Division method and fractal characteristics of overburden gas slow permeability zone in up-dip fully mechanized face of inclined thick coal seam

-

摘要:

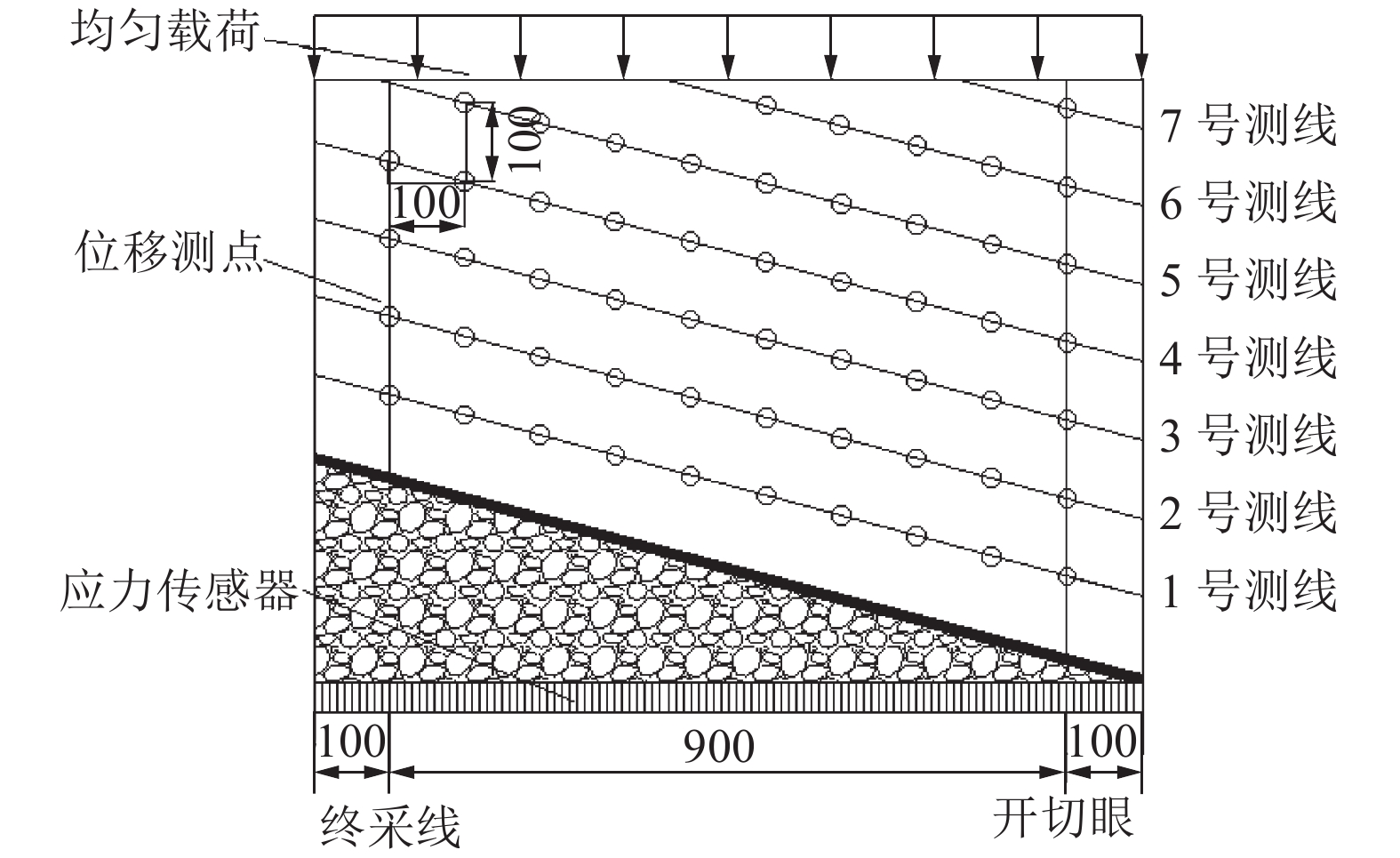

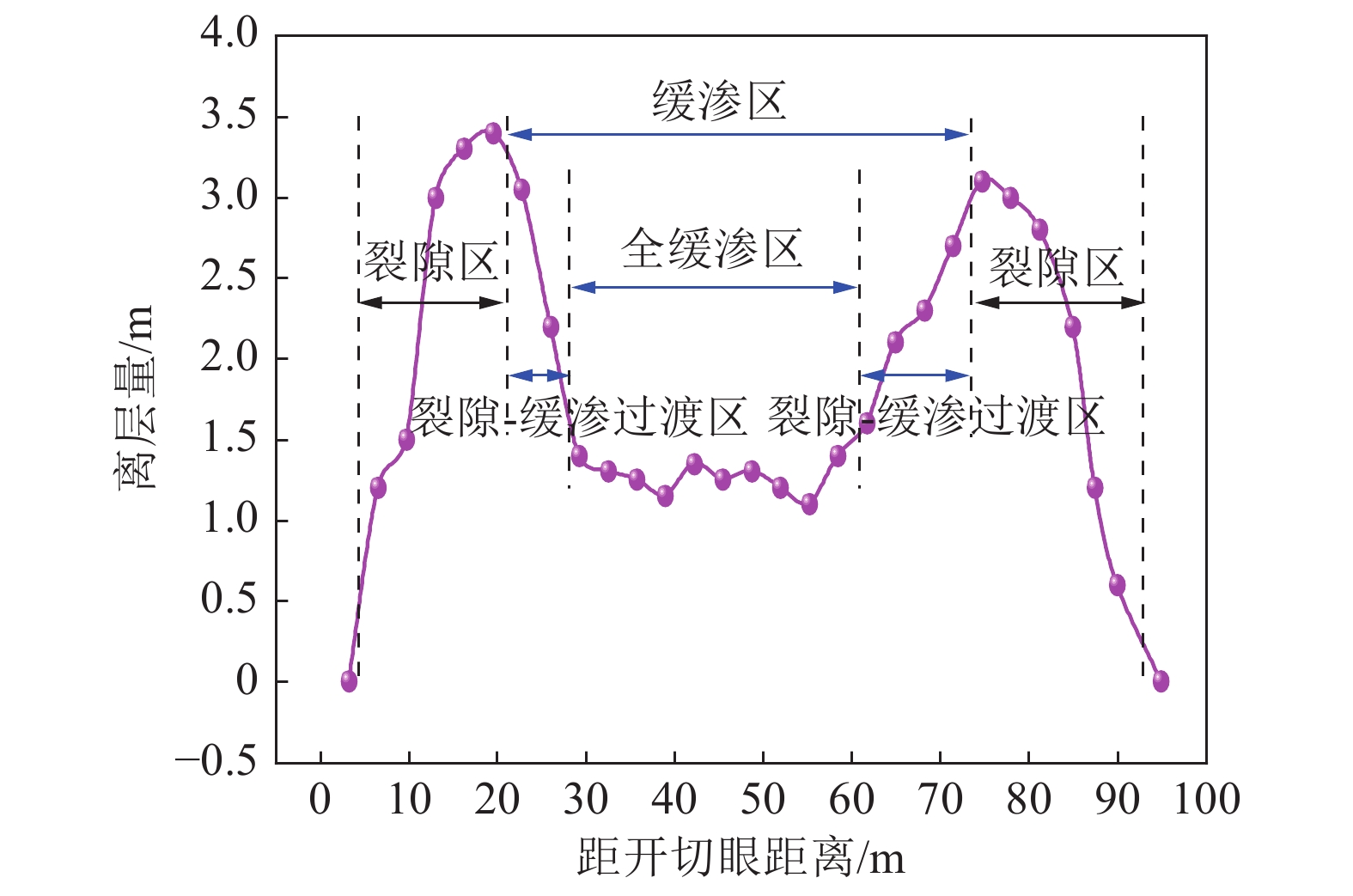

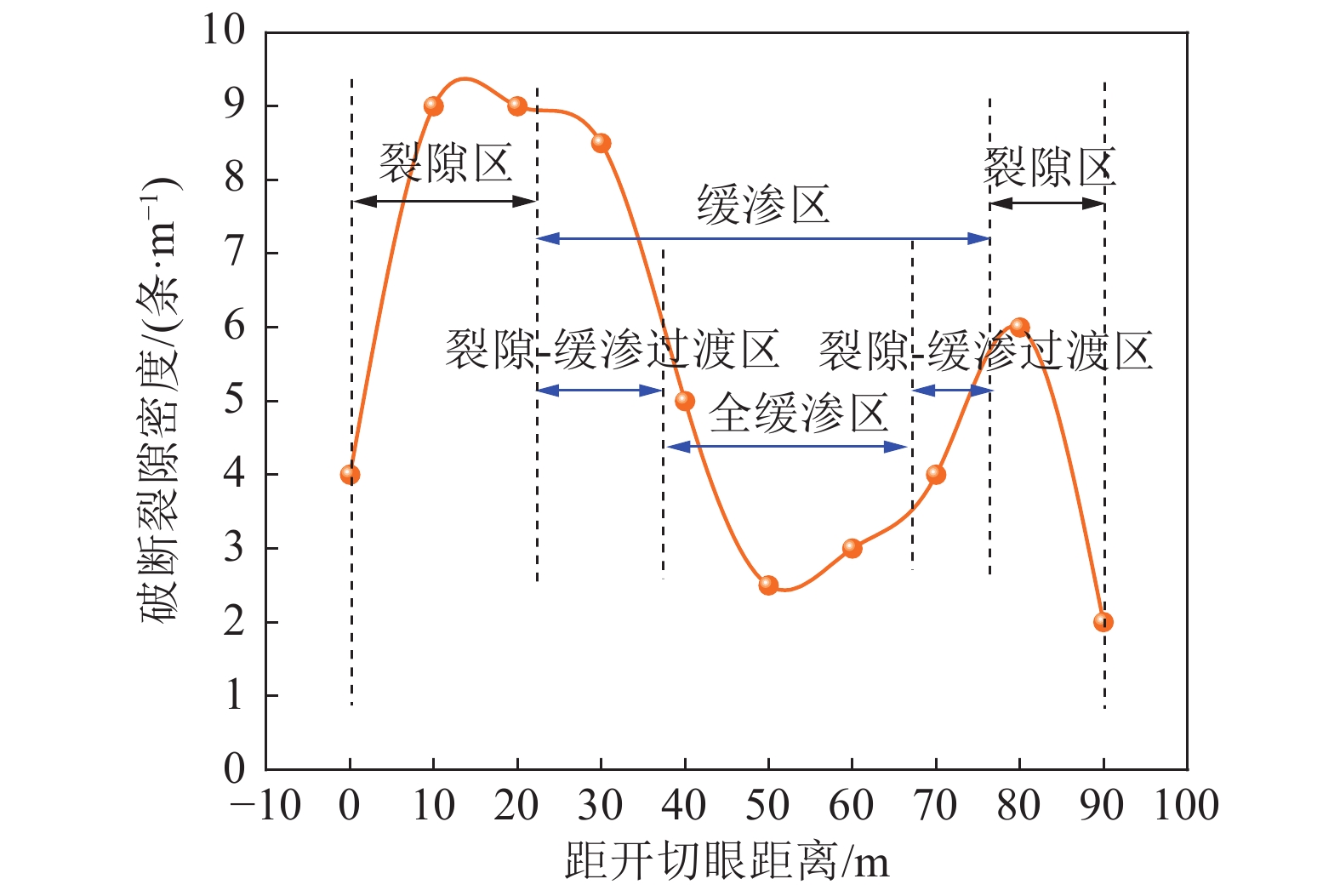

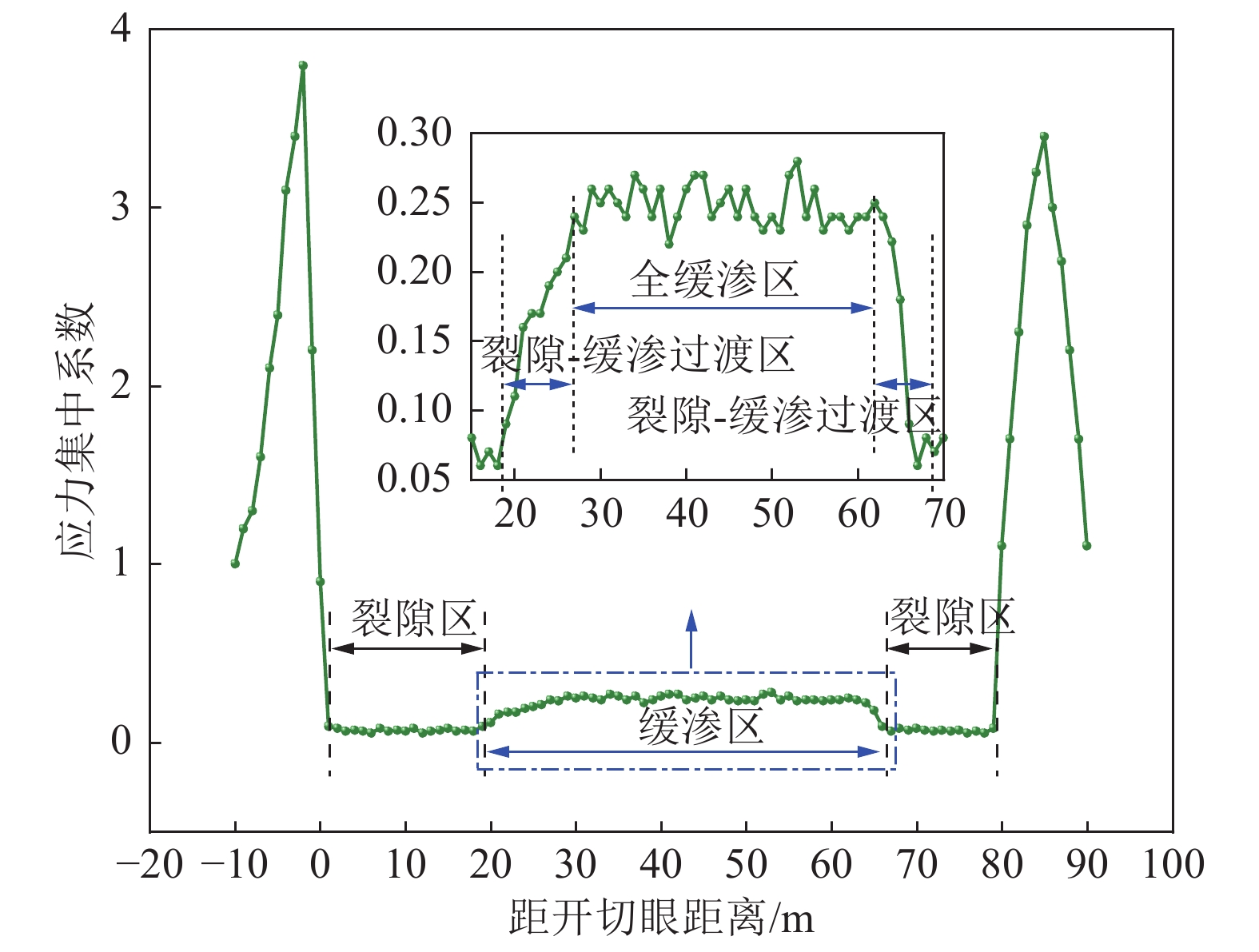

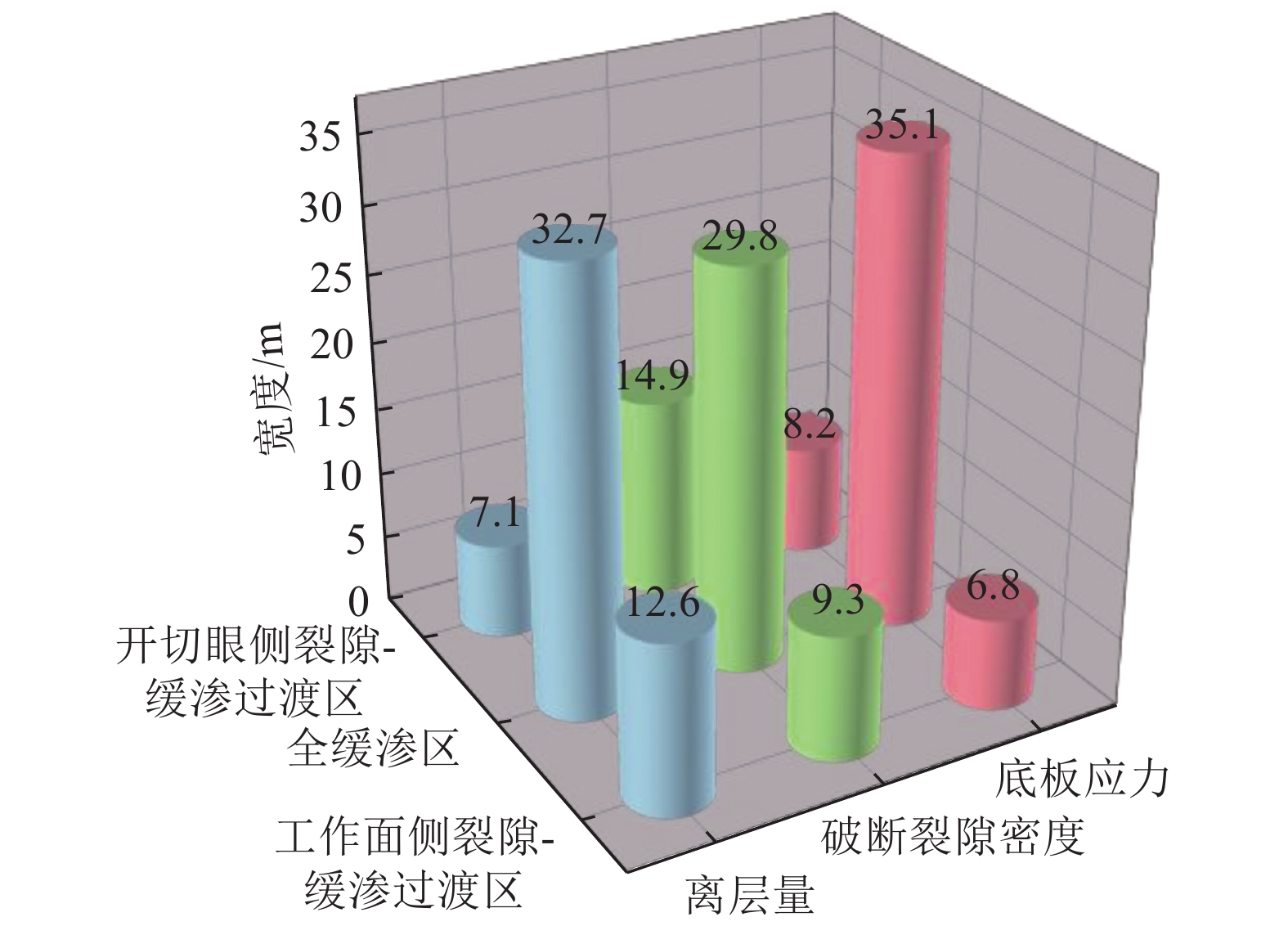

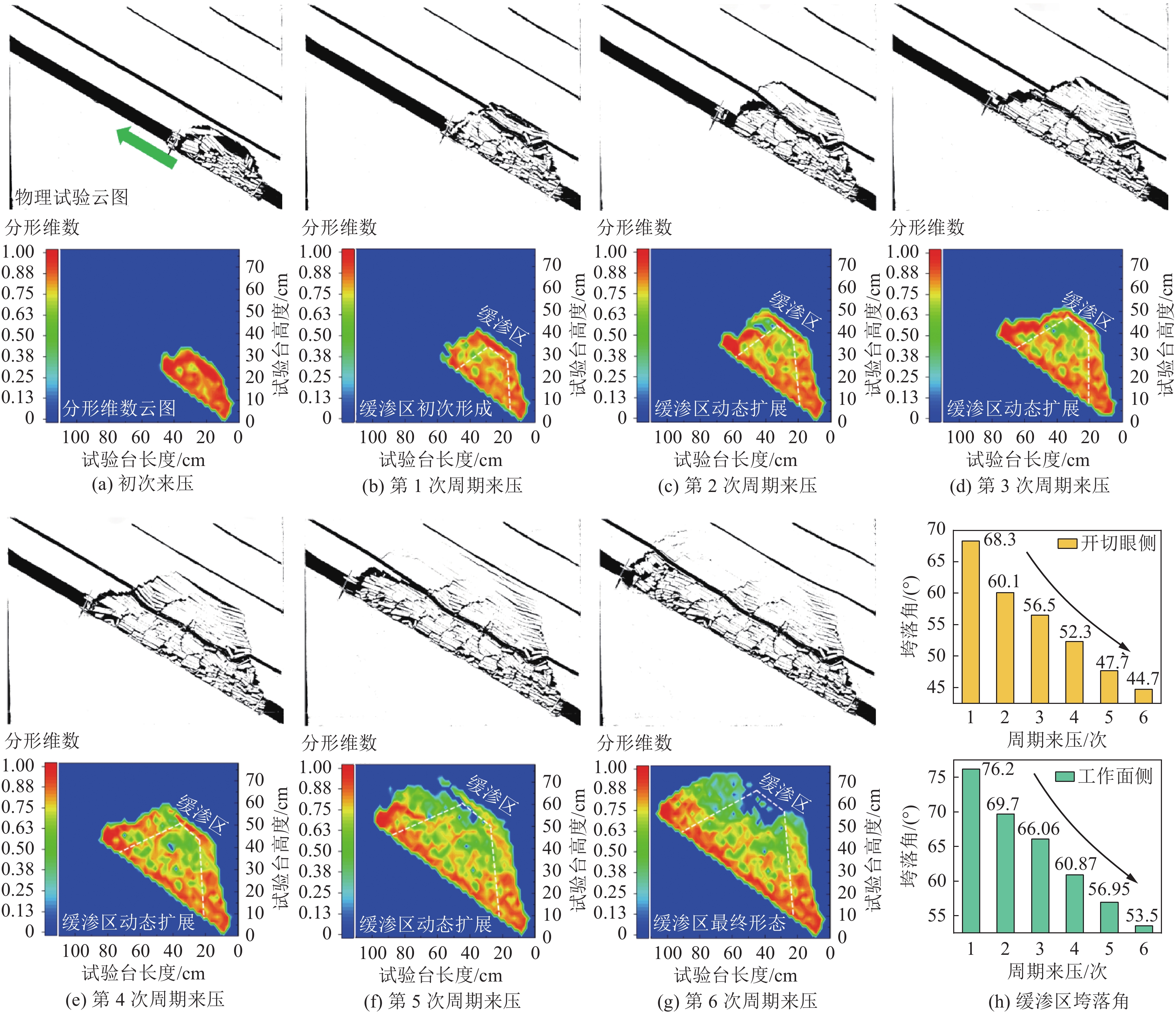

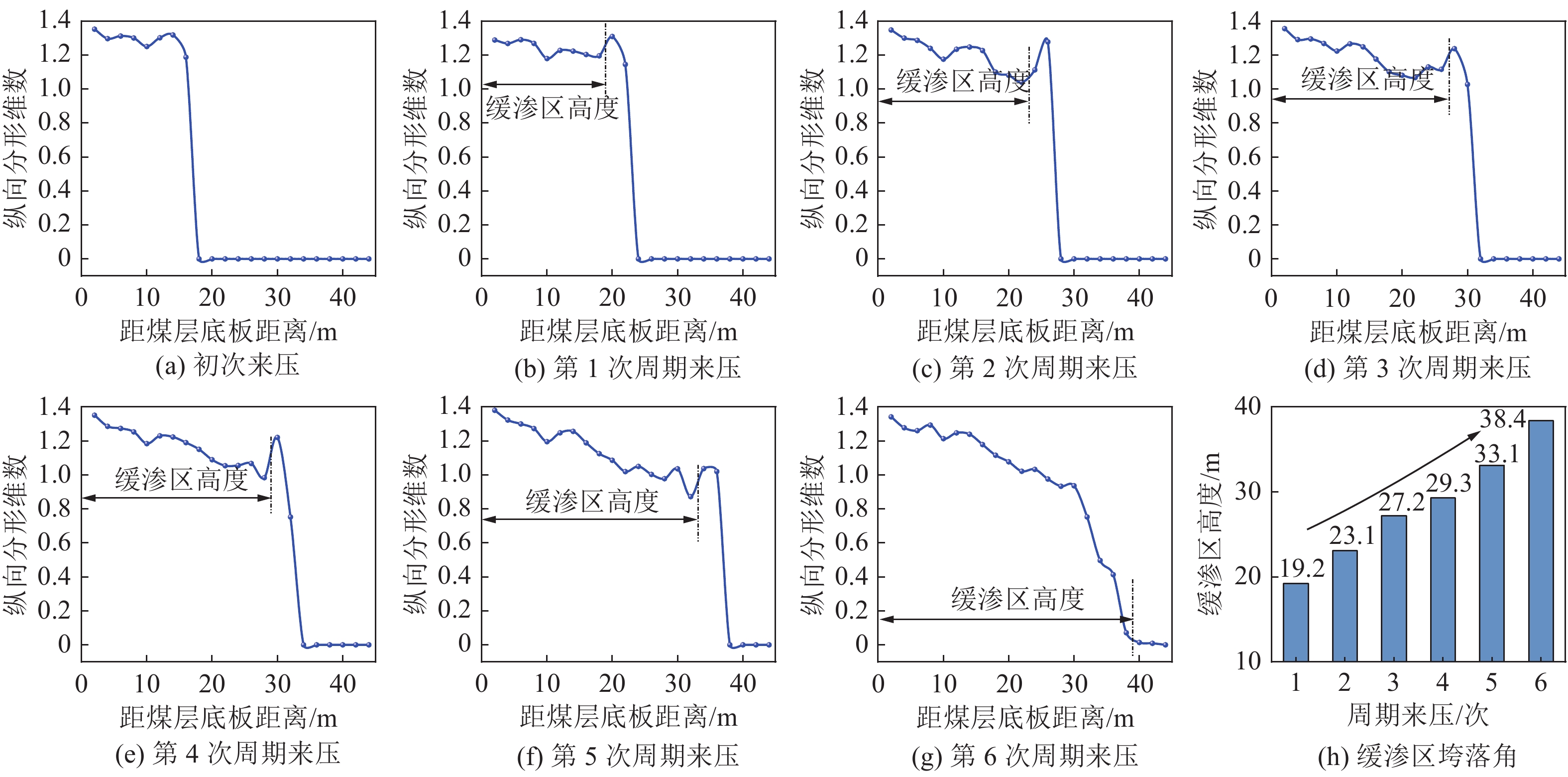

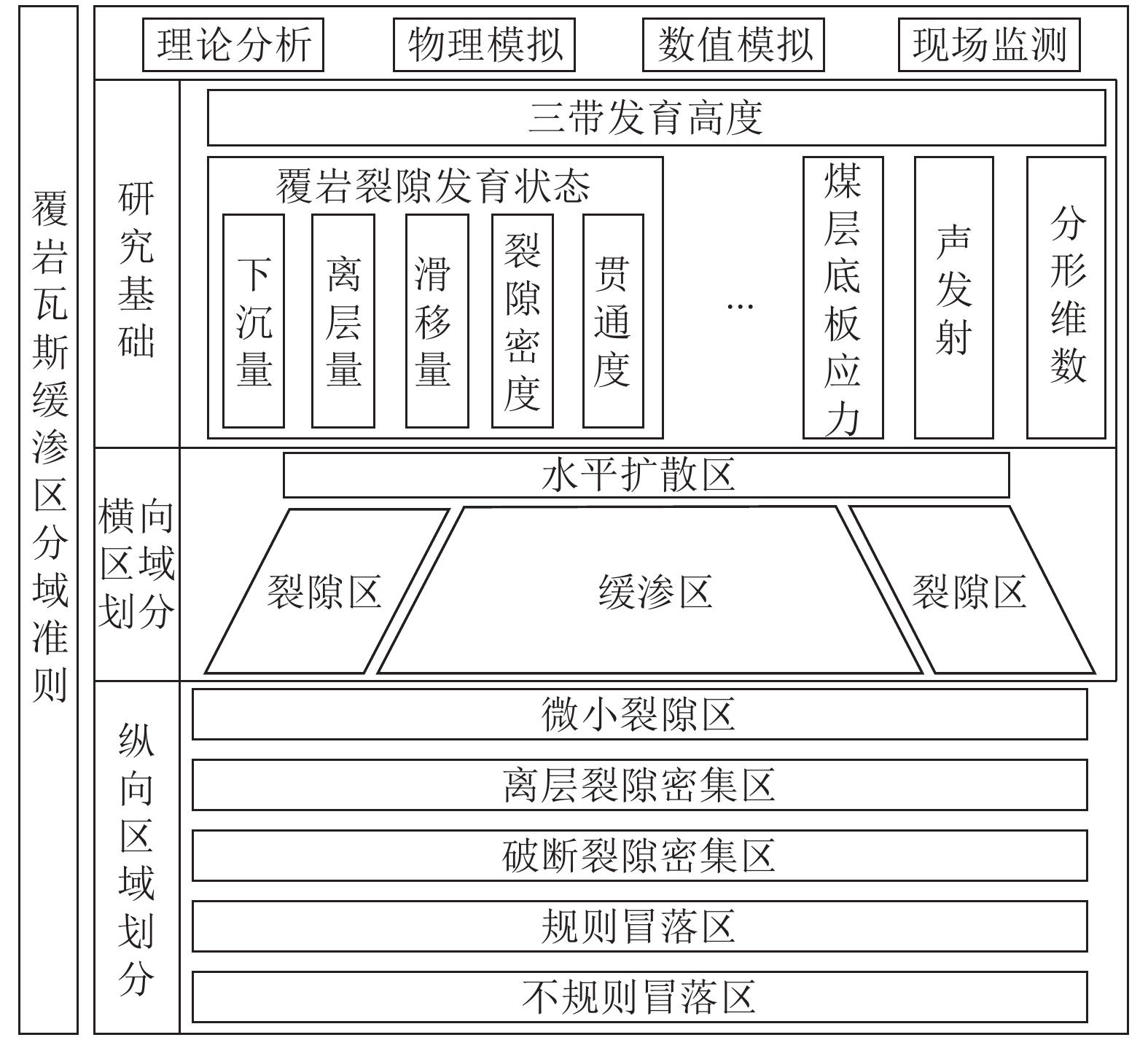

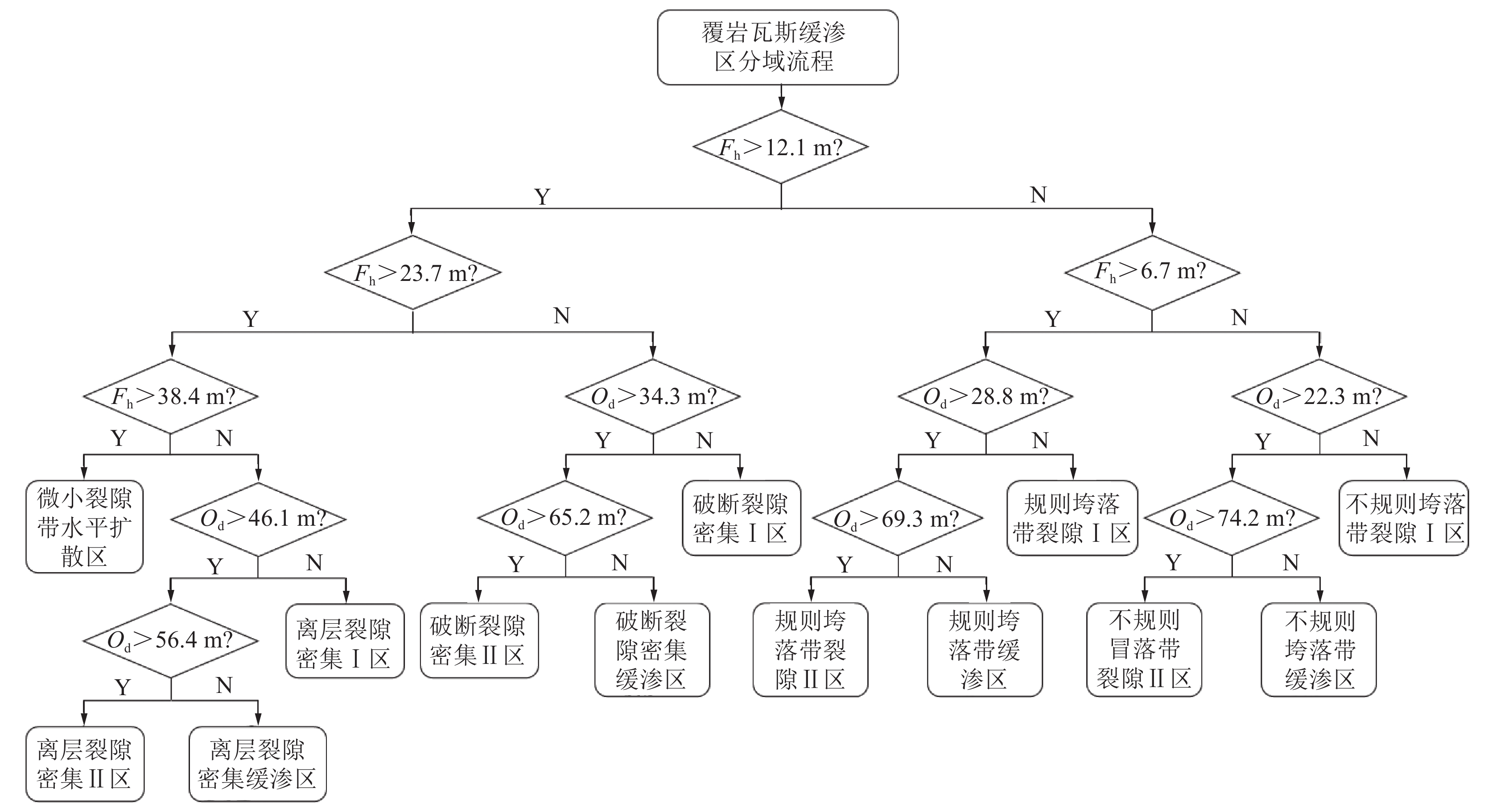

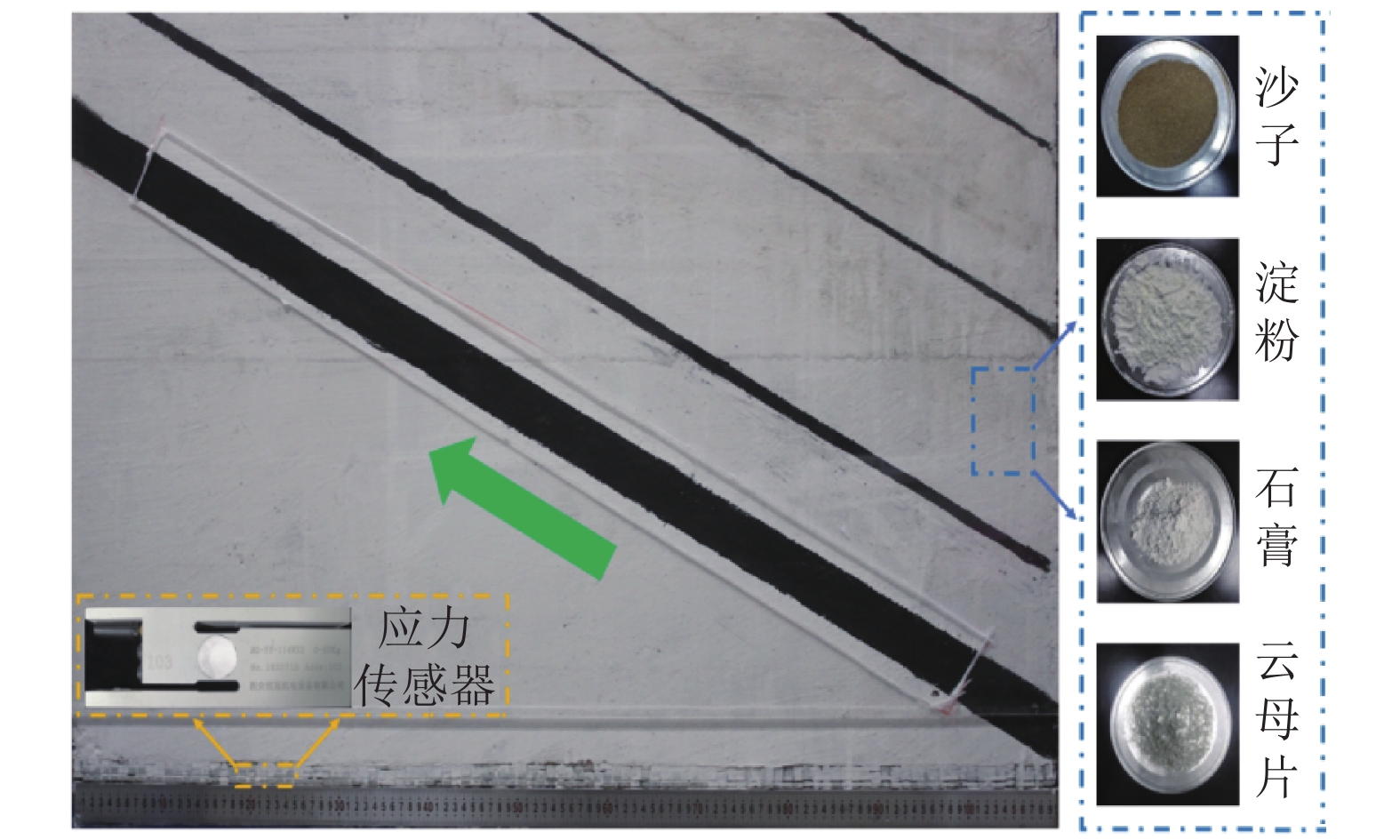

为研究倾斜厚煤层仰斜综采工作面覆岩瓦斯缓渗区的分域方法及分形特征,以分形理论和灰色理论为基础,采用平面物理相似模拟试验方法,开展了仰斜综采工作面覆岩瓦斯缓渗区裂隙演化规律研究,得到了覆岩瓦斯缓渗区的动态扩展规律,进而构建了覆岩瓦斯缓渗区精细分域方法,并采用灰色关联分析方法对覆岩瓦斯缓渗区沿横向(工作面推进方向)和纵向(垂直于煤层底板向上方向)分形维数与离层量、破断裂隙密度及应力集中系数之间的最大关联度分别进行确定。研究结果表明:覆岩瓦斯缓渗区在第一次周期来压后初步形成,其后每次周期来压时,覆岩瓦斯缓渗区两侧的垮落角均不断减小而宽度和高度均不断增大。具体表现为从缓渗区初次形成至缓渗区充分发育期间,缓渗区开切眼侧和工作面侧的垮落角分别从68.3°和76.2°减小到44.7°和53.5°;而缓渗区的宽度和高度分别从16.3 m和19.2 m增大到52.1 m和38.4 m。根据建立的覆岩瓦斯缓渗区分域准则及流程,结合灰色关联分析方法,得到覆岩瓦斯缓渗区沿横向和纵向分形维数变化均与离层量变化相关性最强($ {r_1} $=0.93,$ {r_1}^ * $=0.91),并通过试验验证了理论计算的准确性。因此,在后期确定卸压瓦斯抽采钻孔(巷道)终孔(巷)时,可通过现场观测离层量对覆岩瓦斯缓渗区边界进行判断,研究结果对采空区卸压瓦斯精准高效抽采具有一定的指导意义。

Abstract:In order to study the division method and fractal characteristics of the overburden gas slow permeability zone in up-dip fully mechanized face of inclined thick coal seam, based on the fractal theory and grey theory, the plane physical similarity simulation experiment was used to study the crack evolution law of the overburden gas slow permeability zone in up-dip fully mechanized face. The dynamic expansion law of the overburden gas slow permeability zone was obtained, and then the division method of the overburden gas slow permeability zone was constructed. The grey correlation analysis method was used to determine the maximum correlation degree between the horizontal direction (the advancing direction of the working face) and vertical direction (perpendicular to the upward direction of the coal seam floor) fractal dimensions of the overburden gas slow permeability zone and the separation amount, the fracture density and the stress concentration coefficient. The results show that the overburden gas slow permeability zone is initially formed after the first periodic weighting. After each periodic weighting, the caving angle on both sides of the overburden gas slow permeability zone decreases continuously and the width and height increase continuously. Specifically, from the initial formation of the slow permeability zone to the full development of the slow permeability zone, the caving angles of the open-off cut side and the working face side of the slow permeability zone are reduced from 68.3° and 76.2° to 44.7° and 53.5° respectively. The width and height of the slow permeability zone increased from 16.3 m and 19.2 m to 52.1 m and 38.4 m respectively. According to the established division criterion and process of the overburden gas slow permeability zone, combined with the grey correlation analysis method, it is obtained that the variation of fractal dimension along the horizontal and vertical directions of the overburden gas slow permeability zone has the strongest correlation with the variation of the separation amount ($ {r_1} $=0.93,$ {r_1}^ * $=0.91), and the accuracy of theoretical calculation is verified by experiments. Therefore, when the final hole (roadway) of pressure relief gas extraction borehole (roadway) is determined in the later stage, the boundary of the overburden gas slow permeability area can be judged by field observing the separation amount. The research results have certain guiding significance for accurate and efficient extraction of pressure relief gas in goaf.

-

-

表 1 物理模型相似常数

Table 1 Physical model similarity constants

参数 时间 几何 强度 容重 应力 泊松比 相似常数 10 100 150 1.5 150 1.0 表 2 物理模型相似材料配比

Table 2 Physical model similar material ratio

序号 岩层 厚度/cm 质量/kg 沙子 淀粉 石膏 煤粉 水 20 粉砂岩 7.0 4.13 0.11 0.45 0 0.43 19 砂质泥岩 4.0 4.19 0.20 0.30 0 0.45 18 12煤 0.5 4.23 0.09 0.36 2.11 0.68 17 砂质泥岩 5.0 4.19 0.20 0.30 0 0.45 16 细砂岩 5.0 4.13 0.22 0.33 0 0.43 15 铝质泥岩 4.0 4.18 0.10 0.40 0 0.45 14 细砂岩 2.0 4.13 0.22 0.33 0 0.43 13 砂质泥岩 7.0 4.19 0.20 0.30 0 0.45 12 石灰岩 3.0 4.10 0.29 0.29 0 0.47 11 13煤 0.5 4.23 0.09 0.36 2.11 0.68 10 砂质泥岩 5.0 4.19 0.20 0.30 0 0.45 9 细砂岩 6.0 4.13 0.22 0.33 0 0.43 8 粉砂岩 4.0 4.13 0.11 0.45 0 0.43 7 石灰岩 7.0 4.10 0.29 0.29 0 0.47 6 14煤 1.0 4.23 0.09 0.36 2.11 0.68 5 砂质泥岩 5.0 4.19 0.20 0.30 0 0.45 4 粉砂岩 3.0 4.13 0.11 0.45 0 0.43 3 中砂岩 7.0 4.13 0.14 0.35 0 0.43 2 泥岩 3.0 4.19 0.15 0.40 0 0.45 1 15煤 4.5 4.23 0.09 0.36 2.11 0.68 -

[1] 谢和平. 深部岩体力学与开采理论研究进展[J]. 煤炭学报,2019,44(5):1283−1305. XIE Heping. Research progress on mechanics and mining theory of deep rock mass[J]. Journal of China Coal Society,2019,44(5):1283−1305.

[2] 林海飞,李树刚,赵鹏翔,等. 我国煤矿覆岩采动裂隙带卸压瓦斯抽采技术研究进展[J]. 煤炭科学技术,2018,46(1):28−35. LIN Haifei,LI Shugang,ZHAO Pengxiang,et al. Research progress on pressure released gas drainage technology of mining cracking zone in overburden strata of coal mine in China[J]. Coal Science and Technology,2018,46(1):28−35.

[3] 李树刚,杨二豪,林海飞,等. 深部开采卸压瓦斯精准抽采体系构建及实践[J]. 煤炭科学技术,2021,49(5):1−10. LI Shugang,YANG Erhao,LIN Haifei,et al. Construction and practice of accurate gas drainage system for pressure relief gas in deep mining[J]. Coal Science and Technology,2021,49(5):1−10.

[4] GHABRAIE B,REN G,SMITH J V. Characterising the multi-seam subsidence due to varying mining configuration, insights from physical modelling[J]. International Journal of Rock Mechanics and Mining Sciences,2017,93(3):269−279.

[5] DAVID K,TIMMS W A,BARBOUR S L,et al. Tracking changes in the specific storage of overburden rock during longwall coal mining[J]. Journal of Hydrology,2017,553:304−320. doi: 10.1016/j.jhydrol.2017.07.057

[6] 钱鸣高,许家林. 覆岩采动裂隙分布的“O”形圈特征研究[J]. 煤炭学报,1998,23(5):466−469. QIAN Minggao,XU Jialin. Study on the “O-shape” circle distribution characteristics of mining-induced fractures in the overlaying strata[J]. Journal of China Coal Society,1998,23(5):466−469.

[7] 钱鸣高,许家林. 煤炭开采与岩层运动[J]. 煤炭学报,2019,44(4):973−984. QIAN Minggao,XU Jialin. Coal mining and rock movement[J]. Journal of China Coal Society,2019,44(4):973−984.

[8] YUAN Liang. Theory and practice of integrated coal production and gas extraction[J]. International Journal of Coal Science and Technology,2015,2(1):3−11. doi: 10.1007/s40789-015-0065-2

[9] GUO Hua,YUAN Liang. An integrated approach to study of strata behaviour and gas flow dynamics and its application[J]. International Journal of Coal Science and Technology,2015,2(1):12−21. doi: 10.1007/s40789-015-0059-0

[10] 袁 亮,郭 华,沈宝堂,等. 低透气性煤层群煤与瓦斯共采中的高位环形裂隙体[J]. 煤炭学报,2011,36(3):357−365. YUAN Liang,GUO Hua,SHEN Baotang,et al. Circular overlying zone at longwall panel for efficient methane capture of mutiple coal seams with low permeability[J]. Journal of China Coal Society,2011,36(3):357−365.

[11] 杨 科,谢广祥. 采动裂隙分布及其演化特征的采厚效应[J]. 煤炭学报,2008,33(10):1092−1096. YANG Ke,XIE Guangxiang. Caving thickness effects on distribution and evolution characteristics of mining induced fracture[J]. Journal of China Coal Society,2008,33(10):1092−1096.

[12] 李树刚,林海飞,赵鹏翔,等. 采动裂隙椭抛带动态演化及煤与甲烷共采[J]. 煤炭学报,2014,39(8):1455−1462. LI Shugang,LIN Haifei,ZHAO Pengxiang,et al. Dynamic evolutionof mining fissure elliptic paraboloid zone and extraction coaland gas[J]. Journal of China Coal Society,2014,39(8):1455−1462.

[13] 李树刚,徐培耘,赵鹏翔,等. 采动裂隙椭抛带时效诱导作用及卸压瓦斯抽采技术[J]. 煤炭科学技术,2008,46(9):146−152. LI Shugang,XU Peiyun,ZHAO Pengxiang,et al. Aging induction and pressure relief gas extraction technology of mining-induced fracture ellipsoid strip[J]. Coal science and Technology,2008,46(9):146−152.

[14] 李树刚,刘李东,赵鹏翔,等. 综采工作面覆岩压实区裂隙动态演化规律影响因素分析[J]. 煤炭科学技术,2022,50(1):95−104. LI Shugang,LIU Lidong,ZHAO Pengxiang,et al. Analysis and application of fracture evolution law of overburden compacted area on fully-mechanized mining face under multiple factors[J]. Coal Science and Technology,2022,50(1):95−104.

[15] 赵鹏翔,刘李东,李树刚,等. 煤层倾角对仰斜综采工作面覆岩压实区演化规律的影响[J]. 煤炭科学技术,2021,49(11):65−72. ZHAO Pengxiang,LIU Lidong,LI Shugang,et al. Dip angle effect of evolution coal seam in overburden compacted area of fully mechanized mining face[J]. Coal Science and Technology,2021,49(11):65−72.

[16] 刘洪永,程远平,周红星,等. 综采长壁工作面推进速度对优势瓦斯通道的诱导与控制作用[J]. 煤炭学报,2015,40(4):809−815. LIU Hongyong,CHENG Yuanping,ZHOU Hongxing,et al. Induction and control effect of advancing speed of longwall working face in fully mechanized mining on dominant gas channel[J]. Journal of China Coal Society,2015,40(4):809−815.

[17] 伍永平,解盘石,任世广. 大倾角煤层开采围岩空间非对称结构特征分析[J]. 煤炭学报,2010,35(2):182−184. WU Yongping,XIE Panshi,REN Shiguang. Analysis of asymmetric structure around coal face of steeply dipping seam mining[J]. Journal of China Coal Society,2010,35(2):182−184.

[18] LUO Shenghu,WANG Tong,WU Yongping,et al. Internal mechanism of asymmetric deformation and failure characteristics of the roof for longwall mining of a steeply dipping coal seam[J]. Archives of Mining Science,2021,66(1):101−124.

[19] 解盘石,屈利利,伍永平,等. 大倾角近距离煤层群长壁采场顶板破断机理[J]. 煤炭科学技术,2022,50(2):65−74. XIE Panshi,QU Lili,WU Yongping,et al. Roof breaking mechanism of longwall stope with steeply dipping contugous coal seam group[J]. Coal Science and Technology,2022,50(2):65−74.

[20] ZHOU Shaoping,WU Kan,ZHOU Dawei,et al. Experimental Study on Displacement Field of Strata Overlying Goaf with Sloping Coal Seam[J]. Geotechnical and Geological Engineering,2016,34(6):1847−1856. doi: 10.1007/s10706-016-9993-x

[21] XIE Heping,SANDERSON D J,PEACOCK D C P. A fractal model and energy dissipation for en echelon fractures[J]. Engineering Fracture Mechanics,1994,48(5):655−662. doi: 10.1016/0013-7944(94)90173-2

[22] 谢和平,于广明,杨 伦,等. 采动岩体分形裂隙网络研究[J]. 岩石力学与工程学报,1991,18(2):29−33. XIE Heping,YU Guangming,YANG Lun,et al. Research on the fractal effects of crack network in overburden rock stratnm[J]. Chinese Journal of Rock Mechanics and Engineering,1991,18(2):29−33.

[23] DENG Guangdi,XIE Heping,GAO Mingzhong,et al. Numerical simulation on the evolution of mining-induced fracture network in a coal seam and its overburden under the top coal caving method[J]. Advances in Civil Engineering,2020,5:1−14.

[24] 周宏伟,张 涛,薛东杰,等. 长壁工作面覆岩采动裂隙网络演化特征[J]. 煤炭学报,2011,36(12):1957−1962. ZHOU Hongwei,ZHANG Tao,XUE Dongjie,et al. Evolution of mining-induced crack network in overburden strata of longwall face[J]. Journal of China Coal Society,2011,36(12):1957−1962.

[25] WANG Cheng,ZHANG Nianchao,HAN Yafeng,et al. Experiment research on overburden mining-induced fracture evolution and its fractal characteristics in ascending mining[J]. Arabian Journal of Geosciences,2015,8(1):13−21. doi: 10.1007/s12517-013-1178-9

[26] 杨滨滨,袁世冲,郑德志,等. 近距离煤层重复采动覆岩裂隙时空演化特征研究[J]. 采矿与安全工程学报,2022,39(2):255−263. YANG Binbin,YUAN Shichong,ZHENG Dezhi,et al. Spatial and temporal characteristics of overburden fractures due to repeated mining in close distance coal seams[J]. Journal of Mining and Safety Engineering,2022,39(2):255−263.

[27] 赵毅鑫,令春伟,刘 斌,等. 浅埋超大采高工作面覆岩裂隙演化及能量耗散规律研究[J]. 采矿与安全工程学报,2021,38(1):9−18,30. ZHAO Yixin,LING Chunwei,LIU Bin,et al. Fracture evolution and energy dissipation of overlying strata in shallow-buried underground mining with ultra-high working face[J]. Journal of Mining and Safety Engineering,2021,38(1):9−18,30.

[28] ZHAO Pengxiang,ZHUO Risheng,LI Shugang,et al. Fractal characteristics of gas migration channels at different mining heights[J]. Fuel,2019,271:479−487.

[29] ZHAO Pengxiang,ZHUO Risheng,LI Shugang,et al. Fractal characteristics of methane migration channels in inclined coal seams[J]. Energy,2021,225:127−139.

[30] ZHAO Pengxiang,WANG Jianan,LI Shugang,et al. Effects of recovery ratio on the fracture evolution of the overburden pressure-relief gas migration channel for a fully mechanized working face[J]. Natural Resources Research,2022,31(2):1011−1026. doi: 10.1007/s11053-021-09993-4

[31] 赵鹏翔,卓日升,李树刚,等. 综采工作面推进速度对瓦斯运移优势通道演化的影响[J]. 煤炭科学技术,2018,46(7):99−108. ZHAO Pengxiang,ZHUO Risheng,LI Shugang,et al. The influence of the speed of fully mechanized mining face on the evolution of the dominant channel of gas migration[J]. Coal Science and Technology,2018,46(7):99−108.

[32] 李宏艳,王维华,齐庆新,等. 基于分形理论的采动裂隙时空演化规律研究[J]. 煤炭学报,2014,39(6):1023−1031. LI Hongyan,WANG Weihua,QI Qingxin,et al. Study on fissure development rule of overlying strata influenced by mining based on fractal theory[J]. Journal of China Coal Society,2014,39(6):1023−1031.

[33] 郭明杰,郭文兵,袁瑞甫,等. 基于采动裂隙区域分布特征的定向钻孔空间位置研究[J]. 采矿与安全工程学报,2022,39(4):817−826. GUO Mingjie,GUO Wenbing,YUAN Ruifu,et al. Spatial location determination of directional boreholes based on regional distribution characteristics of mining-induced overburden fractures[J]. Journal of Mining and Safety Engineering,2022,39(4):817−826.

[34] 郭文兵,赵高博,白二虎. 煤矿高强度长壁开采覆岩破坏充分采动及其判据[J]. 煤炭学报,2020,45(11):3657−3666. GUO Wenbing,ZHAO Gaobo,BAI Erhu. Critical failure of overlying rock strata and its criteria induced by high-intensity longwall mining[J]. Journal of China Coal Society,2020,45(11):3657−3666.

[35] 钱鸣高, 石平五, 许家林. 矿山压力与岩层控制[M]. 徐州: 中国矿业大学出版社, 2015: 65−99. QIAN Minggao, SHI Pingwu, XU Jialin. Mine pressure and strata control[M]. Xuzhou: China University of Mining and Technology Press, 2015: 65−99.

[36] 郭文兵. 煤矿开采损害与保护[M]. 北京: 应急管理出版社, 2019: 1−8. GUO Wenbing. Coal mining damage and protection[M]. Beijing: Emergency Management Press, 2019: 1−8.

[37] 白利娜,曾家瑶,高 为. 基于灰色关联分析的盘关向斜煤层气有利井区优选[J]. 煤炭科学技术,2019,47(4):169−173. BAI Li’na,ZENG Jiayao,GAO Wei. Optimization of favorable well of CBM based on grey correlation analysis in Panguan syncline[J]. Coal Science and Technology,2019,47(4):169−173.

-

期刊类型引用(8)

1. 陈泽民,李振雷,钟涛平,宋大钊,刘旭东,胡旭聪. 急倾斜特厚煤层防冲开采方法数值模拟研究. 煤矿安全. 2025(01): 117-127 .  百度学术

百度学术

2. 侯挺,聂谦,薛兴伟. 弱化转移高水平应力技术在巷道修护中的研究与应用. 山东煤炭科技. 2025(01): 12-16 .  百度学术

百度学术

3. 陈学亚,张宁波,刘立明,陈宝宝,付世雄. 遗留煤柱扰动下薄间距动压巷道压裂卸压护巷技术研究. 煤炭工程. 2025(01): 42-51 .  百度学术

百度学术

4. 郭争利,杨真. 水力压裂防治强矿压机理及卸压护巷技术研究. 山西冶金. 2025(01): 204-206 .  百度学术

百度学术

5. 龚惠春,夏广宁,杨生龙,刘鹏,杨龙. 深埋工作面回采巷道复合顶板水压致裂技术应用. 陕西煤炭. 2024(08): 90-94+140 .  百度学术

百度学术

6. 赵会波. 水力压裂裂缝开裂压力影响因素分析及应用. 煤炭工程. 2024(09): 127-135 .  百度学术

百度学术

7. 聂嘉汾,张海东. 不同切顶角度下临空巷道围岩力学响应特征及控制效果. 山西煤炭. 2024(04): 120-127 .  百度学术

百度学术

8. 曹沛沛. 水力切顶卸压在动压巷道围岩控制中应用. 内蒙古煤炭经济. 2024(24): 160-162 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: