移动扫码阅读

煤炭地下气化(UCG)是一种将煤炭在原位状态下进行燃烧气化,最后向地表输出高热值气体的煤炭开发技术[1-2]。该技术经过多年的发展,相关工艺和开发方式已经较为成熟[3]。其核心模式为“U”型井位布置,即一口注气井向煤层内部输入氧气等气化剂,使得煤炭在地层内部发生燃烧、热解等化学反应,再由一口产气井,将生产的高热值气体输出地表[4-5]。与煤炭地面气化的过程不同,UCG过程需要在地下进行钻井形成气化炉[6],此处是煤炭发生燃烧等物理化学反应的主要场所。煤炭气化时,气化炉内温度可高达1 200 ℃[7-8],煤层和围岩在该温度下,其物理化学性质会发生巨大变化,进而影响UCG过程的稳定性和可持续性[9]。

UCG过程的温度场主要分为2个部分:① 气化炉内高温气体在气化过程通过辐射和对流的方式向地层传热。煤炭地下气化时,气化炉内并不是完全的空腔模式,而是由煤焦、灰分等形成高渗透性结构,此处发生的是一系列多场耦合的复杂过程,包括气化过程中传热、传质、渗流、对流等多个过程的综合;气化炉内的温度场由混合气体传热系数决定,煤炭气化时产生的混合气体成分发生动态变化,使得气化炉向围岩传热时,温度场难以达到稳态[1-2]。② 气化炉作为一个整体的热源,高温的混合气体沿着产出气通道运移至地表,在这个过程中,气化炉产生的热量以热对流、热传导的方式向围岩传热,影响围岩的热物理性质和力学性质[1-2]。

基于此,针对煤炭地下气化过程中气化炉的温度变化及传热特征,综合分析了国内外相关研究现状,总结了UCG过程中热量的来源、温度场的变化及其传热特征、气化炉温度随工艺和地质条件的变化情况,提出了主要存在问题,以期为增强气化炉热稳定性、提高UCG成功率方面的研究提供依据。

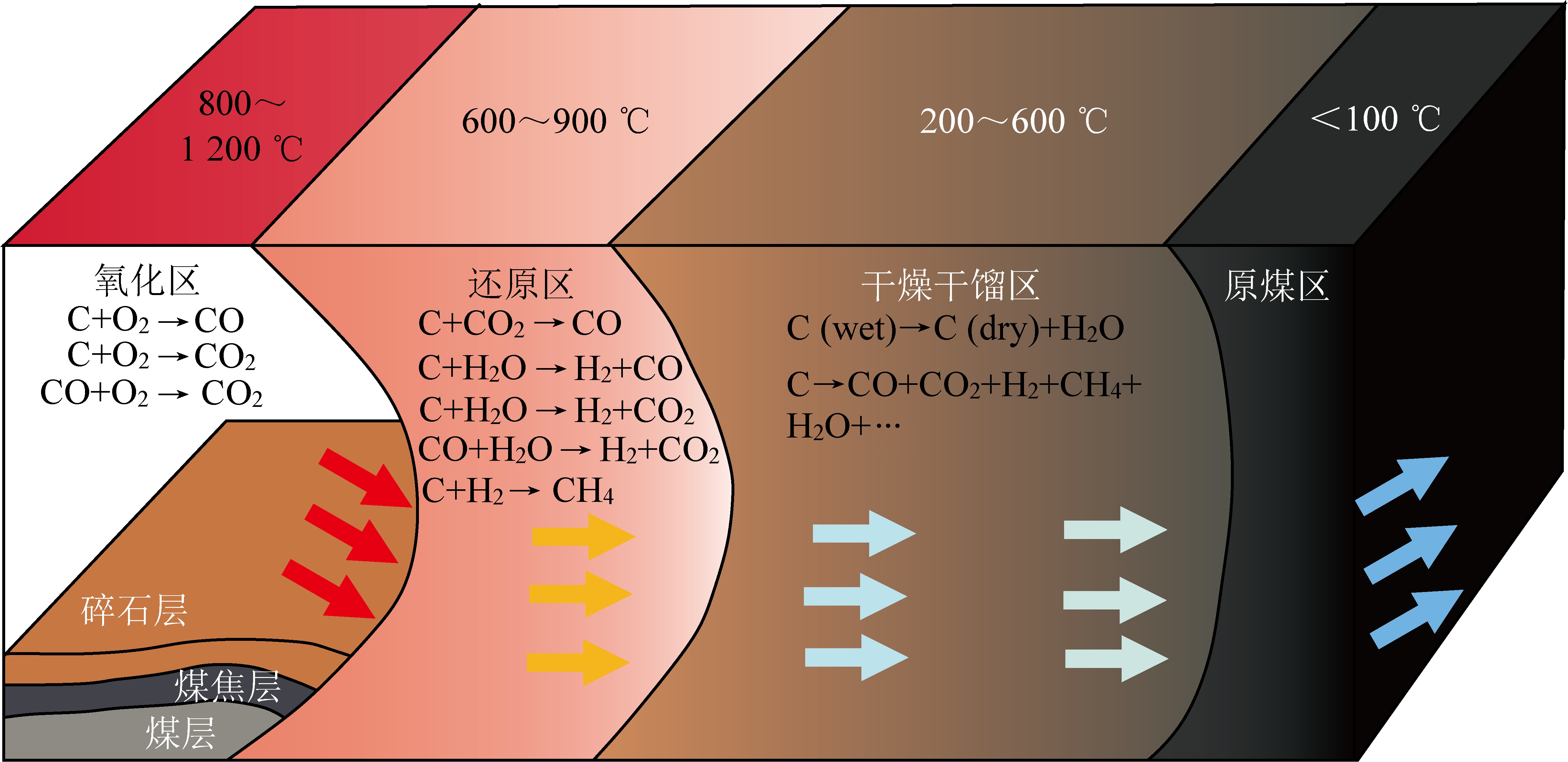

煤炭地下气化是一个复杂多阶段的物理化学过程,根据发生化学反应的不同,沿着气化通道的整个气化炉的区域从内到外可以分为氧化区、还原区、干燥干馏区[10](图1)。由于整个过程发生在地下,地面难以对其进行具体调控,因此这3个区域并没有严格的实际界限[11]。在煤层内,3个区域混合交替存在。氧化区主要发生煤炭的燃烧等氧化放热反应,温度为900~1 200 ℃;还原区主要发生碳的还原反应,温度为600~900 ℃;干燥干馏区在气化炉的最外围,这部分煤层并未暴露在气化剂接触范围内,此处由于受到气化炉传导出的高温影响,煤层在缺氧的情况下发生干馏反应,产生大量气体,温度为200~600 ℃[12]。

图1 UCG过程中三区分布示意[10]

Fig.1 Schematic of three-zone distribution in UCG[10]

煤炭地下气化最主要的能量反应就是煤的燃烧。煤中水分在低温情况下发生蒸发[13-15];含水过高时,水分蒸发会吸收大量热量,导致氧化反应中断致使整个UCG项目失败[16]。当温度高于300 ℃时,还原区煤炭在无氧的情况下开始热解放热,产生大量CO等还原性气体,与邻近煤炭发生反应[15]。

WELLBORN[17]发现气化剂中氧气浓度和摩尔体积分数越高,氧化区的温度越高。POON[18]通过Texas褐煤燃烧试验发现,煤层层理方向决定了气化扩展的优势面,煤中水分和挥发分决定了受热后收缩裂隙的扩展方向,褐煤中黏土矿物决定了受热时热膨胀的主要方向。LIN等[19]利用低挥发分烟煤研究了气化灰烬的影响,发现覆盖的灰烬厚度小于1.3 mm时,不会对氧气扩散造成影响;当灰烬层较厚时,CO发生燃烧导致灰烬融化形成炉渣,阻碍传热。地面通过调控气化剂的注入位置、成分、流速等参数来控制这些复杂的化学反应。

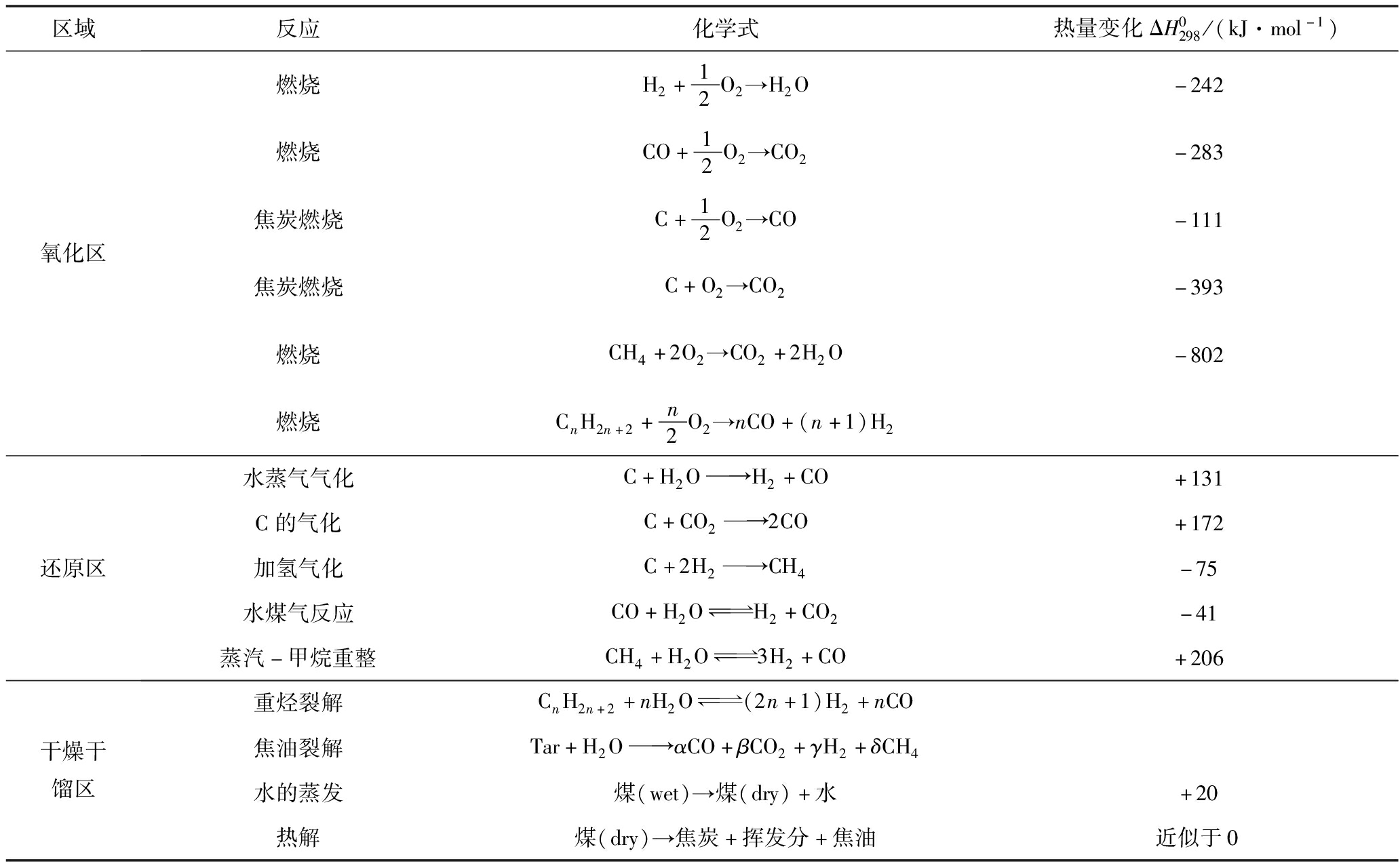

煤炭地下气化时,“三区”逐渐扩大并向前扩展形成链式反应,最终完成气化[20]。在该过程中,气化炉内发生了大量复杂的化学反应[21],这些反应决定了气化过程中热源稳定性和随时间的变化规律,见表1。

表1 煤炭地下气化的化学反应及热量变化[1-2]

Table 1 Chemical reaction and heat change of coal pyrolysis[1-2]

区域反应化学式热量变化ΔH0298/(kJ·mol-1)氧化区燃烧H2+12O2→H2O-242燃烧CO+12O2→CO2-283焦炭燃烧C+12O2→CO-111焦炭燃烧C+O2→CO2-393燃烧CH4+2O2→CO2+2H2O-802燃烧CnH2n+2+n2O2→nCO+(n+1)H2还原区水蒸气气化C+H2O→H2+CO+131C的气化C+CO2→2CO+172加氢气化C+2H2→CH4-75水煤气反应CO+H2O H2+CO2-41蒸汽-甲烷重整CH4+H2O 3H2+CO+206干燥干馏区重烃裂解CnH2n+2+nH2O (2n+1)H2+nCO焦油裂解Tar+H2O→αCO+βCO2+γH2+δCH4水的蒸发煤(wet)→煤(dry)+水+20热解煤(dry)→焦炭+挥发分+焦油近似于0

注:α、β、γ、δ为系数;Tar为焦油。

理想情况下,气化通道纵向截面的温度场为一组平行的矩形或者近矩形,但是由于煤层地质条件和气化工艺不同,热量难以均匀向外传播从而形成规则等温面。

煤层与围岩具有很强的非均质性和各向异性,热导率的各向异性导致热量发生热传导时具有明显方向差异,煤系地层岩石热导率各向异性指数(λmax-λmin)/λmean为0.1~0.4,部分可达0.8。渗透率的各向异性造成了气化剂和产出气发生对流换热时的复杂性,煤层渗透率在3个正交方向上的渗透率之比约为10∶5∶1,高渗透率方向上气化剂扩展速率更快,成为温度场扩展优势方向。气化初期,温度场在气化通道径向上的传播速率大于轴向上,扩展速率之比大于3[22-24]。

气化工艺对于温度场的控制作用也十分明显,当O2/N2混合气和O2/空气混合气气化剂中氧气浓度提高时,注气点的氧化反应强度增大,产生大量热量并随着产出气向前移动,温度场轴向扩展速率逐渐大于径向速率并形成“圆锥形”温度场,这与气化燃空区的扩展规律相异。同时,随着气化剂流量增大,温度场径向上的扩展速率大于轴向上,“圆锥”更加尖锐。然而,O2/H2O气化剂中氧气浓度升高时,水会参与一系列反应使得煤层温度场扩展为不均匀弥散状。温度场在顶底板中的扩展与在煤层中不同,径向扩展速率大于轴向速率[23,25-26]。

煤炭地下气化过程中,气化炉内火焰工作面和燃烧空间区域温度高达1 200 ℃,高温气流以热对流和热传导的方式向围岩传热。许多学者利用物理模拟、试验监测、理论计算和数值模拟方法,对这一过程中温度场特征、气化炉温度动态变化及其传热过程等进行了深入研究[27]。

由于UCG过程发生在地下深部,因此,常规观测手段难以查明气化过程中温度变化情况,特别是气化炉不同区域温度随时间变化的特征。物理模拟可操控性强,可以控制煤炭的成分、倾角等地质条件以及气化剂成分、流速等工艺条件。相关学者利用物理模拟试验对气化过程中的气化剂等因素进行了控制变量法研究,讨论不同地质条件和气化工艺下温度的变化[28]。

为模拟实际的气化过程,有学者利用相似材料模拟地层系统,用竹炭、砂、石膏等材料模拟煤层以及顶底板。研究发现,气化时顶板发生塌陷形成顶板离层结构,离层中充满导热系数远低于岩层的气体,形成了“保温层”,维持气化炉温度[29]。为保证模拟试验和实际情况相吻合,模拟地层系统围岩的厚度最小为0.34 m。影响气化炉温度场的另外一个重要因素是气化剂成分,气化剂中氧气浓度较低时,单位体积内煤基质与气化剂接触面积越大,煤炭的反应越剧烈,产生热量越多,温度场扩展主要受裂隙发育状态控制。氧气浓度较高时,气化剂中高浓度CO2或N2能够延长气化时间,导致气化炉温度场主要向竖直方向发展[23,30-32]。WANG等[33-34]利用内蒙古乌兰察布和新疆褐煤进行模拟试验,通过改变气化剂组分和注气方式,讨论气化过程中温度场的影响范围和变化情况;通过产出气组分测试,划定了气化“三区”的温度范围:氧化区大于900 ℃、还原区600~900 ℃、干燥干馏区300~600 ℃。

UCG物理模拟试验由于试验对象为采集的样品或者相似材料搭建的地层系统,难以模拟真实情况下的地应力、地层流体以及地层接触关系,影响了物理模拟试验的可靠性。

近百年间,世界各国进行了大量先导性试验,探索气化过程中温度场的分布。1975年,美国Wyoming州Hanna煤炭地下气化试验项目设置了气化同步监测井,用以记录煤层及围岩温度场的分布,监测热电偶被安装在煤层和页岩盖层中的不同高度如图2所示(图2中2—图9为热电偶所处位置)。并通过气化结束后的残渣测试气化炉内温度。研究发现,气化炉内温度在245~670 ℃,最高为1 200 ℃[35]。

图2 美国Wyoming州Hanna UCG项目温度监测井示意[35]

Fig.2 Schematic of temperature monitoring well of Hanna UCG project in Wyoming State,USA[35]

由于在实际UCG项目中,布置温度监控井不具备经济性,之后的UCG项目未见设置温度监控井[1-4]。因此科研工作者探索使用其他的监测手段,包括声发射[36]、探地雷达等地球物理方法来研究气化炉的温度场。KOTYRBA等[37-38]利用探地雷达技术监测了UCG实际项目和模拟试验(波兰Barbara煤矿UCG项目)的温度动态变化。但是,这种技术只能用于监测浅层煤炭地下气化项目,对于深部煤层,利用钻孔和气化通道中进行监测则更加合理选择。

为了查明气化过程中温度的精确数值,除利用物理模型来进行试验测试外,相关学者还利用理论计算的办法确定围岩温度场的分布与变化情况。

理论计算主要利用微分方程建立气化通道的高温导热数学模型,确定模型的初始和边界条件,求出围岩导热微分方程的解析解[39-41],分析围岩的传热机理和导热状态。通过对传热过程的简化,利用多层大平壁模型分析求解气化炉顶底板的温度场,利用空心圆柱模型计算气化通道的温度场如图3所示,图3b中C为该层比热容;ρ为该层密度。

图3 圆柱模型和多层大平壁模型[42]

Fig.3 Cylindrical model and multi-layer large flat wall model[42]

理论计算气化通道围岩温度场分布情况时,围岩导热微分方程的区别在于方程边界条件的选取。求解气化炉顶底板的温度场时,一般将远离气化通道无限远处的围岩温度简化为地层温度,并以第四类边界条件为约束,利用Laplace变换,求解出n层围岩温度场的传热方程[41-42]。但是,由于实际地层的温度传导情况较为复杂,在求解导热微分方程解析解时,为了降低求解难度,一般需要设定一些假设条件,如地层各向同性、围岩热导率不随温度变化等[43-45]。

CHENG等[46]类比UCG过程和采空区煤炭自燃(UCSC)过程,建立了表征温度分段线性变化的一维非稳态导热数学模型,讨论了煤层顶板与气体发生对流换热时的温度场。结果表明:在升温和近似稳态阶段,围岩温度持续升高,最高温度出现在围岩边界处;在降温阶段,各点温度先升高后降低,温度曲线峰值逐渐降低并向覆盖层内部移动。在热传导过程中,围岩内存在一条温度曲线簇的包络线,各点温度最高值由包络线决定,且热导率k和热容c的变化对包络线分布和热增量的影响较大,而对流换热系数h的影响较小。基于此研究,WANG等[12]采用同样方法求解煤层温度场在第一类边界条件下的解析解,发现气化炉的温度场由非稳态向稳态转变的时间与气化工作面推进速度成反比,降温阶段对顶板、底板及周边煤层温度场的影响大于升温阶段,升温阶段的影响与气化工作面推进速度有关,但是当气化工作面推进速度超过一定值时,这种影响可忽略不计。

由于煤炭与砂岩等其他沉积岩的热导率差异较大,所以温度场在煤层与顶底板内的影响范围不同。在煤层中的影响范围小于2 m,顶底板中的影响范围小于10 m,气化通道由于存在持续高温气流,影响范围远大于气化炉。BROWN等[47]认为气化炉向围岩传热时,在壁面热通量恒定情况下,温度的影响范围远大于实际情况。LIU等[48]利用显式有限差分法建立了气化炉围岩温度场随时间扩展的数学模型,用微分法求解了气化通道轴向和径向温度场的分布情况。研究发现,随着气化的进行,气化炉温度场的影响范围逐渐扩大,并严重破坏5 m之内煤层与围岩的力学强度;沿气化通道轴向,温度在较长距离内缓慢下降,离氧化区150 m处的气化通道温度仍高于200 ℃[20]。

PERKINS[4,49]建立了零维稳态空穴模型和二维轴对称计算流体动力学模型,计算了高温产出气和煤壁发生自然对流情况下气化通道的散热情况。计算结果表明,离气化炉中心50 m处,温度将趋于稳定,为600 ℃;在径向70 m以外的原岩区域,气化通道不会对围岩产生热效应[50]。

煤炭地下气化是一个三维非稳态综合反应过程,包括了均相和非均相反应[51]。在这个过程中,气化剂和产出气混合在气化通道中不断流动,并与煤层发生一系列可逆的物理化学反应。气化通道中的温度、物质成分、流体状态等,都随着气化过程不断进行而发生空间位置和状态的变化[52-53]。气化通道中的“三区”随着气化工作面向前推进,位置和比例关系也在不断地发生变化,形成稳定的温度场向围岩传热[54]。数值模拟手段对于研究这种极复杂过程具有明显、不可取代的优势[55-58]。

相关学者利用不同的数值模拟软件对UCG过程进行模拟,例如ANSYS/Fluent、ABAQUS、FEMALB[59-60],建立固定床、热-力耦合、热-应力-渗流全耦合等数学模型,探究气化炉的温度分布。模拟发现,当氧化区点火温度为1 366 ℃时,温度场的扩展速率为28.75 ℃/min[61],随着气化进行,“三区”向外扩展,氧化区逐渐扩展至出口[62]。围岩内的扩展速率和影响范围受温度边界条件和气化通道径向延伸速率的影响,径向延伸速率越大,温度的影响范围越小[63]。气化空腔顶板会随气化进行逐渐下陷造成垮落,导致温度场在顶板的影响范围大于底板[42]。

另外,在UCG项目的开发中,形成了专门的数值模拟软件来研究气化过程中的温度场变化情况。Akbarzadeh等[64]利用STARS2012软件结合FLAC©3D,对加拿大Albert省Swan Hills UCG项目的温度场进行了模拟分析,模拟结果表明,温度场随着气化工作面的移动向前推进。JIANG等[65-66]利用STARS对北美西部的煤炭进行模拟,研究了反向燃烧连接技术(RCL)下煤炭燃烧前锋温度的变化特征。KLEBINGAT等[58]利用模拟软件Aspen Plus,对美国Hanna的UCG项目进行模拟。

COMSOL multiphysics是一个多物理场耦合数值模拟软件,特别适合用于UCG复杂的过程模拟[67-68]。气化炉的温度场并不是简单的热源向围岩发生热传导的过程,由于地层的渗透性,传热过程中,渗流场、应力场等多个场也会与温度场发生耦合。XIN等[44]利用COMSOL multiphysics对多层上覆围岩情况下二维非稳态传热过程,进行了数值模拟,发现当气化工作面向前推进导致围岩边界温度线性降低时,围岩温度随时间先升高后降低,热影响范围为气化炉10 m范围内的围岩。赵明东[69]利用COMSOL multiphysics对UCG的温度场进行模拟,发现温度场在顶板的传播范围为20.5 m。

岩石热导率、热扩散率、比热容是岩石传热的重要物理参数,决定了岩石的传热效率。其值受众多因素综合影响,不仅与岩石本身物理结构性质包括组成、孔隙度、渗透率等有关,而且对于它自身所处的状态也有较大的响应,例如岩石所处的围压状态、地层内部的流体情况以及岩石本身的温度[70]。

温度对于岩石热导率、比热容、热扩散率的影响各不相同。高温下,岩浆岩热导率下降较为明显,且在不同温度范围内,下降幅度也不同。温度较低时,升温对于岩浆岩的影响主要是岩石中的自由水减少,引起热导率缓慢下降;温度进一步升高的情况下,岩浆岩中束缚水开始脱出,岩浆岩开始破裂、熔融造成热导率进一步降低(图4)。

图4 几种岩浆岩热导率和热扩散率随温度变化情况[71-74]

Fig.4 Variations of thermal conductivity and thermal diffusivity of several magmatic rocks with temperature[71-74]

在高温下,热扩散率和热导率接近恒定值[71-74]。MIAO[75]利用激光法导热仪(LFA)对白云岩、灰岩、砂岩等沉积岩的热物理性质进行了研究。结果表明:沉积岩热导率和热扩散随着温度的上升逐渐下降,热扩散率降低了70%~75%,而热导率降低了54%~63%,热扩散率受温度的影响更为显著;比热容随着温度上升逐渐变大,在温度较高时,热导率同样趋于定值,如图5所示[76-77]。图5的图注字母加数字均为样品编号,S为砂岩样品,D为白云岩样品,L为灰岩样品,C为大理岩样品,YJSA和SZ均为砂岩样品。

图5 沉积岩、比热容热导率和热扩散率随温度变化情况[73-77]

Fig.5 Changes in thermal conductivity,thermal diffusivity and specific heat capacity of sedimentary rocks with temperature[73-77]

煤与围岩不同,由于煤中存在大量挥发分,煤层受热后热物理性质的变化更为复杂。DENG等[78]利用LFA,测试了不同煤级烟煤在温度小于300 ℃时热物理性质与温度的关系,发现随着温度升高,热扩散率先降低后升高;比热容逐渐增大,然后趋于平稳,直至开始减小;热导率先缓慢后快速地增加,这与前人的研究一致(图6)[78-79]。当温度高于300 ℃,煤炭开始发生热解反应,随着煤层中挥发分大量热解,热导率等参数随着温度上升,呈现不规则的波动趋势[79-80]。

图6 煤热导率、热扩散和比热容率随温度变化情况[78]

Fig.6 Changes in coal thermal conductivity,thermal diffusivity and specific heat capacity with temperature[78]

LUO等[81]利用COMSOL Multiphysics对气化炉的温度场进行模拟分析。结果表明,岩石热导率随着温度的升高而降低,各种岩性表现出相似的行为,这与实验室测试结果一致。同时,得到了气化过程中上覆岩层温度分布情况,围岩温度与距气化炉的距离成比例下降,并受控于气化炉的高度和方向,不同类型岩石的温度梯度不同。

OTTO等[57]利用FLAC©3D建立了2D模型,模拟美国Wyoming州Hanna UCG项目的温度场分布特征,讨论了岩石的热导率随温度变化和不随温度变化情况下,围岩温度场、渗透率、弹性模量等参数的差异性。结果表明,除渗透率对热导率变化响应不强外,其他参数均存在较大差异,忽视热导率与温度的关系会导致过高估计围岩温度。

1)煤炭地下气化是一个多相动态反应的综合过程,固/液/气三相物质发生许多可逆的物理化学反应,并吸收和放出大量热量,大幅度提高了气化炉的温度。温度、压力、渗流等大量因素相互耦合会严重影响整个气化过程,进一步导致气化炉温度场的复杂性。

2)UCG过程中温度场的研究方法主要有4种:物理模拟、试验监测、理论计算、数值建模,但是在实际研究过程中仍存在明显不足。例如,地层接触关系导致的界面热阻使得物理模拟难以恢复原始地层的温度场,经济成本限制了试验监测的运用,理论计算主要针对单一的物理场进行研究,数值模拟对地层做出了大量简化。因此,依托更加经济的监测设备,对UCG过程中温度场实时数据进行收集和分析,有助于更为全面了解煤炭地下气化的能量演化过程,能够为提高气化炉的热稳定性提供依据;另一方面,通过数值模拟软件分析气化过程中物理化学过程的相互影响作用,阐明多物理场之间的耦合机理,能够从理论角度查明UCG温度场演化机制,将是煤炭地下气化十分重要的研究方向之一。

3)由于不同岩性顶底板对温度的敏感性不同,UCG过程中高温将对煤层和围岩的热物理性质产生严重影响。高温使得煤层及其围岩的热导率等参数发生巨大变化,影响气化温度场的计算和模拟。因此,高温下岩石热物理参数的动态变化及其对温度场的控制机理,也是UCG过程的重要研究方向之一。

[1] PERKINS G.Underground coal gasification-Part Ⅱ:fundamental phenomena and modeling[J].Progress in Energy and Combustion Science,2018,67:234-274.

[2] PERKINS G.Underground coal gasification-Part Ⅰ:field demonstrations and process performance[J].Progress in Energy and Combustion Science,2018,67:158-187.

[3] SAMDANI G,AGHALAYAM P,GANESH A,et al.A process model for underground coal gasification-Part-III:parametric studies and UCG process performance[J].Fuel,2018,234:392-405.

[4] PERKINS G,SAHAJWALLA V.Modelling of heat and mass transport phenomena and chemical reaction in underground coal gasification[J].Chemical Engineering Research & Design,2007,85(3):329-343.

[5] PERKINS G,DU TOIT E,COCHRANE G,et al.Overview of underground coal gasification operations at Chinchilla,Australia[J].Energy Sources,2016,38(24):3639-3646.

[6] SHAHBAZI M,NAJAFI M,MARJI M F.On the mitigating environmental aspects of a vertical well in underground coal gasification method[J].Mitigation and Adaptation Strategies for Global Change,2019,24(3):373-398.

[7] LIU Shuiqin,MA Weiping,FRENCH D,et al.Sequential mineral transformation during underground coal gasification with the presence of coal partings[J].International Journal of Coal Geology,2019,208:1-11.

[8] ZHA Xiaoxiong,CHENG Shanshan.Study of transverse section tem-perature distribution in underground coal gasification[J].Applied Mechanics and Materials,2011,71-78:2513-2517.

[9] MALLETT C W.Environmental controls for underground coal gasification[J].Proceedings of the Institution of Mechanical Engineers,2018,232(1):47-55.

[10] ZOU Caineng,CHEN Yangpeng,KONG Lingfeng,et al.Underground coal gasification and its strategic significance to the development of natural gas industry in China[J].Petroleum Exploration and Development,2019,46(2):205-215.

[11] LI Huaizhan,ZHENG Nanshan,GUO Guangli,et al.Measures for reduction of arsenic and cadmium contamination during underground coal gasification without shaft[J].Journal of Cleaner Production,2019,219:960-970.

[12] WANG Jianhua,WANG Zuotang,XIN Lin,et al.Temperature field distribution and parametric study in underground coal gasification stope[J].International Journal of Thermal Sciences,2017,111:66-77.

[13] HOWARD H C.The chemistry of coal utilization[M].New York:John Wiley & Sons,1962:340-94.

[14] ANTHONY D B,HOWARD J B,HOTTEL H C,et al.Rapid devolatilization and hydrogasification of bituminous coal[J].Fuel,1976:55:121-128.

[15] ANTHONY D B,HOWARD J B.Coal devolatilization and hydrogasification[J].AIChE Journal,1976,22(4):625-656.

[16] RICHARDS A P,FLETCHER T H.A comparison of simple global kinetic models for coal devolatilization with the CPD model[J].Fuel,2016, 185:171-180.

[17] WELLBORN T A.Linear burning rates of Texas lignites[D].Austin:The University of Texas at Austin,1981.

[18] POON S S K.The combustion rates of Texas lignite cores[D].Austin:The University of Texas at Austin,1985.

[19] LIN Xi,LIU Qingya,LIU Zhenyu,et al.The role of ash layer in syngas combustion in underground coal gasification[J].Fuel Process Technology,2016,143:169-75.

[20] LIU Hongtao,LIU Shuiqin,CHEN Feng,et al.Mathematical modeling of the underground coal gasification process in one gasification cycle[J].Energy & Fuels,2019,33(2):979-989.

[21] JAVED S B,UPPAL A A,BHATTI A I,et al.Prediction and parametric analysis of cavity growth for the underground coal gasification project Thar[J].Energy,2019,172:1277-1290.

[22] FUCHS S,SCHUTZ F,FÖRSTER H,et al.Evaluation of common mixing models for calculating bulk thermal conductivity of sedimentary rocks:correction charts and new conversion equations[J].Geothermics,2013,47:40-52.

[23] 席建奋.煤炭地下气化过程特征场演化规律研究[D].北京:中国矿业大学(北京),2016.

XI Jianfen.Study on the Evolution Law of Characteristic Fields in the context of Underground Coal Gasification[D].Beijing:China University of Mining and Technology-Beijing,2016.

[24] ALBERT K,SCHULZE M,FRANZ C,et al.Thermal conductivity estimation model considering the effect of water saturation explaining the heterogeneity of rock thermal conductivity[J].Geothermics,2017,66:1-12.

[25] 刘洪涛.富氧CO2煤炭地下气化过程实验与模拟研究[D].武汉:华中科技大学,2019.

LIU Hongtao.Experimental and simulation study on the process of underground gasification of oxygen-enriched CO2 coal[D].WUhan:Huazhong University of Science and Technology,2019.

[26] 周 松,梁 杰.和顺无烟煤地下气化模型试验研究[J].煤炭工程,2017,49(11):138-141.

ZHOU Song,LIANG Jie.Model test study on underground gasification of Heshun anthracite[J].Coal Engineering,2017,49(11):138-141.

[27] LI Huaizhan,GUO Guangli,ZHENG Nanshan.Influence of coal types on overlying strata movement and deformation in underground coal gasification without shaft and prediction method of surface subsidence[J].Process Safety and Environmental Protection,2018,120:302-312.

[28] SAMDANI Ganesh,GANESH Anuradda,AGHALAYAM Preeti,et al.Kinetics of heterogeneous reactions with coal in context of underground coal gasification[J].Fuel,2017,199:102-114.

[29] 刘建明.煤炭地下气化燃空区扩展及顶板稳定性研究[D].徐州:中国矿业大学,2014.

LIU Jianming.Study on the combustion cavity growth and stability of the roof during underground coal gasification[D].Xuzhou:China University of Mining and Technology,2014.

[30] 赵 娟,刘洪涛,潘 霞,等.不同富氧条件下O2/CO2地下气化试验效果研究[J].煤炭科学技术,2017,45(6):214-220.

ZHAO Juan,LIU Hongtao,PAN Xia,et al.Study on O2 /CO2 underground coal gasification effect with different oxygen-enriched conditions[J].Coal Science and Technology,2017,45(6):214-220.

[31] HAMANAKA Akihiro,SU Faqiang,ITAKURA Kenichi,et al.Effect of injection flow rate on product gas quality in underground coal gasification(UCG)based on laboratory scale experiment:development of co-axial ucg system[J].Energies,2017,10(2):238.

[32] DURDAN Milan, KOSTUR Karol.Modelling of heat losses in UCG under laboratory conditions and in situ[C]//Proceedings of the 2015 16th International Carpathian Control Conference,MiskolciEgyetem:2015.

[33] WANG Zhangqing,LIANG Jie,SHI Longxi,et al.Expansion of three reaction zones during underground coal gasification with free and percolation channels[J].Fuel,2017,190:435-443.

[34] WANG Zhangqing,XU Xiyan,CUI Yong.Effect of fixed and removable gas-injection patterns on the expansion of reaction zones during underground coal gasification[J].Energy & Fuels,2019,33(6):4740-4747.

[35] AKBARZADEH H, CHALATURNYK R J.Structural changes in coal at elevated temperature pertinent to underground coal gasification: A review[J].International Journal of Coal Geology, 2014,131:126-146.

[36] SU Faqiang,ITAKURA Kenichi,DEGUCHI Gota,et al.Monitoring of coal fracturing in underground coal gasification by acoustic emission techniques[J].Applied Energy,2017,189:142-156.

[37] KOTYRBA ![]() K.Application of a GPR technique for the monitoring of simulated underground coal gasification in a large-scale model[J].Near Surface Geophysics,2013,11(5):505-516.

K.Application of a GPR technique for the monitoring of simulated underground coal gasification in a large-scale model[J].Near Surface Geophysics,2013,11(5):505-516.

[38] KOTYRBA ![]() Krzysztof.Sensing undergro-und coal gasification by ground penetrating radar[J].Acta Geophysica,2017,65(6):1185-1196.

Krzysztof.Sensing undergro-und coal gasification by ground penetrating radar[J].Acta Geophysica,2017,65(6):1185-1196.

[39] 余恒昌,邓 孝,陈碧琬.矿山地热与热害治理[M].北京:煤炭工业出版社,1991.

[40] 毛节华,许惠龙.中国煤炭资源预测与评价[M].北京:科学出版社,1999.

[41] 乔恒君.地铁隧道围岩传热机制研究[D].南京:南京大学地质工程, 2011.

QIAO Hengjun.study on the heat transfer mechanism of subway tunnel surrounding[D].Nanjing: Nanjing University,2011.

[42] 李怀展.无井式煤炭地下气化岩层移动机理与控制研究[D].徐州:中国矿业大学,2017.

LI Huaizhan.Study on the strata movement mechanisms and control in ucg without shaft[D].Xuzhou:China University of Mining and Technology,2017.

[43] YANG Lanhe.Numerical simulation on three-dimensional nonlinear and unstable seepage of fluid in underground coal gasification[J].Fuel Processing Technology,2003,84(1/3):79-93.

[44] XIN Lin,WANG Zuotang,HUANG Wengang,et al.Temperature field distribution of burnt surrounding rock in UCG stope[J].International Journal of Mining Science and Technology,2014,24(4):573-580.

[45] YANG Lanhe.Three-dimensional non-linear numerical analysis on the oxygen concentration field in underground coal gasification[J].Fuel Processing Technology,2004,85(15):1605-1622.

[46] CHENG Weimin,XIN Lin,WANG Gang,et al.Analytical research on dynamic temperature field of overburden in goaf fire-area under piecewise-linear third boundary condition[J].International Journal of Heat and Mass Transfer,2015,90:812-824.

[47] BROWN Jim,VARDY Alan,ZENG Zhaoyang.Influence of radial seepage on temperature distribution around a cylindrical cavity in a porous medium[J].International Journal of Heat and Mass Transfer,1998,41(11):1531-1541.

[48] LIU Xiaopeng,GUO Guangli,LI Huaizhan.Study on the propagation law of temperature field in surrounding rock of underground coal gasification(UCG)combustion cavity based on dynamic thermal parameters[J].Results in Physics,2019,12:1956-1963.

[49] PERKINS Greg,SAHAJWALLA Veena.Steady-state model for estimating gas production from underground coal gasification[J].Energy & Fuels,2008,22(6):3902-3914.

[50] CHEN Liang,HOU Chaohu,CHEN Jiansheng,et al.A back analysis of the temperature field in the combustion volume space during underground coal gasification[J].Mining Science and Technology(China),2011,21(4):581-585.

[51] EKNELIGODA T C,MARSHALL A M.A coupled thermal-mechanical numerical model of underground coal gasification(UCG)including spontaneous coal combustion and its effects[J].International Journal of Coal Geology,2018,199:31-38.

[52] SATEESH D,RAMESH N M.Laboratory studies on combustion cavity growth in lignite coal blocks in the context of underground coal Gasification[J].Energy,2010,35:2374-2386.

[53] YANG Lanhe.The dynamic temperature field of two-stage underground coal gasification(UCG)[J].Energy Sources.Part A,Recovery,Utilization,and Environmental Effects,2006,28(7):667-680.

[54] 梁 杰.煤炭地下气化过程稳定性及控制技术[M].徐州:中国矿业大学出版社,2001.

[55] RENATO ![]() Ni,Palange Rupesh,et al.Underground coal gasification :a numerical approach to study the formation of syngas and its reactive transport in the surrounding strata[J].Fuel,2019,25(3):349-360.

Ni,Palange Rupesh,et al.Underground coal gasification :a numerical approach to study the formation of syngas and its reactive transport in the surrounding strata[J].Fuel,2019,25(3):349-360.

[56] LIU Hongtao,LIU Shuiqin,CHEN Fengzhao,et al.Mathematical modeling of the underground coal gasification process in one gasification cycle[J].Energy & Fuels,2019,33(2):979-989.

[57] OTTO Christopher,KEMPKA Thomas.Thermo-mechanical simulations of rock behavior in underground coal gasification show negligible impact of temperature-dependent parameters on permeability changes[J].Energies,2015,8(6):5800-5827.

[58] KLEBINGAT Stefan,KEMPKA Thomas,SCHULTEN Marc,et al.Innovative thermodynamic underground coal gasification model for coupled synthesis gas quality and tar production analyses[J].Fuel,2016,183:680-686.

[59] 黄 敏,刘秀敏,贾 民.基于计算流体动力学的煤炭地下气化过程数值模拟[J].煤矿安全,2018,49(7):142-146.

HUANG Min,LIU Xiumin,JIA Min.Numerical simulation of underground coal gasification process based on computational fluid dynamics[J].Coal Mine Safety,2018,49(7):142-146.

[60] YANG Dongmin,SARHOSIS Vasilis,SHENG Yong.Thermal-mechanical modelling around the cavities of underground coal gasification[J].Journal of the Energy Institute,2014,87(4):321-329.

[61] 梁新星,孙春宝,梁 杰,等.深部煤层地下气化化学点火方法研究及数值模拟[J].北京科技大学学报,2013,35(1):8-15.

LIANG Xinxing,SUN Chunbao,LIANG Jie,et al.Research and numerical simulation of chemical ignition method for underground gasification of deep coal seams[J].Journal of University of Science and Technology Beijing,2013,35(1):8-15.

[62] 崔 勇,梁 杰,王 旋.基于非稳态渗流传递的煤炭地下气化数值模拟[J].煤炭学报,2014,39(S1):231-238.

CUI Yong,LIANG Jie,WANG Xuan.Numerical simulation of underground coal gasification based on unsteady seepage transfer[J].Journal of China Coal Society,2014,39(S1):231-238.

[63] XIN Lin,CHENG Weimin,XIE Jun,et al.Theoretical research on heat transfer law during underground coal gasification channel extension process[J].International Journal of Heat and Mass Transfer,2019,142:118409.

[64] AKBARZADEH Kasani Hossein,CHALATURNYK Richard J.Coupled reservoir and geomechanical simulation for a deep underground coal gasification project[J].Journal of Natural Gas Science and Engineering,2017,37:487-501.

[65] ELAHI S.M,NASSIR M,CHEN Z.Effect of various coal constitutive models on coupled thermo-mechanical modeling of underground coal gasification[J].Journal of Petroleum Science and Engineering,2017,154:469-478.

[66] JIANG Liangliang,CHEN Zhangxin,ALI S M Farouq.Modelling of reverse combustion linking in underground coal gasification[J].Fuel,2017,207:302-311.

[67] JOWKAR Amin,SERESHKI Farhang,NAJAFI Mehdi.A new model for evaluation of cavity shape and volume during Underground Coal Gasification process[J].Energy,2018,148:756-765.

[68] JOWKAR Amin,SERESHKI Farhang,NAJAFI Mehdi.Numerical simulation of UCG process with the aim of increasing calorific value of syngas[J].International Journal of Coal Science & Technology,2020,7(1):196-207.

[69] 赵明东.煤炭地下气化覆岩温度和裂隙的试验与数值模拟研究[D].徐州:中国矿业大学(北京),2017.

ZHAO Mingdong.Experimental and numerical simulation research on temperature and fissures of overburden rock in underground coal gasification[D].Xuzhou:China University of Mining and Technology-Beijing,2017.

[70] SIRDESAI N N,MAHANTA Bankim,RANJITH P G,et al.Effects of thermal treatment on physico-morphological properties of Indian fine-grained sandstone[J].Bulletin of Engineering Geology and the Environment,2019,78(2):883-897.

[71] WEN Hu,LU Junhui,XIAO Yang,et al.Temperature dependence of thermal conductivity,diffusion and specific heat capacity for coal and rocks from coalfield[J].Thermal-Chimica Acta,2015,619:41-47.

[72] MIAO S Q,LI H P,CHEN G.Temperature dependence of thermal diffusivity,specific heat capacity,and thermal conductivity for several types of rocks[J].Journal of Thermal Analysis and Calorimetry,2014,115(2):1057-1063.

[73] NABELEK P I,WHITTINGTON A G,HOFMEISTER A M.Strain heating as a mechanism for partial melting and ultrahigh temperature metamorphism in convergent orogens:Implications of temperature-dependent thermal diffusivity and rheology[J].Journal of Geophysical Research,2010.115:1-17.

[74] MERRIMAN Jesse D,WHITTINGTON Alan G,HOFMEISTER Anne M,et al.Thermal transport properties of major Archean rock types to high temperature and implications for cratonic geotherms[J].Precambrian Research,2013,233:358-372.

[75] MIAO Sheqiang,ZHOU Yongsheng.Temperature dependence of thermal diffusivity and conductivity for sandstone and carbonate rocks[J].Journal of Thermal Analysis and Calorimetry,2018,131(2):1647-1652.

[76] ABDULAGATOV I M,ABDULAGATOVA Z Z,KALLAEV S N,et al.Thermal-diffusivity and heat-capacity measurements of sandstone at high temperatures using laser flash and DSC methods[J].International Journal of Thermophysics,2015,36(4):658-691.

[77] BRANLUND J M,HOFMEISTER A M.Factors affecting heat transfer in natural SiO2 solids[J].American Mineralogist.2008,93(10):1620-1629.

[78] DENG Jun,REN Shuaijing,XIAO YANG,et al.Thermophysical properties of coal during low temperature oxidation under different oxygen concentrations[J].Thermochimica Acta,2019,676:186-197.

[79] MELCHIOR E,LUTHER H.Measurement of true specific heats of bituminous coals of different rank,and of a high-temperature coke,in the temperature range 30-350 ℃[J].Fuel,1982(3):1071-1079.

[80] HERRIN J M,DEMING D,Thermal conductivity of U.S.coals[J].Journal of Geophysical Research:Solid Earth.1996,101,25381-25386.

[81] LUO Jian,WANG Lianguo,TANG Furong,et al.Variation in the temperature field of rocks overlying a high-temperature cavity during underground coal gasification[J].Mining Science and Technology(China),2011,21(5):709-713.