为0.003%~0.709%,生烃潜量S1+S2为0.11~82.22 mg/g,为优质烃源岩;Ro为0.5%~2.0%,多为0.8%~1.3%,处于成熟演化阶段[22-23]。煤系致密砂岩有机质类型为Ⅱ2-Ⅲ型,有机质质量分数为0.01%~3.17%,平均0.60%,生烃潜力较好层段有机质质量分数为0.42%~3.17%,平均1.34%。总体上,城子河组暗色砂泥岩为优质烃源岩,为煤系气藏的形成提供了良好的气源保证。

注入/压降试井获得主采煤层温度介于20.57~53.47 ℃,地温梯度为2.10~3.88 ℃/hm;煤储层压力10.77~13.87 MPa,压力系数0.95~1.09,为正常压力系统;煤储层破裂压力18.10~23.72 MPa,破裂压力梯度0.017 2~0.018 4 MPa/m,闭合压力17.11~19.31 MPa,闭合压力梯度0.014 0~0.017 4 MPa/m,处于较高应力场(表1)。

表1 梨树井田城子河组主力煤层注入/压降试井解释成果

Table 1 Injection/pressure dropwell tests of main coal seams in Chengzihe,Lishu minefield

注:JMC1井距离HJD1井1 050 m;龙煤丛式井距离HJD1井1 570 m。

煤层埋深/m渗透率/10-3 μm2储层温度/℃储层压力/MPa压力系数破裂压力/MPa破裂压力梯度/(10-2 MPa·m-1)闭合压力/MPa闭合压力梯度/(10-2 MPa·m-1)测试井14986.290.386~0.67020.5710.771.0918.101.8417.211.74JMC1井,龙煤丛式井221 192.330.15841.4711.330.9520.781.7417.111.42HJD1井321 367.370.19553.4713.871.0123.721.7219.311.40HJD1井

自然状态下,测得煤层及顶底板砂泥岩主要力学参数见表2。主要煤层顶底板抗压强度均大于对应煤层的破裂压力,煤层泊松比明显高于顶底板泥岩、粉砂质泥岩和碳质泥岩,表明顶底板抗压性较好,有利于压裂裂缝在煤层中扩展。

表2 煤系储层主要岩石力学参数

Table 2 Main rock mechanics parameters of coal measures reservoir

注:*数据来源于文献[24],鸡西城子河煤矿23号煤层,深度823 m;**为平均数据。

岩层密度/(g·cm-3)弹性模量/MPa泊松比抗压强度/MPa黏聚力/MPa内摩擦角/(°)抗拉强度/MPa煤层*1.38~1.931.58**987.6~1 612.10.25~0.287.24~20.632.42824.461.158~1.241顶底板砂泥岩2.48~2.622.55**2 400~31 20012 280**0.11~0.270.25**14.9~72.745.16**1.15~14.954.83**32.4~37.834.1**3.23~4.243.80**

HJD1井城子河组气测异常显示较好的含煤层段有10层31 m,岩性组合为煤、粉细砂岩及碳质泥岩、泥岩,气测全烃峰值10.10%~29.87%,峰基比1.98~30.48;气测异常显示较好的非煤层段有8层22 m,岩性以碳质泥页岩、粉砂岩、细砂岩为主,气测全烃峰值16.16%~30.77%,峰基比3.36~14.99。

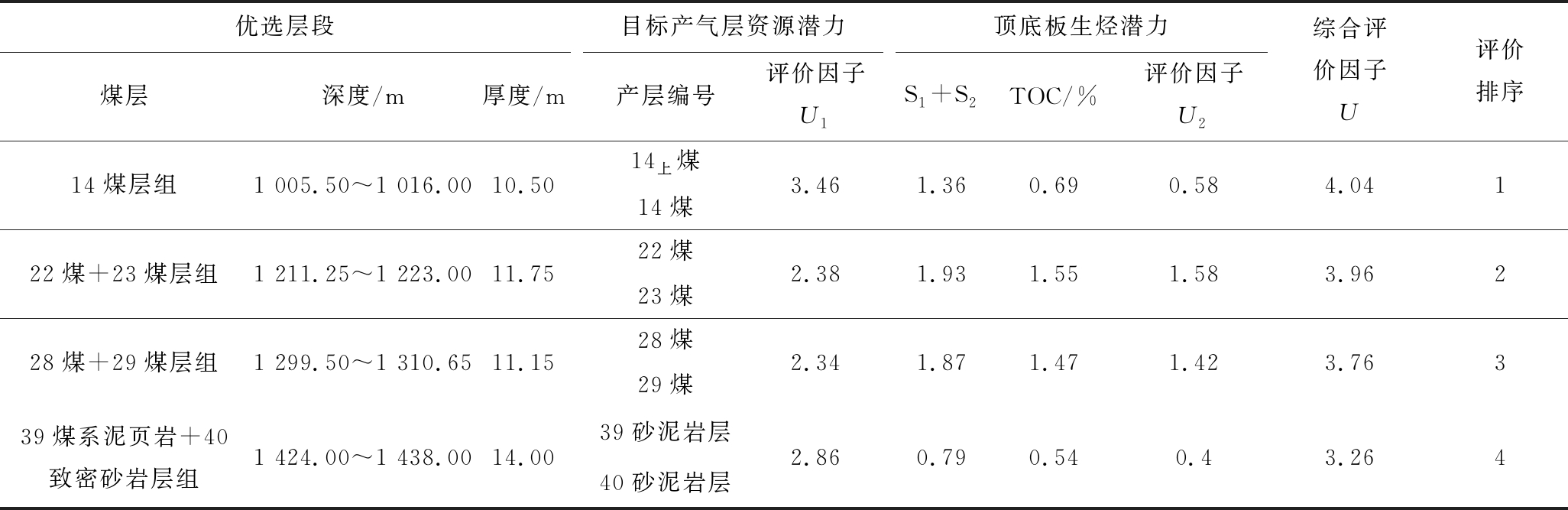

采用加权求和法对含煤层段和非煤层段进行有利层段优选,各项指标的相对重要性系数采用模糊数学方法确定。由于煤层为本区煤系气重要储集层和产气层,其资源潜力决定单井产气量。以含气量和气测异常为主要评价指标,评价煤层资源潜力,并按指标权重计算量化为评价因子Um,优选有利层段依次为:14煤、28煤+29煤、22煤+23煤、12煤、25煤、32煤(表3)。其中,

表3 HJD1井城子河组含煤层段评价优选结果

Table 3 Evaluation and optimization results of coal bearing sections in Chengzihe Formation of Well HJD1

煤层段煤层编号煤层深度/m煤层厚度/m含气量评价含气量/(m3·t-1)系数R1气测异常评价气测全烃峰值/%气测异常厚度/m系数R2综合评价因子Um优选排序12煤14煤22煤+23煤25煤+26煤28煤+29煤12907.15~908.401.2512下921.00~921.500.5014上1 007.90~1 008.350.45141 011.70~1 014.452.75221 212.10~1 213.501.40231 221.95~1 222.500.55251 269.35~1 270.351.00261 274.00~1 274.600.60281 301.30~1 302.351.05291 309.00~1 309.600.60 5.45 6.68 4.56 4.37 4.170.5 29.871 2.00 6.666 2.00 16.892 1.00 10.918 4.00 17.595 2.00 6.575 1.00 8.048 2.00 7.090 1.00 10.106 5.00 16.574 3.00 0.005 2.91 2 3.46 1 2.38 3 2.30 5 2.34 4

Um=GR1+CMR2

(1)

式中:Um为煤层综合评价因子;G为煤层含气量;C为气测全烃峰值;M为气测异常厚度;R1、R2为系数。

煤系砂泥岩既是煤系气主要烃源岩也是储集层。以含气性、生烃潜力为主要评价指标,量化为综合评价因子Uf,优选有利层段依次为:22层、29层、36层、39层、37层(表4)。其中,

表4 HJD1井城子河组非煤层段评价优选结果

Table 4 Evaluation and optimization results of non coal seam sectionsin Chengzihe Formation of Well HJD1

注:地化指标值参考相邻深度取样点地化指标值。

非煤层段序号岩性非煤层段深度/m含气性指标气测全烃峰值/%气测异常厚度/m系数R1生烃潜力指标S1+S2TOC/%系数R2综合评价因子Uf优选排序18碳质泥岩、中砂岩902~90410.8342.0021碳质泥岩、中砂岩、细砂岩954~9556.1291.0026碳质泥岩、细砂岩1 021~1 0226.1291.0029中砂岩、细砂岩1 226~1 2289.3892.0030碳质泥岩、粉砂岩1 236~1 2385.3162.0038细砂岩、碳质泥岩1 391~1 39317.9002.0039中砂岩、碳质泥岩1 426~1 42823.0062.0040中砂岩1 436~1 43819.7632.0041中砂岩、粉砂岩1 447~1 44916.9922.0042中砂岩、细砂岩1 451~1 45219.0821.0043中砂岩、细砂岩1 457~1 45816.1461.000.0051.3650.6911.3650.6911.3650.6911.9291.5461.8661.4680.7850.5420.7850.5420.7850.5420.7850.5420.7850.5420.7850.542 0.50.5830.5040.5051.5811.4220.3990.4460.4170.3880.31100.2911

Uf=CMR1+STR2

(2)

式中:Uf为非煤层综合评价因子;S为生烃潜量S1+S2;T为TOC含量。

HJD1井主要目的是探索煤系气储层改造工艺和层间跨度较大的煤系“三气”合层排采工艺。将煤层、煤系砂泥岩层均作为“煤系气烃源岩层及储集层”,根据煤系主要含气层和烃源岩发育特征,以目标产气层资源潜力(厚度、含气性)、非煤层段的生烃潜力为主要评价指标,按指标权重计算量化为评价因子U,参考产层组埋深、跨度等因素,进行合采产层优化组合,自下而上确定了4个目标层段,分别为:① 39煤系碳质泥页岩+40致密砂岩层组;② 28煤+29煤层组;③ 22煤+23煤层组;④ 14煤层组。4个目标层段产气层厚度分别为4.00、1.65、1.95和3.20 m,目标层段间距分别为113.35、76.50和195.25 m(表5、图2),均为正常地层压力状态(表1)。

表5 HJD1井城子河组合采产层优化组合与评价

Table 5 Optimal combination and evaluation of commingled production layers in Chengzihe Formation of Well HJD1

优选层段煤层深度/m厚度/m目标产气层资源潜力产层编号评价因子U1顶底板生烃潜力S1+S2TOC/%评价因子U2综合评价因子U评价排序14煤层组1 005.50~1 016.0010.5014上煤14煤3.461.360.690.584.04122煤+23煤层组1 211.25~1 223.0011.7522煤23煤2.381.931.551.583.96228煤+29煤层组1 299.50~1 310.6511.1528煤29煤2.341.871.471.423.76339煤系泥页岩+40致密砂岩层组1 424.00~1 438.0014.0039砂泥岩层40砂泥岩层2.860.790.540.43.264

U= U1+U2

(3)

式中:U为产层组综合评价因子;U1为资源潜力综合评价因子;U2生烃潜力综合评价因子。

1)39煤系碳质泥页岩+40致密砂岩层组岩性组合以“煤系碳质泥岩+致密砂岩”为特征,目标产气层为中砂岩和碳质泥岩,为HJD1井埋藏深度最大、含气性最好的非煤含气层段,对探索深部煤系砂泥岩储层改造及排采具重要意义。

2)28煤+29煤层组岩性组合以“煤层+煤系碳质泥岩+煤层”为特征;目标产气层为28煤层、29煤层,层间煤系碳质泥岩及粉砂岩具有较好的含气性和生烃潜力,具有煤系“三气”发育特征。

3)22煤+23煤层组岩性组合以“煤层+煤系砂岩+煤层”为特征,目标产气层为22煤层、23煤层,煤层间粉砂岩和碳质泥岩含气性及生烃潜力高,该段为HJD1井气测异常显示最连续、厚度最大、含气量较高、生烃潜量最大的层段,具有典型的煤系气富集特征。

4)14煤层组岩性组合以“煤层+煤层”为特征,煤层结构为0.75(0.80)1.20(煤层厚度(类矸厚度)煤层厚度),目标产气层为14上煤层、14煤层和层间碳质泥岩和泥质粉砂岩,该段为HJD1井含气性最好的煤层层段。

水力压裂改造方式下,优化多目标层段射孔位置、射孔段长度对于实现煤系气储层均衡改造至关重要[25-26]。HJD1井主要产气层为煤层和煤系致密砂岩、泥页岩。对煤层为主要产气层的层段,为预留煤层产气通道、沟通顶板煤系页岩气和致密砂岩气,射孔段采取射开目标煤层、扩射顶底板方案,以充分改造煤层及顶底板含气性较好的煤系砂泥岩储层,最大限度释放产气潜能。与单一煤层气开发顶板短距离扩射相比,本次增加扩射距离和层数,共扩射煤层顶板6层,扩射长度0.70~1.80 m,扩射煤层底板5层,扩射长度0.50~2.65 m。对煤系砂泥岩产气层段,尽量改造主产气层及其上下含气性较好层段,扩射39煤系砂泥岩产层顶底板2层2.00 m,扩射40煤系砂泥岩顶板1层0.45 m。射孔段长度为煤层厚度的1.8~6.3倍,为砂泥岩产气层厚度的1.2~3.0倍(表6、图2)。采用2.0% KCl活性水射孔液、电缆输送102枪127弹分段射孔,按初始相位角90°螺旋布孔,孔眼垂向密度16 孔/m,4段共射孔483个。

表6 HJD1井城子河组优选目标层段及射孔层段数据

Table 6 Data of optimized target intervals and perforation intervals in Chengzihe formation of Well HJD1

优选层段煤层深度/m厚度/m目标产气层段产层编号深度/m厚度/m射孔层段深度/m层厚/m累计长度/m岩性14煤层组1 005.50~1 016.0010.5014上煤1 007.90~1 008.350.451 005.50~1 008.352.8514煤1 011.70~1 014.452.751 011.00~1 016.005.007.85煤、细砂岩煤、碳质泥岩、泥岩、细砂岩22煤+23煤层组1 211.25~1 223.0011.7522煤1 212.10~1 213.501.401 211.25~1 215.003.7523煤1 221.95~1 222.500.551 221.00~1 223.002.005.75煤、碳质泥岩、粉砂岩、细砂岩煤、细砂岩28煤+29煤层组1 299.50~1 310.6511.1528煤1 301.30~1 302.351.051 299.50~1 305.005.5029煤1 309.00~1 309.600.601 307.35~1 310.653.308.80煤、碳质泥岩、粉砂岩、细砂岩煤、碳质泥岩、粉砂岩39煤系泥页岩+40致密砂岩层组1 424.00~1 438.0014.0039砂泥岩层1 426.00~1 428.002.001 424.00~1 430.006.0040砂泥岩层1 436.00~1 438.002.001 435.55~1 438.002.458.45中砂岩、细砂岩、碳质泥岩中砂岩、粉砂岩

图2 HJD1井城子河组煤系目标层段、射孔层段及储层改造效果综合图

Fig.2 Schematic of optimized coal measure intervals,perforated intervals and reconstructed intervals of Chengzihe Formation coal measures of Well HJD1

4.2.1 支撑剂

根据煤系气储层敏感性测试结果,HJD1井采用“2.0%KCl+0.2%压裂用高效助排剂+0.1%杀菌剂+清水”的活性水压裂液配方。不同压裂阶段选用不同粒径的石英砂支撑剂以保证压裂缝的开启度,其中前置液阶段煤层段选用0.212~0.425 mm石英砂、煤系碳质泥页岩+致密砂岩层段选用0.150 mm和0.212~0.425 mm目石英砂,以降低滤失、控制多裂缝产生;携砂液前期采用0.212~0.425 mm石英砂支撑次裂缝,中期采用0.425~0.850 mm石英砂支撑主裂缝,后期采用0.850~1.180 mm石英砂提高近井裂缝的导流能力,尾追时提高砂比,防止排采吐砂。

4.2.2 压裂工艺与施工参数

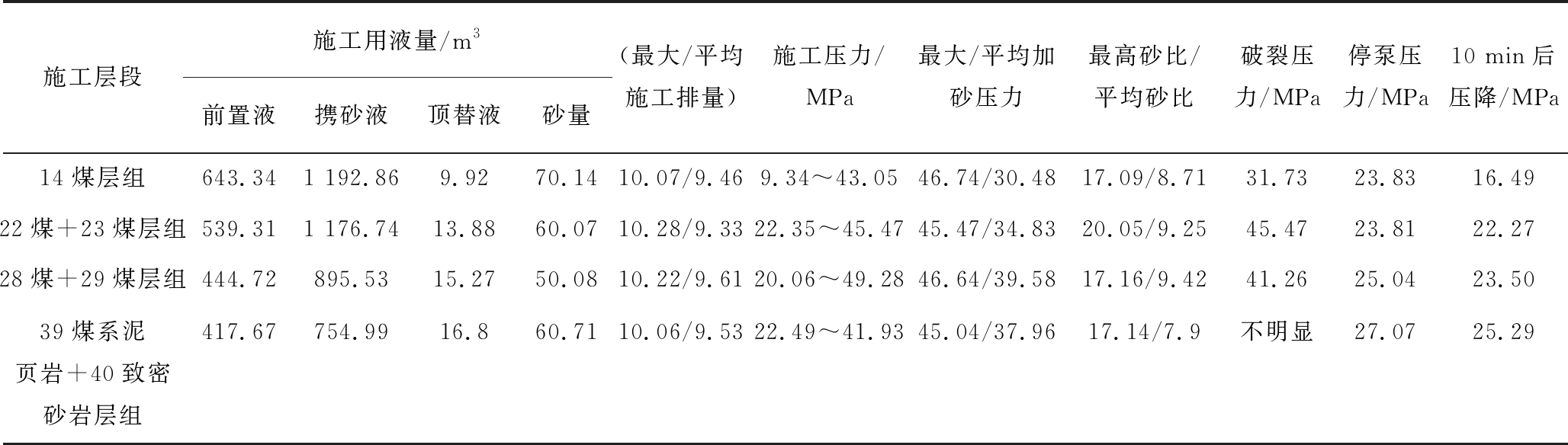

为达到理想的煤系气储层改造与产气效果[27],HJD1井水力压裂具有“大液量、大砂量、高前置液比例、大排量、高砂比、高压力”等特点。具体表现在:单层总液量1 200~1 800 m3,铺砂量5.7~10.4 m3/m,提高前置液比例至45%~55%;采用大排量(9.33~10.28 m3/min)、高砂比(7.9%~9.4%)和较高的施工压力(45.0~46.7 MPa)。在携砂液阶段,根据不同岩性组合层段对携砂液排量和砂比变化的敏感程度,实时调整注入施工压力和注入排量,实现了煤系致密砂岩储层和煤层最大规模的水力压裂[15],达到了预期的体积压裂改造效果(表7、图3)。

图3 HJD1井城子河组煤系水力压裂施工曲线

Fig.3 Hydraulic fracturing construction curves of coal measures in Chengzihe formation,Well HJD1

表7 HJD1井水力压裂施工参数

Table 7 Hydraulic fracturing operating parameters of Well HJD1

施工层段施工用液量/m3前置液携砂液顶替液砂量(最大/平均施工排量)施工压力/MPa最大/平均加砂压力最高砂比/平均砂比破裂压力/MPa停泵压力/MPa10 min后压降/MPa14煤层组643.341 192.869.9270.1410.07/9.469.34~43.0546.74/30.4817.09/8.7131.7323.8316.4922煤+23煤层组539.311 176.7413.8860.0710.28/9.3322.35~45.4745.47/34.8320.05/9.2545.4723.8122.2728煤+29煤层组444.72895.5315.2750.0810.22/9.6120.06~49.2846.64/39.5817.16/9.4241.2625.0423.5039煤系泥页岩+40致密砂岩层组417.67754.9916.860.7110.06/9.5322.49~41.9345.04/37.9617.14/7.9不明显27.0725.29

1)39煤系泥页岩+40致密砂岩层组泥质含量较高,脆性较差,压裂施工过程中地层破裂压力不明显,前置液阶段施工压力较低且平稳,携砂液阶段施工压力对排量、砂比较为敏感,采用了“两级段塞、两级阶梯加砂”的施工工艺,控制加砂排量和砂比大小,平均加砂排量9.53 m3/min,平均砂比7.9%,平均施工压力37.96 MPa,最大施工压力45.04 MPa。

2)28煤+29煤层组地层破裂压力为41.26 MPa,前置液阶段施工压力较高且平稳下降,携砂液阶段施工压力较高且波动较大,易发生砂堵,采用“三段阶梯式加砂”的施工工艺,以大排量、高砂比泵注加砂,平均施工排量9.61 m3/min,平均砂比9.42%,最高砂比达17.16%,平均加砂压力39.58 MPa,最大压力46.64 MPa。

3)22煤+23煤层组地层破裂压力为45.47 MPa,前置液阶段施工压力下降幅度较大,携砂液阶段施工压力较高且相对平稳,易发生砂堵,采用“两级阶梯式+斜坡式加砂、投球分压”的施工工艺,以中等排量、高砂比泵注加砂;为形成复杂裂缝网络,停泵投球分压1次,封堵效果较好;平均施工排量9.33 m3/min,平均砂比9.25%,最高砂比20.05%;施工压力22.35~45.47 MPa,平均压力34.83 MPa。

4)14煤层组地层破裂压力为31.73MPa,前置液阶段施工压力较低且稳定,携砂液阶段施工压力较低但波动较大,易发生砂堵,采用“多级阶梯式加砂、投球分压”的施工工艺,以大排量、中砂比泵注加砂;为形成复杂裂缝网络,停泵投球分压1次,封堵效果较好;平均施工排量9.46 m3/min,平均砂比8.71%,最高砂比17.09%;平均施工压力30.48 MPa,最大施工压力46.74 MPa。

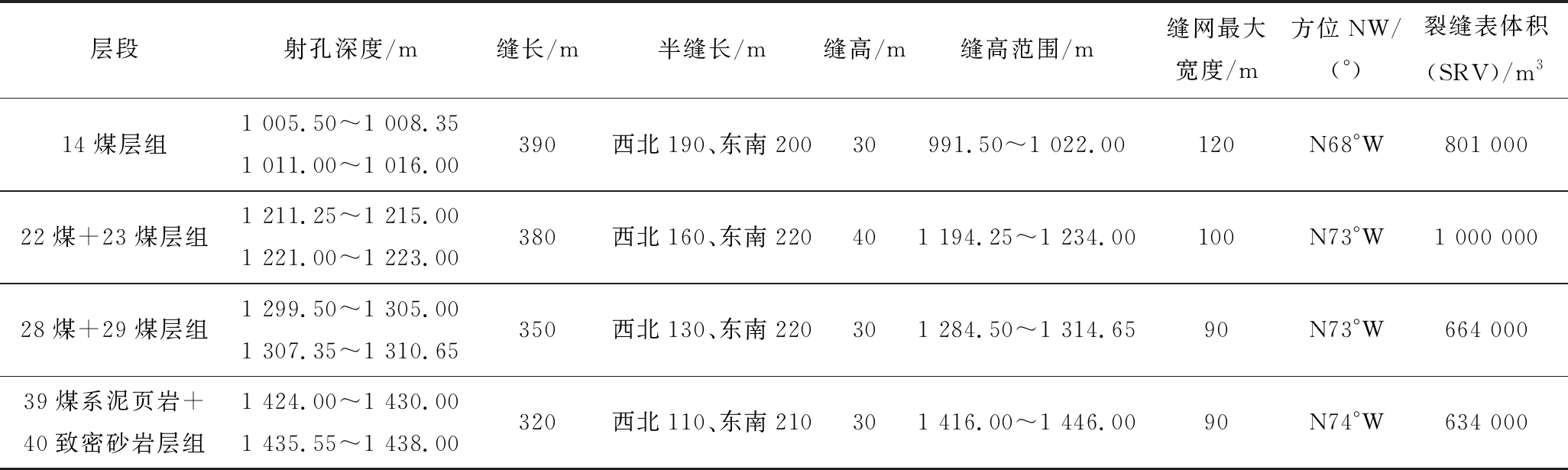

采用能量扫描四维影像法实时监测获得HJD1井压裂层段人工裂缝缝网的产状特征(表8)。4个压裂层段均产生了垂直缝网,方位为NW68°~74°,缝网长为320~390 m、高为30~40 m、最大宽度90~120 m,单层影响体积为(63.4~100.0)×104 m3。压裂缝网高度合计130.00 m,垂向上贯穿了多个煤层、薄煤层、煤线、碳质泥岩、粉砂岩、细砂岩、中砂岩等,各层横向缝长相当,具有高导流能力和高渗流面积,实现了均衡改造。

表8 HJD1井压裂裂缝监测数据

Table 8 Fracture monitoring data sheet of Well HJD1

层段射孔深度/m缝长/m半缝长/m缝高/m缝高范围/m缝网最大宽度/m方位NW/(°)裂缝表体积(SRV)/m314煤层组1 005.50~1 008.351 011.00~1 016.00390西北190、东南20030991.50~1 022.00120N68°W801 00022煤+23煤层组1 211.25~1 215.001 221.00~1 223.00380西北160、东南220401 194.25~1 234.00100N73°W1 000 00028煤+29煤层组1 299.50~1 305.001 307.35~1 310.65350西北130、东南220301 284.50~1 314.6590N73°W664 00039煤系泥页岩+40致密砂岩层组1 424.00~1 430.001 435.55~1 438.00320西北110、东南210301 416.00~1 446.0090N74°W634 000

HDJ1井溢流阶段累计排出压裂液1 672.31 m3,开抽前压裂液反排率达27.8%;开抽后41 d见套压, 产气14个月累产气量73.4 ×104 m3,产气量达到5 666 m3/d;累产水量6 778 m3,平均产水量14.0 m3/d,证实了差异性水力压裂工艺在鸡西盆地深部煤系气储层压裂改造取得良好效果。

1)鸡西盆地梨树井田城子河组煤层、暗色泥岩、砂岩互层发育段既是优质烃源岩,也是有利含气层。烃源岩有机质类型为Ⅲ型、Ⅱ2型,有机质丰度0.42%~7.46%,热演化程度较好,生烃潜量0.11~82.22 mg/g,源-储匹配关系好。煤层现场解吸含气量3.36~7.88 m3/t,煤系砂泥岩空气干燥基含气量0.28~3.46 m3/t。

2)以资源潜力和生烃潜力为主要评价指标,采用加权求和法优选煤层和非煤层有利层段;参考岩性组合、目标产气层埋深和层间跨度等指标对合采产层组合优化,自下而上优选了39煤系泥页岩+40致密砂岩层组、28煤+29煤层组(煤层+煤系泥岩+煤层)、22煤+23煤层组(煤层+煤系砂岩+煤层)、14煤组为合采目标层段。

3)为充分释放产气层组产气潜力,增加射孔段长度为煤层厚度的1.8~6.3倍,砂泥岩含气层厚度的1.2~3.0倍;优化提高了前置液比例(45%~55%),采用“大液量(1 200~1 800 m3)、大砂量(5.7~10.4 m3/m)、大排量(9.33~10.28 m3/min)、高砂比(7.9%~9.4%)、高注入压力(45.0~46.7 MPa)、多级阶梯式加砂”的施工工艺对煤系气储层进行差异性压裂改造,结合投球分压技术,使“煤层+煤系砂/泥岩+煤层”组合改造效果显著提升。

致谢 感谢中国矿业大学周效志副教授对本文提出修改建议。

[1] 秦 勇,吴建光,申 建,等.煤系气合采地质技术前缘性探索[J].煤炭学报,2018,43(6):1504-1516.

QIN Yong,WU Jianguang,SHEN Jian,et al.Frontier research of geological technology for coal mmeasure gas joint-mining [J].Journal of China Coal Society,2018,43(6):1504-1516.

[2] 秦 勇,申 建,沈玉林.叠置含气系统共采兼容性:煤系“三气”及深部煤层气开采中的共性地质问题[J].煤炭学报,2016,41(1):14-23.

QIN Yong,SHEN Jian,SHEN Yulin.Joint mining compatibility of superposed gas bearing systems:a general geological problem for extraction of three natural gases and deep CBM in coal series [J].Journal of China Coal Society,2016,41(1):14-23.

[3] 傅雪海,德勒恰提·加娜塔依,朱炎铭,等.煤系非常规天然气资源特征及分隔合采技术[J].地学前缘,2016,23(3):36-40.

FU Xuehai,DELEQIATI Jianatayi,ZHU Yanming,et al.Resources characteristics and separated reservoirs’ drainage of unconven-tional gas in coal measures[J].Earth Science Frontiers,2016,23(3):36-40.

[4] 梁 冰,石迎爽,孙维吉,等.中国煤系“三气”成藏特征及共采可能性[J].煤炭学报,2016,41(1):167-173.

LIANG Bing,SHI Yingshuang,SUN Weiji,et al.Reservoir forming of characteristics of “the three gas” in coal measure and the possibility of commingling in China[J].Journal of China Coal Society,2016,41(1):167-173.

[5] 侯晓伟,朱炎铭,付长青,等.沁水盆地压裂裂缝展布对煤系“三气”共采的指示意义[J].中国矿业大学学报,2016,45(4):729-738.

HOU Xiaowei,ZHU Yanming,FU Changqing,et al.Fractures distribution of Qinshui basin and its indicative significance to unconventional gas co-exploration in coal measures[J].Journal of China University of Mining & Technology,2016,45(4):729-738.

[6] 易同生,周效志,金 军.黔西松河井田龙潭煤系煤层气—致密气成藏特征及共探共采技术[J].煤炭学报,2016,41(1):212-220.

YI Tongsheng,ZHOU Xiaozhi,JIN Jun.Reservoir formation characteristics and co-exploration and concurrent production technology of Longtan coal measure coalbed methane and tight gas in Songhe field,western Guizhou[J].Journal of China Coal Society,2016,41(1):212-220.

[7] 王龙伟.分层压裂在煤层气开发中的应用[J].能源与节能,2020,172(1):49-51,53.

WANG Longwei.Application of layered fracturing in coalbed methane develpoment[J].Energy and Energy Conservation,2020,172,(1):49-51,53.

[8] 刘欣佳,张遂安,靳建虎,等.煤成(层)气资源综合开发中的合层压裂可行性评价[J].煤炭学报,2018,43(6):1687-1693.

LIU Xinjia,ZHANG Sui’an,JIN Jianhu,et al.Feasibility evaluation of commingle fracturing in the integrated development of coal-derived gas resources[J].Journal of China Coal Society,2018,43(6):1687-1693.

[9] 陈 捷,易同生,金 军.黔西松河井田煤层群合层分段压裂影响因素及参数优化[J].煤田地质与勘探,2018,46(5):153-158,166.

CHEN Jie,YI Tongsheng,JIN Jun.Influencing factors and parameter optimization of staged fracturing in thin and medium coal seam group in Songhe mine in weastern Guizhou[J].Coal Geology & Exploration,2018,46(5):153-158,166.

[10] BI Caiqin,ZHANG Jiaqiang,SHAN Yansheng,et al.Geological cha-

racteristics and co-exploration and co-production methods of Upper Permian Longtan coal measure gas in Yangmeishu Syncline,Western Guizhou Province,China[J].China Geology,2020,3(1):38-51.

[11] 孙 伟,熊远贵,王 倩,等.煤系地层多层合压射孔层位及高度的优化[J].天然气地球科学,2019,30(4):566-573.

SUN Wei,XIONG Yuangui,WANG Qian,et al.Optimization of perforated interval of multilayer commingled fracturing in coal measure strata[J].Natural Gas Geoscience,2019,30(4):566-573.

[12] 陈贞龙,王 烽,陈 刚,等.延川南深部煤层气富集规律及开发特征研究[J].煤炭科学技术,2018,46(6):80-84,194.

CHEN Zhenlong,WANG Feng,CHEN Gang,et al.Study on enrichment law and development features of deep coalbed methane in South Yanchuan Field [J].Coal Science and Technology,2018,46(6):80-84,194.

[13] 申 建,秦 勇,张 兵,等.鄂尔多斯盆地东缘临兴区块煤系叠置含气系统及其兼容性[J].煤炭学报,2018,43(6):1614-1619.

SHEN Jian,QIN Yong,ZHANG Bing,et al.Superimposing gas-bearing system in caol measures and its compatibility in Linxing block,east Oedos Basin[J].Journal of China Coal Society,2018,43(6):1614-1619.

[14] 孟尚志,李 勇,吴 翔,等.煤层气和致密气合采产能方程及影响因素[J].煤炭学报,2018,43(6):1709-1715.

MENG Shangzhi,LI Yong,WU Xiang,et al.Productivity equation and influencing factors of co-producing coalbed methane and tight gas[J].Journal of China Coal Society,2018,43(6):1709-1715.

[15] 毕彩芹,单衍胜,逄 礴,等.鸡西盆地煤炭资源枯竭矿区钻获高含气量煤系储层[J].中国地质,2018,45(6):1306-1307.

BI Caiqin,SHAN Yansheng,PANG Bo,et al.High gas coal reservoir drilled in coal resource exhausted mining area of Jixi Basin[J].Geology in China,2018,45(6):1306-1307.

[16] 秦 勇,申 建,沈玉林.叠置含气系统共采兼容性:煤系“三气”及深部煤层气开采中的共性地质问题[J].煤炭学报,2016,41(1):14-23.

QIN Yong,SHEN Jian,SHEN Yulin.Joint mining compatibility of superposed gas bearing systems:a general geological problem for extraction of three natural gases and deep CBM in coal series [J].Journal of China Coal Society,2016,41(1):14-23.

[17] 王世辉,谭宝德,张正和,等.鸡西盆地梨树镇坳陷城子河组成煤环境及其对煤层分布的控制作用[J].大庆石油地质与开发,2014,33(5):174-178.

WANG Shihui,TAN Baode,ZHANG Zhenghe,et al.Coal-accumulating environments and their controls on the coalbed distribution in Chenzihe Formation of Lishuzhen depression of Jixi Basin [J].Petroleum Geology and Oilfield Development in Daqing,2014,33(5):174-178.

[18] 王伟明,卢双舫,王世辉,等.鸡西盆地致密砂岩气存在的可能性[J].石油与天然气地质,2012,33(3):385-391,398.

WANG Weiming,LU Shuangfang,WANG Shihui,et al.Possibility of tight sand gas reservoirs in Jixi Basin [J].Oil & Gas Geology,2012,33(3):385-391,398.

[19] 刘金霖,李怀滨,张雪冰,等.鸡西盆地煤储层孔隙特征及主控因素[J].石油实验地质,2018,40(5):691-698.

LIU Jinlin,LI Huaibin,ZHANG Xuebing,et al.Pore characteristics and controlling factors of coal reservoirs from Jixi Basin [J].Petroleum Geology & Experiment,2018,40(5):691-698.

[20] 毕彩芹,张家强,单衍胜.基于鸡西盆地JMC1井的煤层气储层特征分析[J].煤矿安全,2017,48(3):152-155.

BI Caiqin,ZHANG Jiaqiang,SHAN Yansheng.Analysis of coalbed methane reservoir characteristics based on JMC1 Well of Jixi Basin [J].Safety in Coal Mines,2017,48(3):152-155.

[21] 王宇航,王有智.煤储层特征及其对吸附能力的影响:以鸡西盆地城子河组为例[J].中国煤炭地质,2016,28(8):33-37,67.

WANG Yuhang,WANG Youzhi.Coal reservoir characteristics and their impacts on adsorptivity:a case study of Chengzihe formation in Jixi Basin [J].Coal Geology of China,2016,28(8):33-37,67.

[22] 李占东,马金龙,刘文超,等.鸡西盆地梨树镇坳陷晚白垩世构造演化与油气成藏条件[J].大地构造学与成矿学,2011,35(1):47-55.

LI Zhandong,MA Jinlong,LIU Wenchao,et al.Late Cretaceous tectonic evolution and hydrocarbon accumulation conditions in lishuzhen depression,Jixi Basin[J].Geotectonica et Metallogenia,2011,35(1):47-55.

[23] 何 星,杨建国,李映雁,等.鸡西盆地烃源岩特征与评价[J].大庆石油地质与开发,2008,27(4):42-44.

HE Xing,YANG Jianguo,LI Yingyan,et al.Characteristics and evaluation of source rocks in Jixi Basin[J].Petroleum Geology & Oilfield Development in Daqing,2008,27(4):42-44.

[24] 官 兵,李士斌,高 溯,等.鸡西盆地梨树镇坳陷城子河组煤岩物理力学特性实验研究[J].中国煤炭地质,2015,27(5):28-31.

GUAN Bing,LI Shibin,GAO Su,et al.Experimental study on physical and mechanical properties of coal and rock of Chengzihe formation in lishuzhen depression,Jixi Basin[J].Coal Geology in China,2015,27(5):28-31.

[25] 陈金宏.射孔参数对煤层压裂效果影响分新[J].中国煤层气,2015,12(6):22,27-29.

CHEN Jinhong.Analysis of Coalbed Fracturing Influences of Perforation Parameters[J].China Coalbed Methane,2015,12(6):22,27-29.

[26] 郭 洋,杨胜来,王欣然.煤层气井射孔参数对产能的影响[J].油气井测试,2012,21(1):13-15.

GUO Yang,YANG Shenglai,WANG Xinran.Effect of perforation parameters on productivity of coalbed methane wells[J].Well Testing,2012,21(1):13-15.

[27] 秦 勇,吴建光,张争光,等.基于排采初期生产特征的煤层气合采地质条件分析[J].煤炭学报,2020,45(1):241-257.

QIN Yong,WU Jianguang,ZHANG Zhengguang,et al.Analysis of geological conditions for coalbed methane co-production based on production characteristics in early stage of drainage[J].Journal of China Society,2020,45(1):241-257.