Active and passive full-space collaborative control technology and engineering application in deep roadways

-

摘要:

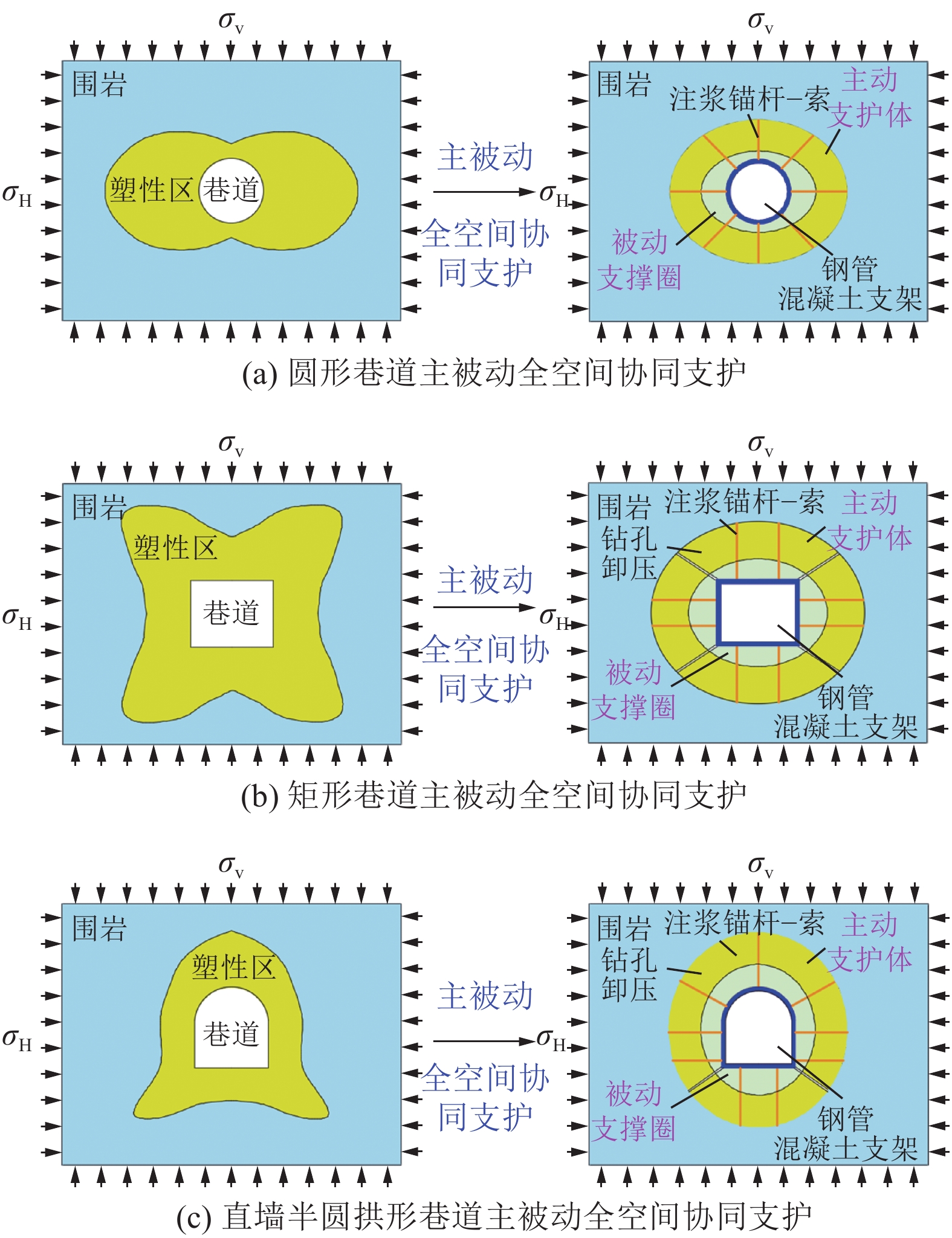

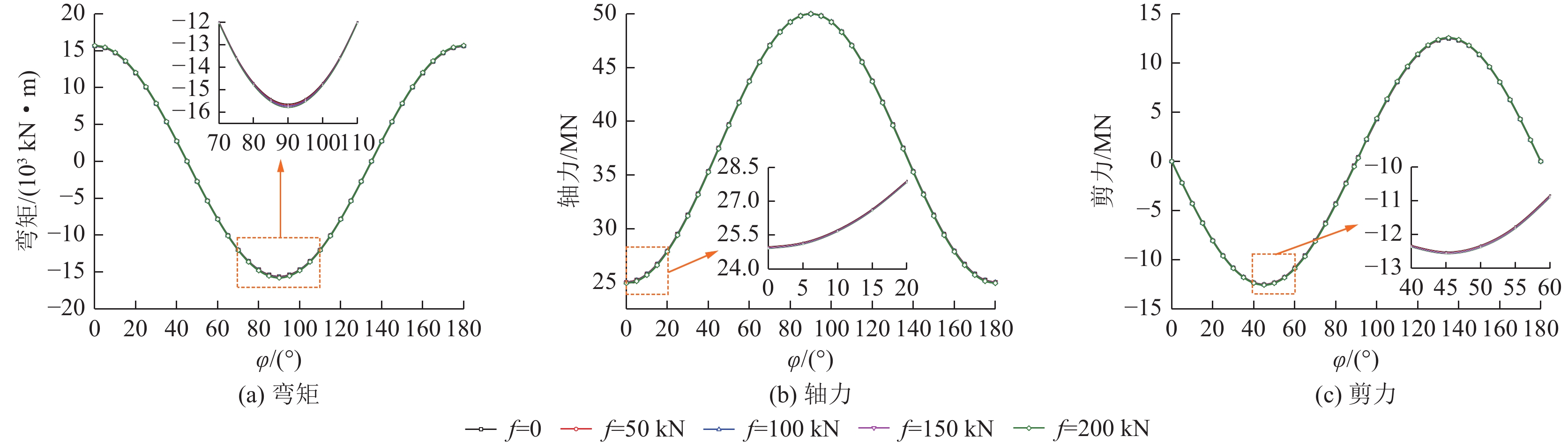

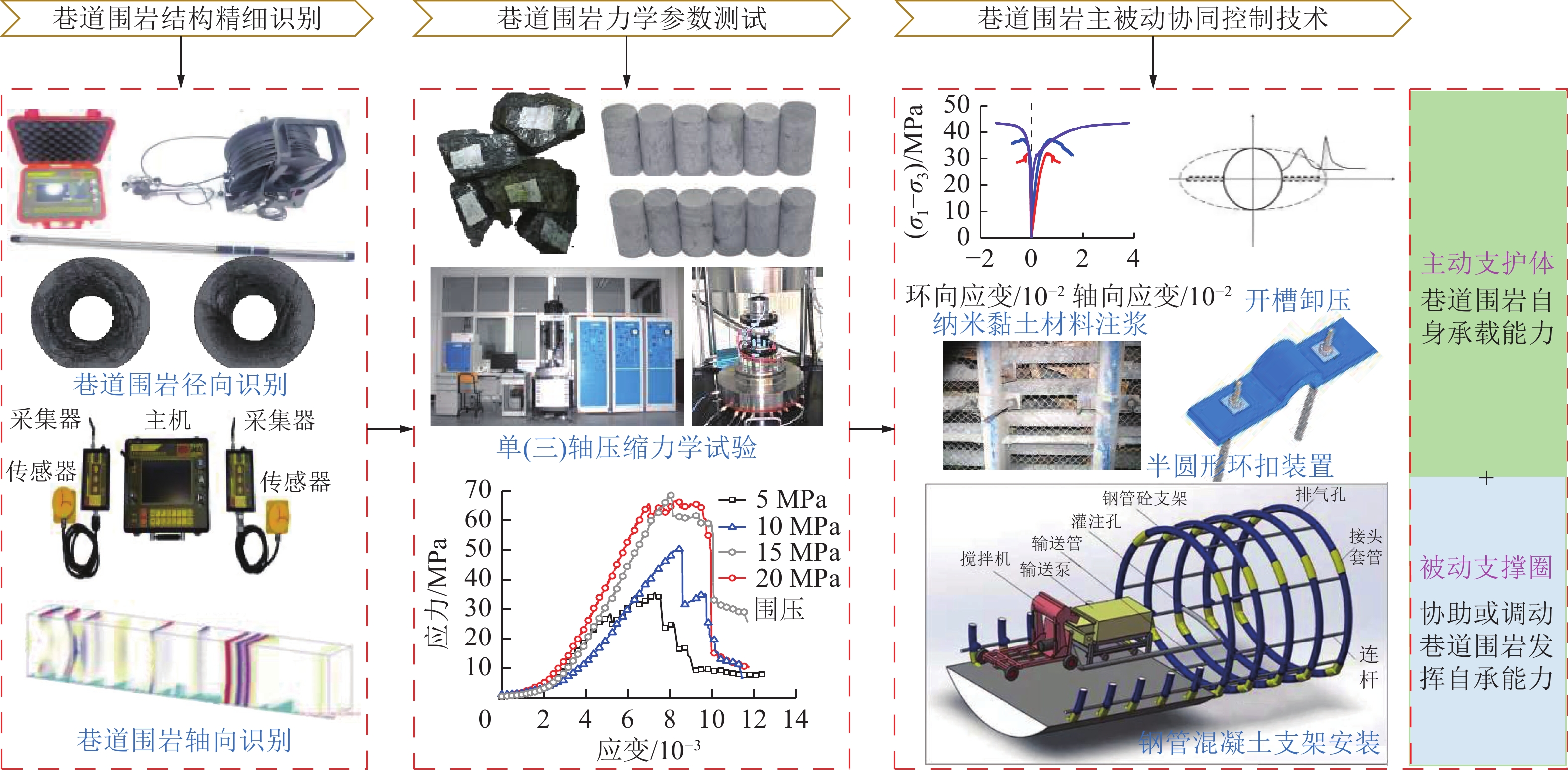

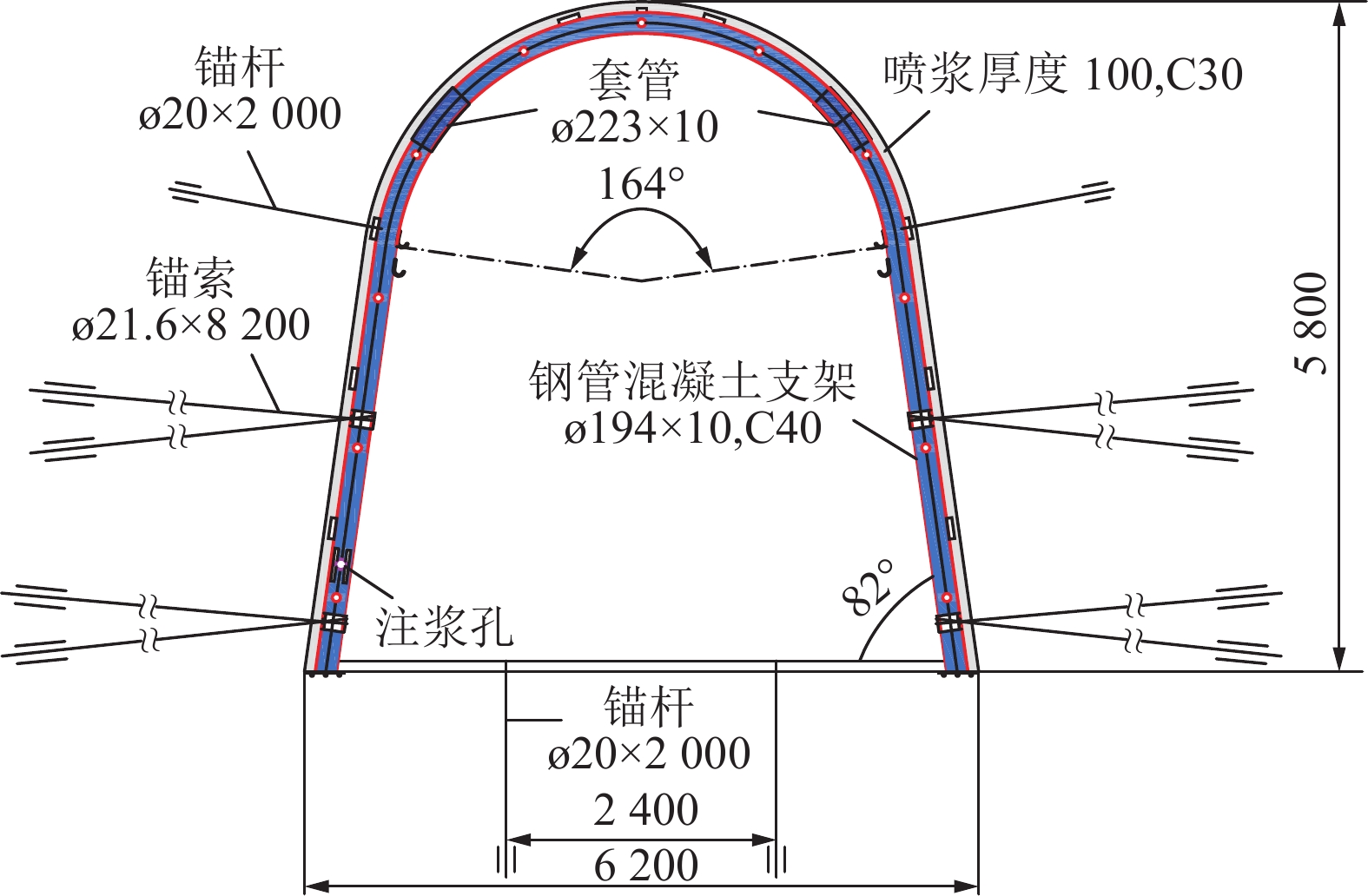

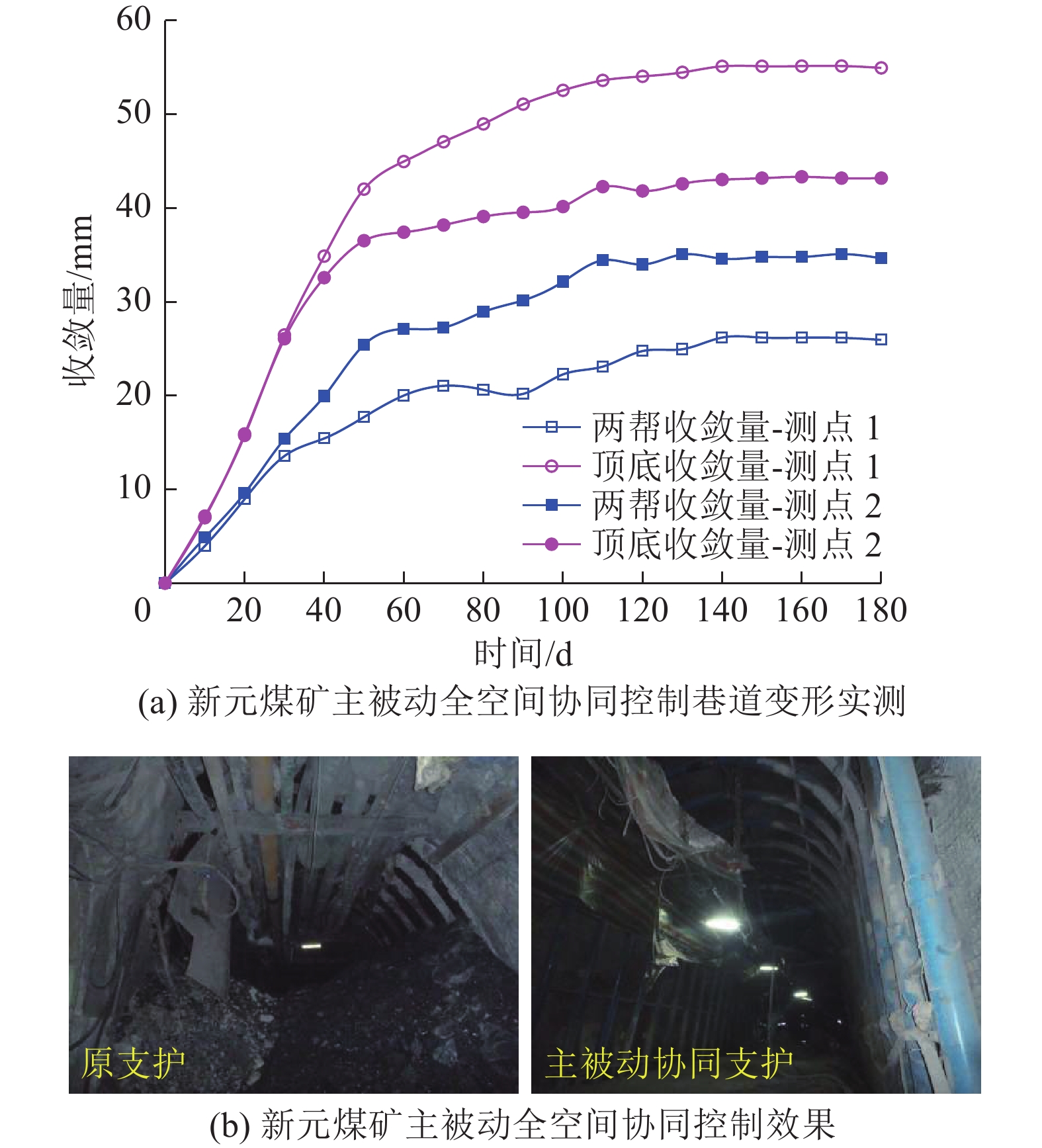

深部巷道由于赋存环境复杂及受到深部地应力作用,加上断面形状尺寸多样,使得巷道的破坏形式多元化。通过系统分析深井软岩巷道受到高应力、动压等因素影响,对比了最大地应力、最大抗压强度以及相对应的支护方式,提出采用应力强度比来评价巷道围岩支护的难易程度。进一步提出了深部巷道主被动全空间协同控制理念,其核心为通过卸压、注浆和锚杆−索等主动支护方式来控制巷道变形,发挥围岩的自承能力,形成主动支护体,恢复其部分承载能力;使用钢管混凝土支架、U型钢等具有较高支护阻力的被动支护方式,构成被动支撑圈,协助或调动巷道围岩发挥承载能力。进而分析了钢管混凝土支架与锚杆−索的协同支护力学机理,形成了主被动全空间协同控制技术及施工工艺并进行了现场应用。研究表明,打设锚杆−索可以降低钢管混凝土支架的弯矩和剪力,同时降低了支架轴力,保护了钢管和抗拉性能较差的核心混凝土,保证了钢管混凝土支架能够提供较高的支护阻力;主被动全空间协同控制技术在晋城胡底煤矿、阳泉新元煤矿等深部动压巷道与软岩巷道中进行了成功应用,进一步发展了深部巷道等强支护理论与技术。

Abstract:Due to the complex environment and ground stress at depth, and the various cross-sectional shapes and sizes, the damage types of deep roadways are diversified. The maximum ground stress, maximum compressive strength, and the corresponding support methods are compared by systematically analyzing the influence of high stress and dynamic pressure on the deep weak surrounding rock of roadways. And the stress intensity ratio is proposed to evaluate the support difficulty of surrounding rock of roadways. Then, the concept of active-passive full space collaborative control is proposed, and the core of the concept is to control the deformation of the roadway through active support methods such as destressing, grouting and bolt-cable to bring the self-supporting capacity of the surrounding rock of roadway into play, forming an active support body, and restoring its partial bearing capacity. Using passive support methods such as concrete-filled steel tube sets and U-shaped steel sets with high support resistance to form a passive support ring to assist or mobilize the bearing capacity of the rock surrounding roadways. Additionally, the mechanical mechanism of the collaborative support for concrete-filled steel tube sets and bolt-cable were analyzed, and the active-passive full space collaborative control technology and construction technique were developed and applied in the field. The study shows that the bolt-cable can reduce the bending moment and shear force of the concrete-filled steel tube sets, while reducing the axial force of the support and protecting the steel tube and the core concrete with poor tensile properties. The active-passive full space cooperative control technology has been successfully applied in deep roadway subjected to dynamic pressure and weak rock roadway in Jincheng Hudi Coal Mine and Yangquan Xinyuan Coal Mine, which has further developed the theory and technology of equal-strength support in deep roadway.

-

-

表 1 煤矿巷道支护方式统计

Table 1 Statistics of support methods in coal mine roadway

巷道特点 埋深/m 最大地应力/MPa 围岩峰值强度/MPa k 支护方式 分类 富水软岩巷道[17] 1 000 39.08 34.27 1.14 锚杆索+底板松动爆破+注浆加固的底鼓联合控制方案 主动+被动 大埋深复合软岩巷道[18] 600 25.78 23.60 1.09 锚杆索+喷浆+钢带 主动+弱被动 近距采空区回采巷道[19] 230 9.00 4.59 1.96 锚杆+锚索+W钢带+单体支柱 主动+弱被动 软岩巷道[15] 600 14.58 5.09 2.86 锚网索喷+钢管混凝土组合支架 主动+强被动 深地动压巷道[20] 1 100 26.56 49.60 0.54 锚网索喷+钢管混凝土组合支架 主动+强被动 高应力软岩巷道[21] 1 000 25.12 10.08 2.49 高预应力(锚杆索)强力支护+注浆改性 强主动 弱胶结软岩巷道[22] 540 16.20 7.80 2.08 锚网索梁支护结构+全断面喷浆耦合支护 主动+弱被动 普通运输大巷[23] 800 20.00 74.50 0.27 锚网索喷 主动+弱被动 弱冲击地压巷道[24] 670 25.13 23.13 1.09 锚网索+U型棚+爆破卸压 主动+被动 强冲击巷道[25] 580 35.95 22.00 1.63 水力压裂+锚杆索 主动 大断面过陷落柱巷道[26] 712 13.40 5.00 2.68 超前注浆+锚网索支护 主动 硬岩高抽巷[27] 500 21.60 25.67 0.84 锚杆索 主动 构造应力场开拓大巷[28] 720 31.00 24.00 1.29 锚网索喷 主动+弱被动 深部坚硬顶板回采巷道[29] 700 19.53 81.10 0.24 恒阻大变形锚杆索 强主动 深部软弱破碎巷道[30] 1 000 30.00 23.50 1.28 锚杆喷+注浆 主动+弱被动 深井冲击地压巷道[31] 684 23.94 17.60 1.36 钻孔卸压+锚杆索 主动 软弱围岩巷道[32] 500 13.50 45.00 0.30 喷射混凝土+注浆+锚杆索 主动+弱被动 深井交岔点巷道[33] 1 250 47.00 43.37 1.08 钢管混凝土组合支架+锚杆索+壁后卸压 强被动+主动 深井采动应力巷道[34] 1 130 37.30 31.56 1.18 36U型钢+锚杆索+网梁 被动+主动 软弱破碎巷道[35] 580 28.11 32.64 0.86 U型钢+锚杆+长锚索 被动+主动 深井破碎巷道[36] 1 000 30.00 43.48 0.69 锚网索喷+U型钢支架+注浆+底板锚注 主动+被动 软岩马头门[37] 680 32.74 16.39 2.00 锚网喷+锚索+全断面钢筋混凝土+钢纤维混凝土砌碹支护 主动+被动 软岩巷道[38] 350 8.20 8.81 0.93 恒阻大变形锚杆索+全断面混凝土喷层+底角注浆锚管 强主动+被动 软岩淋水巷道[39] 700 17.13 18.20 0.94 锚杆索+喷射混凝土+金属网+25U型钢+注浆 主动+弱被动 深井巷道[40] 1 271 31.78 31.74 1.00 全断面高预应力、高强度锚杆索+注浆 强主动 强膨胀性软岩巷道[41] 463 27.70 16.00 1.73 锚杆索+反底拱+铺设干石灰粉 主动+被动 深井高应力软岩巷道[42] 1 040 40.00 7.00 5.71 锚杆索梁网+36U型钢可缩性长环形支架+注浆 主动+被动 深部高应力巷道[43] 1 200 42.90 70.50 0.61 锚杆网喷+钢管混凝土支架 主动+强被动 千米深井厚顶煤巷道[44] 990 34.60 8.60 4.02 锚杆+钢带+让压型锚索箱梁支护系统 主动+被动 高应力软岩巷道[45] 836 26.33 14.00 1.88 锚杆索网梁喷+U29金属支架 主动+被动 大断面破碎硐室[46] 540 30.00 60.00 0.50 锚杆索+底拱U36可缩性支架+注浆 主动+被动 深部油页岩巷道[47] 850 35.00 50.30 0.70 锚杆索梁+喷浆 主动+弱被动 软弱回采巷道[48] 380 9.50 12.77 0.74 锚杆索网梁+可缩性工字钢 主动+被动 深部巷道[49] 800 27.81 15.00 1.85 高预应力锚杆索网+超前注浆+架棚 强主动+被动 大厚度泥岩顶板煤巷[50] 500 25.50 20.00 1.28 高强度螺纹钢锚杆+锚索+网+喷层 主动+被动 铁矿高应力巷道[51] 537 25.10 81.10 0.31 锚杆+网+钢筋梯子梁 主动+弱被动 深部岩巷[52] 700 21.60 37.82 0.57 锚杆索+适当注浆 主动 深部开采巷道[53] 952 85.40 50.29 1.70 锚杆索网梁+29U型钢 主动+被动 软岩巷道[54] 330 8.64 6.62 1.31 锚杆索网喷+注浆 主动+被动 软弱破碎巷道[55] 550 16.13 22.88 0.70 锚杆索+砌碹+喷层 主动+弱被动 -

[1] 康红普. 我国煤矿巷道围岩控制技术发展 70 年及展望[J]. 岩石力学与工程学报,2021,40(1):1−30. KANG Hongpu. 70 years and prospect of surrounding rock control technology in China’s coal mine roadway[J]. Chinese Journal of Rock Mechanics and Engineering,2021,40(1):1−30.

[2] 康红普. 我国煤矿巷道锚杆支护技术发展60年及展望[J]. 中国矿业大学学报,2016,45(6):1071−1081. doi: 10.13247/j.cnki.jcumt.000583 KANG Hongpu. The development of bolting technology in coal mine roadway in China for 60 years and its prospect[J]. Journal of China University of Mining & Technology,2016,45(6):1071−1081. doi: 10.13247/j.cnki.jcumt.000583

[3] KANG Hongpu,JIANG Pengfei,WU Yongzheng,et al. A combined “ground support-rock modification-destressing” strategy for 1000-m deep roadways in extreme squeezing ground condition[J]. International Journal of Rock Mechanics and Mining Sciences,2021,142:104746. doi: 10.1016/j.ijrmms.2021.104746

[4] 何满潮,郭志飚. 恒阻大变形锚杆力学特性及其工程应用[J]. 岩石力学与工程学报,2014,33(7):1297−1308. doi: 10.13722/j.cnki.jrme.2014.07.001 HE Manchao,GUO Zhibiao. Mechanical properties and engineering application of constant resistance and large deformation anchor rod[J]. Chinese Journal of Rock Mechanics and Engineering,2014,33(7):1297−1308. doi: 10.13722/j.cnki.jrme.2014.07.001

[5] 何满潮,李 晨,宫伟力. 恒阻大变形锚杆冲击拉伸实验及其有限元分析[J]. 岩石力学与工程学报,2015,34(11):2179−2187. doi: 10.13722/j.cnki.jrme.2015.0871 HE Manchao,LI Chen,GONG Weili. Impact tensile test and finite element analysis of anchor rod with constant resistance and large deformation[J]. Chinese Journal of Rock Mechanics and Engineering,2015,34(11):2179−2187. doi: 10.13722/j.cnki.jrme.2015.0871

[6] HE Manchao,WANG Qi. Excavation compensation method and key technology for surrounding rock control[J]. Engineering Geology,2022,307:106784. doi: 10.1016/j.enggeo.2022.106784

[7] 马念杰,赵志强,冯吉成. 困难条件下巷道对接长锚杆支护技术[J]. 煤炭科学技术,2013,41(9):117−121. doi: 10.13199/j.cnki.cst.2013.09.027 MA Nianjie,ZHAO Zhiqiang,FENG Jicheng. Long bolt support technology for roadway butt joint under difficult conditions[J]. Coal Science and Technology,2013,41(9):117−121. doi: 10.13199/j.cnki.cst.2013.09.027

[8] 侯朝炯,王襄禹,柏建彪,等. 深部巷道围岩稳定性控制的基本理论与技术研究[J]. 中国矿业大学学报,2021,50(1):1−12. doi: 10.13247/j.cnki.jcumt.001242 HOU Chaojiong,WANG Xiangyu,BAI Jianbiao,et al. Basic theory and technology research on stability control of surrounding rock in deep roadway[J]. Journal of China University of Mining & Technology,2021,50(1):1−12. doi: 10.13247/j.cnki.jcumt.001242

[9] 左建平,洪紫杰,于美鲁,等. 破碎围岩梯度支护模型及分级控制研究[J]. 中国矿业大学学报,2022,51(2):221−231. doi: 10.3969/j.issn.1000-1964.2022.2.zgkydxxb202202002 ZUO Jianping,HONG Zijie,YU Meilu,et al. Research on gradient support model and grading control of broken surrounding rock[J]. Journal of China University of Mining & Technology,2022,51(2):221−231. doi: 10.3969/j.issn.1000-1964.2022.2.zgkydxxb202202002

[10] 王 猛,王襄禹,肖同强. 深部巷道钻孔卸压机理及关键参数确定方法与应用[J]. 煤炭学报,2017,42(5):1138−1145. doi: 10.13225/j.cnki.jccs.2016.0867 WANG Meng,WANG Xiangyu,XIAO Tongqiang. Drilling pressure relief mechanism of deep roadway and determination method and application of key parameters[J]. Journal of China Coal Society,2017,42(5):1138−1145. doi: 10.13225/j.cnki.jccs.2016.0867

[11] 左建平,史 月,刘德军,等. 深部软岩巷道开槽卸压等效椭圆模型及模拟分析[J]. 中国矿业大学学报,2019,48(1):1−11. doi: 10.13247/j.cnki.jcumt.000960 ZUO Jianping,SHI Yue,LIU Dejun,et al. Equivalent ellipse model and simulation analysis of deep soft rock roadway slotting and pressure relief[J]. Journal of China University of Mining & Technology,2019,48(1):1−11. doi: 10.13247/j.cnki.jcumt.000960

[12] 姜鹏飞,康红普,王志根,等. 千米深井软岩大巷围岩锚架充协同控制原理、技术及应用[J]. 煤炭学报,2020,45(3):1020−1035. doi: 10.13225/j.cnki.jccs.SJ20.0236 JIANG Pengfei,KANG Hongpu,WANG Zhigen,et al. Cooperative control principle, technology and application of surrounding rock bolting and filling in soft rock roadway of kilometer deep shaft[J]. Journal of China Coal Society,2020,45(3):1020−1035. doi: 10.13225/j.cnki.jccs.SJ20.0236

[13] 马明杰,杨新安,谢文兵,等. 可缩性U型钢支架承载性能足尺试验研究[J]. 中南大学学报(自然科学版),2023,54(1):280−291. MA Mingjie,YANG Xin’an,XIE Wenbing,et al. Full-scale experimental study on bearing capacity of retractable U-shaped steel support[J]. Journal of Central South University (Science and Technology),2023,54(1):280−291.

[14] 刘德军,左建平,郭 淞,等. 深部巷道钢管混凝土支架承载性能研究进展[J]. 中国矿业大学学报,2018,47(6):1193−1211. doi: 10.13247/j.cnki.jcumt.000942 LIU Dejun,ZUO Jianping,GUO Song,et al. Research progress on bearing capacity of concrete-filled steel tube support in deep roadway[J]. Journal of China University of Mining & Technology,2018,47(6):1193−1211. doi: 10.13247/j.cnki.jcumt.000942

[15] 王 军,卢文岩,邢鲁义,等. 软岩巷道交岔点钢管混凝土组合支架支护技术研究[J]. 岩石力学与工程学报,2022,41(3):573−586. WANG Jun,LU Wenyan,XING Luyi,et al. Research on the support technology of steel tube concrete composite support at the intersection of soft rock roadway[J]. Chinese Journal of Rock Mechanics and Engineering,2022,41(3):573−586.

[16] 张 农,魏 群,吴建生. 煤矿巷道喷涂柔膜技术及适用性[J]. 煤炭科学技术,2022,50(1):78−85. doi: 10.3969/j.issn.0253-2336.2022.1.mtkxjs202201006 ZHANG Nong,WEI Qun,WU Jiansheng. Soft film spraying technology and applicability in coal mine roadway[J]. Coal Science and Technology,2022,50(1):78−85. doi: 10.3969/j.issn.0253-2336.2022.1.mtkxjs202201006

[17] 程敬义,魏泽捷,白纪成,等. 基于爆破卸压的深部构造应力富水软岩巷道底鼓控制技术研究[J]. 煤炭科学技术,2022,50(7):117−126. CHENG Jingyi,WEI Zejie,BAI Jicheng,et al. Research on floor heave control technology of deep structural stress water-rich soft rock roadway based on blasting pressure relief[J]. Coal Science and Technology,2022,50(7):117−126.

[18] 邹佩国,任胜文. 大埋深复合软岩顶板围岩控制关键技术研究[J]. 煤炭科学技术,2022,50(S1):81−88. ZOU Peiguo,REN Shengwen. Research on key technology of surrounding rock control of large buried composite soft rock roof[J]. Coal Science and Technology,2022,50(S1):81−88.

[19] 冯国瑞,郝晨良,王朋飞,等. 近距采空区下回采巷道非对称变形机理及控制对策[J]. 中国矿业大学学报,2022,51(4):617−631. doi: 10.3969/j.issn.1000-1964.2022.4.zgkydxxb202204001 FENG Guorui,HAO Chenliang,WANG Pengfei,et al. Asymmetric deformation mechanism and control measures of mining roadway under close goaf[J]. Journal of China University of Mining & Technology,2022,51(4):617−631. doi: 10.3969/j.issn.1000-1964.2022.4.zgkydxxb202204001

[20] 黄万朋,孙远翔,陈绍杰. 岩石蠕变扰动效应理论及其在深地动压工程支护中的应用[J]. 岩土工程学报,2021,43(9):1621−1630. HUANG Wanpeng,SUN Yuanxiang,CHEN Shaojie. The theory of rock creep disturbance effect and its application in deep ground dynamic pressure engineering support[J]. Chinese Journal of Geotechnical Engineering,2021,43(9):1621−1630.

[21] 程利兴,康红普,姜鹏飞,等. 深井沿空掘巷围岩变形破坏特征及控制技术研究[J]. 采矿与安全工程学报,2021,38(2):227−236. doi: 10.13545/j.cnki.jmse.2019.0586 CHENG Lixing,KANG Hongpu,JIANG Pengfei,et al. Research on deformation and failure characteristics and control technology of surrounding rock of deep shaft driving along goaf[J]. Journal of Mining & Safety Engineering,2021,38(2):227−236. doi: 10.13545/j.cnki.jmse.2019.0586

[22] 蔡金龙,涂 敏,张华磊. 侏罗系弱胶结软岩回采巷道变形失稳机理及围岩控制技术研究[J]. 采矿与安全工程学报,2020,37(6):1114−1122. doi: 10.13545/j.cnki.jmse.2020.06.005 CAI Jinlong,TU Min,ZHANG Hualei. Research on deformation and instability mechanism of mining roadway and surrounding rock control technology in Jurassic weakly cemented soft rock[J]. Journal of Mining & Safety Engineering,2020,37(6):1114−1122. doi: 10.13545/j.cnki.jmse.2020.06.005

[23] 王 猛,宋子枫,郑冬杰,等. FLAC3D中岩石能量耗散模型的开发与应用[J]. 煤炭学报,2021,46(8):2565−2573. WANG Meng,SONG Zifeng,ZHENG Dongjie,et al. Development and application of rock energy dissipation model in FLAC3D[J]. Journal of China Coal Society,2021,46(8):2565−2573.

[24] 张晨阳,潘俊锋,夏永学,等. 底煤厚度对巷道底板冲击地压的影响机制及其应用分析[J]. 煤炭学报,2020,45(12):3984−3994. doi: 10.13225/j.cnki.jccs.2020.0835 ZHANG Chenyang,PAN Junfeng,XIA Yongxue,et al. The influence mechanism and application analysis of the thickness of bottom coal on the rockburst of roadway floor[J]. Journal of China Coal Society,2020,45(12):3984−3994. doi: 10.13225/j.cnki.jccs.2020.0835

[25] 王 博,姜福兴,朱斯陶,等. 陕蒙接壤深部矿区区段煤柱诱冲机理及其防治[J]. 采矿与安全工程学报,2020,37(3):505−513. doi: 10.13545/j.cnki.jmse.2020.03.009 WANG Bo,JIANG Fuxing,ZHU Sitao,et al. The mechanism of coal pillar induced erosion and its prevention and control in the deep mining area adjacent to Shaanxi and Mongolia[J]. Journal of Mining & Safety Engineering,2020,37(3):505−513. doi: 10.13545/j.cnki.jmse.2020.03.009

[26] 宋卫华,邸春雷,闫万俊,等. 大断面矩形巷道过陷落柱构造带支护技术[J]. 采矿与安全工程学报,2019,36.(6):1178−1192. doi: 10.13545/j.cnki.jmse.2019.06.014 SONG Weihua,DI Chunlei,YAN Wanjun,et al. Support technology of large section rectangular roadway through collapse column structural zone[J]. Journal of Mining & Safety Engineering,2019,36.(6):1178−1192. doi: 10.13545/j.cnki.jmse.2019.06.014

[27] 程 桦,唐 彬,唐永志,等. 深井巷道全断面硬岩掘进机及其快速施工关键技术[J]. 煤炭学报,2020,45(9):3314−3324. doi: 10.13225/j.cnki.jccs.2019.0927 CHENG Hua,TANG Bin,TANG Yongzhi,et al. Full-section hard rock roadheader for deep roadway and its key technology for rapid construction[J]. Journal of China Coal Society,2020,45(9):3314−3324. doi: 10.13225/j.cnki.jccs.2019.0927

[28] 王书文,鞠文君,潘俊锋,等. 构造应力场煤巷掘进冲击地压能量分区演化机制[J]. 煤炭学报,2019,44(7):2000−2010. doi: 10.13225/j.cnki.jccs.2018.1101 WANG Shuwen,JU Wenjun,PAN Junfeng,et al. Regional evolution mechanism of rock burst energy in coal roadway driving in tectonic stress field[J]. Journal of China Coal Society,2019,44(7):2000−2010. doi: 10.13225/j.cnki.jccs.2018.1101

[29] 张 勇,孙晓明,郑有雷,等. 深部回采巷道防冲释能耦合支护技术及应用[J]. 岩石力学与工程学报,2019,38(9):1860−1869. doi: 10.13722/j.cnki.jrme.2018.1514 ZHANG Yong,SUN Xiaoming,ZHENG Youlei,et al. Coupled support technology and application of erosion prevention and energy release in deep mining roadway[J]. Chinese Journal of Rock Mechanics and Engineering,2019,38(9):1860−1869. doi: 10.13722/j.cnki.jrme.2018.1514

[30] 刘泉声,邓鹏海,毕 晨,等. 深部巷道软弱围岩破裂碎胀过程及锚喷−注浆加固FDEM数值模拟[J]. 岩土力学,2019,40(10):4065−4083. doi: 10.16285/j.rsm.2018.1032 LIU Quansheng,DENG Penghai,BI Chen,et al. FDEM numerical simulation of fracture and expansion process of soft surrounding rock in deep roadway and reinforcement by bolting and shotcreting and grouting[J]. Rock and Soil Mechanics,2019,40(10):4065−4083. doi: 10.16285/j.rsm.2018.1032

[31] 舒凑先,姜福兴,魏全德,等. 疏水诱发深井巷道冲击地压机理及其防治[J]. 采矿与安全工程学报,2018,35(4):780−786. doi: 10.13545/j.cnki.jmse.2018.04.016 SHU Caoxian,JIANG Fuxing,WEI Quande,et al. Mechanism and prevention of rockburst in deep roadway induced by drainage[J]. Journal of Mining & Safety Engineering,2018,35(4):780−786. doi: 10.13545/j.cnki.jmse.2018.04.016

[32] 陈顺满,吴爱祥,王少勇,等. 软弱围岩巷道变形机理及返修控制技术[J]. 中国矿业大学学报,2018,47(4):830−837. doi: 10.13247/j.cnki.jcumt.000892 CHEN Shunman,WU Aixiang,WANG Shaoyong,et al. Deformation mechanism and repair control technology of roadway in soft surrounding rock[J]. Journal of China University of Mining & Technology,2018,47(4):830−837. doi: 10.13247/j.cnki.jcumt.000892

[33] 王 军,黄万朋,左建平,等. 深井交岔点围岩流变扰动效应及钢管混凝土组合支架支护技术研究[J]. 岩石力学与工程学报,2018,37(2):461−472. doi: 10.13722/j.cnki.jrme.2017.1197 WANG Jun,HUANG Wanpeng,ZUO Jianping,et al. Research on the rheological disturbance effect of surrounding rock at the intersection of deep shaft and the support technology of concrete-filled steel tube composite support[J]. Chinese Journal of Rock Mechanics and Engineering,2018,37(2):461−472. doi: 10.13722/j.cnki.jrme.2017.1197

[34] 张建国. 平煤超千米深井采动应力特征及裂隙演化规律研究[J]. 中国矿业大学学报,2017,46(5):1041−1049. doi: 10.13247/j.cnki.jcumt.000737 ZHANG Jianguo. Study on mining stress characteristics and fracture evolution law of Pingshan ultra-kilometer deep well[J]. Journal of China University of Mining & Technology,2017,46(5):1041−1049. doi: 10.13247/j.cnki.jcumt.000737

[35] 吴爱祥,胡 建,黄明清,等. 软弱破碎围岩运输巷道变形机理及修复支护[J]. 中南大学学报(自然科学版),2017,48(8):2162−2168. WU Aixiang,HU Jian,HUANG Mingqing,et al. Deformation mechanism and repair support of transportation roadway in soft and broken surrounding rock[J]. Journal of Central South University(Science and Technology),2017,48(8):2162−2168.

[36] 孟庆彬,韩立军,张 建,等. 深部高应力破碎软岩巷道支护技术研究及其应用[J]. 中南大学学报(自然科学版),2016,47(11):3861−3872. MENG Qingbin,HAN Lijun,ZHANG Jian,et al. Research and application of support technology for deep high-stress broken soft rock roadway[J]. Journal of Central South University(Science and Technology),2016,47(11):3861−3872.

[37] 宋朝阳,纪洪广,张月征,等. 主应力对弱胶结软岩马头门围岩稳定性影响[J]. 采矿与安全工程学报,2016,33(6):965−971. doi: 10.13545/j.cnki.jmse.2016.06.002 SONG Chaoyang,JI Hongguang,ZHANG Yuezheng,et al. Effect of principal stress on the stability of the surrounding rock of the weakly cemented soft rock Matoumen[J]. Journal of Mining & Safety Engineering,2016,33(6):965−971. doi: 10.13545/j.cnki.jmse.2016.06.002

[38] 郝育喜,王 炯,袁 越,等. 沙吉海煤矿弱胶结膨胀性软岩巷道大变形控制对策[J]. 采矿与安全工程学报,2016,33(4):684−691. doi: 10.13545/j.cnki.jmse.2016.04.018 HAO Yuxi,WANG Jiong,YUAN Yue,et al. Control measures for large deformation of weak cemented expansive soft rock roadway in Shajihai Coal Mine[J]. Journal of Mining & Safety Engineering,2016,33(4):684−691. doi: 10.13545/j.cnki.jmse.2016.04.018

[39] 张红军,李海燕,李术才,等. 深部软岩巷道围岩变形机制及支护技术研究[J]. 采矿与安全工程学报,2015,32(6):955−962. doi: 10.13545/j.cnki.jmse.2015.06.014 ZHANG Hongjun,LI Haiyan,LI Shucai,et al. Research on surrounding rock deformation mechanism and support technology of deep soft rock roadway[J]. Journal of Mining & Safety Engineering,2015,32(6):955−962. doi: 10.13545/j.cnki.jmse.2015.06.014

[40] 康红普,范明建,高富强,等. 超千米深井巷道围岩变形特征与支护技术[J]. 岩石力学与工程学报,2015,34(11):2227−2241. doi: 10.13722/j.cnki.jrme.2015.0859 KANG Hongpu,FAN Mingjian,GAO Fuqiang,et al. Surrounding rock deformation characteristics and support technology of roadway in ultra-kilometer deep mine[J]. Chinese Journal of Rock Mechanics and Engineering,2015,34(11):2227−2241. doi: 10.13722/j.cnki.jrme.2015.0859

[41] 杨晓杰,庞杰文,娄浩朋. 亭南煤矿强膨胀性软岩巷道底臌变形力学机制[J]. 煤炭学报,2015,40(8):1761−1767. doi: 10.13225/j.cnki.jccs.2014.1217 YANG Xiaojie,PANG Jiewen,LOU Haopeng. Mechanical mechanism of floor heave deformation of strong expansive soft rock roadway in Tingnan Coal Mine[J]. Journal of China Coal Society,2015,40(8):1761−1767. doi: 10.13225/j.cnki.jccs.2014.1217

[42] 张广超,何富连. 深井高应力软岩巷道围岩变形破坏机制及控制[J]. 采矿与安全工程学报,2015,32(4):571−577. doi: 10.13545/j.cnki.jmse.2015.04.008 ZHANG Guangchao,HE Fulian. Deformation and failure mechanism and control of surrounding rock of high stress soft rock roadway in deep mine[J]. Journal of Mining & Safety Engineering,2015,32(4):571−577. doi: 10.13545/j.cnki.jmse.2015.04.008

[43] 黄万朋,高延法,王 军. 扰动作用下深部岩巷长期大变形机制及控制技术[J]. 煤炭学报,2014,39(5):822−828. doi: 10.13225/j.cnki.jccs.2013.0752 HUANG Wanpeng,GAO Yanfa,WANG Jun. Long-term large deformation mechanism and control technology of deep rock roadway under disturbance[J]. Journal of China Coal Society,2014,39(5):822−828. doi: 10.13225/j.cnki.jccs.2013.0752

[44] 李为腾,李术才,王 琦,等. 深部厚顶煤巷道围岩变形破坏机制模型试验研究[J]. 岩土力学,2013,34(10):2847−2856. doi: 10.16285/j.rsm.2013.10.025 LI Weiteng,LI Shucai,WANG Qi,et al. Model test study on deformation and failure mechanism of surrounding rock in deep thick roof coal roadway[J]. Rock and Soil Mechanics,2013,34(10):2847−2856. doi: 10.16285/j.rsm.2013.10.025

[45] 余伟健,杜少华,王卫军,等. 高应力软岩近距离巷道工程的掘进扰动与稳定性[J]. 岩土工程学报,2014,36(1):57−64. doi: 10.11779/CJGE201401003 YU Weijian,DU Shaohua,WANG Weijun,et al. Excavation disturbance and stability of high stress soft rock close roadway engineering[J]. Chinese Journal of Geotechnical Engineering,2014,36(1):57−64. doi: 10.11779/CJGE201401003

[46] 韦四江,勾攀峰,于春生. 大断面破碎硐室围岩蠕变模拟及控制技术[J]. 采矿与安全工程学报,2013,30(4):489−494. WEI Sijiang,GOU Panfeng,YU Chunsheng. Creep simulation and control technology for surrounding rock of large section broken chamber[J]. Journal of Mining & Safety Engineering,2013,30(4):489−494.

[47] 赵红超,曹胜根,张科学,等. 深部油页岩巷道变形破坏机理及稳定性控制研究[J]. 采矿与安全工程学报,2012,29(2):178−184. doi: 10.3969/j.issn.1673-3363.2012.02.006 ZHAO Hongchao,CAO Shenggen,ZHANG Kexue,et al. Research on deformation and failure mechanism and stability control of deep oil shale roadway[J]. Journal of Mining & Safety Engineering,2012,29(2):178−184. doi: 10.3969/j.issn.1673-3363.2012.02.006

[48] 张 杰. 软弱巷道围岩变形破坏综合分析[J]. 岩石力学与工程学报,2011,30(S2):3428−3433. ZHANG Jie. Comprehensive analysis of deformation and failure of surrounding rock of weak roadway[J]. Chinese Journal of Rock Mechanics and Engineering,2011,30(S2):3428−3433.

[49] 袁 亮,薛俊华,刘泉声,等. 煤矿深部岩巷围岩控制理论与支护技术[J]. 煤炭学报,2011,36(4):535−543. doi: 10.13225/j.cnki.jccs.2011.04.014 YUAN Liang,XUE Junhua,LIU Quansheng,et al. Surrounding rock control theory and support technology of deep rock roadway in coal mine[J]. Journal of China Coal Society,2011,36(4):535−543. doi: 10.13225/j.cnki.jccs.2011.04.014

[50] 杨永康,季春旭,康天合,等. 大厚度泥岩顶板煤巷破坏机制及控制对策研究[J]. 岩石力学与工程学报,2011,30(1):58−67. YANG Yongkang,JI Chunxu,KANG Tianhe,et al. Study on failure mechanism and control measures of coal roadway with thick mudstone roof[J]. Chinese Journal of Rock Mechanics and Engineering,2011,30(1):58−67.

[51] 于言平. 高应力破裂岩体地压显现及其控制技术[J]. 北京科技大学学报,2009,31(5):537−541. doi: 10.13374/j.issn1001-053x.2009.05.011 YU Yanping. Ground pressure behavior of high stress fractured rock mass and its control technology[J]. Journal of Beijing University of Science and Technology,2009,31(5):537−541. doi: 10.13374/j.issn1001-053x.2009.05.011

[52] 张 华,刘 建,李 鹏,等. 深部岩巷稳定性控制方法及实例研究[J]. 岩石力学与工程学报,2008,27(S2):3913−3918. ZHANG Hua,LIU Jian,LI Peng,et al. Stability control method and case study of deep rock roadway[J]. Chinese Journal of Rock Mechanics and Engineering,2008,27(S2):3913−3918.

[53] 姜耀东,刘文岗,赵毅鑫,等. 开滦矿区深部开采中巷道围岩稳定性研究[J]. 岩石力学与工程学报,2005,24(11):1857−1862. doi: 10.3321/j.issn:1000-6915.2005.11.007 JIANG Yaodong,LIU Wengang,ZHAO Yixin,et al. Study on stability of roadway surrounding rock in deep mining in Kailuan Mining Area[J]. Chinese Journal of Rock Mechanics and Engineering,2005,24(11):1857−1862. doi: 10.3321/j.issn:1000-6915.2005.11.007

[54] 李常文,周景林,韩洪德. 组合拱支护理论在软岩巷道锚喷设计中应用[J]. 辽宁工程技术大学学报,2004,23(5):594−596. LI Changwen,ZHOU Jinglin,HAN Hongde. Application of combined arch support theory in bolting and shotcreting design of soft rock roadway[J]. Journal of Liaoning Technical University,2004,23(5):594−596.

[55] 李文平,王继成,王凯平,等. 复杂峒室群软弱破碎岩体孤立岩墙加固研究[J]. 岩石力学与工程学报,2004,23(1):79−85. doi: 10.3321/j.issn:1000-6915.2004.01.015 LI Wenping,WANG Jicheng,WANG Kaiping,et al. Study on reinforcement of isolated rock wall in weak and fractured rock mass of complex chamber group[J]. Chinese Journal of Rock Mechanics and Engineering,2004,23(1):79−85. doi: 10.3321/j.issn:1000-6915.2004.01.015

[56] 左建平,文金浩,刘德军,等. 深部巷道等强支护控制理论[J]. 矿业科学学报,2021,6(2):148−159. doi: 10.19606/j.cnki.jmst.2021.02.002 ZUO Jianping,WEN Jinhao,LIU Dejun,et al. Control theory of uniform strength support in deep roadway[J]. Journal of Mining Science and Technology,2021,6(2):148−159. doi: 10.19606/j.cnki.jmst.2021.02.002

[57] ZUO Jianping,LIU Haiyan,LIU Dejun,et al. Theoretical analysis and numerical simulation on the coupled support technology of concrete-filled steel tube and bolt-cable in deep roadway[J]. Journal of Central South University,2023,30(1):257−275. doi: 10.1007/s11771-023-5222-y

下载:

下载: