Prediction method of surface subsidence due to underground coal gasification under thermal coupling

-

摘要:

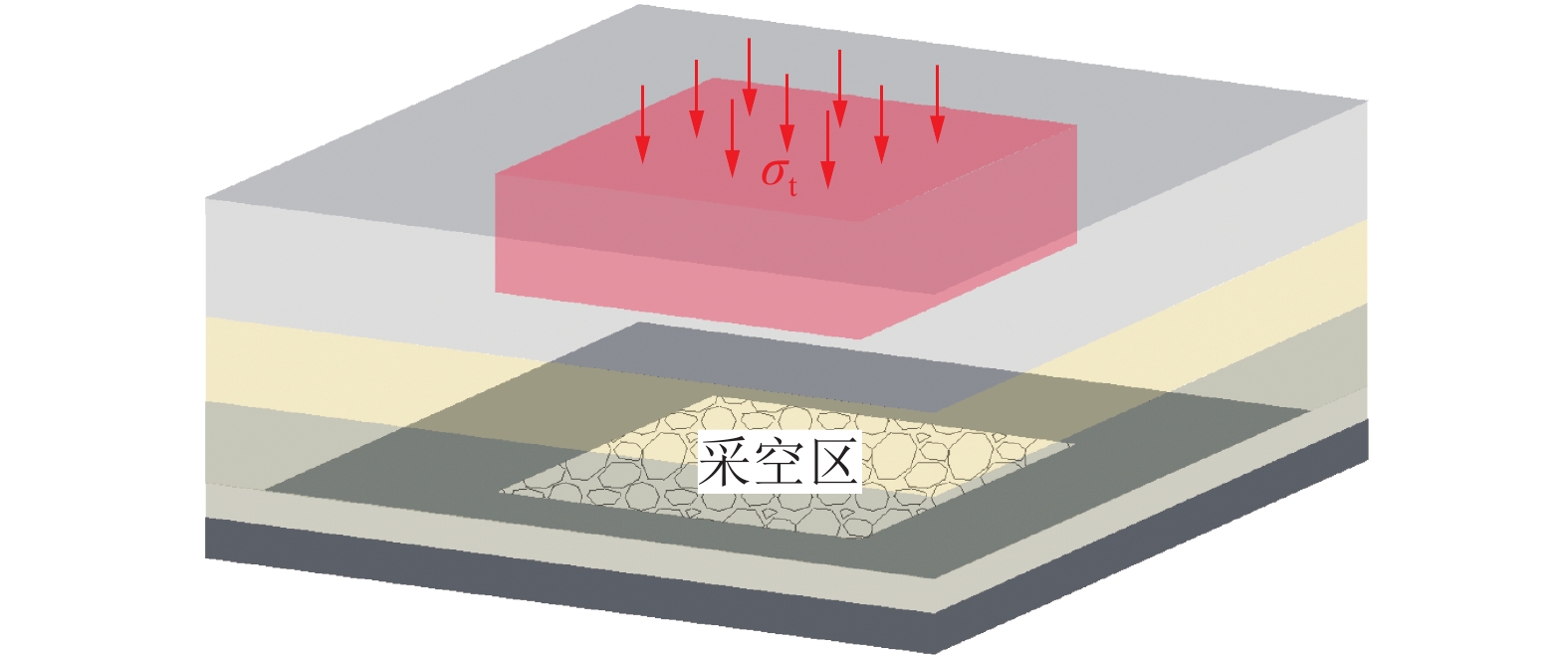

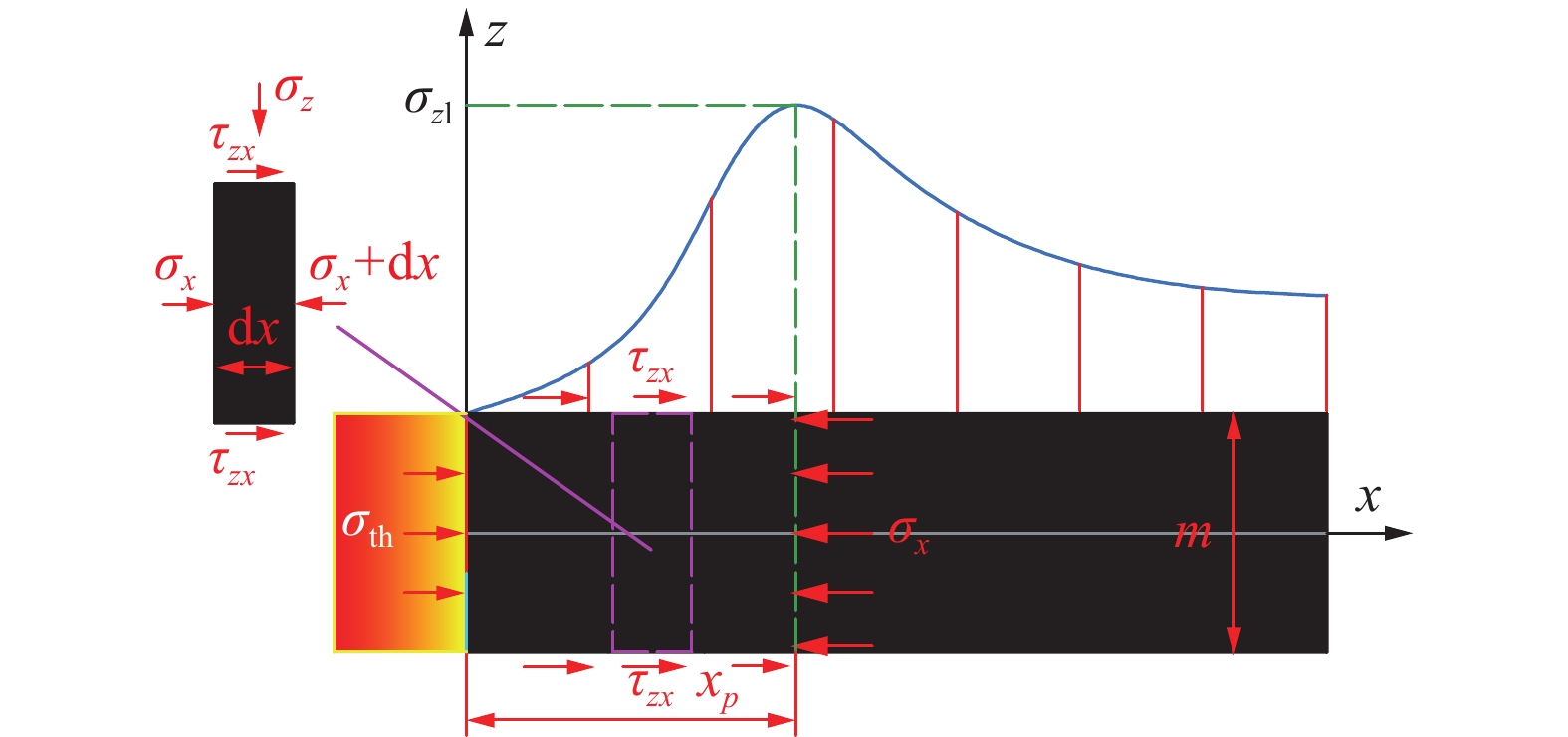

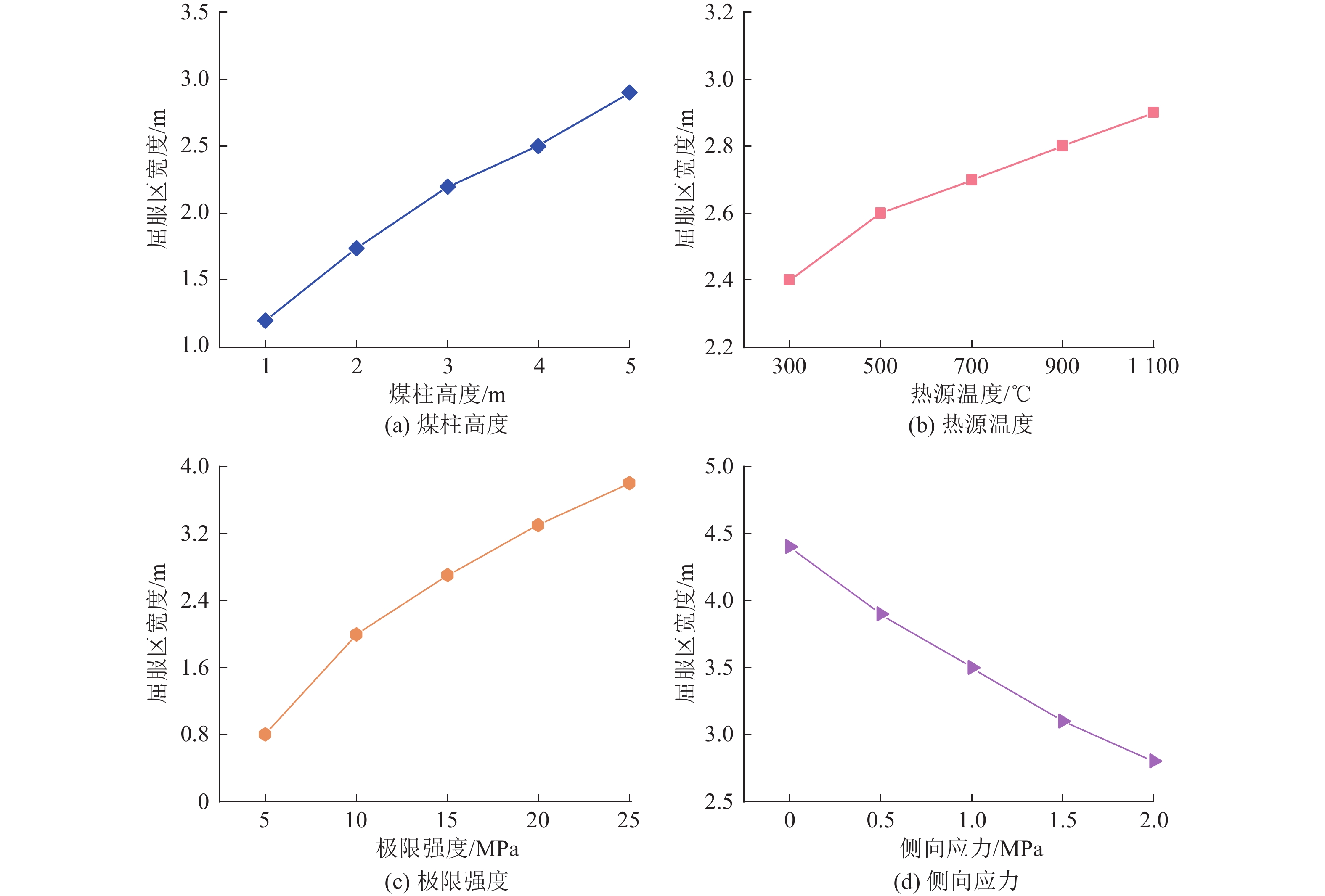

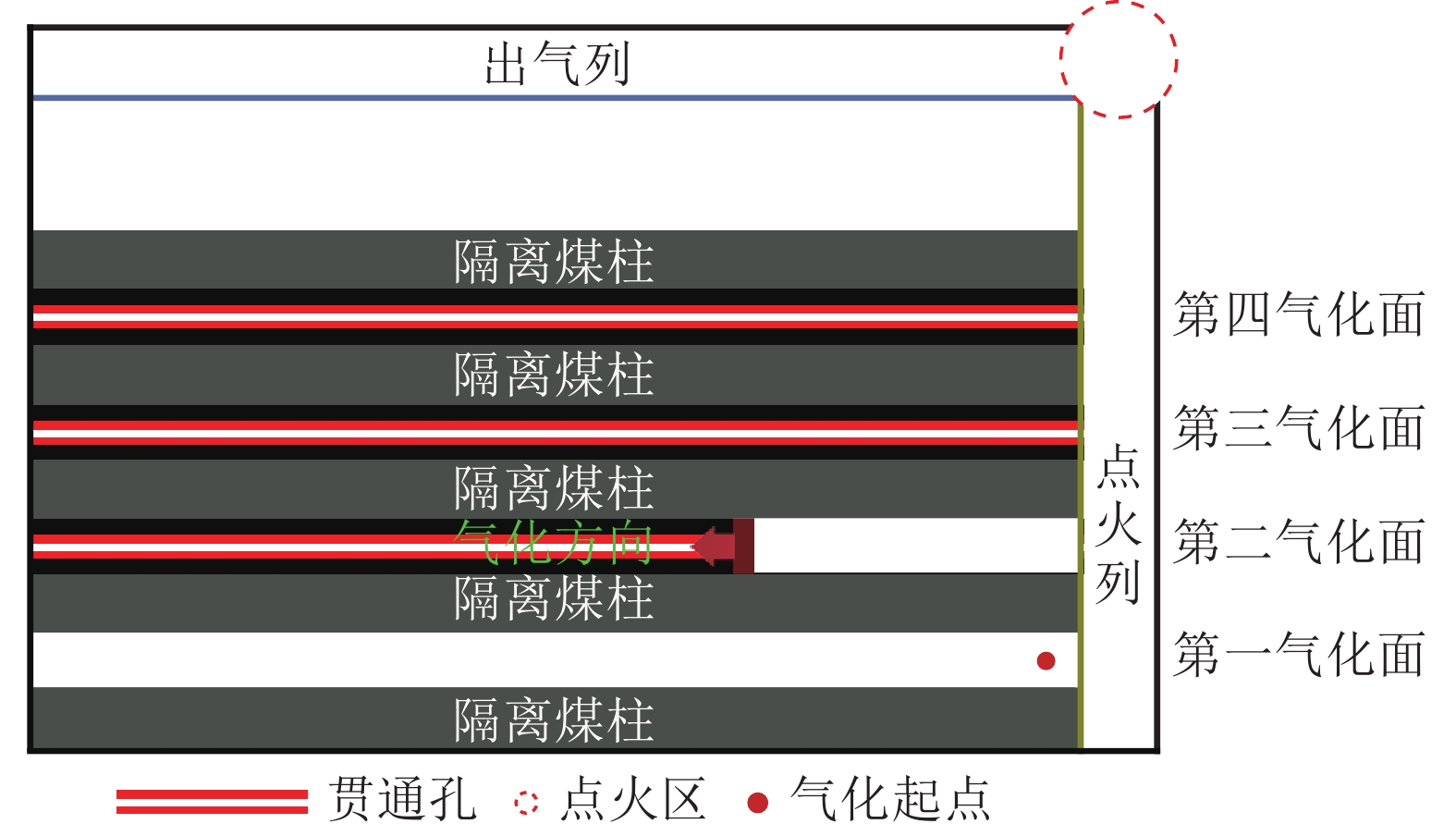

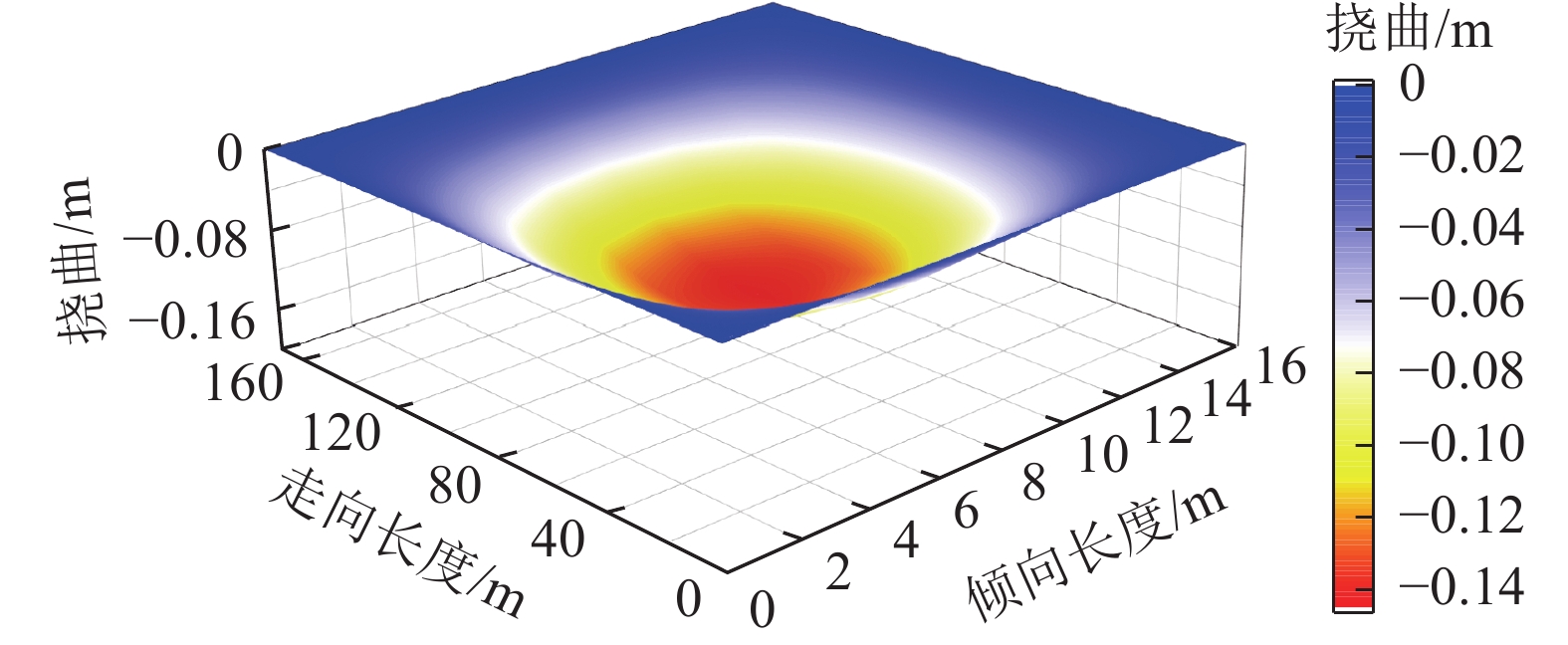

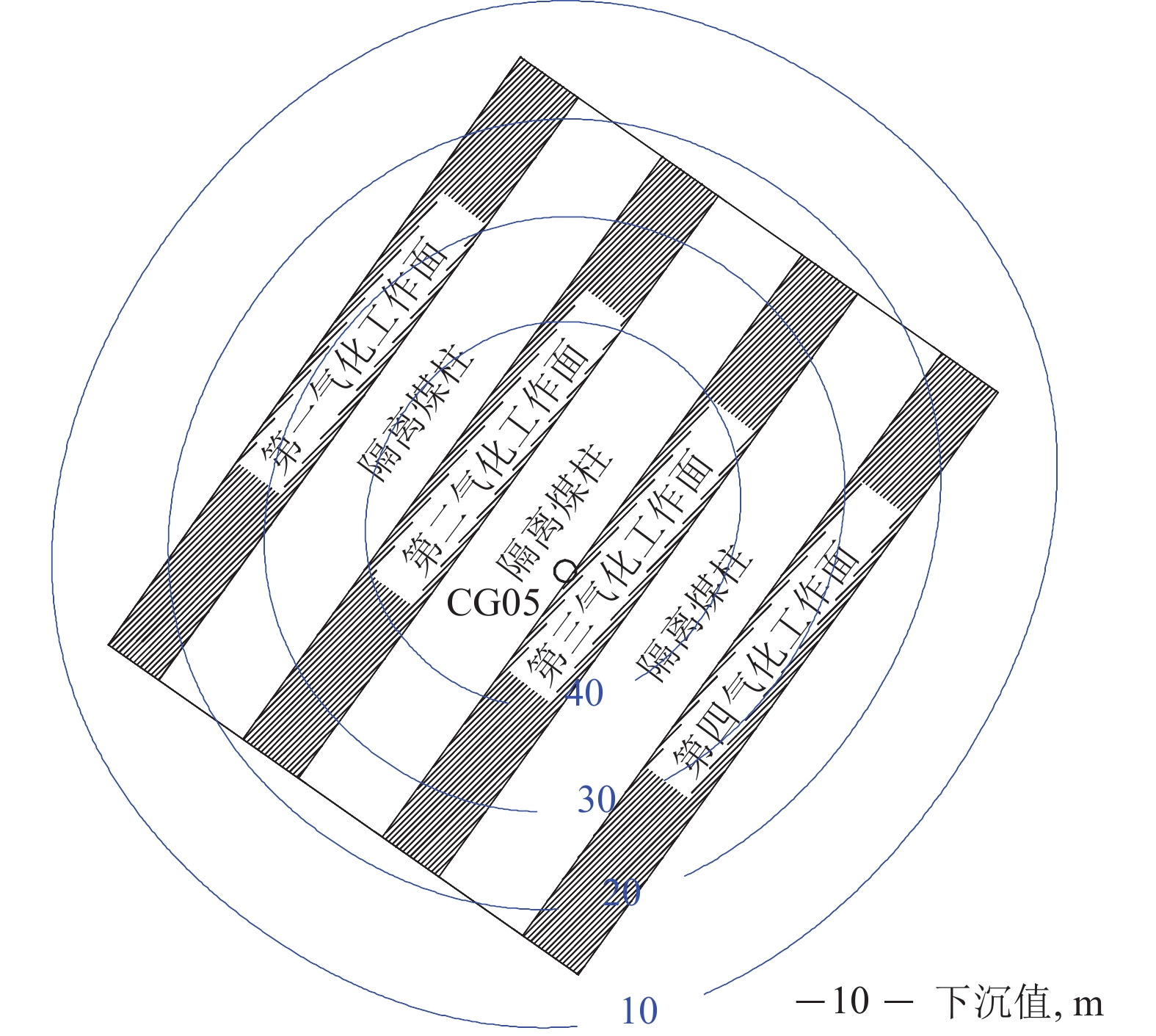

煤炭地下气化是煤炭低碳绿色开采技术体系的重要组成,煤炭行业“双碳”目标的实施使得煤炭地下气化迎来良好的发展机遇。然而煤炭地下气化也会引起岩层移动及地表变形,导致利用地下气化回收井工难以开采的“三下”压煤时,严重威胁地面建(构)筑物安全。如何兼顾煤炭地下气化特点准确的预测其地表沉陷,已成为制约煤炭地下气化产业化应用的重要瓶颈之一。基于此,结合“条采−面采”后退式地下气化工艺特点,探究了热力耦合作用下煤炭地下气化引起地表沉陷的诱因,得出地下气化产生地表沉陷的根源是岩层挠曲与焦化隔离煤柱压缩变形。在此基础上,建立了热力耦合作用下煤炭地下气化顶板挠曲变形计算方法以及基于D-P准则的气化煤柱屈服模型与压缩计算方法,进而根据等效下沉空间原理构建了热力耦合作用下煤炭地下气化地表沉陷精准预测模型,并通过乌兰察布煤炭地下气化地表沉陷的实测数据验证了新方法的有效性和准确性。

Abstract:Underground coal gasification (UCG) is an essential part of the low-carbon green coal mining technology system. The implementation of the “double carbon” goal of the coal industry has brought excellent development opportunities for UCG. However, UCG will also cause rock movement and surface deformation, resulting in serious threat to safety of ground buildings (structures) when use UCG to recover the “three under” coal that is difficult to mine by underground mining methods. How to accurately predict the subsidence considering characteristics of UCG has become one of the critical bottlenecks limiting the industrial application of UCG. Based on this, combined with the characteristics of ‘strip mining-surface mining’ backward UCG process, this paper explores the causes of surface subsidence caused by UCG under the thermal coupling, and concludes that the root of surface subsidence caused by UCG is the deflection of rock strata and the compression deformation of coking barrier coal pillar. Further, the calculation method of deflection deformation of UCG roof under thermal-mechanical coupling is established, and the yield model and compression calculation method of gasification coal pillar based on D-P criterion are proposed. Then, according to the principle of equivalent subsidence space, an accurate prediction model of surface subsidence of UCG under thermal coupling is constructed, and the effectiveness and accuracy of the new method are verified by the measured data of UCG in Ulanqab. The research results have important practical significance for promoting the recovery of difficult-to-mine “three under” coal resources and the industrialization for UCG.

-

-

表 1 岩层分布及其力学参数

Table 1 Rock strata distribution and its mechanical parameters

岩性 厚度/m 泊松比 平均重力密度/(kg·m3) 抗拉强度/MPa 粉砂岩 15 0.26 2 205 1.12 泥岩 2 0.28 2 147 0.83 粉砂岩 1 0.26 2 205 1.12 泥岩 9 0.28 2 147 0.83 粉砂岩 2 0.26 2 205 1.12 泥岩 2 0.28 2 147 0.83 细粒砂岩 1 0.32 2 311 0.83 泥岩 4 0.28 2 147 0.83 细粒砂岩 1 0.32 2 311 0.83 泥岩 5 0.28 2 147 0.83 煤层 3 0.23 1 400 0.50 泥岩 3 0.28 2 147 0.83 砂质泥岩 1 0.25 2 316 0.71 砂质泥岩 3 0.25 2 316 0.71 泥岩 4 0.28 2 147 0.83 煤层 5 0.23 1 400 0.50 表 2 岩层热物理参数

Table 2 Thermal physical parameters of rock strata

岩性 导热系数λ/(W•m−1•K−1) 比热容c/(J•kg−1•K−1) 时间t/s 密度/(kg•m−3) 热扩散系数a/(m2•s−1) 泥岩 1.202 890 7776000 2316 5.83×10−7 砂岩 1.2 1010 7776000 2205 5.39×10−7 表 3 岩层弹性模量随温度的变化规律

Table 3 Variation law of elastic modulus of rock strata with temperature

岩性 拟合函数 公式编号 泥岩 $E\left[ {T(x)} \right] = 4 \times {10^{ - 8} }{\left[ {T(x)} \right]^3} - 5 \times {10^{ - 5} }{\left[ {T(x)} \right]^2} + 2.14 \times {10^{ - 2} }\left[ {T(x)} \right] + 1.085\;6$ (40) 砂质泥岩 $E\left[ {T(x)} \right] = 2 \times {10^{ - 8} }{\left[ {T(x)} \right]^3} - 3 \times {10^{ - 5} }{\left[ {T(x)} \right]^2} + 1.41 \times {10^{ - 2} }\left[ {T(x)} \right] + 0.918\;6$ (41) -

[1] 刘 峰,郭林峰,赵路正. 双碳背景下煤炭安全区间与绿色低碳技术路径[J]. 煤炭学报,2022,47(1):1−15. LIU Feng,GUO Linfeng,ZHAO Luzheng. Research on coal safety range and green low-carbon technology path under the dual-carbon background[J]. Journal of China Coal Society,2022,47(1):1−15.

[2] 易同生,秦 勇,周永锋,等. 煤炭地下气化项目技术经济评价研究进展述评[J]. 煤田地质与勘探,2023,51(7):1−16. YI Tongsheng,QIN Yong,ZHOU Yongfeng,et al. Review of research progress on techno-economic evaluation of UCG project[J]. Coal Geology & Exploration,2023,51(7):1−16.

[3] BELLO Mufutau Opeyemi,SOLARIN Sakiru Adebola. Searching for sustainable electricity generation: The possibility of substituting coal and natural gas with clean energy[J]. Energy & Environment,2022,33(1):21.

[4] CHEN Liang, TANG Chuan. Modelling analysis on construction of low-carbon cities based on energy consumption optimisation[J]. Journal of Environmental Protection and Ecology, 2017, 18(2): 10.

[5] YANG Zhangbin,WANG Xiaojing. Research on low-carbon capability evaluation model of city regional integrated energy system under energy market environment[J]. Processes,2022,10(10):19.

[6] XU Baoping. , ZHOU Shaoxiang, HAO Lin. Approach and practices of district energy planning to achieve low carbon outcomes in China[J]. Energy Policy,2015,83:109−122. doi: 10.1016/j.enpol.2015.04.008

[7] 秦 勇,易同生,汪凌霞,等. 面向项目风险控制的煤炭地下气化地质条件分析[J]. 煤炭学报,2023,48(1):290−306. QIN Yong,YI Tongsheng,WANG Lingxia,et al. Analysis of geological conditions for risk control of UCG project[J]. Journal of China Coal Society,2023,48(1):290−306.

[8] IMRAN Muhammad,KUMAR Dileep,KUMAR Naresh,et al. Environmental concerns of underground coal gasification[J]. Renewable and Sustainable Energy Reviews,2014,31:600−610. doi: 10.1016/j.rser.2013.12.024

[9] 王家臣,杨胜利,刘淑琴,等. 急倾斜煤层开采技术现状与流态化开采构想[J]. 煤炭科学技术,2022,50(1):48−59. WANG Jiachen,YANG Shengli,LIU Shuqin,et al. Technology status and fluidized mining conception for steeply inclined coal seams[J]. Coal Science and Technology,2022,50(1):48−59.

[10] 王 冀,孔令学,白 进,等. 煤气化灰渣中残炭对灰渣流动性影响的研究进展[J]. 洁净煤技术,2021,27(1):181−192. WANG Ji,KONG Lingxue,BAI Jin,et al. Research progress on the effect of residual carbon in coal gasification slag on ash and slag flow property[J]. Clean Coal Technology,2021,27(1):181−192.

[11] 梁 杰,余 力. “长通道、大断面”煤炭地下气化新工艺[J]. 中国煤炭,2002,28(12):8−10,13. LIANG Jie,YU Li. Underground coal gasification by the new technique of "long passage with large cross section"[J]. China Coal,2002,28(12):8−10,13.

[12] FALSHTYNSKYI Volodymyr S,DYCHKOVSKYI Roman O,LOZYNSKYI Vasyl G,et al. Determination of the technological parameters of borehole underground coal gasification for thin coal seams[J]. Journal of Sustainable Mining,2013,12(3):8−16. doi: 10.7424/jsm130302

[13] BRITTEN Jerald A, THORSNESS Charles B. A model for cavity growth and resource recovery during underground coal gasification[J]. Situ, 1989.

[14] BHUTTO Abdul Waheed,BAZMI Aqeel Ahmed,ZAHEDI Gholamreza. Underground coal gasification: From fundamentals to applications[J]. Progress in Energy and Combustion Science,2013,39(1):189−214. doi: 10.1016/j.pecs.2012.09.004

[15] PERKINS Greg. Underground coal gasification – Part I: Field demonstrations and process performance[J]. Progress in Energy and Combustion Science,2018,67:158−187. doi: 10.1016/j.pecs.2018.02.004

[16] 辛 林,王作棠,黄温钢,等. 条带气化开采覆岩移动与地表沉陷实测分析[J]. 采矿与安全工程学报,2014,31(3):447−455. XIN Lin,WANG Zuotang,HUANG Wengang,et al. Measurement analysis of overlying strata movement and surface subsidence by UCG strip mining[J]. Journal of Mining and Safety Engineering,2014,31(3):447−455.

[17] 黄温钢,王作棠,夏元平,等. 煤炭地下气化热-力耦合作用下条带开采数值模拟研究[J]. 煤炭科学技术,2022,50(8):16−23. HUANG Wengang,WANG Zuotang,XIA Yuanping,et al. Numerical simulation of strip mining under thermal-mechanical coupling of underground coal gasification[J]. Coal Science and Technology,2022,50(8):16−23.

[18] DERBIN Y G, WALKER J, WANATOWSKI D. Modelling surface subsidence during underground coal gasification[C]. 2nd International Conference on Geo-Mechanics, Geo-Energy and Geo-Resources (IC3G): 20193-9.

[19] 郭广礼,李怀展,查剑锋,等. 无井式煤炭地下气化岩层及地表移动与控制[J]. 煤炭学报,2019,44(8):2539−2546. GUO Guangli,LI Huaizhan,ZHA Jianfeng,et al. Movement and control of strata and surface during UCG without shaft[J]. Journal of China Coal Society,2019,44(8):2539−2546.

[20] EKRIELIGODA T C,MARSHALL A M. A coupled thermal-mechanical numerical model of underground coal gasification (UCG) including spontaneous coal combustion and its effects[J]. International Journal of Coal Geology,2018,199:8.

[21] LI Huaizhan,GUO Guangli,ZHA Jianfeng,et al. Research on the surface movement rules and prediction method of underground coal gasification[J]. Bulletin of Engineering Geology and Environment,2016,75(3):1133−1142. doi: 10.1007/s10064-015-0809-7

[22] 李怀展. 无井式煤炭地下气化岩层移动机理与控制研究[D]. 徐州: 中国矿业大学, 2017. LI Huaizhan. Study on the strata movement mechanisms and control in UCG without shaft[D]. Xuzhou: China University of Mining and Technology, 2017.

[23] 唐芙蓉,王连国,贺 岩,等. 煤炭地下气化场覆岩运动规律的数值模拟研究[J]. 煤炭工程,2013,45(5):79−82. TANG Furong,WANG Lianguo,HE Yan,et al. Study on numerical simulation of overburden strata movement law above underground coal gasification filed[J]. Coal Engineering,2013,45(5):79−82.

[24] 王 喆,梁 杰,侯腾飞,等. 高温对煤炭地下气化围岩损伤的影响[J]. 煤炭学报,2022,47(6):2270−2278. WANG Zhe,LIANG Jie,HOU Tengfei,et al. Influence of high temperature on surrounding rock damage of underground coal gasification[J]. Journal of China Coal Society,2022,47(6):2270−2278.

[25] 刘鸿文. 板壳理论[M]. 杭州: 浙江大学出版社, 1987. [26] 何福保, 沈亚鹏. 板壳理论[M]. 西安: 西安交通大学出版社, 1993. [27] 张广超, 曲 治, 孟祥军, 等. 远场高位厚硬岩层破断运动机理及响应规律研究[J/OL]. 煤炭科学技术: 1−12[2023-10-23]. DOI: 10.13199/j.cnki.cst.2022-2027. ZHANG Guangchao, QU Zhi, MENG Xiangjun, et al. Study on the Mechanism and Response Law of Fracture Movement on the Super-High Position Hard-and-Hick Strata[J/OL]. Coal Science and Technology, 2023: 1−12[2023-10-23]. DOI: 10.13199/j.cnki.cst.2022-2027.

[28] 翟所业,张开智. 用弹性板理论分析采场覆岩中的关键层[J]. 岩石力学与工程学报,2004,23(11):1856−1860. ZHAI Suoye,ZHANG Kaizhi. Analysis on key layer of overlying strata with elastic slab theory[J]. Chinese Journal of Rock Mechanics and Engineering,2004,23(11):1856−1860.

[29] 杨雪强,凌平平,向胜华. 基于系列Drucker-Prager破坏准则评述土坡的稳定性[J]. 岩土力学,2009,30(4):865−870. YANG Xueqiang,LING Pingping,XIANG Sheng hua. Comments on slope stability based on a series of Drucker-Prager failure criteria[J]. Rock and Soil Mechanics,2009,30(4):865−870.

[30] 李 浩,白海波,武建军,等. D-P随机损伤本构模型及其在预防陷落柱突水中的应用[J]. 岩土力学,2018,39(12):4577−4587. LI Hao,BAI Haibo,WU Jianjun,et al. D-P stochastic damage constitutive model and its application in preventing water inrush of karst collapsed column[J]. Rock and Soil Mechanics,2018,39(12):4577−4587.

[31] WANG Rui,BAI Jianbiao,YAN Shuai,et al. An innovative approach to theoretical analysis of partitioned width & stability of strip pillar in strip mining[J]. International Journal of Rock Mechanics and Mining Sciences,2020,129:104301. doi: 10.1016/j.ijrmms.2020.104301

[32] 邢闯闯,王 俊,宁建国,等. 动载扰动下深井护巷煤柱失稳破坏机理[J]. 煤炭科学技术,2023,51(3):29−36. XING Chuangchuang,WANG Jun,NING Jianguo,et al. Instability failure mechanism of coal pillar in deep mine under dynamic disturbance[J]. Coal Science and Technology,2023,51(3):29−36.

[33] 郭广礼, 查剑锋. 矿山开采沉陷学[M]. 徐州: 中国矿业大学出版社, 2020. [34] 邓喀中, 谭志祥, 姜岩, 等. 变形监测及沉陷工程学[M]. 徐州: 中国矿业大学出版社, 2014. [35] 唐芙蓉. 煤炭地下气化燃空区覆岩裂隙演化及破断规律研究[D]. 徐州: 中国矿业大学, 2013. TANG Furong. Fracture evolution and breakage of overlying strata of combustion space area in underground coal gasification [D]. Xuzhou: China University of Mining and Technology, 2013.

[36] 刘潇鹏. 煤炭地下气化高温烧变围岩移动破坏机理研究[D]. 徐州: 中国矿业大学, 2019. LIU Xiaopeng. Study on high temperature burnt surrounding rock movement and failure mechanism in UCG [D]. Xuzhou: China University of Mining and Technology, 2019.

[37] HUANG Wengang,WANG Zuotang. Mechanical performance evolution and size determination of strip coal pillars with an account of thermo- mechanical coupling in underground coal gasification[J]. International Journal of Rock Mechanics and Mining Sciences,2021,142:13.

[38] 万志军. 非均质岩体热力耦合理论与煤炭地下气化通道稳定性[M]. 徐州: 中国矿业大学出版社, 2009.

下载:

下载: