Multi-parameter fine sensing method of deformation and failure process of coal seam mining floor

-

摘要:

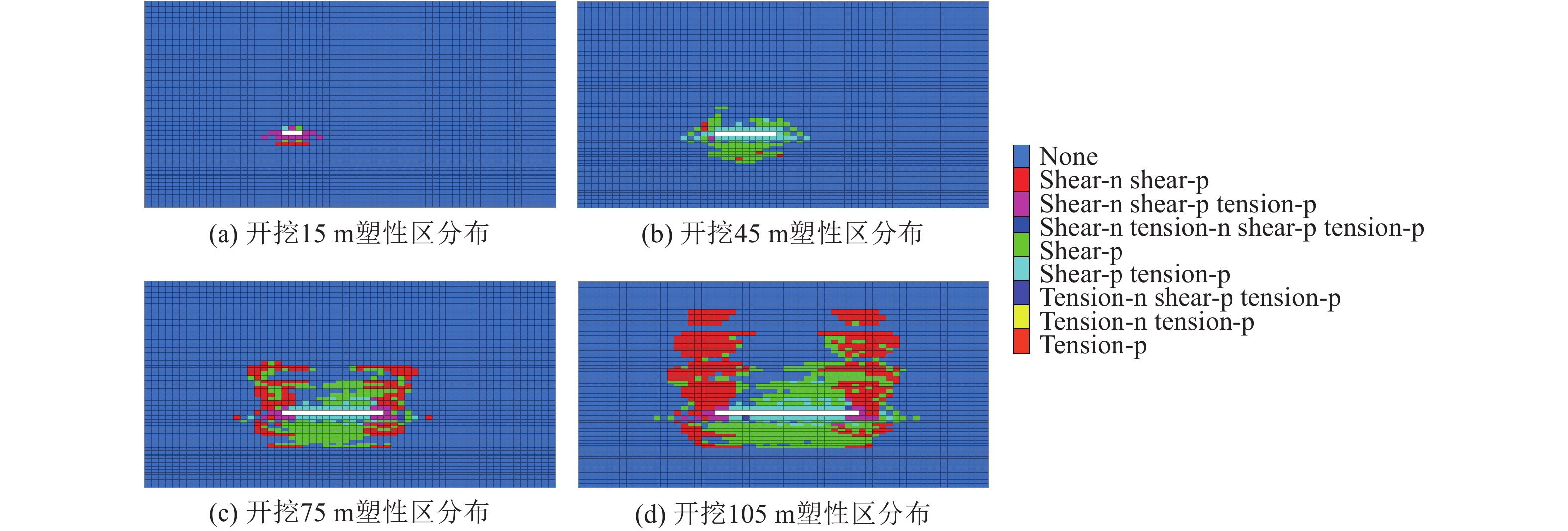

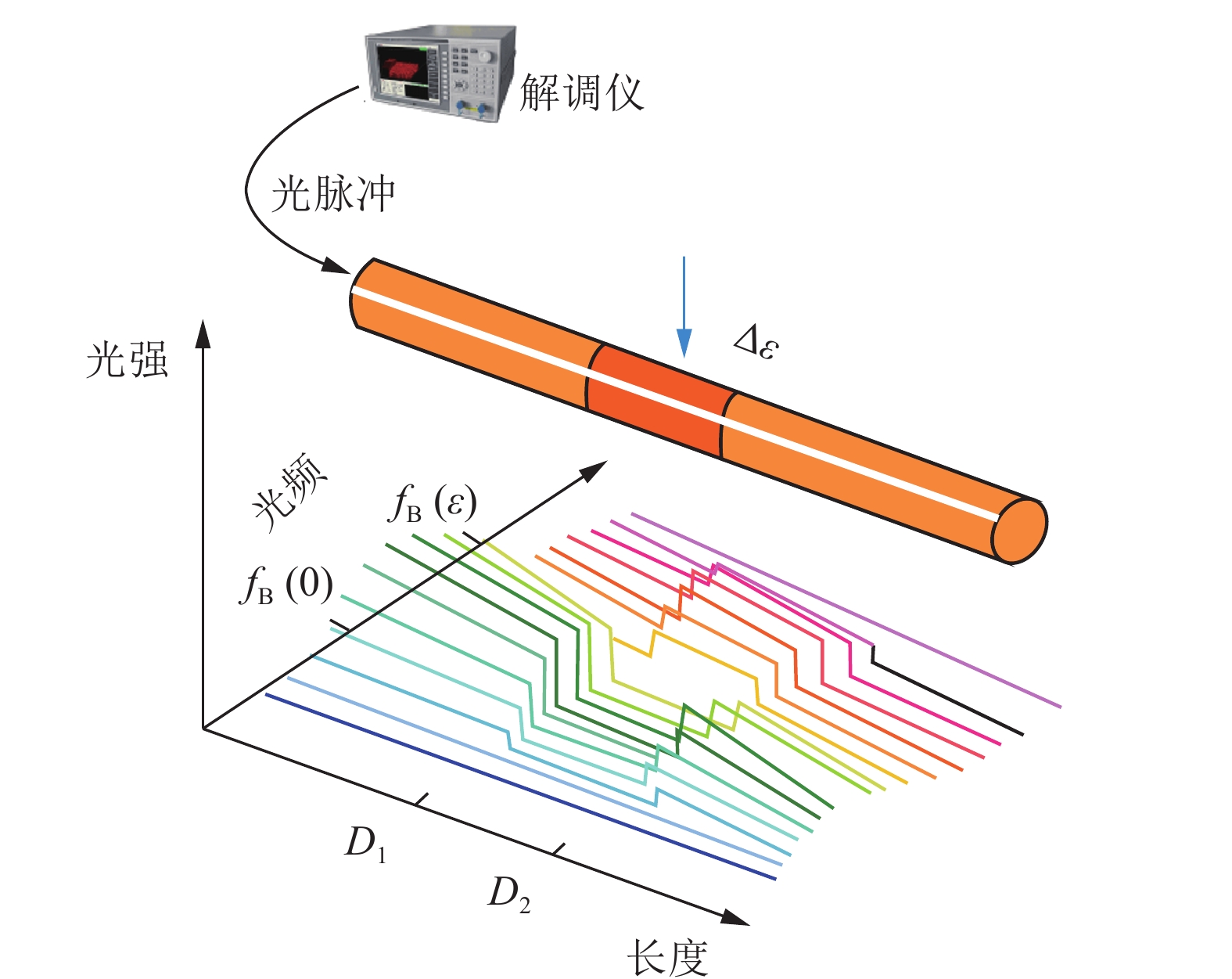

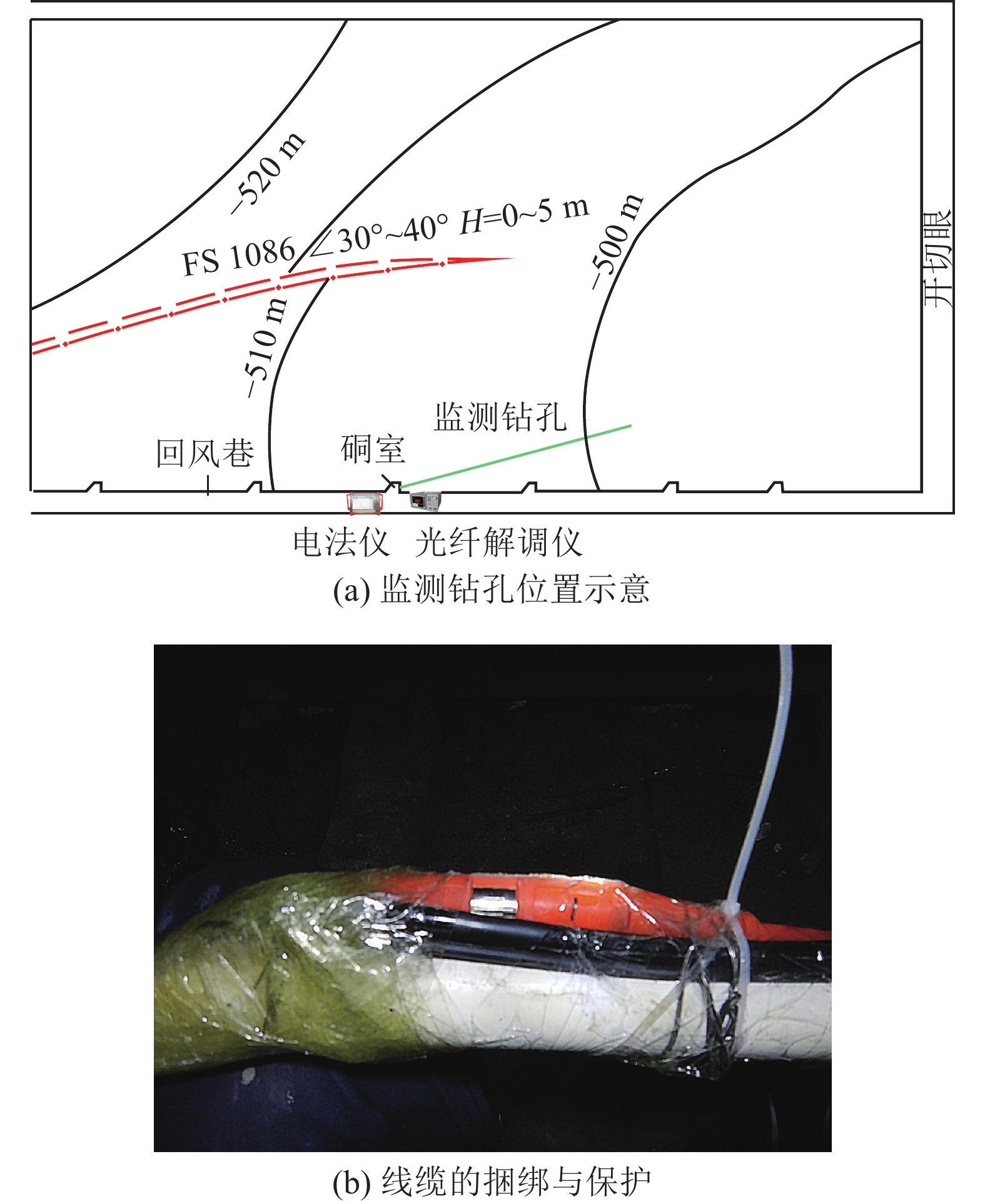

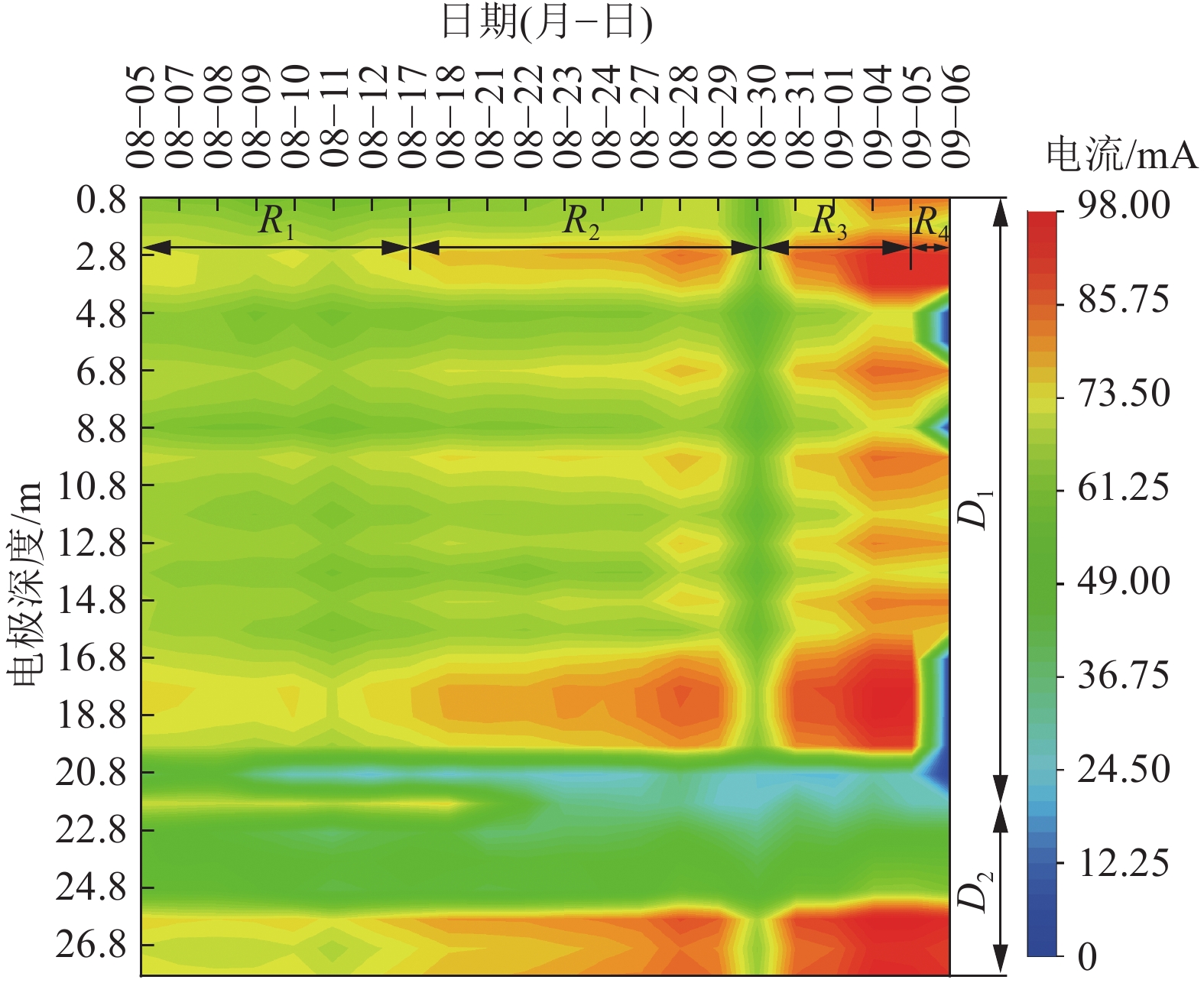

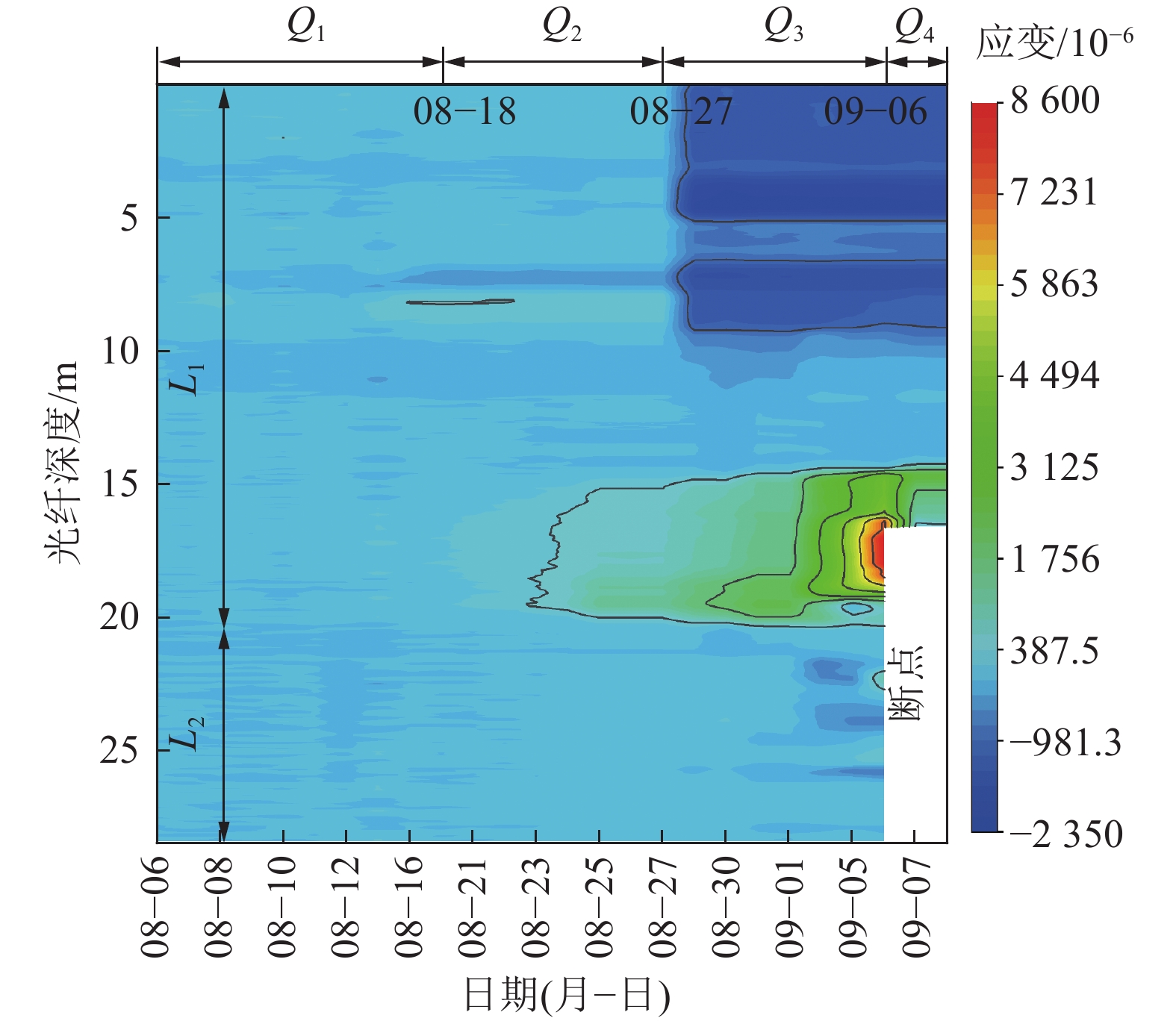

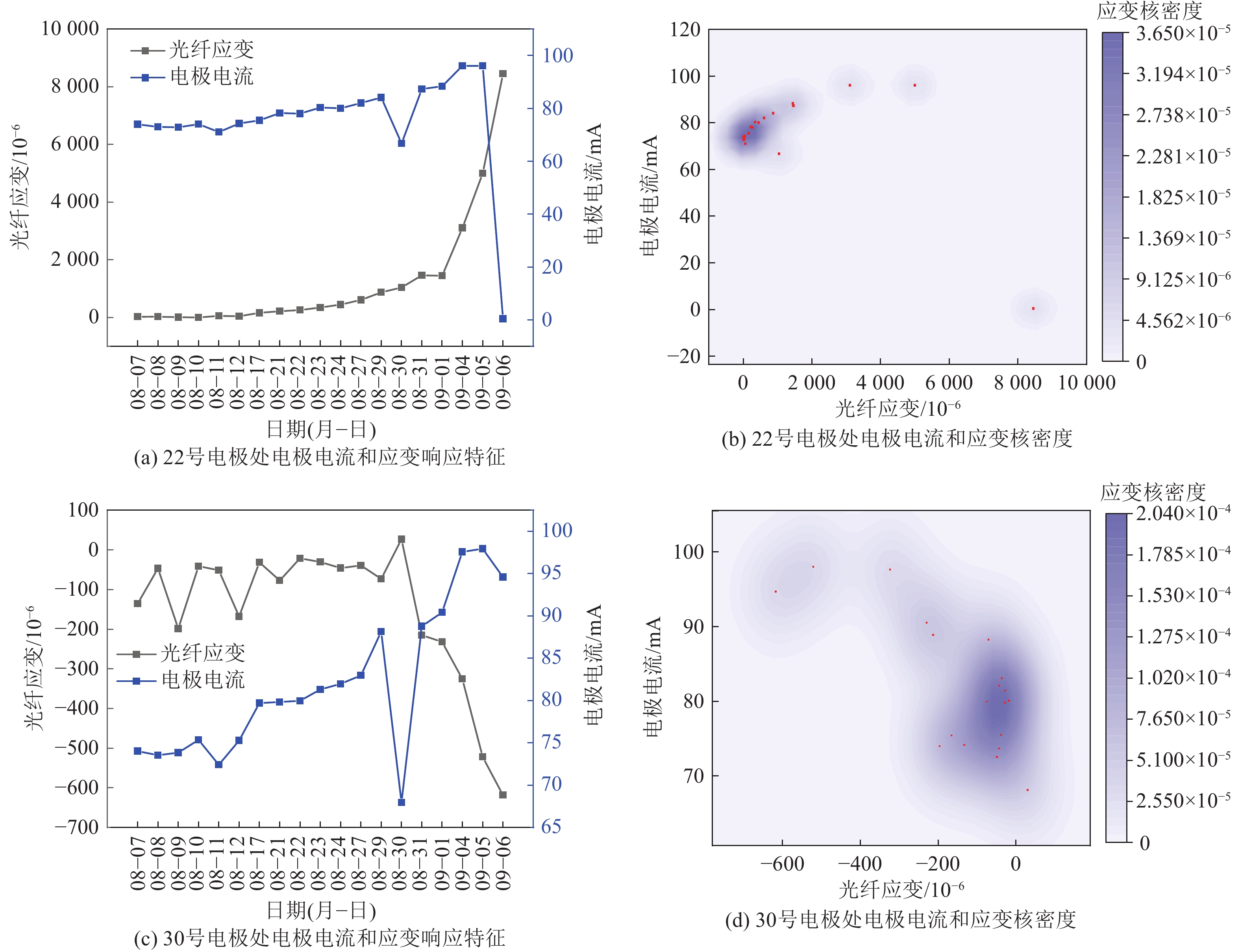

煤层采动过程中,通过测试参数感知底板变形破坏过程是采场地质保障的有效方式。利用有限差分法构建煤层采动底板破坏数值模型,获取塑性区的分布和演化特征,结果显示底板破坏深度为21 m。在煤层底板钻孔中植入电缆和分布式光纤,通过对电极电流值和光纤应变的连续采集,获得采动效应下的特征参数图谱,进一步分析底板的变形破坏程度。结果表明:电极电流的初始值在40 mA以上。随着工作面的推进电流值轻微升高,当工作面推进到孔口附近时,电流降到1 mA以下,岩层破坏;光纤测试方面,随着工作面的推进光纤应变不断增大,当工作面靠近孔口时,光纤应变峰值为8.589×10−3,之后岩层破裂,能量释放,光纤应变回弹。电极电流和光纤应变参数图谱显示底板的变形破坏过程分为4个阶段,分别为无影响阶段、微影响阶段、显著影响阶段和破坏阶段。监测数据对底板变形破坏过程起到了良好表征作用,但存在一定差异,具体表现在超前应力和破裂伊始的感知上,电极电流的响应要略早于光纤应变。电极电流的结果显示底板破坏深度为20.8 m,光纤应变的结果显示底板破坏深度为21.0 m。构建电极电流值和应变值的核密度图,对于底板浅部的监测点,数据点离散程度较大;而埋深较大的监测点受动效应影响较小,回采过程中数据点分布较为集中,离散程度较小。通过多测试参数联合感知,实现煤层采动底板变形破坏过程的精细表征和评价。

Abstract:Sensing the floor deformation and damage process by testing parameters during coal seam mining is an effective way to secure the geology of the quarry. A numerical model of coal seam mining floor failure was constructed by using the finite difference method to obtain the distribution and evolution characteristics of the plastic zone, which showed a floor failure depth of 21 m. Electric Cables and distributed optical fibers were implanted in the coal floor borehole, and the characteristic parameter profiles under the mining effect were obtained through the continuous acquisition of electrode current values and optical fiber strain values to further analyze the deformation and failure. The result showed that the initial value of electrode current was above 40 mA, and the current value increases slightly as the working face advances, and when the working face advances near the borehole, the current value dropped to less than 1 mA and the rock formation was failure; as for the fiber optic test, the fiber optic strain value increased continuously as the working face advances, and the peak fiber optic strain was 8.589×10−3 when the working face was near the monitoring borehole, after which the rock formation ruptured and the energy was released, and the fiber optic The strain value bounced back after the rock rupture and energy release. The mapping of electrode current and fiber optic strain parameters showed that the deformation and failure process of the floor was divided into four stages, namely, no impact stage, micro impact stage, significant impact stage, and failure stage. The monitoring data provided a good characterization of the deformation and failure process of the floor, but there were some differences, specifically in the perception of the overstress and the beginning of rupture, with the response of the electrode current slightly earlier than the fiber optic strain. The results of the electrode current showed that the floor failure depth was 20.8 m, and the results of the fiber optic strain showed that the floor failure depth was 21 m. The kernel density maps of electrode current values and strain values were constructed. For the monitoring points in the shallow part of the floor, the data points were more discrete; while the monitoring points in the deeper burial were less affected by the dynamic effect, and the data points were more concentrated and less discrete during the recovery process. Through the joint sensing of multiple test parameters, we can realize the fine characterization and evaluation of the deformation and failure process of the coal seam mining floor.

-

-

表 1 主采煤层顶、底岩性分布

Table 1 Lithology distribution of top and bottom of main coal seam

地质

年代岩性 层厚/m 累深/m 二

叠

系泥岩 5.0 477.7 砂质泥岩 5.6 482.7 粉砂岩 8.9 488.3 砂质泥岩 7.3 497.2 A组煤 7.4 504.5 砂质泥岩 2.0 511.9 细砂岩 5.5 513.9 砂质泥岩 4.4 519.4 泥岩 5.2 523.8 石

炭

系灰岩 2.8 529.0 细砂岩 5.2 531.8 灰岩 0.9 537.0 表 2 数值模型力学参数

Table 2 Numerical model mechanics parameters

岩层 体积模量/

GPa剪切模量/

GPa黏聚力/

MPa内摩擦角/

(°)抗拉强度/

MPa细砂岩 1.84 1.78 3.22 35 2.52 粉砂岩 2.69 1.65 2.98 34 2.38 砂质泥岩 1.21 1.36 2.45 33 2.05 煤 0.08 0.09 1.48 26 0.40 泥岩 1.08 1.24 2.05 31 1.75 灰岩 1.92 1.92 3.95 36 3.12 顶板 2.85 2.32 2.42 33 2.40 表 3 回采工作面与监测断面位置关系

Table 3 Relationship between working face and monitoring borehole location

日期(月-日) 距离/m 日期(月-日) 距离/m 日期(月-日) 距离/m 08-05 130.1 08-21 78.2 08-31 29.8 08-07 123.3 08-22 70.8 09-01 25.0 08-08 121.6 08-23 67.0 09-04 13.6 08-09 118.5 08-24 62.2 09-05 9.8 08-10 115.2 08-27 49.4 09-06 6.1 08-12 109.1 08-28 44.6 09-07 1.8 08-17 92.1 08-29 40.9 09-08 −3.2 08-18 89.1 08-30 33.9 表 4 监测点处数据极差和标准差统计

Table 4 Statistics of data range and standard deviation at monitoring points

数据来源 计算值 极差 标准差 22号电极处电流值 95.7 19.8 22号电极处应变值 8449.8 2156.5 30号电极处电流值 30.0 8.8 30号电极处应变值 645.3 174.1 -

[1] 谢和平. 深部岩体力学与开采理论研究进展[J]. 煤炭学报,2019,44(5):1283−1305. XIE Heping. Research review of the state key research development program of China: Deep rock mechanics and mining theory[J]. Journal of China Coal Society,2019,44(5):1283−1305.

[2] 彭苏萍. 我国煤矿安全高效开采地质保障系统研究现状及展望[J]. 煤炭学报, 2020, 45(7): 2331−2345. PENG Suping. Current status and prospects of research on geological assurance system for coal mine safe and high efficient mining[J]. Journal of China Coal Society, 2020, 45(7), 2331−2345.

[3] GUO Jinshuai,MA Liqiang,ZHANG Dongsheng. Management and utilization of high-pressure floor-confined water in deep coal mines[J]. Mine Water and the Environment,2019,38(4):780−797. doi: 10.1007/s10230-019-00639-9

[4] ZHANG Yujun. Mechanism of water inrush of a deep mining floor based on coupled mining pressure and confined pressure[J]. Mine Water and the Environment,2021,40(2):366−377. doi: 10.1007/s10230-020-00743-1

[5] ZHAO Jinhai,CHEN Juntao,ZHANG Xinguo,et al. Distribution characteristics of floor pore water pressure based on similarity simulation experiments[J]. Bulletin of Engineering Geology and the Environment,2020,79(9):4805−4816. doi: 10.1007/s10064-020-01835-6

[6] 朱术云,姜振泉,侯宏亮. 相对固定位置采动煤层底板应变的解析法及其应用[J]. 矿业安全与环保,2008,35(1):18−20. ZHU Shuyun,JIANG Zhenquan,HOU Hongliang. Analytical method and its application of floor strain of mining coal seam in relative fixed position[J]. Mining safety and Environmental Protection,2008,35(1):18−20.

[7] 孟祥瑞,徐铖辉,高召宁,等. 采场底板应力分布及破坏机理[J]. 煤炭学报,2010,35(11):1832−1836. MENG Xiangrui,XU Chenghui,GAO Zhaoning,et al. Stress distribution and failure mechanism of stope floor[J]. Journal of China Coal Society,2010,35(11):1832−1836.

[8] 鲁海峰,姚多喜,胡友彪,等. 水压影响下煤层底板采动破坏深度弹性力学解[J]. 采矿与安全工程学报,2017,34(3):452−458. LU Haifeng,YAO Duoxi,HU Youbiao,et al. Elastic mechanical solution of coal seam floor failure depth under water pressure[J]. Journal of Mining and Safety Engineering,2017,34(3):452−458.

[9] 王连国,韩 猛,王占盛,等. 采场底板应力分布与破坏规律研究[J]. 采矿与安全工程学报,2013,30(3):317−322. WANG Lianguo,HAN Meng,WANG Zhansheng,et al. Study on stress distribution and failure law of stope floor[J]. Journal of Mining and Safety Engineering,2013,30(3):317−322.

[10] 张保良,郭惟嘉,张新国,等. 煤层开采底板承压水导升模拟试验系统研制与应用[J]. 煤炭学报,2016,41(8):2057−2062. ZHANG Baoliang,GUO Weijia,ZHANG Xinguo,et al. Development and application of analogue testing system for floor confined water rise in coal mining[J]. Journal of China Coal Society,2016,41(8):2057−2062.

[11] 王进尚,姚多喜,黄 浩. 煤矿隐伏断层递进导升突水的临界判据及物理模拟研究[J]. 煤炭学报,2018,43(7):2014−2020. doi: 10.13225/j.cnki.jccs.2017.1252 WANG Jinshang,YAO Duoxi,HUANG Hao. Critical criterion and physical simulation research on progressive ascending water inrush in hidden faults of coal mines[J]. Journal of China Coal Society,2018,43(7):2014−2020. doi: 10.13225/j.cnki.jccs.2017.1252

[12] 李杨杨,张士川,孙煕震,等. 煤层采动底板突水演变过程可视化试验平台研制与试验研究[J]. 煤炭学报,2021,46(11):3515−3524. LI Yangyang,ZHANG Shichuan,SUN Xizhen,et al. Development and experimental study on visualization test platform for water inrush evolution process of coal seam mining floor[J]. Journal of China Coal Society,2021,46(11):3515−3524.

[13] 张玉军,张志巍,肖 杰,等. 承压水体上煤层底板下位隐伏断层采动突水机制研究[J]. 煤炭科学技术,2023,51(2):283−291. ZHANG Yujun,ZHANG Zhiwei,XIAO Jie,et al. Study on mining water inrush mechanism of buried fault under coal seam floor above confined water body[J]. Coal Science and Technology,2023,51(2):283−291.

[14] 马文著,周晓敏,谭 帅. 承压水上煤层底板破坏特征研究:以山西义棠煤矿为例[J]. 采矿与岩层控制工程学报,2020,2(3):23−31. MA Wenzhu,ZHOU Xiaomin,TAN Shuai. Study on failure characteristics of coal seam floor above confined water: a case study of Shanxi Yitang Coal Mine[J]. Journal of Mining and Strata Control Engineering,2020,2(3):23−31.

[15] 孙庆先,牟 义,杨新亮. 红柳煤矿大采高综采覆岩“两带”高度的综合探测[J]. 煤炭学报,2013,38(S2):283−286. SUN Qingxian,MOU Yi,YANG Xinliang. Comprehensive detection of “Two Zones” height of overlying rock with large mining height in Hongliu Coal Mine[J]. Journal of China Coal Society,2013,38(S2):283−286.

[16] WU Rongxin,HU Zean,HU Xiongwu. Principle of using borehole electrode current method to monitor the overburden stratum failure after coal seam mining and its application[J]. Journal of Applied Geophysics,2020,179:104111. doi: 10.1016/j.jappgeo.2020.104111

[17] LIU Chao,LI Shugang,CHENG Cheng. Activation characteristics analysis on concealed fault in the excavating coal roadway based on microseismic monitoring technique[J]. International Journal of Mining Science and Technology,2017,27(5):883−887. doi: 10.1016/j.ijmst.2017.06.023

[18] 张平松,刘盛东,吴荣新. 地震波CT技术探测煤层上覆岩层破坏规律[J]. 岩石力学与工程学报,2004,13(15):2510−2513. ZHANG Pingsong,LIU Shengdong,WU Rongxin. Observation of overburden failure of coal seam by CT of seismic wave[J]. Chinese Journal of Rock Mechanics and Engineering,2004,13(15):2510−2513.

[19] LIU Shuai,YANG Ke,TANG Chunan. Rupture and migration law of disturbed overburden during slicing mining of steeply dipping thick coal seam[J]. Advances in Civil Engineering,2020,4:1−11.

[20] LI X Y, ZHANG L M, JIANG S H, et al. Assessment of slope stability in the monitoring parameter space[J]. Journal of Geotechnical and Geoenvironmental Engineering 2016, 142(7): 04016029.

[21] 吴荣新,吴茂林,曹建富,等. 厚松散层薄基岩坚硬顶板工作面覆岩破坏电法监测[J]. 煤炭科学技术,2020,48(1):239−245. WU Rongxin,WU Maolin,CAO Jianfu,et al. Electrical monitoring of overburden failure in hard roof working face with thick loose layer and thin bedrock[J]. Coal Science and Technology,2020,48(1):239−245.

[22] 张平松,刘 畅,欧元超,等. 准格尔煤田特厚煤层开采底板破坏特征综合测试研究[J]. 煤田地质与勘探,2021,49(1):263−269. ZHANG Pingsong,LIU Chang,OU Yuanchao,et al. Comprehensive testing research on floor damage characteristics of mining extra-thick seam in Jungar Coalfield[J]. Coal Geology & Exploration,2021,49(1):263−269.

[23] LIU Chang, ZHANG Pingsong, SHANG Jianxuan, et al. Comprehensive research on the failure evolution of the floor in upper mining of deep and thick coal seam[J]. Journal of Applied Geophysics, 2022, 206: 1−11.

[24] 张平松,刘盛东,吴荣新,等. 采煤面覆岩变形与破坏立体电法动态测试[J]. 岩石力学与工程学报,2009,28(9):1870−1875. ZHANG Pingsong,LIU Shengdong,WU Rongxin,et al. Dynamic detection of overburden deformation and failure in mining workface by 3D resistivity method[J]. Chinese Journal of Rock Mechanics and Engineering,2009,28(9):1870−1875.

[25] SHI Bin,ZHANG Dan,ZHU Honghu,et al. DFOS applications to geo-engineering monitoring[J]. Photonic Sensors,2021,11(2):158−186. doi: 10.1007/s13320-021-0620-y

[26] 刘志民,刘希高,杜毅博,等. 电法测量接地电阻计算方法及影响因素仿真分析[J]. 煤田地质与勘探,2015,43(2):96−100. doi: 10.3969/j.issn.1001-1986.2015.02.020 LIU Zhimin,LIU Xigao,DU Yibo,et al. Calculation method and analysis of influence factors of the grounding resistance in electrical measurement[J]. Coal Geology & Exploration,2015,43(2):96−100. doi: 10.3969/j.issn.1001-1986.2015.02.020

下载:

下载: