移动扫码阅读

移动扫码阅读

煤层气、页岩气、致密砂岩气作为非常规油气,在我国能源结构中发挥着重要的作用[1-3]。煤、泥页岩和致密砂岩都是非均质性很强的多孔介质,具有不同的孔隙结构特征[4-6],研究其孔隙结构差异性及对吸附能力的影响,对煤层气、页岩气和致密砂岩气勘探开发具有重要意义。

国内外学者对煤[7-8]、页岩和砂岩孔隙结构及吸附能力进行了广泛的研究[9-12]。但目前针对煤、泥页岩和砂岩孔隙结构差异性对比研究及其对甲烷吸附的影响方面的研究鲜有报道。开展煤、页岩及砂岩的孔隙结构及吸附能力差异性的对比研究,对煤层气、页岩气和致密砂岩气的储集机理及富集规律,对“三气”共采的研究具有重要的意义。总体上对煤岩孔隙结构的研究方法主要有扫描电镜和CT成像技术等为主图像分析法和压汞[13-14]、低温液氮吸附[15]、低温二氧化碳吸附等为主的流体注入法2种类型[16-17]。图像分析方法能够直接观测到煤岩样品的孔隙结构形态,但很难做到对孔径分布的定量分析;流体注入测试方法具有测试定量化、精准度高等特点,但不同测试方法仅能表征某一范围内孔隙,无法表征煤岩全面范围的孔隙。压汞试验只对大孔测试比较精确,对50 nm以下的孔隙测试不够精准;低温液氮吸附试验主要用于测试纳米级孔隙,对2 nm 以下孔隙测试不够精确;低温二氧化碳吸附试验主要测试2 nm以下孔隙,无法对大于2nm以上孔隙进行测试。

基于以上不同测试手段的特点,笔者采用压汞、低温液氮吸附、低温二氧化碳吸附测试方法,对煤、页岩和砂岩等样品进行测试,进行微孔-中孔-大孔多种尺度的测试方法,对煤岩的孔隙结构进行全面表征研究,研究煤、页岩和砂岩孔隙结构的差异性,并进行了不同样品的甲烷等温吸附试验,分析孔隙结构对甲烷吸附的影响,探讨不同非常规储层的储集机理。

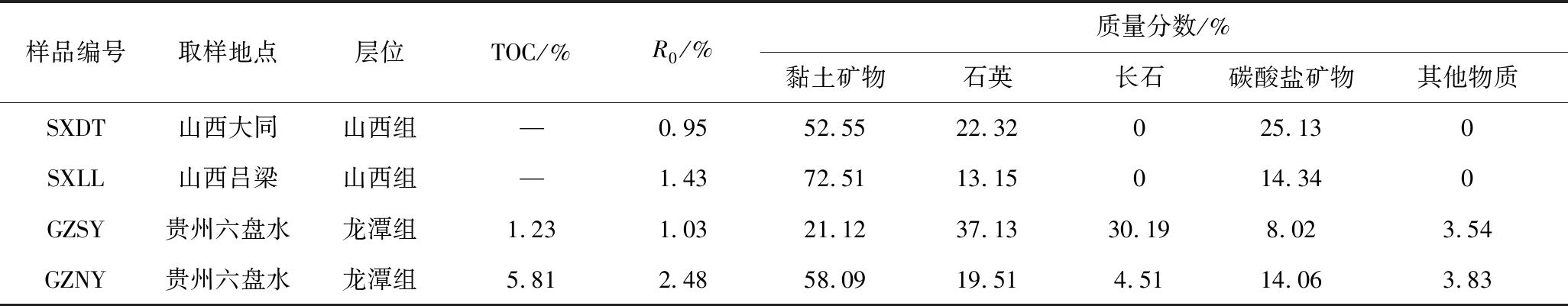

试验样品分别为山西吕梁碾焉煤矿焦煤、山西大同王村煤矿气煤和贵州六盘水页岩和砂岩。样品具体情况见表1。

表1 样品信息

Table 1 Sample information

样品编号取样地点层位TOC/%R0/%质量分数/%黏土矿物石英长石碳酸盐矿物其他物质SXDT山西大同山西组—0.9552.5522.32025.130SXLL山西吕梁山西组—1.4372.5113.15014.340GZSY贵州六盘水龙潭组1.231.0321.1237.1330.198.023.54GZNY贵州六盘水龙潭组5.812.4858.0919.514.5114.063.83

研究采用低温CO2吸附试验、N2吸附试验、压汞试验联合的综合测试方法,结合等温吸附方法,对煤、页岩和砂岩孔隙结构和吸附特征进行研究。

1)低温 CO2吸附试验,试验设备为美国康塔公司 Autosorb iQ Station 2型比表面积和孔隙分析仪。测试方法为温度在273 K,相对压力0.05~0.99条件下,以气态CO2为吸附质,进行吸附试验。

2)低温N2吸附试验。试验设备为北京精微高博公司的JW—BK122型孔径分析仪,测试方法为在77 K温度,相对压力0.001~0.995条件下,以气态N2为吸附质,进行吸附解吸试验。

3)压汞试验。试验设备为美国康塔公司的Poremaster-60型压汞试验仪,测试方法为在不同压力条件下,向样品中注入汞,对注汞压力和注汞体积进行分析。

4)等温吸附试验。试验设备MACT-II型等温吸附试验仪进行测试,测试方法参照等(GB/T 19560—2008)温吸附试验方法和(GB/T 35210.1—2017)《页岩甲烷等温吸附测定方法》,测试温度为30 ℃,最高试验压力为10 MPa。

按照DFT模型,对试验测试结果进行分析,结果见表2和如图1所示。样品的孔容和孔比表面积在孔径0.55 nm和0.8 nm左右出现2个峰值点,随着孔径的减小,表现出“增加—减小—增加—减小”的变化规律。

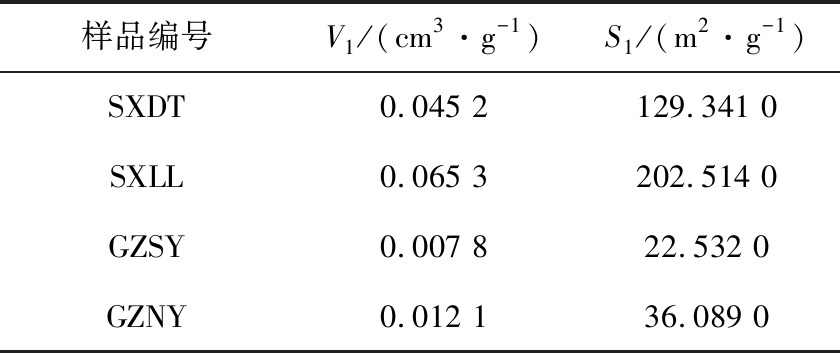

表2 基于低温CO2吸附试验的样品孔隙结构特征

Table 2 Pore structure characteristics of samples by low temperature CO2 adsorption experiment

样品编号V1/(cm3·g-1)S1/(m2·g-1)SXDT0.045 2129.341 0SXLL0.065 3202.514 0GZSY0.007 822.532 0GZNY0.012 136.089 0

注:采用IUPAC分类方案,V1为孔径小于2 nm孔容,S1为孔径小于2 nm孔比表面积。

图1 低温CO2吸附法样品孔容和孔容比表面积分布

Fig.1 Distribution of pore volume and specific surface area of samples by low temperature CO2 adsorption

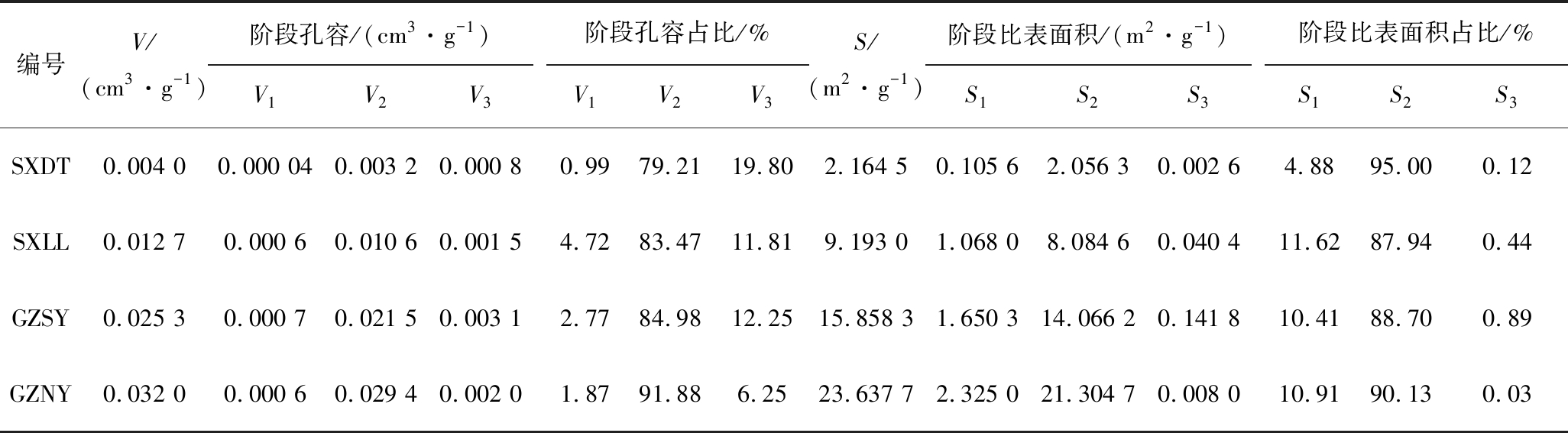

按照IUPAC分类方案,对N2吸附试验结果进行分析,结果见表3。

表3 基于低温N2吸附试验的样品孔隙结构特征

Table 3 Pore structure characteristics of samples by low temperature N2 adsorption experiment

编号V/(cm3·g-1)阶段孔容/(cm3·g-1)V1V2V3阶段孔容占比/%V1V2V3S/(m2·g-1)阶段比表面积/(m2·g-1)S1S2S3阶段比表面积占比/%S1S2S3SXDT0.004 00.000 040.003 20.000 80.9979.2119.802.164 50.105 62.056 30.002 64.8895.000.12SXLL0.012 70.000 60.010 60.001 54.7283.4711.819.193 01.068 08.084 60.040 411.6287.940.44GZSY0.025 30.000 70.021 50.003 12.7784.9812.2515.858 31.650 314.066 20.141 810.4188.700.89GZNY0.032 00.000 60.029 40.002 01.8791.886.2523.637 72.325 021.304 70.008 010.9190.130.03

注:V为总孔容;S为总比表面积;V1为孔径小于2 nm孔容;V2为孔径2~50 nm孔容;V3为孔径大于50 nm孔容;S1为孔径小于2 nm孔比表面积;S2为孔径2~50 nm孔比表面积;S3为孔径大于50 nm孔比表面积。

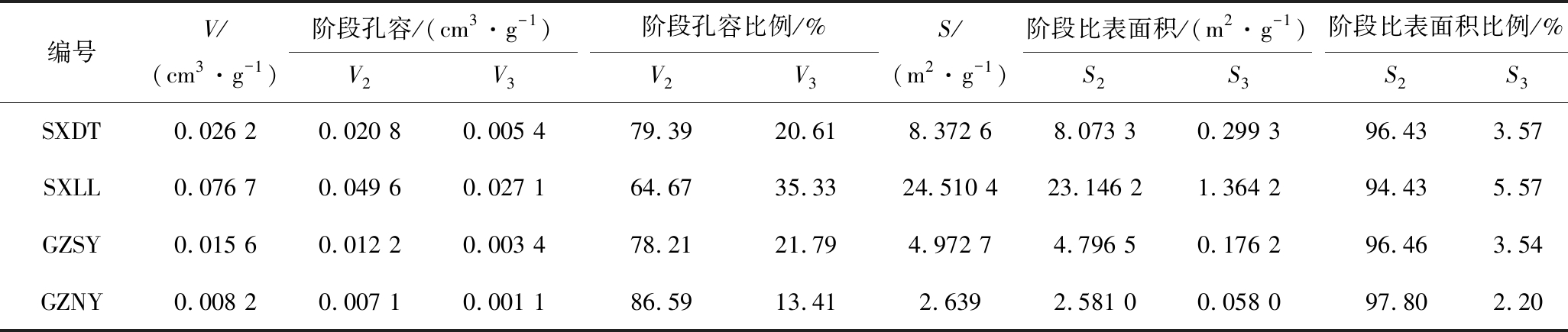

按照IUPAC分类方案,对压汞试验数据进行分析,结果见表4。

表4 基于压汞试验的样品孔隙结构特征

Table 4 Pore structure characteristics of samples by mercury intrusion experiments

编号V/(cm3·g-1)阶段孔容/(cm3·g-1)V2V3阶段孔容比例/%V2V3S/(m2·g-1)阶段比表面积/(m2·g-1)S2S3阶段比表面积比例/%S2S3SXDT0.026 20.020 80.005 479.3920.618.372 68.073 30.299 396.433.57SXLL0.076 70.049 60.027 164.6735.3324.510 423.146 21.364 294.435.57GZSY0.015 60.012 20.003 478.2121.794.972 74.796 50.176 296.463.54GZNY0.008 20.007 10.001 186.5913.412.6392.581 00.058 097.802.20

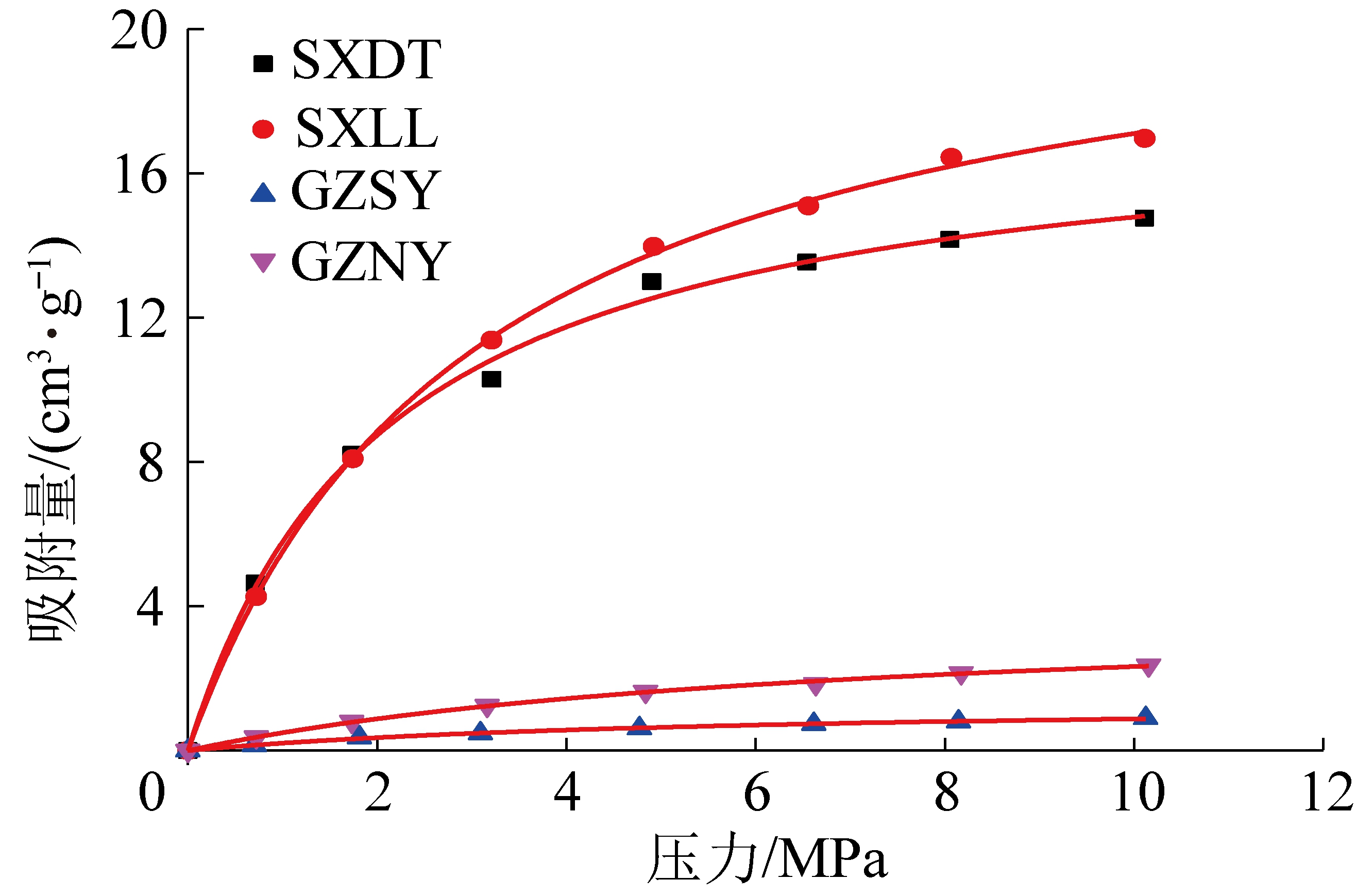

等温吸附曲线如图3所示,经Langmuir方程拟合得到SXDT、SXLL、GZSY和GZNY的Langmuir体积(VL)分别为17.87、22.31、1.37和3.95 cm3/g。

图2 低温N2吸附法样品孔容和孔容比表面积分布

Fig.2 Distribution of pore volume and specific surface area of samples by low temperature N2 adsorption

图3 等温吸附曲线

Fig.3 Isothermal adsorption curve

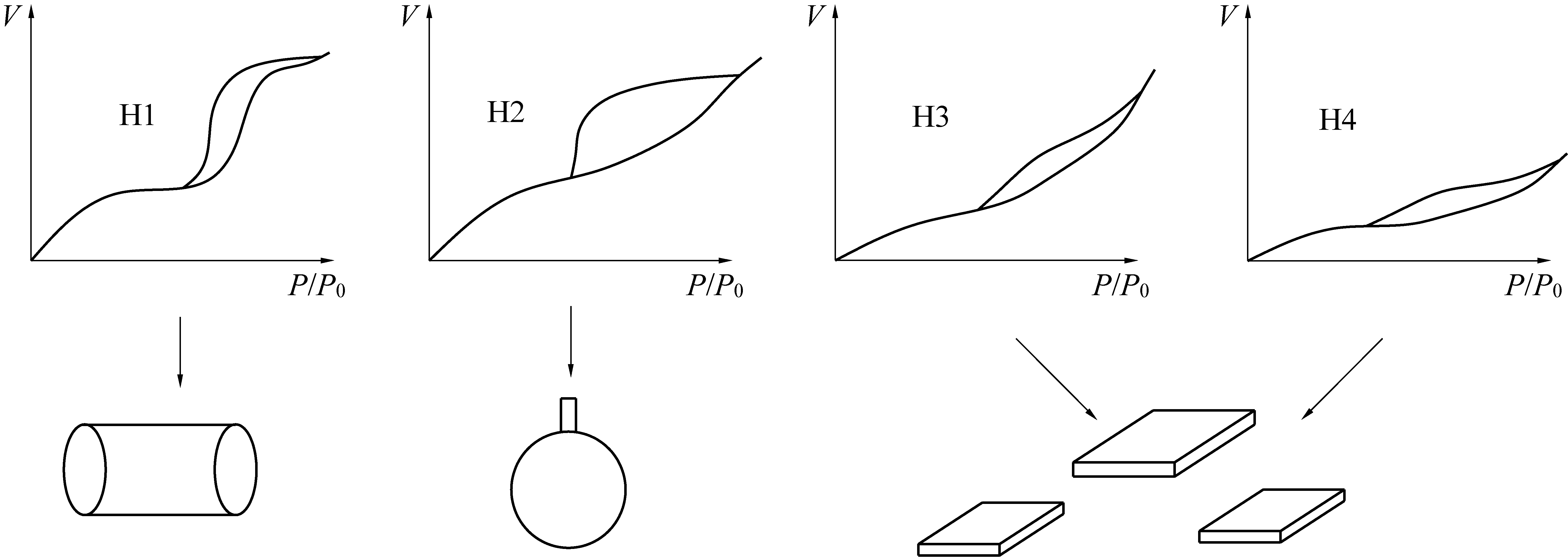

由严继民等[18]提出的凝聚理论可知,毛细孔固体材料吸附解吸试验的吸附-解吸2条曲线会重叠或者分离,吸附-解吸2条曲线开口大小及形状在一定程度上能够反应被测试样品的孔隙结构[19]。低温液氮吸附-解吸曲线如图4所示。

图4 低温液氮吸附-解吸曲线

Fig.4 Adsorption-desorption curve of low temperature liquid nitrogen

国际理论与应用化学联合会(IUPAC)根据吸附—解吸两条曲线开口大小及形状,将吸附回线分为4类(图5),其中,H1类对应两端开放的圆筒形孔隙,H2类对应墨水瓶形孔隙,H3类和H4类对应狭缝形孔隙。从图5可以看出,煤吸附-解吸曲线与H2类接近,说明煤中主要发育狭缝形孔隙;页岩和砂岩吸附-解吸曲线与H3类接近,说明页岩和砂岩中主要含有墨水瓶形孔。

图5 脱附曲线分类及其孔隙结构类型[20]

Fig.5 Classification of desorption curve and pore structure[20]

煤、页岩和砂岩孔隙从微孔、介孔和大孔均有广泛分布,采用单一方法难以对孔隙结构进行全面测试。从测试原理来看,上述3种方法均有各自的优势孔径段,能够对该段的孔径分布进行准确表征。二氧化碳吸附法可以有效测试2 nm以下的微孔,无法对介孔和大孔进行测试;低温氮气吸附法可以有效测试2~50 nm孔径段孔隙,对微孔和大孔测试不够精确;压汞试验在实际操作过程中,当进汞压力较大时(>10 MPa),会导致煤基质压缩变形和孔隙破坏,所以压汞法对50 nm以下的孔隙测试不够精确。因此,以低温二氧化碳吸附法、低温液氮吸附法和压汞法分别表征微孔、介孔和大孔。

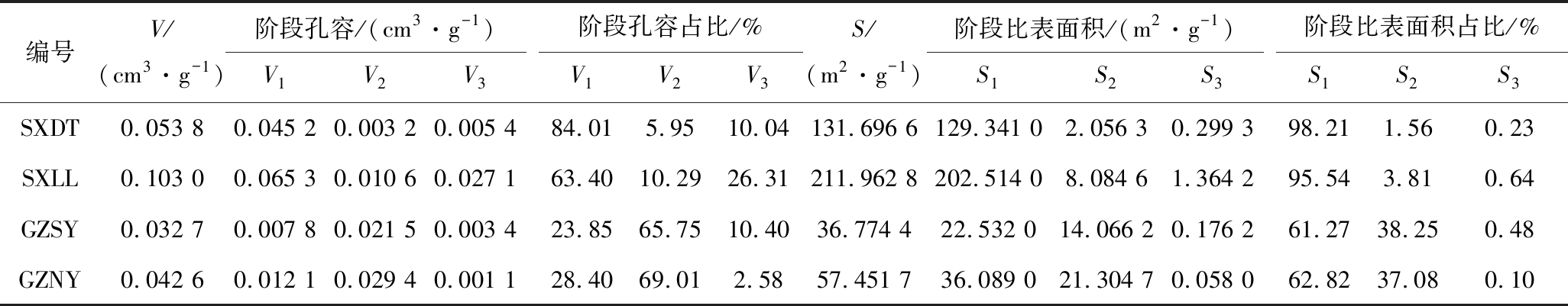

将低温二氧化碳吸附数据与低温氮气吸附数据在2 nm处进行衔接,低温氮气吸附数据与压汞数据在50 nm处进行衔接,统计了样品的孔容和比表面积,见表5,并绘制了不同样品孔容和比表面积的微孔、介孔和大孔的分布比例,如图6所示。

从表5中和图6中可以看出,煤与页岩、砂岩具有不同孔径分布特征,煤中微孔最为发育,SXDT煤样微孔孔容和比表面积比例分别为84.01%和98.21%,SXLL煤样微孔孔容和比表面积比例分别为63.40%和95.54%。

图6 样品不同阶段孔径的孔容和比表面积分布比例

Fig.6 Distribution ratio of pore volume and specific surface area of pore diameter in different stages of sample

表5 样品全孔径段孔径分布特征

Table 5 Pore size distribution characteristics of sample with the full pore diameter

编号V/(cm3·g-1)阶段孔容/(cm3·g-1)V1V2V3阶段孔容占比/%V1V2V3S/(m2·g-1)阶段比表面积/(m2·g-1)S1S2S3阶段比表面积占比/%S1S2S3SXDT0.053 80.045 20.003 20.005 484.015.9510.04131.696 6129.341 02.056 30.299 398.211.560.23SXLL0.103 00.065 30.010 60.027 163.4010.2926.31211.962 8202.514 08.084 61.364 295.543.810.64GZSY0.032 70.007 80.021 50.003 423.8565.7510.4036.774 422.532 014.066 20.176 261.2738.250.48GZNY0.042 60.012 10.029 40.001 128.4069.012.5857.451 736.089 021.304 70.058 062.8237.080.10

页岩和砂岩具有相似的孔径分布特征,砂岩和页岩介孔最为发育,砂岩介孔孔容和比表面积比例分别为65.75%和38.25%,页岩介孔孔容和比表面积比例分别为69.01%和37.08%。

整体来看,孔容和比表面积大小顺序依次为煤样>页岩>砂岩,这是由于煤中微孔较为发育,微孔为煤提供了大部分的孔容和比表面积。

为表明孔径对甲烷吸附的影响,做出了微孔比表面积、介孔比表面积小于50 nm孔表面积与朗格缪尔体积(VL)拟合曲线,如图7所示。

图7 不同孔径比表面积与朗缪尔体积关系

Fig.7 Relationship between Langmuir volume and the specific surface area of pores with different pore diameters

从图7中可以看出,样品Langmuir体积(VL)与中孔比表面积呈负相关,与微孔比表面积和小于50 nm孔隙比表面积均具有强烈的正相关性,拟合系数分别达到0.948 2和0.912 0,表明比表面正是气体吸附的场所,比表面越大,甲烷分子吸附的点位就越多,吸附量越大。煤对甲烷的吸附能力远远大于页岩和砂岩,主要是由于煤微孔提供了大量的比表面积,煤微孔发育远远大于砂岩和页岩。

1)所测样品中,煤中主要发育狭缝形孔隙,页岩和砂岩中主要发育墨水瓶形孔。

2)煤、页岩和砂岩孔隙结构具有较大的差异性,煤微孔发育程度远远大于页岩和砂岩。煤中微孔为煤提供了大部分的孔容和比表面积,其中微孔孔容占总孔容的60%以上,微孔比表面积占总比表面积的95%以上;页岩和砂岩的孔容主要有介孔提供,介孔孔容占到总孔容的65%以上,比表面积由微孔提供,微孔比表面积占到总比表面积的61%以上。

3)不同样品对甲烷吸附能力顺序依次为煤>页岩>砂岩,对甲烷吸附主要受控于孔比表面积,微孔为煤对甲烷的吸附提供了更多的空间和吸附点位,所以煤对甲烷吸附能力远远大于页岩和砂岩。

[1] 邓恩德,姜秉仁,高 为,等.黔西地区龙潭组煤系泥页岩孔隙结构及分形特征研究[J].煤炭科学技术,2020,48(8):184-190.

DENG Ende,JIANGBingren,GAO Wei,et al.Study on pore structure and fractal characteristics of shale from coal measures of longtan formation in westen guizhou[J].Coal Science and Technology,2020,48(8):184-190.

[2] 张雪芬,陆现彩,张林晔,等.页岩气的赋存形式研究及其石油地质意义[J].地球科学进展,2010,25(6):597-598.

ZHANG Xuefen,LU Xiancai,ZHANG Linye,et al.Occurrences of shale gas their petroleum geological significance[J].Advances In Earth Science,2010,25(6):597-598.

[3] 王 祥,刘玉华,张 敏,等.页岩气形成条件及成藏影响因素研究[J].天然气地球科学,2010,21(2):350-356.

WANG Xiang,LIU Yuhua,ZHANG Min,et al.Conditions of Formation and Accumulation for Shale Gas[J].Natural Gas Geoscience,2010,21(2):350-356.

[4] 黄 婷,刘 正.榆社—武乡区块煤储层孔隙结构特征及其影响因素分析[J].煤炭科学技术,2019,47(7):227-233.

HUANG Ting,LIU Zheng.Analysis on pore structure characteristics and influencing factors of coal reservoir in Yushe-Wuxiang Block[J].Coal Science and Technology,2019,47(7):227-233.

[5] 高 尚,王 亮,高 杰,等.基于分形理论的不同变质程度硬煤孔隙结构试验研究[J].煤炭科学技术,2018,46(8):93-100.

GAO Shang,WANG Liang,GAO Jie,et al.Experimental study on pore structures of hard coal with different metamorphic grade based on fractal theory[J].Coal Science and Technology,2018,46(8):93-100.

[6] 李 惠,王福国,李 振,等.六盘水煤田杨梅树向斜主要煤层孔隙结构特征研究[J].煤炭科学技术,2019,47(7):234-243.

LI Hui,WANG Fuguo,LI Zhen,et al.Study on pore properties of main coal seams of Yangmeishu syncline in Liupanshui coalfield[J].Coal Science and Technology,2019,47(7):234-243.

[7] 李 阳,张玉贵,张 浪,等.基于压汞、低温N2吸附和CO2吸附的构造煤孔隙结构表征[J].煤炭学报,2019,44(4):220-228.

LI Yang,ZHANG Yugui,ZHANG Lang,et al.Characterization on pore structure of tectonic coals based on the method of mercury intrusion,carbon dioxide adsorption and nitrogen adsorption[J].Journal of China Coal Society,2019,44 (4):220-228

[8] 戚灵灵,王兆丰,杨宏民,等.基于低温氮吸附法和压汞法的煤样孔隙研究[J].煤炭科学技术,2012,40 (8):36-39,87.

QI Lingling,WANG Zhaofeng,YANG Hongmin,et al.Study on Porosity of Coal Samples Based on Low Temperature Nitrogen Adsorption Method and Mercury Porosimetry[J].Coal Science and Technology,2012,40 (8):36-39,87.

[9] 陈尚斌,朱炎铭,王红岩,等.川南龙马溪组页岩气储层纳米孔隙结构特征及其成藏意义[J].煤炭学报,2012,37(3):438-444.

CHEN Shangbin,ZHU Yanming,WANG Hongyan,et al.Structure characteristics and accumulation significance of nanopores in Longmaxi shale gas reservoir in the southern Sichuan Basin[J].Journal of China Coal Society,2012,37 (3):438-444.

[10] 韩双彪,张金川,杨 超,等.渝东南下寒武页岩纳米级孔隙特征及其储气性能[J].煤炭学报,2013,38(6):1038-1043.

HAN Shuangbiao,ZHANG Jinchuan,YANG Chao,et al.The characteristics of nanoscale pore and its gas storage capability in the Lower Cambrian shale of southeast Chongqing[J].Journal of China Coal Society,2013,38(6):1038-1043.

[11] 张 凯,汤达祯,陶 树,等.不同变质程度煤吸附能力影响因素研究[J].煤炭科学技术,2017,45(5):192-197.

ZHANG Kai,TANG Dazhen,TAO Shu,et al.Study on influencing factors of coal adsorption capacity of different metamorphic degrees[J].Coal Science and Technology,2017,45 (5):192-197.

[12] 王曦蒙,刘洛夫,汪 洋,等.川南地区龙马溪组页岩高压甲烷等温吸附特征[J].天然气工业,2019,39(12):32-39.

WANG Ximeng,LIU Luofu,WANG Yang,et al.High-pressure isothermal methane adsorption characteristic of Longmaxi Formation shale in the southern Sichuan Basin[J].Natural Gas Industry.2019,39 (12):32-39

[13] PENG C,ZOU C C,YANG Y Q,et al.Fractal analysis of high rank coal from Southeast Qinshui Basin by using gas adsorption and mercury porosimetry[J].Journal of Petroleum Science &Engineering,2017,156:235-249.

[14] PAN J N,ZHAO Y Q,HOU Q L,et al.Nanoscale pores in coal related to coal rank and deformation structures[J].Transport in Porous Media,2015,107(2):543-554.

[15] 张云峰,臧起彪,孙 博,等.基于氮吸附和压汞数据确定致密储层孔径分布:以松辽盆地大安油田扶余油层为例[J].深圳大学学报理工版,2018,35(4):353-361.

ZHANG Yunfeng,ZANG Qibiao,SUN Bo,et al.Determination of pore-throat size distribution of tight reservoirs based on nitrogen adsorption and mercury injection data:an example from Fuyu oil layer in Daan oilfield of Songliao basin[J].Journal of Shenzhen University(Science &Engineering),2018,35 (4):353-361.

[16] 何 庆,何 生,董 田,等.鄂西下寒武统牛蹄塘组页岩孔隙结构特征及影响因素[J].石油实验地质,2019,41(4):530-539

HE Qing,HE Sheng,DONG Tian,et al.Pore structure characteristics and controls of Lower Cambrian Niutitang Formation,western Hubei Province[J].Petroleum Geology and Experiment,2019,41 (4),530-539

[17] 陈居凯,朱炎铭,崔兆帮,等.川南龙马溪组页岩孔隙结构综合表征及其分形特征[J].岩性油气藏,2018,30(1):55-62.

CHEN Jukai,ZHU Yanming,CUI Zhaobang,et al.Pore structure and fractal characteristics of Longmaxi shale in southern Sichuan Basin[J].Lithologic Reservoirs,2018,30 (1):55-62.

[18] 严继民,张启元.吸附与聚集[M].北京:科学出版社,1979.

[19] 降文萍,宋孝忠,钟玲文.基于低温液氮实验的不同煤体结构煤的孔隙特征及其对瓦斯突出影响[J].煤炭学报,2011,36(4):609-614.

JIANG Wenping,SONG Xiaozhong,ZHONG Lingwen.Research on the pore properties of different coal body structure coals and the effects on gas outburst based on the low-temperature nitrogen adsorption method[J].Journal of China Coal Society,2011,36(4):609-614.

[20] WANG W M,WANG Zh X,CHEN X,et al.Fractal nature of porosity in volcanic tight reservoirs of the San Tanghu Basin and its relationship to pore formation processes[J].Fractals,2018,26(2):1-15.