Study on optimization of well pattern and well spacing for CBM development:Taking Daning Block as an example

-

摘要:

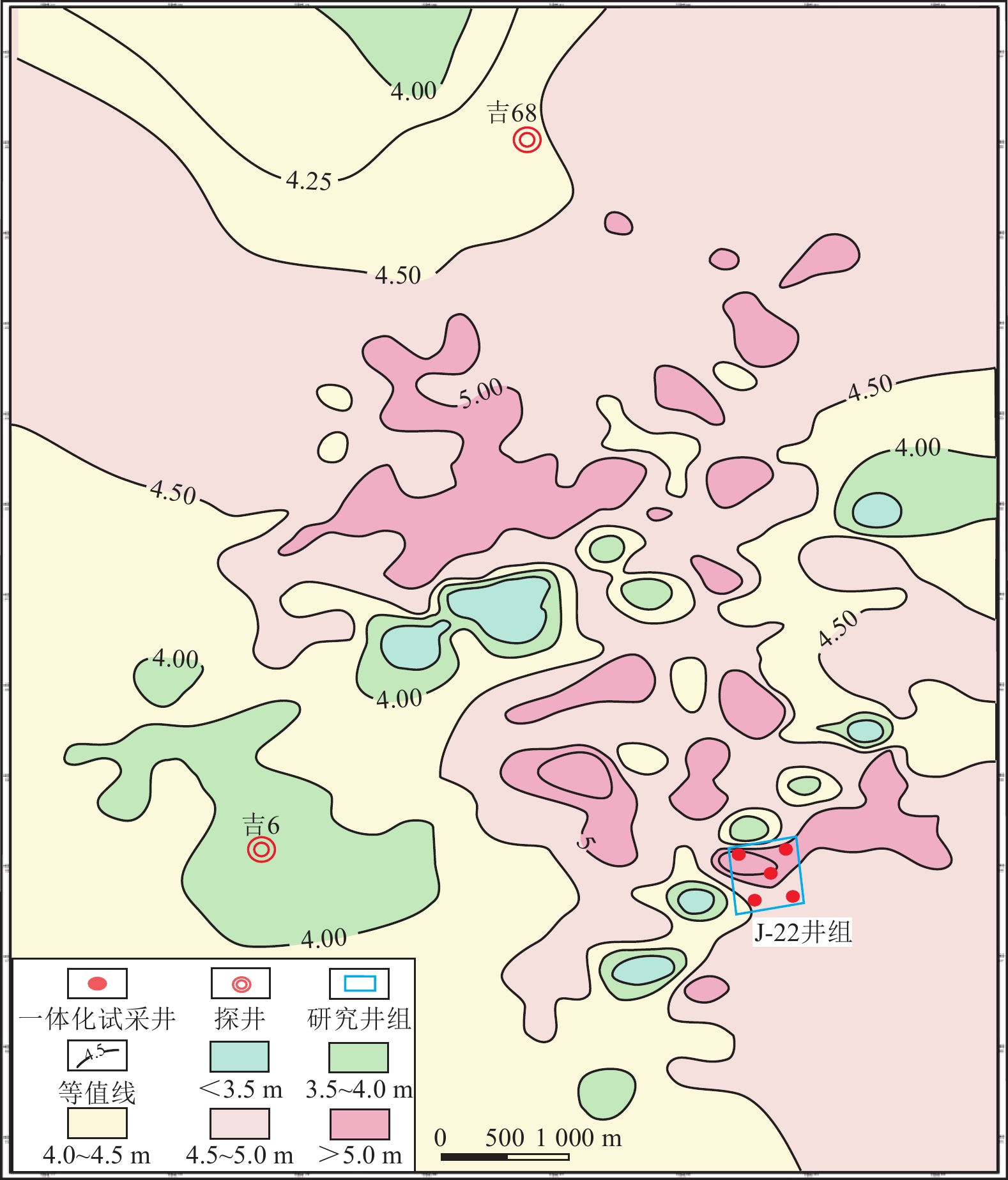

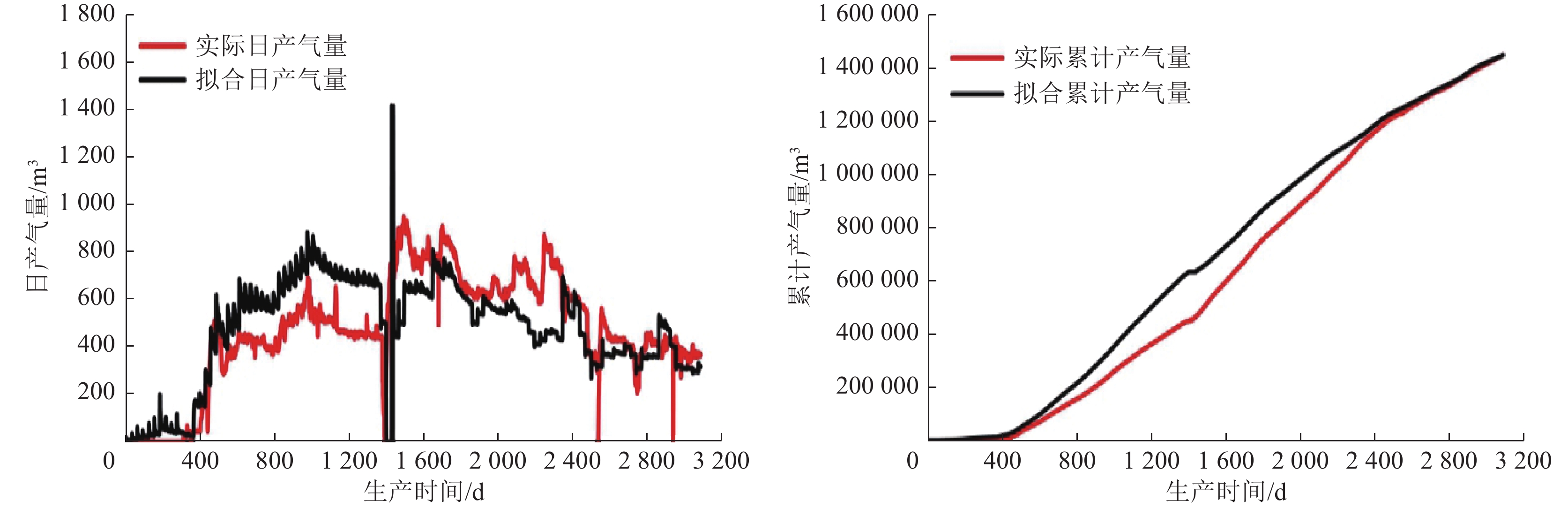

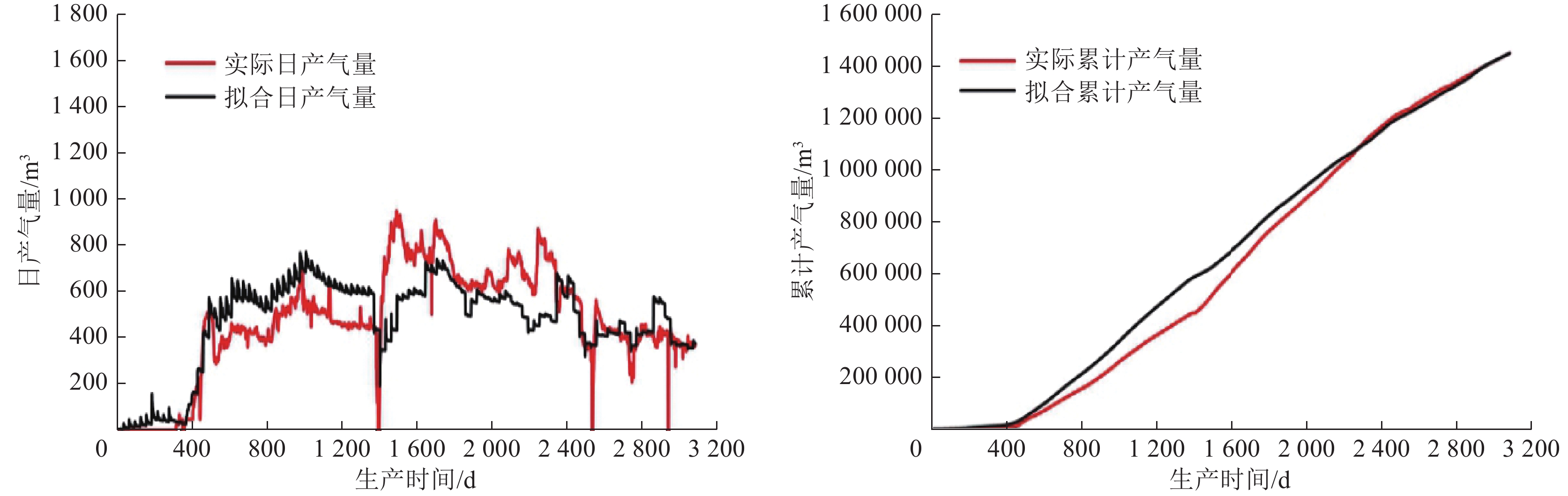

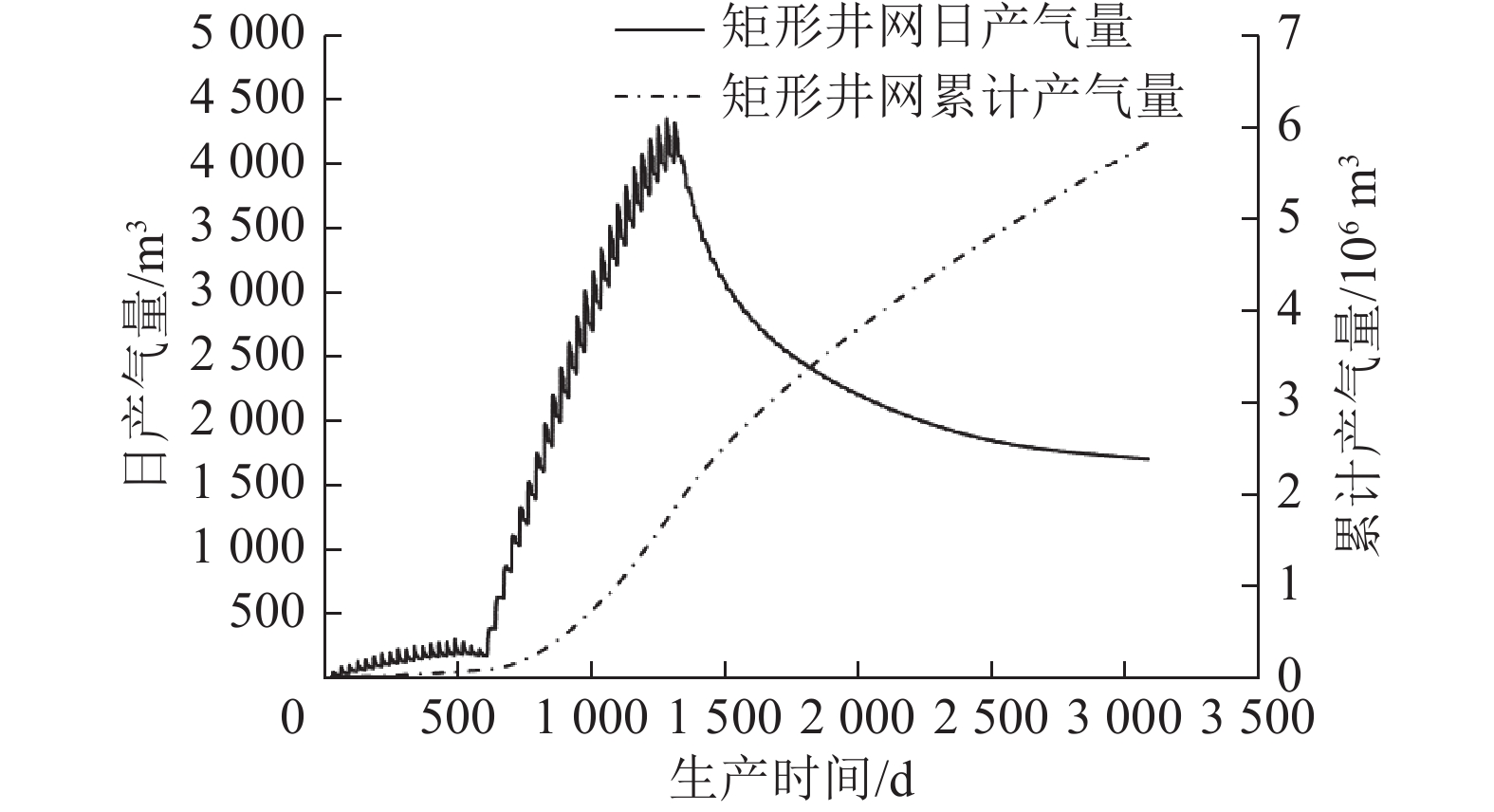

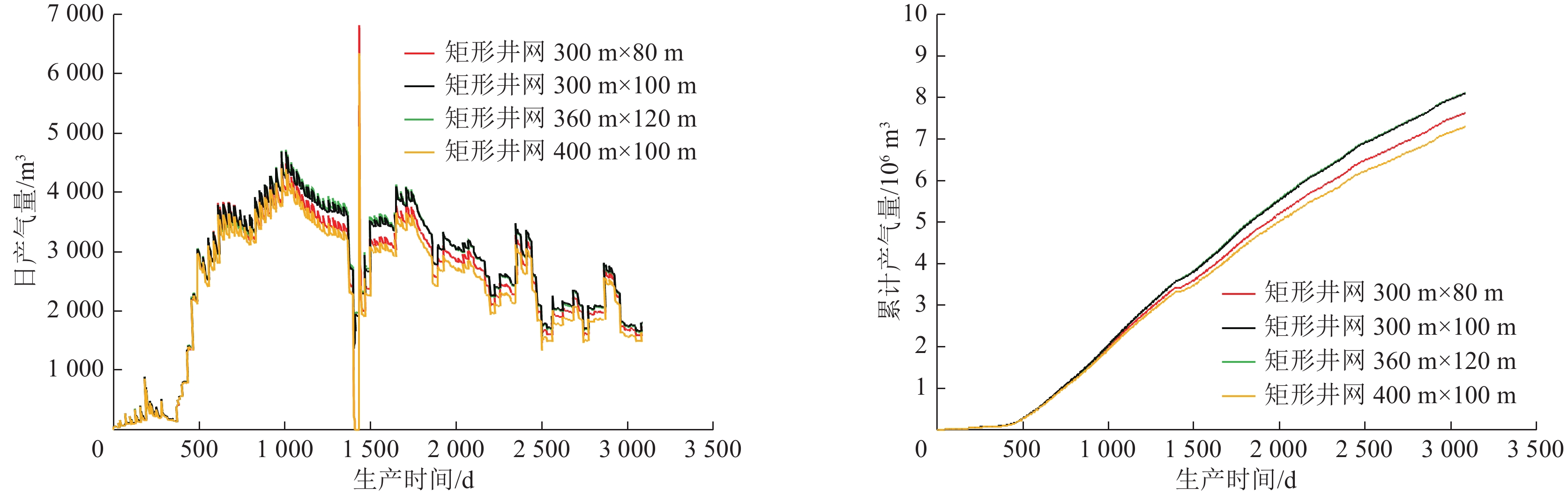

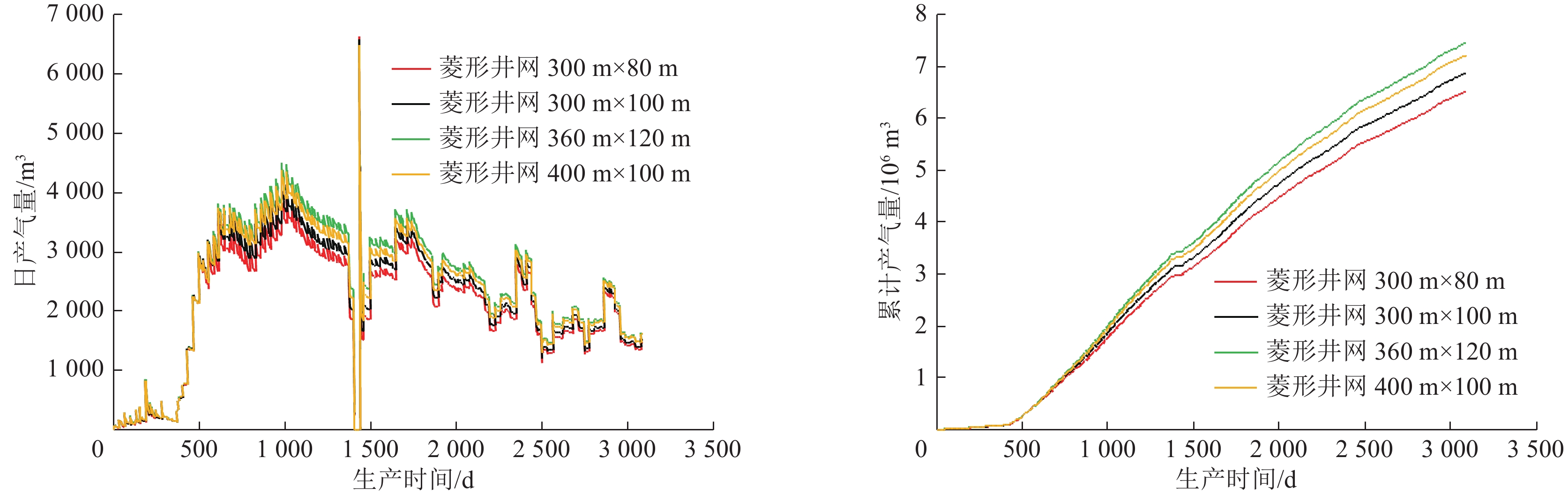

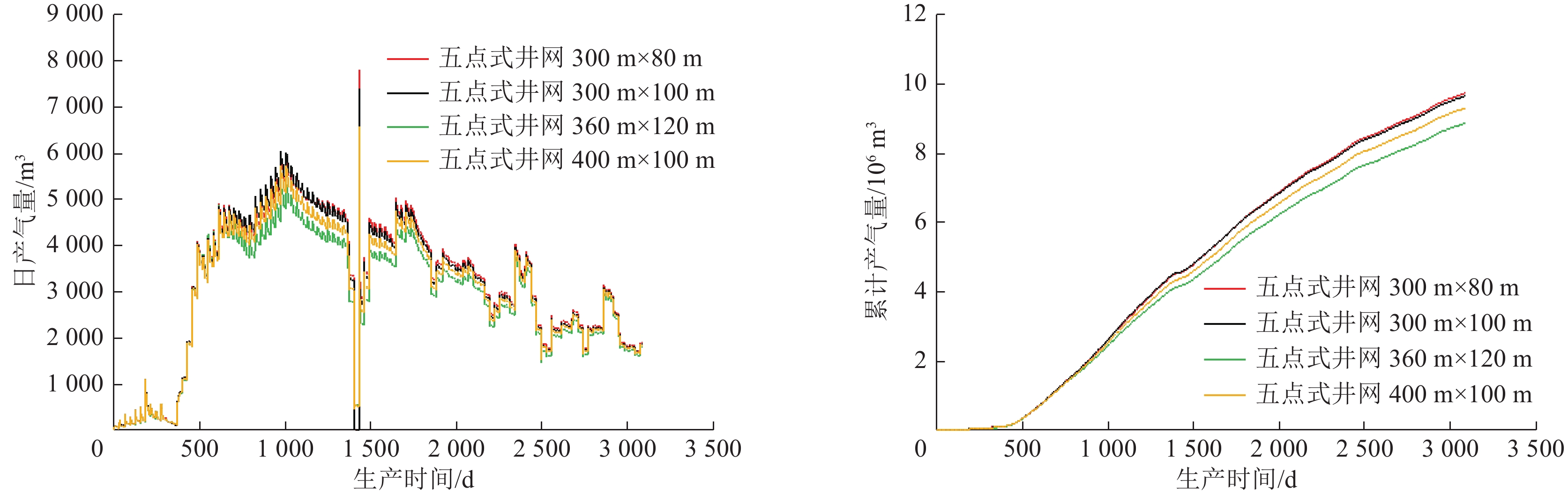

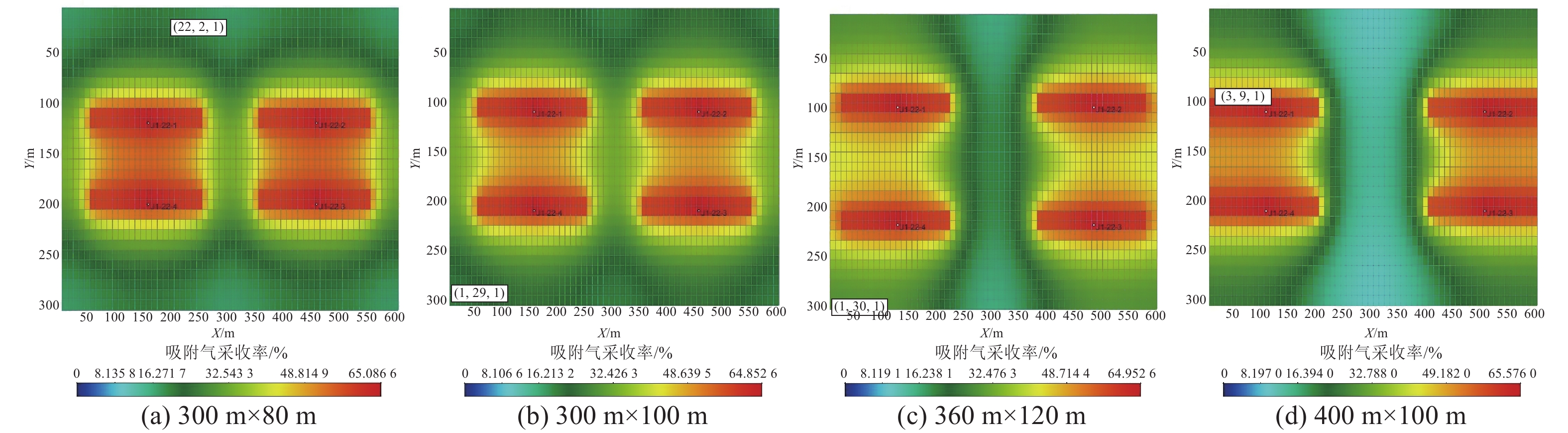

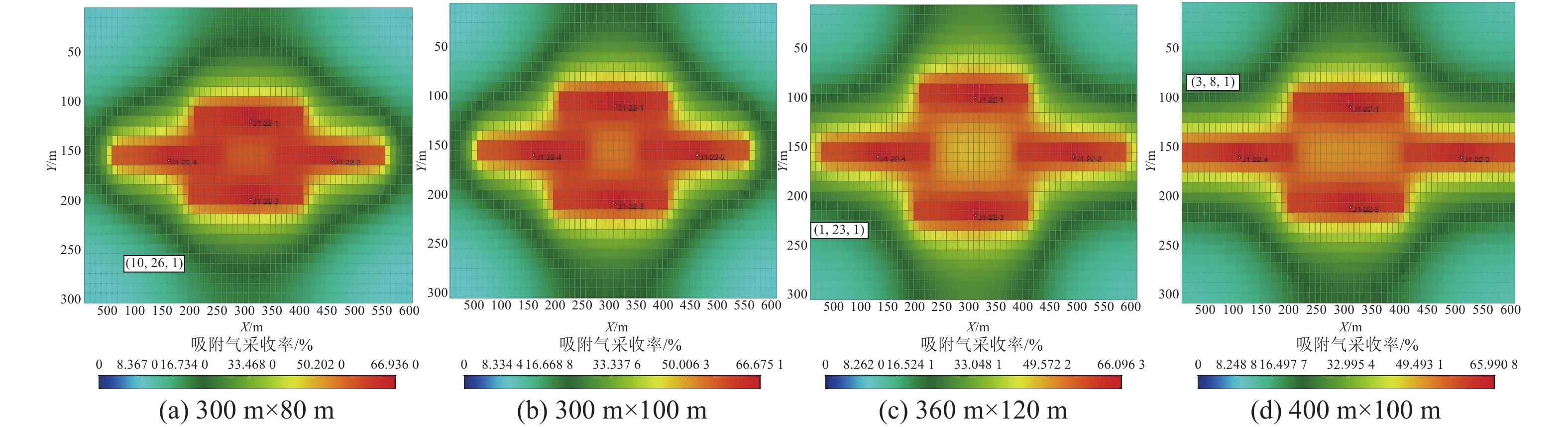

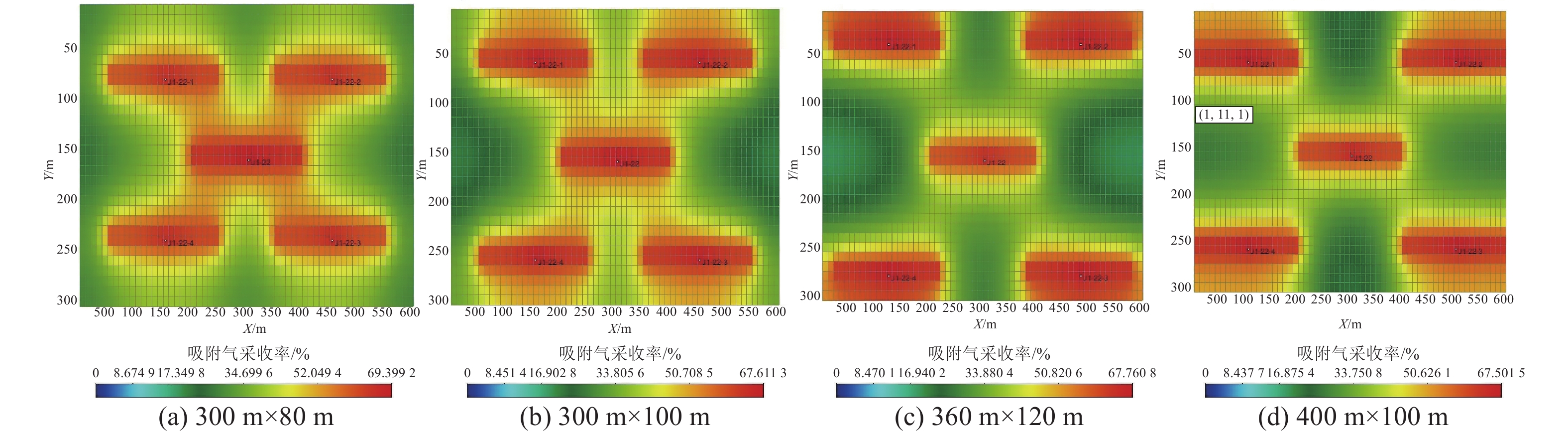

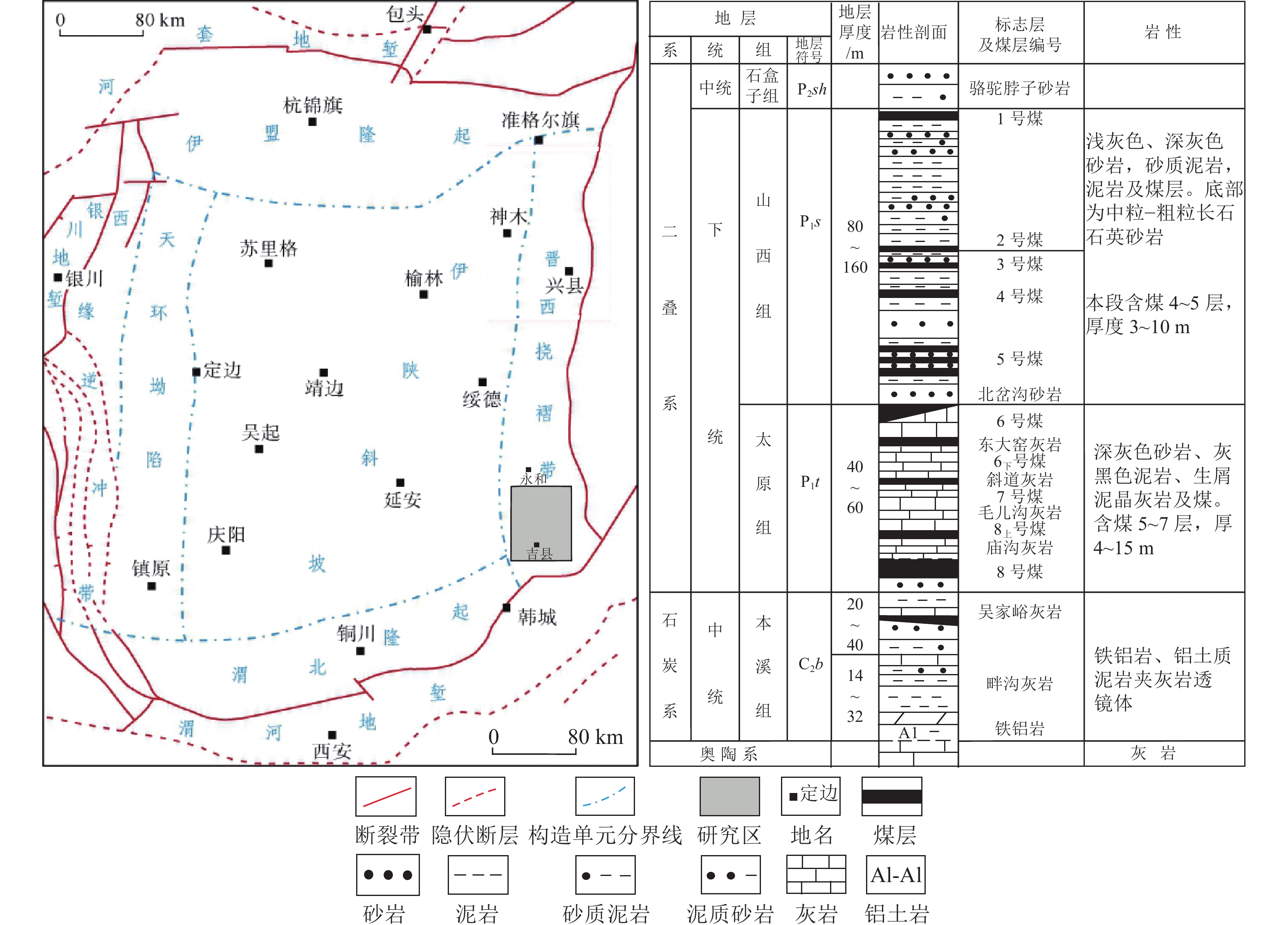

煤层气井网优化设计与部署是煤层气开发方案编制的关键部分,合理的井网部署不仅可以优化煤层气产量,还可降低煤层气开发成本,提高经济效益。针对这一问题,以鄂尔多斯盆地大宁区块为研究对象,系统分析了研究区煤层条件及煤储层特征,确定了煤层气开发适用的井型和井网方位。结果显示:大宁区块山西组5号煤层具有厚度大,结构简单,含气量高,渗透率低等特点,煤层顶底板封隔性好,资源潜力巨大。煤层气开发井型应以定向井为主,水平井为辅,配合相应的井网进行规模开发,井网方位为NE66°;利用煤层气产能数值模拟软件COMET3,对大宁区块当前采用的井网样式和井排距进行产能预测,模拟评价了不同井网样式和不同井排距开放方案下的产能。数值模拟结果表明:当前大宁区块煤层气开发所采用的井网样式和井排距,在排采3 086 d后,煤层气采收率仅为19.03%,煤层气资源动用程度低。在井排距为300 m×80 m和400 m×100 m(即井排距比为4∶1)时五点式井网的单井累计产气量最大,在井排距为300 m×100 m和360 m×120 m(即井排距比为3∶1)时矩形井网单井累计产气量最大,据此认为大宁区块在设置4∶1的井排距比时应选用五点式井网,设置3∶1的井排距比时应选用矩形井网,井网样式和井排距经过优选后,煤层气采收率分别达44.18%和36.85%,煤层气资源动用程度大幅度提高。

Abstract:CBM well pattern optimization design and deployment is a key part of CBM development plan formulation. Reasonable well pattern deployment can not only optimize CBM production, but also reduce CBM development costs and improve economic benefits. In response to this problem, taking Daning block in the Ordos Basin as the research object, the coal seam conditions and coal reservoir characteristics in the study area were systematically analyzed, and the suitable well type and well pattern orientation for CBM development were determined. The results show that the No.5 coal seam of Shanxi Formation in the Daning block has the characteristics of large thickness, simple structure, high gas content and low permeability. The well type of CBM development should be mainly directional wells, supplemented by horizontal wells, with the corresponding well pattern for large-scale development, and the well pattern orientation is NE66°; using the CBM productivity numerical simulation software COMET3, the current use of the Daning block is analyzed. The productivity was predicted based on the well pattern and well spacing, and the productivity under the open scheme of different well pattern and well spacing was simulated and evaluated. Numerical simulation results show that the CBM recovery rate is only 19.03% after

3086 d of well pattern and well spacing used in the current CBM development in the Daning block, indicating a low degree of CBM resource production. When the well spacing is 300 m×80 m and 400 m×100 m (that is, the well spacing ratio is 4∶1), the cumulative gas production of a single well in the five-spot well pattern is the largest. That is, when the well row spacing ratio is 3∶1), the cumulative gas production of a single well in the rectangular well pattern is the largest. Therefore, it is considered that the five-point well pattern should be selected when setting the well row spacing ratio of 4∶1 in the Daning block, and the 3∶1 Rectangular well pattern should be selected for the well spacing ratio of 1. After the well pattern and well spacing are optimized, the CBM recovery rate reaches 44.18% and 36.85% respectively, and the CBM resource production degree is greatly improved.-

Keywords:

- CBM /

- Daning block /

- COMET3 /

- productivity simulation /

- well pattern optimization

-

-

表 1 历史拟合参数可调性

Table 1 Adjustability of historical fitting parameters

调整幅度较大参数 调整幅度较小参数 确定参数 裂隙渗透率 含气量 初始条件 裂隙孔隙率 等温吸附曲线 储层构造 气−水相对渗透率曲线 解吸时间 厚度 裂缝半长 含水层性质 气−水的PVT参数 表皮系数 井孔生产指数 压缩系数 毛管压力 表 2 历史拟合前后主要参数对比

Table 2 Comparison table of main parameters before and after history matching

模型参数 初始值 拟合值 变化率/% 初始数据来源 J-22 J-22-2 J-22 J-22-2 J-22 J-22-2 储层压力/MPa 9.44 9.47 9.44 9.47 0 0.00 排采数据 渗透率/10−3 μm2 0.008 0.027 0.13 0.07 1525 159.30 测井资料 孔隙度/% 3.29 2.80 2.4 1.94 −27.1 31.00 测井资料 表皮系数 −1.42 −1.42 −1.72 −1.78 −21.1 −25.40 邻井试井资料 兰氏体积/(m3·t−1) 24.03 26.00 26 26.00 8.2 0.00 试验资料 兰氏压力/MPa 2.020 2.20 2.2 2.20 8.9 0.00 试验资料 解吸压力/MPa 4.14 6.71 4.14 6.71 0 0.00 试验资料 裂缝孔隙率/% 60.00 4.00 55 3.80 −8.3 −5.00 邻井试井资料 裂缝渗透率/10−3 μm2 30.00 40.00 25 48.00 −16.7 20.00 邻井试井资料 表 3 不同井网样式和井排距总累计产气量与单井累计产气量对比

Table 3 Comparison of the total cumulative gas production of different well pattern and well spacing and the cumulative gas production of a single well

井网样式 井距×排距/( m× m) 300 ×80 300×100 360×120 400×100 300×300 井网累计产气量

/m3五点式 9 733 472 9 653 390 8 866 629 9 305 845 4 423 519 菱形 6 505 448 6 858 600 7 442 008 7 208 799 5 791 646 矩形 7 631 998 8 109 732 8 119 016 7 300 382 5 822 511 单井累计产气量

/m3五点式 1 946 694 1 930 678 1 773 326 1 861 169 884 704 菱形 1 626 362 1 714 650 1 860 502 1 802 200 1 447 912 矩形 1 908 000 2 027 433 2 029 754 1 825 096 1 455 628 -

[1] 赵 欣,姜 波,徐 强,等. 煤层气开发井网设计与优化部署[J]. 石油勘探与开发,2016,43(1):84−90. ZHAO Xin,JIANG Bo,XU Qiang,et al. Well pattern designated deployment for CBM development[J]. Petroleum Exploration and Development,2016,43(1):84−90.

[2] 孟召平,张 昆,杨焦生,等. 沁南东区块煤储层特征及煤层气开发井网距优化[J]. 煤炭学报,2018,43(9):2525−2533. MENG Zhaoping,ZHANG Kun,YANG Jiaosheng,et al. Characteristics of lump coal reservoir and optimization of well spacing for CBM development in Eastern Qin nan [J] Journal of China Coal Society,2018,43 (9):2525−2533

[3] 王晓梅,张 群,张培河,等. 煤层气储层数值模拟研究的应用[J]. 天然气地球科学,2004,15(6):664−668. Wang Xiaomei,ZHANG Qun,ZHANG Peihe ,et al. Application of numerical simulation of CBM reservoirs[J]. Natural Gas Geoscience,2004,15(6):664−668.

[4] 王 宁,王运海,程 翠,等. 数值模拟技术在煤层气开发井网设计中的应用—以鄂尔多斯盆地延川南区块为例[J]. 油气藏评价与开发,2014,4(6):61−65. WANG Ning,WANG Yunhai,CHENG Cui ,et al. Application of numerical simulation technology in well pattern design for CBM development—taking the south Yan chuan block in the Ordos Basin as an example[J]. Reservoir Evaluation and Development,2014,4(6):61−65.

[5] 印薇薇,张海峰,苏 羽. 潘庄区块煤层气开发井网优化数值模拟研究[J]. 中国煤层气,2022,19(3):7−11. doi: 10.3969/j.issn.1672-3074.2022.03.002 YIN Weiwei,ZHANG Haifeng,SU Yu. Numerical simulation study of well pattern optimization for CBM development in Pan zhuang block[J]. China Coalbed Methane,2022,19(3):7−11. doi: 10.3969/j.issn.1672-3074.2022.03.002

[6] 郭 晨,秦 勇,韦重韬. 基于COMET3软件的煤储层数值模拟方法[J]. 中国煤炭地质,2010,23(1):18−23. GUO Chen,QIN Yong,WEI Chongtao. Numerical simulation method of coal reservoir based on COMET3 software[J]. China Coal Geology,2010,23(1):18−23.

[7] 史 进,吴晓东,韩国庆,等. 煤层气开发井网优化设计[J]. 煤田地质与勘探,2011,39(6):20−23. SHI Jin,WU Xiaodong,HAN Guoqing,et al. Optimization design of CBM well grid patter[J]. Coal Geology & Exploration,2011,39(6):20−23.

[8] 关之朕,张松航,唐书恒,等. 煤层气开发井网密度和井距优化研究—以韩城北区块为例[J]. 煤炭科学技术,2022,23(9):1−11. GUAN Zhizhen,ZHANG Songhang ,TANG Shuheng,et al. Optimization of well pattern density and well spacing for CBM development: taking HAN cheng North block as an example [J]. Coal Science and Technology,2022,23(9):1−11.

[9] 杨秀春,徐凤银,王虹雅,等. 鄂尔多斯盆地东缘煤层气勘探开发历程与启示[J]. 煤田地质与勘探,2022,50(3):30−41. YANG Xiuchun,XU Fengyin,WANG Hongya,et al. Exploration and development process of CBM in eastern margin of Ordos Basin and its enlightenment[J]. Coal Geology & Exploration,2022,50(3):30−41.

[10] 牟 宣,王 科,姚晓莉. 大宁−吉县地区煤层气成因分析[J]. 中国煤层气,2016,13(2):26−30. MU Xuan,WANG Ke,YAO Xiaoli. Origin of CBM in Da ning-Ji xian area[J]. China Coalbed Methane,2016,13(2):26−30.

[11] 李贵山,于振锋,杨晋东,等. 沁水盆地郑庄区块煤层气水平井钻井体系优化[J]. 煤炭科学技术,2023,51(4):118−126. doi: 10.13199/j.cnki.cst.2021-0670 LI Guishan,YU Zhenfeng,YANG Jindong,et al. Optimization of drilling system for CBM horizontal wells in Zhengzhuang Block of Qinshui Basin[J]. Coal Science and Technology,2023,51(4):118−126. doi: 10.13199/j.cnki.cst.2021-0670

[12] 李奇贤,许 江,彭守建,等. 多压力系统气藏合采物理模拟研究进展评述[J]. 煤炭科学技术,2023,51(9):149−159. LI Qixian,XU Jiang,PENG Shoujian,et al. Review on the progress for physical simulation for gas reservoirs co-production in multi-pressure system[J]. Coal Science and Technology,2023,51(9):149−159.

[13] 石军太,李相方,张冬玲,等. 煤层气直井开发井网适应性优选[J]. 煤田地质与勘探,2012,40(2):28−30. SHI Juntai,LI Xiangfang,Zhang Dongling,et al. Optimal adaptation of well network for CBM direct well development[J]. Coal Geology & Exploration,2012,40(2):28−30.

[14] LIU Y ,WANG F ,TANG H ,et al. Well type and pattern optimization method based on fine numerical simulation in coal-bed methane reservoir[J]. Environmental Earth Sciences,2015,73(10):5877−5890.

[15] 刘亚然,毕彩芹,单衍胜,等. 六盘水松沙地区煤层气地质特征及勘探潜力分析[J]. 中国煤炭地质,2018,30(12):15−20,47. LIU Yaran,BI Caiqin,SHAN Yansheng,et al. Analysis on geological characteristics and exploration potential of coalbed methane in Songsha area of Liupanshui[J]. China Coal Geology,2018,30(12):15−20,47.

[16] 康永尚,邓 泽,皇甫玉慧,等. 中煤阶煤层气高饱和—超饱和带的成藏模式和勘探方向[J]. 石油学报,2020,41(12):1555−1566. KANG Yongshang,DENG Ze,HUANGFU Yuhui,et al. Accumulation model and exploration direction of medium-rank coalbed methane highly saturated-supersaturated zone[J]. Chinese Journal of Petroleum,2020,41(12):1555−1566.

[17] 刘世奇, 高 德, 桑树勋, 等. 不同粒度构造煤的视电阻率特征[J]. 煤炭科学技术,2022,50(12):162−169. LIU Shiqi, GAO Deyi, SANG Shuxun, et al. Characteristics of apparent resistivity of coals with different particlesizes[J]. Coal Science and Technology,2022,50(12):162−169.

[18] 刘川庆,朱卫平,夏 飞,等. 鄂尔多斯盆地大宁—吉县区块煤层气水平井分段压裂实践[J]. 天然气工业,2018,38(11):112−117. LIU Chuanqing,ZHU Weiping,XIA Fei,et al. Staged fracturing practice in horizontal wells of coalbed methane in Daning-Jixian block,Ordos Basin[J]. Natural Gas Industry,2018,38(11):112−117.

[19] BAKER M A,MAZUMDER S,SHARMA H,et al. Well design and well spacing optimisation in unconventional plays[A]. SPE Asia Pacific Oil and Gas Conference and Exhibition[C]. Society of Petroleum Engineers,2012.

[20] Jerrald L Saulsberry,Paul S Schafer,Richard A Schraufnagel. A guide to coalbed methane reservoir engineering [M]. Chicago:Gas Research Institute,1996.

[21] 李晓龙,张红强,姜在炳. 基于CBM-SIM 的煤层气井网优化设计[J]. 煤矿安全,2017,48(12):157−160. LI Xiaolong,ZHANG Hongqiang,JIANG Zaibing. Coalbed methane well pattern optimization design based on CBM-SIM[J]. Safety in Coal Mines,2017,48(12):157−160.

[22] YOUNG G B C. Computer modeling and simulation of coalbed methane resources[J]. International Journal of Coal Geology,1998,35(1/4):369−379.

[23] 王之朕,张松航,唐书恒,等. 煤层气开发井网密度和井距优化研究−以韩城北区块为例[J]. 煤炭科学技术,2023,51(3):148−157. doi: 10.13199/j.cnki.cst.2022-0477 WANG Zhizhen,ZHANG Songhang,TANG Shuheng,et al. Study on well pattern density and well spacing of coalbed methane development: taking Hanchengbei Block as an example[J]. Coal Science and Technology,2023,51(3):148−157. doi: 10.13199/j.cnki.cst.2022-0477

[24] 桑浩田,桑树勋,周效志,等. 沁水盆地南部煤层气井生产历史拟合与井网优化研究[J]. 山东科技大学学报(自然科学版),2011,30(4):58−65. SANG Haotian,SANG Shuxun,ZHOU Xiaozhi,et al. Research on production history matching and well pattern optimization of coalbed methane wells in southern Qinshui Basin[J]. Journal of Shandong University of Science and Technology (Natural Science Edition),2011,30(4):58−65 .

[25] 李 丹,苏现波. 煤与煤层气资源开发全过程阶段划分及其开发效果评价[J]. 煤炭科学技术,2023,51(3):137−147. LI Dan,SU Xianbo. Stage division and development effect evaluation of whole process of coal and coalbed methane resources development[J]. Coal Science and Technology,2023,51(3):137−147.

[26] 赵 雯,朱炎铭,张晓莉,等. 煤层气井历史拟合评述[J]. 中国煤层气,2010,7(3):20−25. ZHAO Wen,ZHU Yanming,ZHANG Xiaoli,et al. Review on history matching of coalbed methane wells[J]. China Coalbed Methane,2010,7(3):20−25.

下载:

下载: