Fracture evolution of coal under uniaxial compression based on X-ray microscopic imaging

-

摘要:

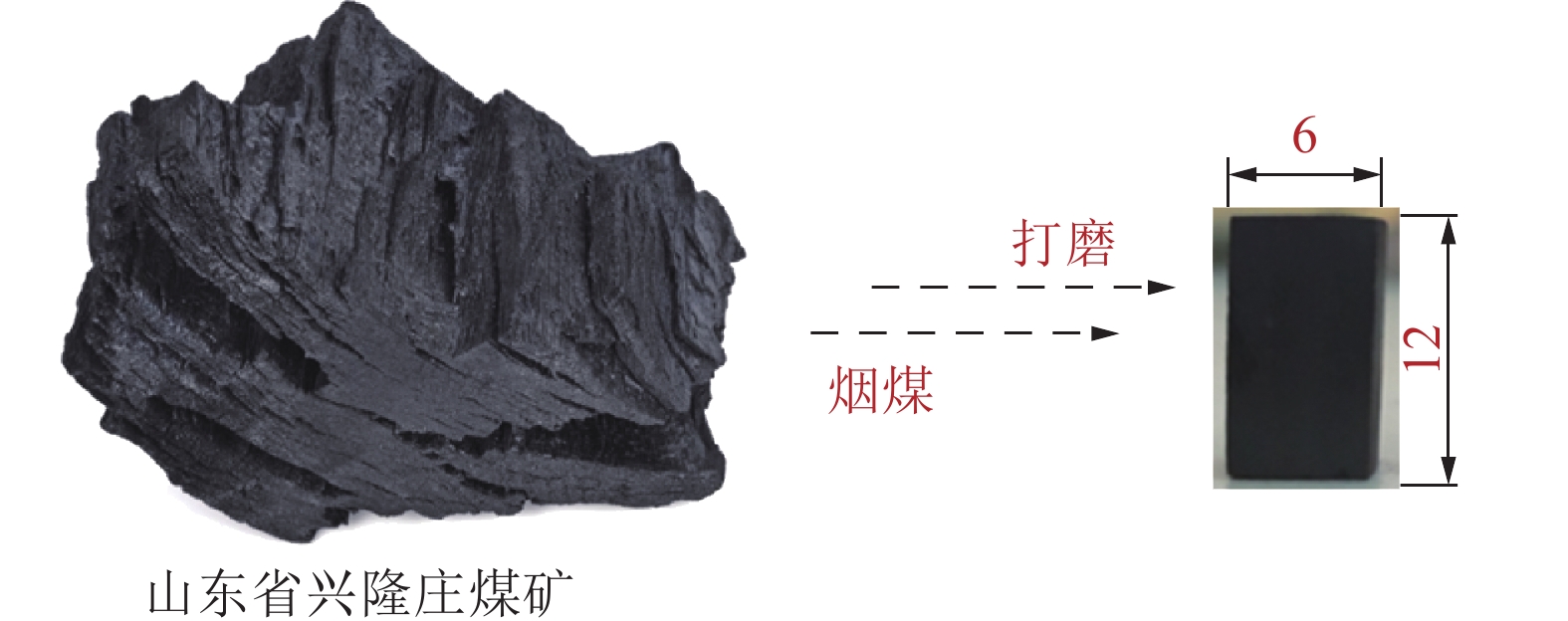

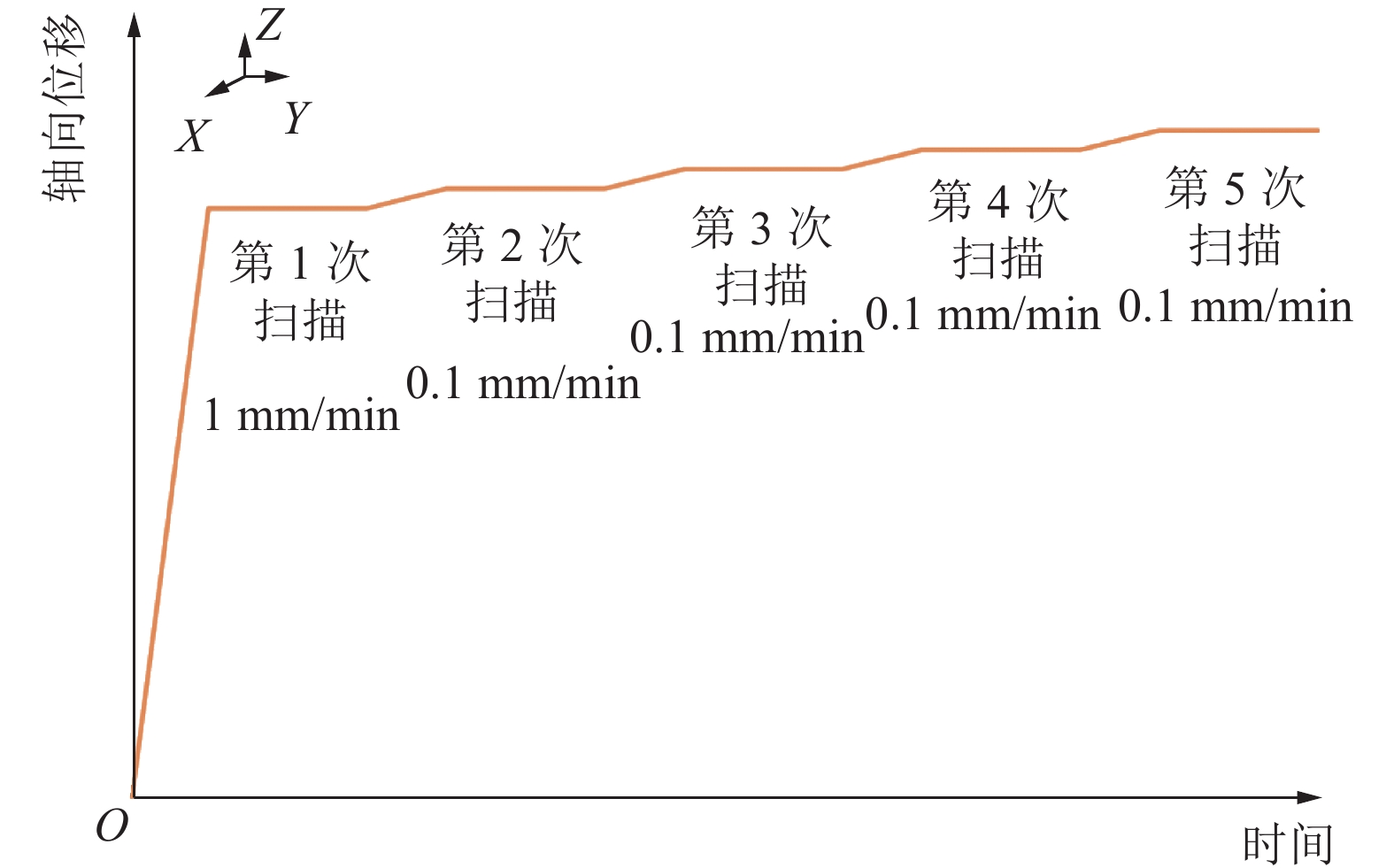

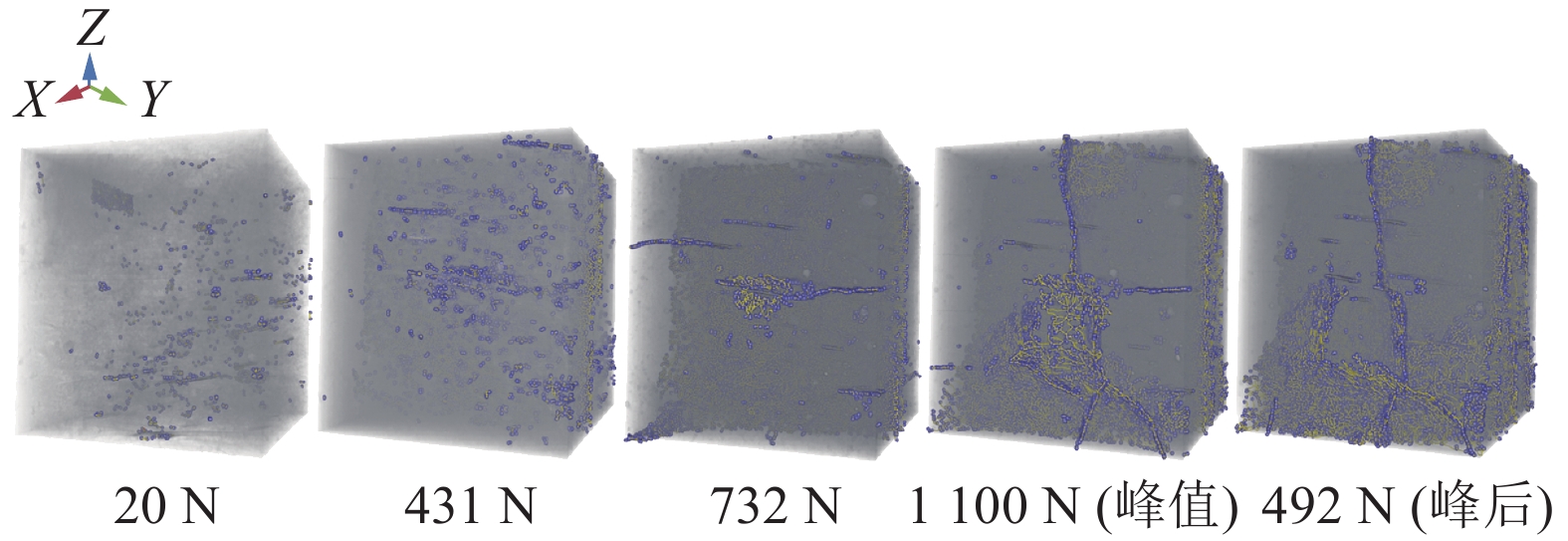

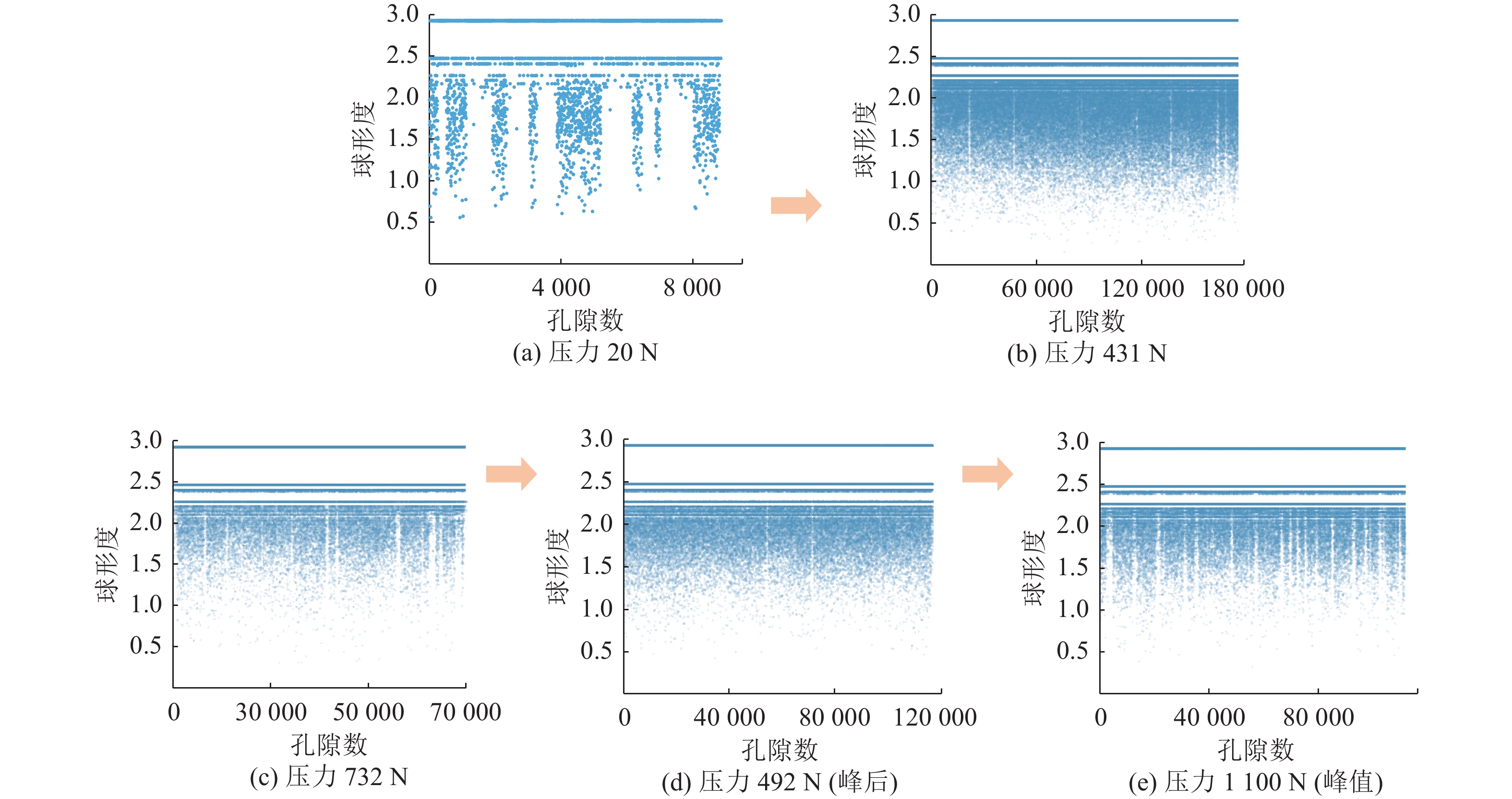

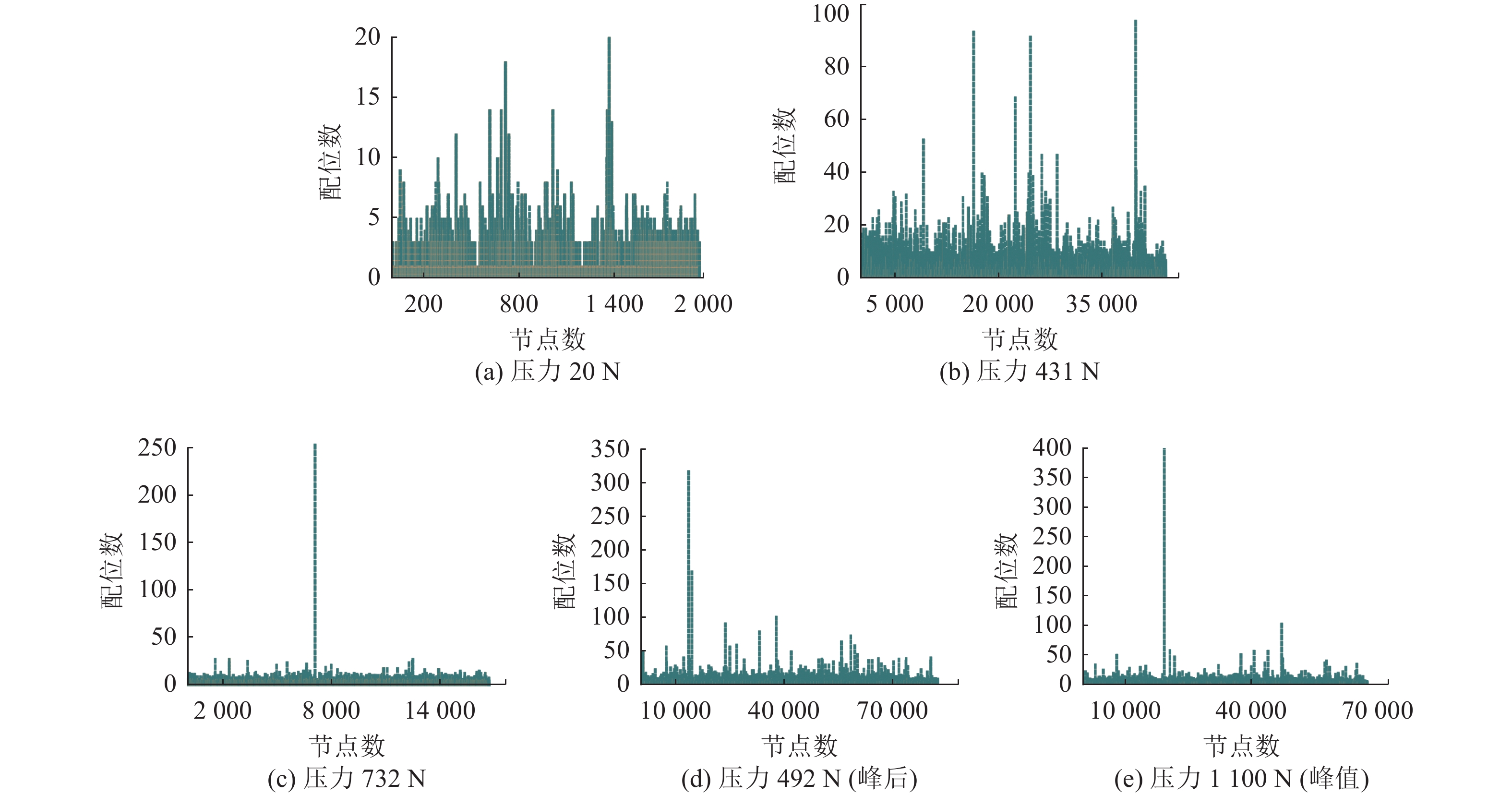

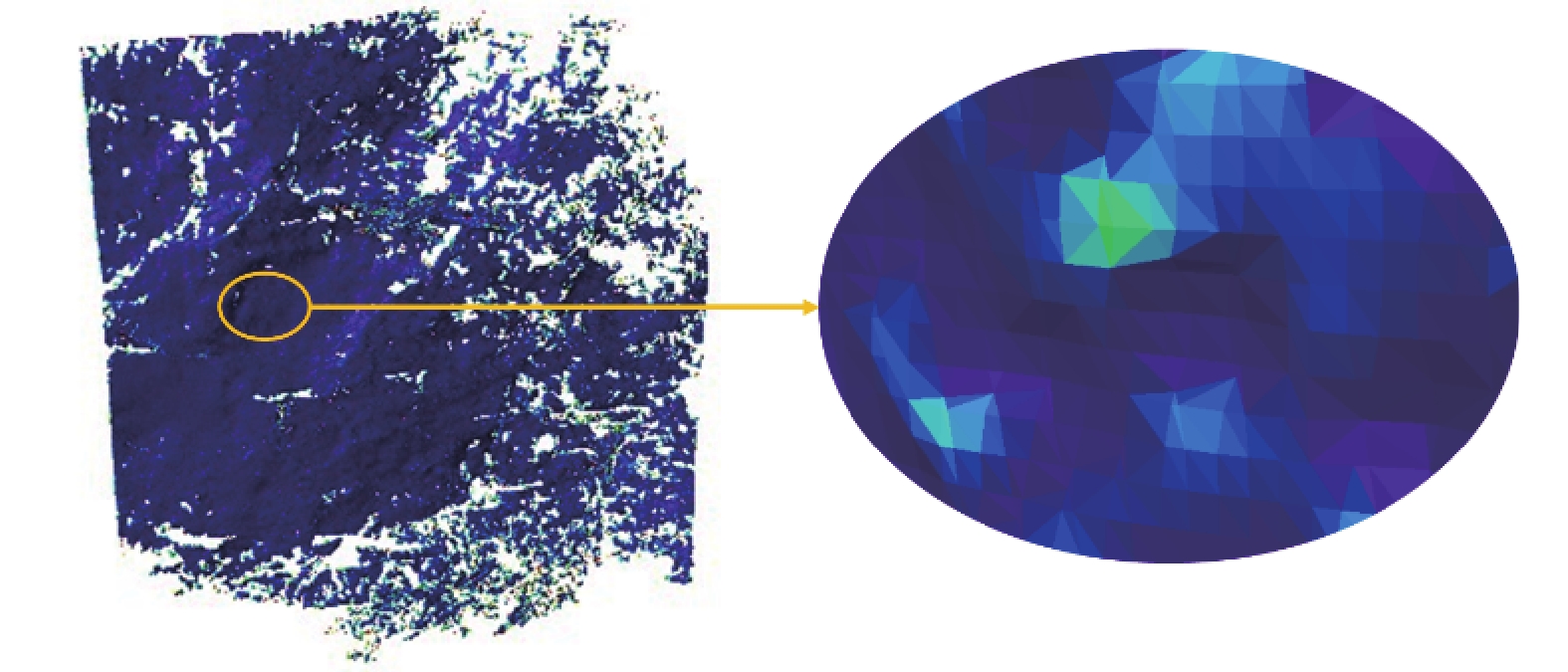

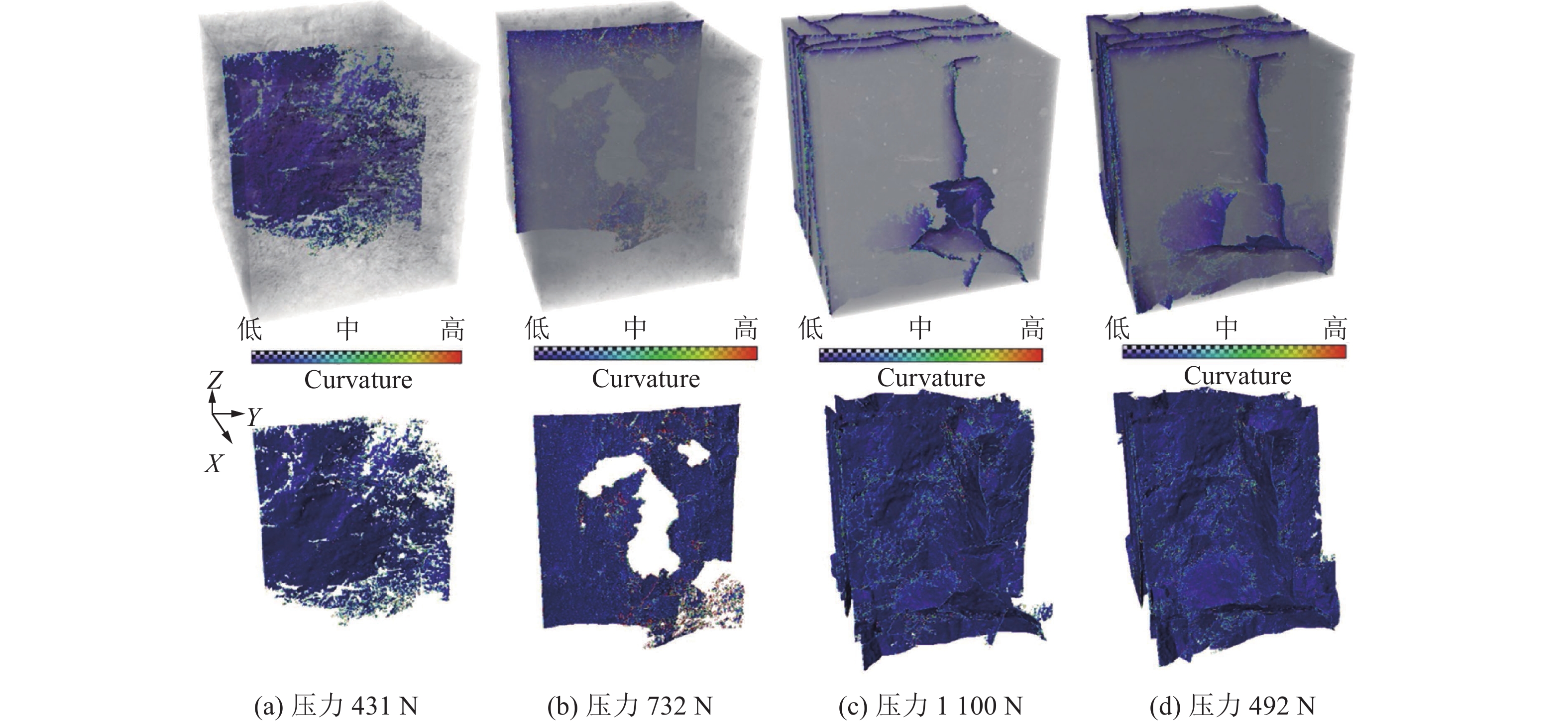

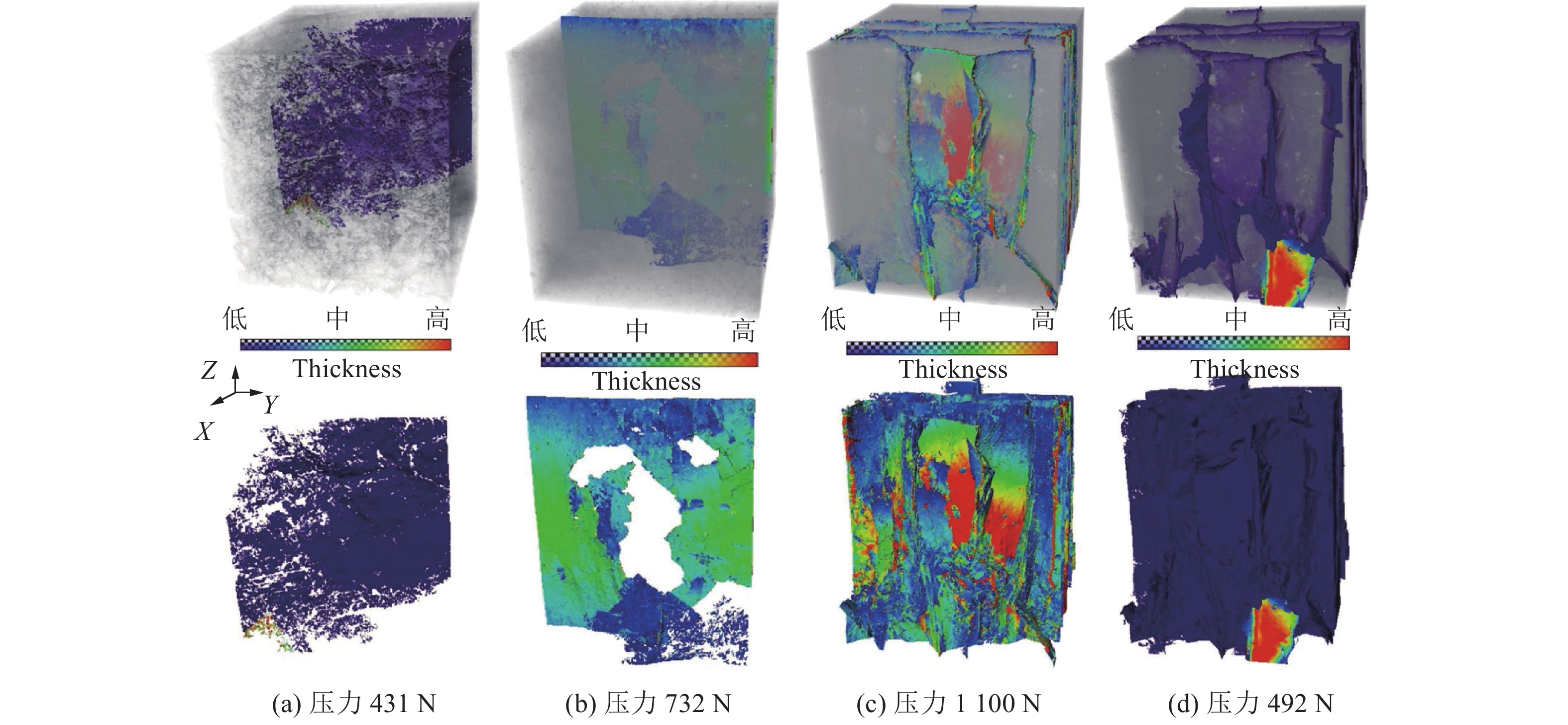

为研究煤岩细观结构特征随着轴向应力增加的演化规律,利用NanoVoxel-3502E X射线三维显微镜与Deben原位加载实验台进行煤岩单轴压缩试验,获取不同应变条件下的CT数据,并结合三维可视化软件AVIZO,研究煤样试件的孔隙裂隙分布特征,统计分析煤样试件孔隙裂隙细观参数-球形度、配位数、曲率和开度。揭示了煤样在单轴压缩情况下的细观结构空间分布特征及随时间的展布规律,细观结构随轴向应力的演化规律。研究表明:微小裂隙在20~732 N过程中大量出现,孔隙增多,在431~732 N过程中孔隙球形度集中分布范围变窄,部分孔裂隙逐渐融合进入裂隙网络,部分孔裂隙被压实压密,732 N时部分孔隙被压实压密,导致孔裂隙减少90000个,裂隙曲率逐渐增大、裂隙逐渐开度变大,配位数集中率更高,同时也说明煤样内部连通性更好,732 N是裂隙网络发育的巅峰。轴向力达到1100 N(峰值)时,形成复杂的裂隙网络。随着单轴压缩过程的推进,部分孔裂隙虽然在732 N被压实压密,但由于轴向力的增大以及残余荷载的作用,孔裂隙的增多是必然趋势,峰值和峰后仍然存在微小孔裂隙,但峰后裂隙较窄,球形度更多的是集中在1.5~2.0。贯通裂隙的曲率在裂隙网络的边缘普遍较高,即裂隙网络边缘为裂隙发育带。为研究煤样的时空演化规律提供了一种可行的技术手段,对于阐释煤岩细观结构时空演化过程具有实际意义。

Abstract:In order to study the evolution of the microstructure characteristics of coal with increasing axial stress, this paper used NanoVoxel-3502E X-ray three-dimensional microscope and Deben in-situ loading test rig to carry out uniaxial compression tests of coal to obtain CT data under different strain conditions, Combined with the three-dimensional visualization software AVIZO, extracted the pores and fractures of the coal sample, studyed the pore and fracture distribution characteristics of the coal sample, and statistically analyzed the microscopic parameters of the number of pores, sphericity, and coordination number, curvature, thickness and other meso-structure parameters. It revealed the spatial distribution characteristics of the mesostructure of the coal sample under uniaxial compression and its distribution law over time, and the evolution law of the mesostructure with the axial stress. Studies have shown that small fractures appear in large numbers from 20 N to 732 N, and the number of pores increases. During the process from 431 N to 732 N, the concentrated distribution range of pore sphericity became narrower. Some pores and fractures gradually merged into the fracture network, and some pores and fractures were compressed. Part of the pores were compacted at 732 N, resulted in a reduction of 90,000 pores. The curvature of the fractures gradually increased, the fractures gradually became thicker, and the coordination number concentration ratio was higher. It also showed that the coal sample was internally connected. 732 N was the pinnacle of fracture network development. When the axial force reached 1100 N (peak), a complex fracture network was formed. With the advancement of the uniaxial compression process, although some pores and fractures were compacted at 732 N, due to the increase in axial force and residual load, the increase of pores and fractures was an inevitable trend, and there were still small pores and fractures after the peak, but the post-peak fractures were thinner, and the sphericity was more concentrated in 1.5-2.0. The curvature of the interconnected fractures was generally higher at the edges of the fracture network, the edges of the fracture network were fracture development zones. This paper provided a feasible technical means for studying the temporal and spatial evolution of coal samples, and has practical significance for interpreting the temporal and spatial evolution of the meso-structure of coal.

-

Keywords:

- CT /

- uniaxial compression /

- in-situ tests /

- mesoscopic structure /

- coal /

- fracture evolution of coal

-

-

表 1 位移-轴向力关系与三维扫描参数

Table 1 Displacement-axial force telationship and 3D scanning parameters

加载速率/

(mm·min−1)轴向位移/

mm轴向力/

N扫描电流/

μA扫描电压/

kV1.0 0.146 20 100 130 0.1 0.246 431 0.346 732 0.446 1100 0.546 492 -

[1] 程远平,周红星. 煤与瓦斯突出预测敏感指标及其临界值研究进展[J]. 煤炭科学技术,2021,49(1):146−154. CHENG Yuanping,ZHOU Hongxing. Research progress of sensitive index and critical values for coal and gas outburst prediction[J]. Coal Science and Technology,2021,49(1):146−154.

[2] 李树刚,杨二豪,林海飞,等. 深部开采卸压瓦斯精准抽采体系构建及实践[J]. 煤炭科学技术,2021,49(5):1−10. LI Shugang,YANG Erhao,LIN Haifei,et al. Construction and practice of accurate gas drainage system for pressure relief gas in deep mining[J]. Coal Science and Technology,2021,49(5):1−10.

[3] 程卫民,周 刚,陈连军,等. 我国煤矿粉尘防治理论与技术20年研究进展与展望[J]. 煤炭科学技术,2020,48(2):1−20. CHENG Weimin,ZHOU Gang,CHEN Lianjun,et al. Research progress and prospect of dust control theory and technology in China’s coal mines in the past 20 years[J]. Coal Science and Technology,2020,48(2):1−20.

[4] HUANG Xinru,CHEN Hong,LONG Ruyin,et al. Development and validation of the quality of life scale for Chinese coal miners with pneumoconiosis (QOL-CMP): Measurement method and empirical study[J]. Journal of Cleaner Production,2019,232:1062−1075. doi: 10.1016/j.jclepro.2019.05.398

[5] LIU Rulin,CHENG Weimin,YU Yanbin,et al. An impacting factors analysis of miners' unsafe acts based on HFACS-CM and SEM[J]. Process Safety & Environmental Protection,2019

[6] 王登科,李文睿,魏建平,等. 基于分形表征的粗糙微纳米孔隙瓦斯气体传输方程[J]. 煤炭学报,2019,44(11):3432−3440. WANG Dengke,LI Wenrui,WEI Jianping,et al. Gas transport equation in rough micro-nano pore based on fractal characterization[J]. Journal of China Coal Society,2019,44(11):3432−3440.

[7] ZHANG Kaizhong,CHENG Yuanping,WANG Liang,et al. Pore morphology characterization and its effect on methane desorption in water-containing coal: An exploratory study on the mechanism of gas migration in water-injected coal seam[J]. Journal of Natural Gas Science and Engineering,2020,75:103152. doi: 10.1016/j.jngse.2020.103152

[8] CHENG Weimin,LIU Zhen,YANG He,et al. Non-linear seepage characteristics and influential factors of water injection in gassy seams[J]. Experimental Thermal and Fluid Science,2018,91:41−53. doi: 10.1016/j.expthermflusci.2017.10.002

[9] 葛修润,任建喜,蒲毅彬,等. 煤岩三轴细观损伤演化规律的CT动态试验[J]. 岩石力学与工程学报,1999(5):497−502. doi: 10.3321/j.issn:1000-6915.1999.05.001 GE Xiurun,REN Jianxi,PU Yibin,et al. CT dynamic test of triaxial meso-damage evolution of coal and rock[J]. Chinese Journal of Rock Mechanics and Engineering,1999(5):497−502. doi: 10.3321/j.issn:1000-6915.1999.05.001

[10] 陈辉辉,张小波,姚 池,等. 高温作用后岩石裂隙渗流试验及其模型分析[J]. 煤炭学报,2019,44(9):2760−2766. doi: 10.13225/j.cnki.jccs.2018.1217 CHEN Huihui,ZHANG Xiaobo,YAO Chi,et al. Experimental and model analysis of rock fracture seepage after high temperature action[J]. Journal of China Coal Society,2019,44(9):2760−2766. doi: 10.13225/j.cnki.jccs.2018.1217

[11] WANG Pengfei,TIAN Chang,LIU Ronghua,et al. Mathematical model for multivariate nonlinear prediction of SMD of X-type swirl pressure nozzles[J]. Process Safety and Environmental Protection,2019,125:228−237. doi: 10.1016/j.psep.2019.03.023

[12] 郭建春,陈付虎,苟 波,等. 酸压裂缝体形态与流动能力的控制因素:以鄂尔多斯盆地大牛地气田下奥陶统马家沟组马五_5亚段储层为例[J]. 天然气工业,2020,40(6):69−77. GUO Jianchun,CHEN Fuhu,GOU Bo,et al. Controlling factors of acid-compressed fracture body morphology and flow capacity: A case study of reservoir in Ma 5 sub-member of Lower Ordovician Majiagou Formation, Daniudi gas field, Ordos Basin[J]. Natural Gas Industry,2020,40(6):69−77.

[13] 李 静,孔祥超,宋明水,等. 储层岩石微观孔隙结构对岩石力学特性及裂缝扩展影响研究[J]. 岩土力学,2019,40(11):4149−4156,4164. LI Jing,KONG Xiangchao,SONG Mingshui,et al. Study on the influence of reservoir rock micro-pore structure on rock mechanical properties and crack propagation[J]. Rock and Soil Mechanics,2019,40(11):4149−4156,4164.

[14] TANG Hudan. Multi-scale crack propagation and damage acceleration during uniaxial compression of marble[J]. International Journal of Rock Mechanics and Mining Sciences,2020,131:104330. doi: 10.1016/j.ijrmms.2020.104330

[15] 伍天华,周 喻,王 莉,等. 单轴压缩条件下岩石孔-隙相互作用机制细观研究[J]. 岩土力学,2018,39(S2):463−472. doi: 10.16285/j.rsm.2018.0957 WU Tianhua,ZHOU Yu,WANG Li,et al. Mesoscopic study on the mechanism of rock pore-gap interaction under uniaxial compression[J]. Rock and Soil Mechanics,2018,39(S2):463−472. doi: 10.16285/j.rsm.2018.0957

[16] JI Huaijun,MAO Yingnan,SU Hetao. Effects of organic micromolecules in bituminous coal on its microscopic pore characteristics[J]. Fuel,2020,262:116529. doi: 10.1016/j.fuel.2019.116529

[17] XIN Fudong,XU Hao,TANG Dazhen,et al. Pore structure evolution of low-rank coal in China[J]. International Journal of Coal Geology,2019,205:126−139. doi: 10.1016/j.coal.2019.02.013

[18] 尹光志,黄 滚,代高飞,等. 基于CT数的煤岩单轴压缩破坏的分叉与混沌分析[J]. 岩土力学,2006(9):1465−1470. doi: 10.3969/j.issn.1000-7598.2006.09.006 YIN Guangzhi,HUANG Gun,DAI Gaofei,et al. Bifurcation and chaos analysis of coal rock failure under uniaxial compression based on CT number[J]. Rock and Soil Mechanics,2006(9):1465−1470. doi: 10.3969/j.issn.1000-7598.2006.09.006

[19] 朱红光,谢和平,易 成,等. 岩石材料微裂隙演化的CT识别[J]. 岩石力学与工程学报,2011,30(6):1230−1238. ZHU Hongguang,XIE Heping,YI Cheng,et al. CT identification of microfracture evolution in rock materials[J]. Chinese Journal of Rock Mechanics and Engineering,2011,30(6):1230−1238.

[20] 孟巧荣,赵阳升,胡耀青. 微焦点显微CT在煤岩热解中的应用[J]. 煤炭学报,2013,38(3):430−434. MENG Qiaorong,ZHAO Yangsheng,HU Yaoqing. Application of microfocus micro CT in coal pyrolysis[J]. Journal of China Coal Society,2013,38(3):430−434.

[21] 陆太进,戴 慧,田庚凡,等. 基于气体吸附法和X射线Micro-CT三维成像技术定量解析天然和电化学处理绿松石孔隙特征[J]. 地学前缘,2020,27(5):247−253. LU Taijin,DAI Hui,TIAN Gengfan,et al. Pore characteristics of natural and electrochemically treated turquoise were quantitatively analyzed by gas adsorption method and X-ray micro-CT three-dimensional imaging technology[J]. Earth Science Frontiers,2020,27(5):247−253.

[22] 刘京红,姜耀东,赵毅鑫,等. 煤岩破裂过程CT图像的分形描述[J]. 北京理工大学学报,2012,32(12):1219−1222. doi: 10.3969/j.issn.1001-0645.2012.12.003 LIU Jinghong,JIANG Yaodong,ZHAO Yixin,et al. Fractal description of CT images of coal rock fracture process[J]. Transaction of Beijing Institute of Technology,2012,32(12):1219−1222. doi: 10.3969/j.issn.1001-0645.2012.12.003

[23] 朱 琳,党发宁,丁卫华,等. 基于CT技术和灰度共生矩阵理论研究不同荷载作用下混凝土的细观损伤演化过程[J]. 土木工程学报,2020,53(8):97−107. doi: 10.15951/j.tmgcxb.2020.08.010 ZHU Lin,DANG Faning,DING Weihua,et al. Coupled X-ray computed tomography and grey level co-occurrence matrices theory as a method for detecting microscopic damage of concrete under different loads[J]. China Civil Engineering Journal,2020,53(8):97−107. doi: 10.15951/j.tmgcxb.2020.08.010

[24] 钟江城,王子辉,王路军,等. 基于CT三维重构的深部煤体损伤演化规律[J]. 煤炭学报,2019,44(5):1482−1494. doi: 10.13225/j.cnki.jccs.2019.6007 ZHONG Jiangcheng,WANG Zihui,WANG Lujun,et al. Characteristics of damage evolution of deep coal based on CT three-dimensional reconstruction[J]. Journal of China Coal Society,2019,44(5):1482−1494. doi: 10.13225/j.cnki.jccs.2019.6007

[25] LIU Shiqi,SANG Shuxun,HU Qiujia,et al. Characteristics of high-rank coal structure parallel and perpendicular to the bedding plane via NMR and X-ray CT[J]. Petroleum Science,2020,17(4):925−938. doi: 10.1007/s12182-020-00462-w

[26] 杜向琴,张 臻,娄宗科,等. 基于CT图像的细观混凝土孔隙缺陷研究[J]. 建筑材料学报,2020,23(3):603−610. DU Xiangqin,ZHANG Zhen,LOU Zongke,et al. Study on pore defects of mesoscopic concrete based on CT images[J]. Journal of Building Matlabs,2020,23(3):603−610.

[27] 韩燕华,谢作为,刘 方,等. 基于CT图像的再生混凝土内部微变形演化分析[J]. 华南理工大学学报(自然科学版),2019,47(5):73−80. HAN Yanhua,XIE Zuowei,LIU Fang,et al. Internal micro-deformation analysis of recycled aggregate concrete based on CT images[J]. Journal of South China University of Technology (Natural Science Edition),2019,47(5):73−80.

[28] 侯志强,王 宇,刘冬桥,等. 三轴疲劳-卸围压条件下大理岩力学特性试验研究[J]. 岩土力学,2020,41(5):1510−1520. HOU Zhiqiang,WANG Yu,LIU Dongqiao,et al. Experimental study on mechanical properties of marble under triaxial fatigue and unloading confining pressure[J]. Rock and Soil Mechanics,2020,41(5):1510−1520.

[29] 郎颖娴,梁正召,董 卓. 玄武岩三维细观孔隙模型重构与直接拉伸数值试验[J]. 工程科学学报,2019,41(8):997−1006. LANG Yingxian,LIANG Zhengzhao,DONG Zhuo. Three-dimensional microscopic model reconstruction of basalt and numerical direct tension tests[J]. Chinese Journal of Engineering,2019,41(8):997−1006.

[30] 廉培庆,高文彬,汤 翔,等. 基于CT扫描图像的碳酸盐岩油藏孔隙分类方法[J]. 石油与天然气地质,2020,41(4):852−861. LIAN Peiqing,GAO Wenbin,TANG Xiang,et al. A method for pore classification of carbonate reservoir based on CT scan images[J]. Oil & Gas Geology,2020,41(4):852−861.

[31] 莫云龙,李宏艳,邓志刚,等. 不同冲击倾向性煤能量响应初始损伤效应分析[J]. 采矿与安全工程学报,2020,37(6):1205−1212. MO Yunlong,LI Hongyan,DENG Zhigang,et al. Initial damage effect analysis of coal energy response with different bursting liability[J]. Journal of Mining and Safety Engineering,2020,37(6):1205−1212.

[32] W. BRENT Lindquist. Pore and throat size distributions measured from synchrotron X-ray tomographic images of Fontainebleau sandstones[J]. Journal of Geophysical Research,2000:1052139.

[33] LI Zhentao,LIU Dameng,CAI Yidong,et al. Multi-scale quantitative characterization of 3-D pore-fracture networks in bituminous and anthracite coals using FIB-SEM tomography and X-ray μ-CT[J]. Fuel,2017,209:43−53. doi: 10.1016/j.fuel.2017.07.088

[34] ZHANG Yifei,NIU Suyun,DU Zhongming,et al. Dynamic fracture evolution of tight sandstone under uniaxial compression in high resolution 3D X-ray microscopy[J]. Journal of Petroleum Science and Engineering,2020,195:107585. doi: 10.1016/j.petrol.2020.107585

[35] ZHANG Guanglei,P G RANJITH,LIANG Weiguo,et al. Stress-dependent fracture porosity and permeability of fractured coal: An in-situ X-ray tomography study[J]. International Journal of Coal Geology,2019,213:103279. doi: 10.1016/j.coal.2019.103279

[36] SUN Xiaoyang,TAKEDA Shi-ichi,WISNOM Michael R,et al. In situ characterization of trans-laminar fracture toughness using X-ray Computed Tomography[J]. Composites Communications,2020:100408.

[37] WANG Y,HOU Z Q,HU Y Z. In situ X-ray micro-CT for investigation of damage evolution in black shale under uniaxial compression[J]. Environmental Earth Sciences,2018,77(20):278−288.

-

期刊类型引用(15)

1. 范任重. 高应力大采高工作面回采巷道围岩控制技术. 西部探矿工程. 2025(02): 83-87+91 .  百度学术

百度学术

2. 闫学忠. 非中空锚索高预应力全长锚固与注浆技术研究. 能源与环保. 2025(01): 279-286 .  百度学术

百度学术

3. 涂敏,郭福鑫. “蝶形托板-锚索”匹配性及锚索防剪保护机理研究. 采矿与安全工程学报. 2025(02): 306-316 .  百度学术

百度学术

4. 汪占领,刘志文,赵华山,李永元,程利兴. 特厚煤层大巷变形破坏特征及控制技术研究. 煤炭工程. 2024(04): 53-59 .  百度学术

百度学术

5. 吴晓宇,周豪,吴晓伟. 近距离下煤层中空注浆锚索注浆前后周边剪应力作用机理. 煤炭工程. 2024(04): 112-118 .  百度学术

百度学术

6. 李建志. 开拓大巷变形破坏机理分析及控制措施研究. 西部探矿工程. 2024(09): 134-137 .  百度学术

百度学术

7. 吴宁. 注浆锚索主动式超前支护巷道围岩变形控制技术. 煤炭科技. 2024(06): 57-62+66 .  百度学术

百度学术

8. 孙长全. 大跨度大空间建筑预应力型钢混凝土组合结构施工技术研究. 粉煤灰综合利用. 2024(06): 115-119 .  百度学术

百度学术

9. 傅翔,黄平,陈柏林,彭海游,黄祥超. 坡顶带临空建筑高边坡切脚滑坡抢险加固技术. 山西建筑. 2023(04): 90-92+96 .  百度学术

百度学术

10. 赵明洲,方娟,辛程鹏,李回贵. 回采煤巷大厚度泥质层状顶板失稳机理及控制对策. 矿业研究与开发. 2023(04): 75-81 .  百度学术

百度学术

11. 李天棚,陈江,张焙炎,谈文州. 近距离煤层重复采动下巷道变形机制及稳定控制技术. 煤炭科技. 2023(04): 182-188 .  百度学术

百度学术

12. 路广安. 山寨煤矿高应力巷道底板动态控制方法. 山东煤炭科技. 2023(08): 191-193 .  百度学术

百度学术

13. 郭军亮. 强动压巷道柔性锚杆支护方案设计及工业性试验分析. 西部探矿工程. 2023(10): 123-125 .  百度学术

百度学术

14. 姚强岭,徐强,何杰,李英虎,刘伟冬. 基于有效锚固层厚度的近距离煤层下伏巷道支护技术数值模拟研究. 能源与环保. 2023(11): 1-6 .  百度学术

百度学术

15. 王坤. 杜儿坪矿73907胶带巷超前支护技术研究与应用. 煤. 2023(12): 44-48+60 .  百度学术

百度学术

其他类型引用(6)

下载:

下载: