0 引 言

我国煤矿地质较为复杂,据统计,现有煤层中具有致密完整、回采后难以及时垮落的厚硬顶板的煤层约占总量的1/3,这些煤层一旦垮落很容易造成冲击矿压等灾害,对矿井安全生产带来严重威胁[1-2]。针对此类坚硬岩层,目前使用较多的技术有炸药爆破和水力压裂泄压等方法,其中水力压裂技术通过将高压流体注入煤层,使岩石中原生裂缝扩张或形成人工裂纹,并逐渐扩展延伸形成新的裂缝网络系统,从而达到破坏岩层结构的作用。相较于炸药爆破方法,水力压裂技术具有,安全性高、且在泄压的同时可达到预先释放煤层瓦斯的作用,因此近年来该项技术在我国部分煤矿处理坚硬顶板过程中得到了较为广泛的应用,并取得了良好的效果[3-6]。

受行业趋势的影响,对压裂所形成的裂缝的几何形态(方位、缝长和缝高等)的研究受到越来越多学者的重视[7-8]。目前压裂效果评价的方法主要有数值模拟法和裂缝监测法,前者是通过数值软件结合工程参数对理想地层进行模拟研究,目前主要应用于实验室研究;在实际的工程应用中采用裂缝监测法较多,该方法通过电透视法、微震法监测和井温测试等方法对裂缝进行评价,在部分工程应用中无法提供巷道供透视法、微震法监测方法布设传感器进行探测,而井温测试方法测量参数单一,探测效果不明显[9-12]。此外井下钻孔中视频测井技术可以有效地看清裂缝的开口位置,但无法判断裂缝的几何形态[13]。刘盛东等[14]、李世宇[15]在全空间瞬变电磁探测的基础上,受传统测井方法的启发,提出了钻孔瞬变电磁探测方法,并在不同工程环境对该方法效果进行检验,准确定位了钻孔周边的低阻异常。范涛等[16-18]利用三分量钻孔瞬变电磁探测方法对裂缝进行探测,该方法应用于陕西韩城某煤矿瓦斯抽采孔水力压裂效果检测中,对钻孔60~110 m区间分别进行压裂前、压裂后探测,划定了裂缝空间形态,取得了良好的应用效果,但是由于采用人力推送的工艺,无法适用于长距离定向钻孔中水力压裂效果检测。

因此,笔者采用一种钻孔内三分量动源动接收瞬变电磁装置,采用钻机推送的方式对某矿坚硬顶板定向长钻孔水力压裂效果进行试验研究,对压裂段进行压裂前、压裂后分别探测,并提取纯异常场对裂缝发育规律进行分析。

1 三分量钻孔瞬变电磁探测基础

1.1 理论基础

在瞬变电磁探测中,Maxwell的微分表达式为

∇![]()

(1)

∇×H=J

(2)

∇·B=0

(3)

∇·E=0

(4)

其中,

B=μH

(5)

J=σE

(6)

式中,B、H、E分别为磁感应强度、磁场强度和电场强度;μ和σ分别为介质体的磁导率和电导率;J为传导电流密度。

由式(3)可知,上述方程组中关于磁场的3个分量中仅有2个分量彼此独立,因此存在下列方程:

(7)

(8)

(9)

式(7)—式(9)是计算三分量响应的理论基础[19-21]。

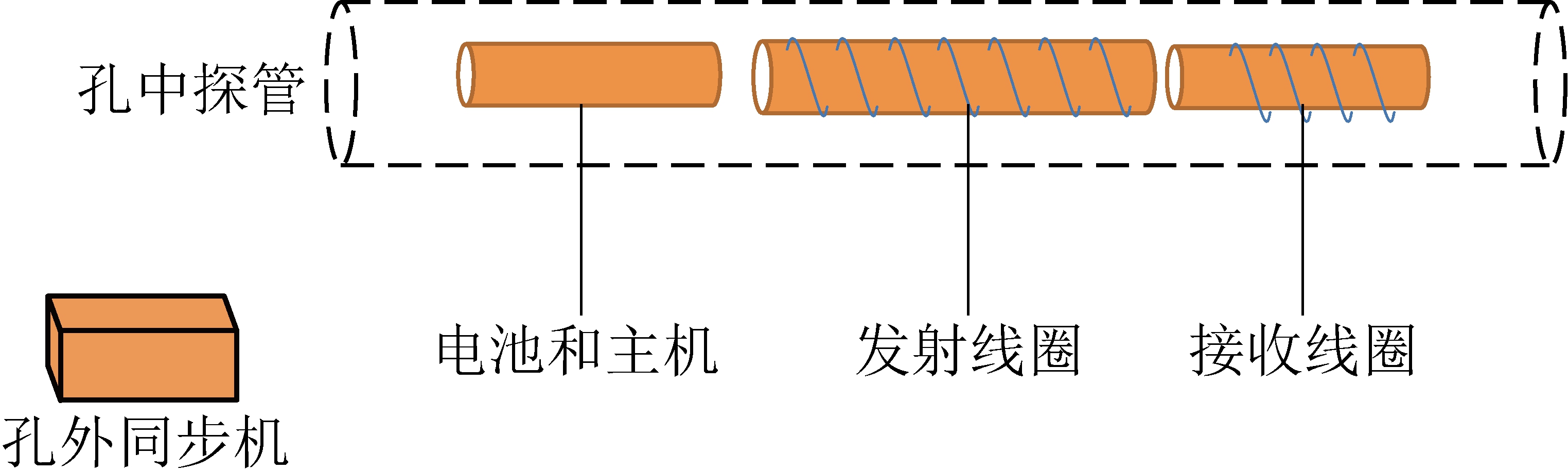

矿井三分量钻孔瞬变电磁探测原理如图1所示,其中T为发射线圈;R为相互正交的3个接收线圈,是由与发射线圈同轴的Z分量接收线圈Rz,与发射线圈正交的X分量接收线圈Rx,以及与发射线圈正交的Y分量接收线圈Ry共同组成。发射线圈添加阶跃激励向周围岩层发射脉冲电磁信号,通过三分量接收线圈采集,实现全空间地质异常体的距离探测和方位识别[14-15]。

图1 三分量钻孔瞬变电磁探测原理示意

Fig.1 Three-component drilling transient electromagnetic detection principle

1.2 探测装置

设计的钻孔三分量探测装置如图2所示,包括孔中探管和孔口同步机2部分。孔中探管由电池主机、发射电路和接收探头3个模块组成,是装置的核心电路部分;孔外同步机主要是用来下发测量参数以及测量过程中时钟同步。探测时,钻机推送探管沿钻孔延伸方向按一定点距测量2次场信号。

图2 三分量钻孔瞬变电磁探测装置示意

Fig.2 Three-component drilling transient electromagnetic detection device

2 数据处理方法

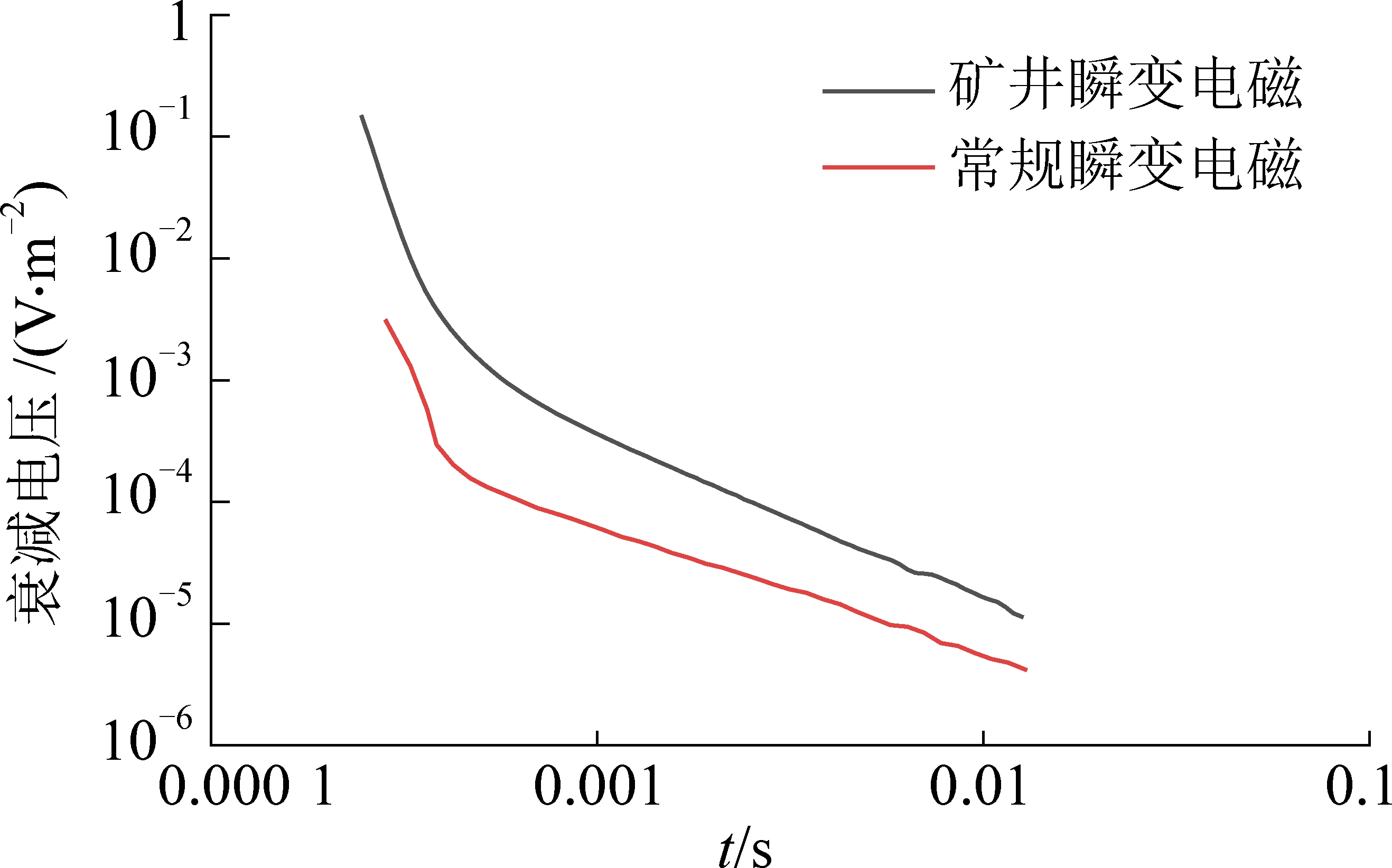

2.1 Z分量数据处理

钻孔瞬变电磁Z分量数据处理方法与矿井瞬变电磁探测相同。将装置至于物理模型中进行数据采集,钻孔装置与常规装置接收信号对比如图3所示,信号衰减规律基本相同,因此数据处理方法可参考常规矿井瞬变电磁,采用预处理技术对电感影响进行校正,对校正后的数据则可应用多种反演成像方法进行处理解释[22-24]。

图3 矿井瞬变电磁装置与钻孔装置实测曲线对比

Fig.3 Comparison of measured curves of mine equipment and drilling equipmen

2.2 XY分量数据处理

常规瞬变电磁探测中仅探测了与发现线框轴向同向的Z分量数据,对于三分量钻孔瞬变电磁中XY分量的数据数据处理方法,通过数值模拟计算,在分析响应特征的基础上,总结了一套XY分量的数据处理方法[25]。

2.2.1 装置旋转角度校正

三分量瞬变电磁探测装置在钻孔中施工时,由于受推送工艺影响,装置必然会在钻孔内发生旋转,因此,实际地层XY分量数据需要通过工具面角进行相应变换得到。

为了方便分析,记开孔处装置工具面角为α0,孔中α0第i个测点位置的工具面角为αi,则仪器在钻孔内的旋转角度为

Δα=αi-α0

(10)

装置在第i个测量点处校正后的X和Y分量感应电动势为

Vi,x=Vi,x′cosΔα+Vi,y′sinΔα

(11)

Vi,y=Vi,x′sinΔα+Vi,y′cosΔα

(12)

式中,Vi,x′和Vi,y′为装置在第i个测量点处实测的水平分量感应电动势。

2.2.2 异常方位计算

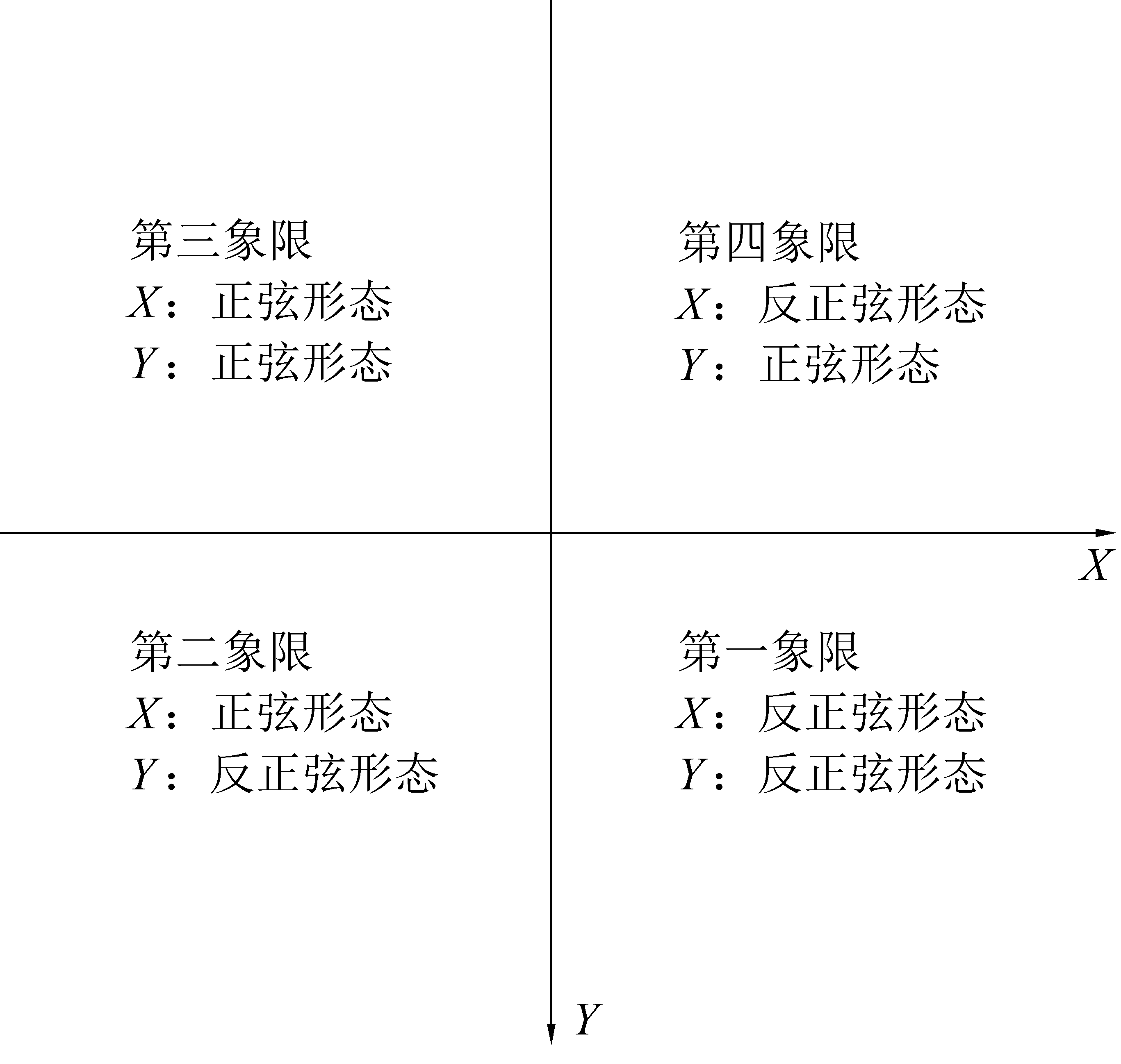

三分量瞬变电磁探测中异常方位角度与XY水平分量的探测信息密切相关,因此探测可以从水平分量信息着手研究异常的方位。采用COMSOL 有限元软件建立数值计算模型如图4所示,规定X分量与Y分量正方向之间区域为第1象限,逆时方向依次定义为二、三、四象限。

图4 三维有限元数值计算模型

Fig.4 Finite element numerical calculation model

钻孔瞬变电磁检测水力压裂效果时采用压裂前和压裂后分别探测,由于2次探测的主要环境差异为压裂所致,因此认为两次探测成果差异即为纯压裂场效果。相对固定板状低阻异常体位置,通过移动探测装置的方式分别计算无异常体和有异常体XY水平分量和异常体位置关系,并提取纯异常场导致的信号变化特征。

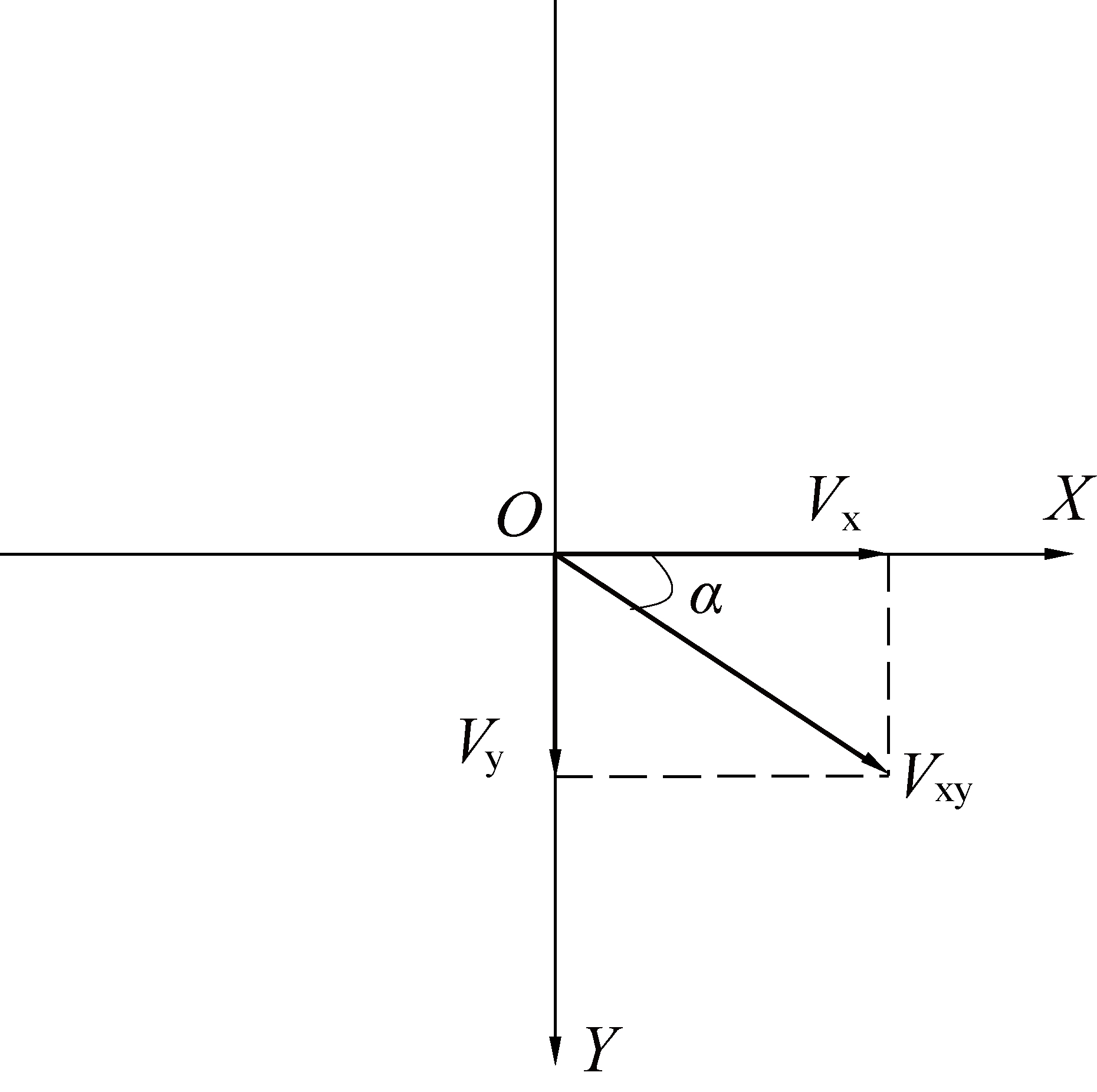

产生的瞬变电磁XY分量探测曲线会发生波“正弦”或“反正弦”形态(图5)。模拟不同象限异常时纯异常场曲线特征,可归纳为如图6所示“正弦”与“反正弦”形态的组合,因此可根据图7判断异常体所在象限。

图5 水平分量异常场形态组合

Fig.5 Horizontal component abnormal field combination

图6 异常位于不同象限时水平分量响应形态

Fig.6 Horizontal component response curve in different quadrant

图7 异常体偏转角度

Fig.7 Abnormal body deflection angle

水平分量异常场幅值之间的三角函数关系(图5),按照下式计算出异常体在该象限内的偏转角度θ。

(4)

最后根据异常体所在象限,求出异常体中心的方位角α:①异常体在第1象限:α=θ;②异常体在第2象限:α=π-θ;③异常体在第3象限:α=π+θ;④异常体在第4象限:α=2π-θ。

2.3 三维成像方法

三分量钻孔瞬变电磁水力压裂检测方法提供了丰富的裂缝坐标信息,为了更直观显示裂缝沿钻孔轨迹分布情况,对异常体进行三维立体成像[26]。

通过散点坐标空间旋转后,可以借助Voxler软件散点绘图功能实现立体成像,具体步骤如下:

1)绘制钻孔轨迹。

2)将视电阻率成像图沿钻孔轨迹展开,并根据视电阻率分布划分出几个明显的条带状异常区段,标记为主裂缝。

3)每一区段通过2.2节的方法计算的有异常中心方位,根据方位角度计算实际空间中裂缝几何形态,并用Voxler软件以散点图立体成像显示主要裂缝的形态。

上述步骤中,采用散点空间旋转的方式按指定角度旋转。为了方便计算,忽略钻孔高程变化,因此钻孔轨迹主要由方位角度决定。以对应钻孔轨迹点为旋转中心进行旋转可得探测成果坐标,方法如图8所示。

图8 散点空间旋转方法

Fig.8 Scattered space rotation method

3 探测应用

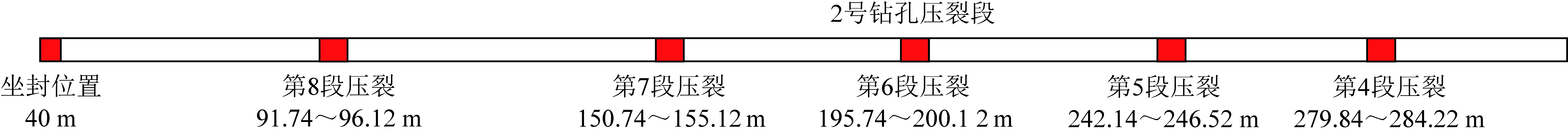

神东某矿2号钻孔深417 m,采用水力压裂技术拟提高坚硬煤体裂隙发育程度、降低煤层整体强度,压裂段布置如图9所示。为了检测压裂的效果,采用三分量瞬变电磁法探测了钻孔深度40~315 m区间。

图9 钻孔压裂段布置

Fig.9 Borehole fracturing section layout

图10为压裂前后的钻孔瞬变电磁Z分量处理结果,其中图10a为压裂前的处理结果,图10b为压裂后的处理结果,成果图中横坐标为钻孔深度,纵坐标为钻孔径向距离。由图10a中看出,压裂前的视电阻率等值线分布比较均匀,在成果中零星分布圈闭低阻区,这与压裂前,测区内围岩的视电阻率分布相对比较均匀、规律吻合。从压裂后的图10b可以发现,测区中出现了局部较大区域的低阻异常,这与压裂导致岩层局部充水吻合,但无法从成果图中直观看出裂缝的发育规律。

图10 Z分量压裂前后对比

Fig.10 Comparison of Z component before and after hydraulic fracturing

为了更清楚的识别异常分布与发育情况,将压裂前的探测成果当做背景场,在压裂后的探测成果中减去背景场,提取出纯异常场,计算成果如图11所示,成果图中横坐标为钻孔深度,纵坐标为钻孔径向距离。通过对纯异常的提取,可以看出钻孔径向距离0~10 m整体视电阻值较低,且异常发育最远距离约为30 m。按照异常强弱和条带状不同,可将图中异常分为6个区域。综合分析图9—11发现,6个异常区,均与实际压裂点存在良好对应关系。

图11 纯异常场探测平面成果

Fig.11 Results of pure anomaly field detection plane

根据前述异常方位计算方法,可得6个异常方位位于钻孔的径向的不同方位,将探测成果进行立体成像,成果如图12所示。图12中可以清晰展示裂缝空间分布位置,便于对水力压裂效果进行评价。

图12 异常空间分布展示

Fig.12 Display of abnormal spatial distribution

4 结 论

1)采用三分量钻孔瞬变电磁技术分别在水力压裂前和压裂后进行孔旁探测,压裂后视电阻率值较压裂前有明显较低,可以看出压裂导致视电阻率发生变化,但无法直观显示裂缝的方位。

2)纯异常探测成果图中,异常区域与压裂段布设位置吻合,且异常条带性明显,因此可以认为纯异常成果中的异常区域即为水力压裂诱导所致裂缝。

3)矿井钻孔中的探测实例通过对坚硬顶板水力压裂钻孔压裂前后的对比探测,成果直观显示出了压裂的影响范围和裂缝的空间发育情况。基于钻机推送的三分量钻孔瞬变电磁技术可以有效对水力压裂诱导所致裂缝进行探测,成果可用于分析裂缝位置与发育情况,对坚硬顶板灾害治理具有重要意义。

[1] 冯彦军,康红普.定向水力压裂控制煤矿坚硬难垮顶板试验[J].岩石力学与工程学报,2012,31(6):1148-1155.

FENG Yanjun,KANG Hongpu. Test on hard and stable roof control by means of directional hydraulic fracturing in coal mine[J]. Chinese Journal of Rock Mechanics and Engineering,2012,31(6):1148-1155.

[2] 于 斌,段宏飞.特厚煤层高强度综放开采水力压裂顶板控制技术研究[J]. 岩石力学与工程学报,2014,33(4):778-785.

YU Bin,DUAN Hongfei. Research on roof control technology of hydraulic fracturing in high strength fully mechanized caving mining of extra-thick coal seam[J]. Chinese Journal of Rock Mechanics and Engineering,2014,33(4):778-785.

[3] 康红普,冯彦军.定向水力压裂工作面煤体应力监测及其演化规律[J].煤炭学报,2012,37(12):1953-1959.

KANG Hongpu,FENG Yanjun. Monitoring of stress change in coal seam caused by directional hydraulic fracturing in working face with strong roof and its evolution[J]. Journal of China Coal Society,2012,37(12):1953-1959.

[4] 陈冬冬,孙四清,张 俭,等. 井下定向长钻孔水力压裂煤层增透技术体系与工程实践[J]. 煤炭科学技术, 2020, 48(10): 84-89.

CHEN Dongdong, SUN Siqing, ZHANG Jian,et al. Technical system and engineering practice of coal seam permeability improvement through underground directional long borehole hydraulic fracturing[J]. Coal Science and Technology, 2020, 48(10): 84-89.

[5] 康红普,张 镇,黄志增.我国煤矿顶板灾害的特点及防控技术[J].煤矿安全,2020,51(10):24-33,38.

KANG Hongpu,ZHANG Zhen,HUANG Zhizeng. Characteristics of roof disasters and controlling techniques of coal mine in China[J]. Safety in Coal Mines,2020,51(10):24-33,38.

[6] 康红普,徐 刚,王彪谋,等.我国煤炭开采与岩层控制技术发展40a及展望[J].采矿与岩层控制工程学报,2019,1(2):7-39.

KANG Hongpu,XU Gang,WANG Biaomou,et al.40 a and prospect of coal mining and strata control technology development in China[J]. Journal of Mining and Strata Control Engineering,2019,1(2):7-39.

[7] 袁永榜.水力压裂增透效果综合物探检验技术研究[J].矿业安全与环保,2019,46(2):20-24.

YUAN Yongbang. Research on comprehensive geophysical exploration technique experimental for permeability enhanced effect of hydraulic fracturing[J]. Mining Safety & Environmental Protection,2019,46(2):20-24.

[8] 孟召平,王宇恒,张 昆,等. 沁水盆地南部煤层水力压裂裂缝及地应力方向分析[J]. 煤炭科学技术, 2019, 47(10):216-222.

MENG Zhaoping,WANG Yuhen,ZHANG Kun,et al. Analysis of hydraulic fracturing cracks for coal reservoirs and in-situ stress direction in Southern Qinshui Basin[J]. Coal Science and Technology, 2019, 47(10): 216-222.

[9] 牟全斌,闫志铭,张 俭. 煤矿井下定向长钻孔水力压裂瓦斯高效抽采技术[J]. 煤炭科学技术, 2020, 48(7):296-303.

MOU Quanbin,YAN Zhiming,ZHANG Jian. High efficiency gas drainage technology of hydraulic fracturing with directional long drilling in underground coal mine[J]. Coal Science and Technology, 2020, 48(7): 296-303.

[10] 赵 丹. 水力压裂增透预抽瓦斯技术在马堡煤矿的应用研究[D].阜新:辽宁工程技术大学,2019.

ZHAO Dan. Application research of gas pre-drainage technology by hydraulic fracturing permeability improvement in mapu coal mine[D]. Fuxin:Lianning Technical University,2019.

[11] 朱亚东洋. 适于井地联合监测的井下微地震信号采集关键技术研究[D].长春:吉林大学,2018.

ZHU Yadongyang. Research on the key technology of underground microseismic signal acquisition suitable for well-ground joint monitoring[D]. Changchun:Jilin University,2018.

[12] 康向涛. 煤层水力压裂裂缝扩展规律及瓦斯抽采钻孔优化研究[D].重庆:重庆大学,2014.

KANG Xiangtao. Research on the law of coal seam hydraulic fracturing crack propagation and optimization of gas drainage drilling[D]. Chongqing:Chongqing University,2014.

[13] 蔡光明. 高速铁路桥梁底面裂缝的视频检测系统研究[D].北京:北京交通大学,2011.

CAI Guangming. Study on the video detection system of crack on the bottom of high-speed rail bridge[D]. Beijing:Beijing Jiaotong University,2011.

[14] 高 彬. 矿井多通道瞬变电磁响应特征研究[D].徐州:中国矿业大学,2019.

GAO Bin. Study on the characteristics of mine multichannel transient electromagnetic response[D]. Xuzhou:China University of Mining and Technology,2019.

[15] 李世宁. 矿井巷孔瞬变电磁法应用研究[D]. 徐州:中国矿业大学,2016.

LI Shining. Study on the mine tunnel-drilling transient electromagnetic method and its application[D]. Xuzhou:China University of Mining and Technology,2016.

[16] 范 涛.孔巷瞬变电磁动源定接收方法探测采空区试验[J].煤炭学报,2017,42(12):3229-3238.

FAN Tao. Experimental study on the exploration of coal mine goaf by dynamic source and fixed reception Roadway-Borehole TEM detection method[J]. Journal of China Coal Society,2017,42(12):3229-3238.

[17] 赵 睿,范 涛,李宇腾,等.钻孔瞬变电磁探测在水力压裂效果检测中的应用[J].煤田地质与勘探,2020,48(4):41-45.

ZHAO Rui,FAN Tao,LI Yuteng,et al. Application of borehole transient electromagnetic detection in the test of hydraulic fracturing effect[J]. Coal Geology & Exploration,2020,48(4):41-45.

[18] 范 涛,程建远,王保利,等.应用瞬变电磁虚拟波场成像方法检测井下煤层气水力压裂效果的试验研究[J].煤炭学报,2016,41(7):1762-1768.

FAN Tao,CHENG Jianyuan,WANG Baoli,et al. Experimental study on imaging method of TEM pseudo wave-field to detect the effect of underground coal-bed gas hydraulic fracturing[J]. Journal of China Coal Society,2016,41(7):1762-1768.

[19] 李 貅.瞬变电磁测深的理论与应用[M]. 西安:陕西科学技术出版社,2002.

LI Xiu. Theory and application of transient electromagnetic sounding[M]. Xi′an:Shaanxi Science and Technology Press,2002.

[20] 刘 剑.导电薄板的三分量瞬变电磁响应规律研究[D].长沙:中南大学,2009.

LIU Jian. Three-component TEM response on thin plate conductor[D].Changsha:Central South University,2009.

[21] JAN K. Rainey,JEFFREY S DeVries,BRIAN D Sykes. Estimation and measurement of flat or solenoidal coil inductance for radiofrequency NMR coil design[J].Journal of Magnetic Resonance,2007,187(1):27-37.

[22] 范 涛,赵 兆,吴 海,等.矿井瞬变电磁多匝回线电感影响消除及曲线偏移研究[J].煤炭学报,2014,39(5):932-940.

FAN Tao,ZHAO Zhao,WU Hai,et al. Research on inductance effect removing and curve offset for mine TEM with multi small loops[J]. Journal of China Coal Society,2014,39(5):932-940.

[23] 杨海燕,岳建华,胡文武,等.多匝回线的自感对瞬变电磁早期信号的影响特征[J].物探化探计算技术,2007(2):96-98,85.

YANG Haiyan,YUE Jianhua,HU Wenwu,et al. The characteristics of the early signal in TEM affected by self-induction of multiturn coil[J]. Computing Techniques for Geophysical and Geochemical Exploration,2007(2):96-98,85.

[24] 李学潜,韩德品,王 程,等. 巷-孔瞬变电磁法在探测含导水构造中的应用[J]. 中国煤炭地质,2019,31(2):77-82.

LI Xueqian,HAN Depin,WANG Cheng,et al. Application of roadway - borehole tem in water - bearing and water conducting structure prospecting[J]. Coal Geology of China,2019,31(2):77-82.

[25] 李博凡.井下孔中瞬变电磁探测异常响应特征模拟研究[D].西安:西安科技大学,2016.

LI Bofan. The abnormal response characteristics simulation research of the underground bore-hole transient electromagnetic method[D]. Xi′an:Xi′an University of Science and Technology,2016.

[26] FAN Tao,LI Hongtai,LIU Lei,et al. Stereo imaging method of borehole transient electromagnetic apparent resistivity based on clustering algorithm[J]. Journal of Earth Sciences and Environment2021,43(2):343-355.