Breakage characteristics of casing and prevention and control measures in mining wells based on the evolution law of stress and crack fields in overlying strata

-

摘要:

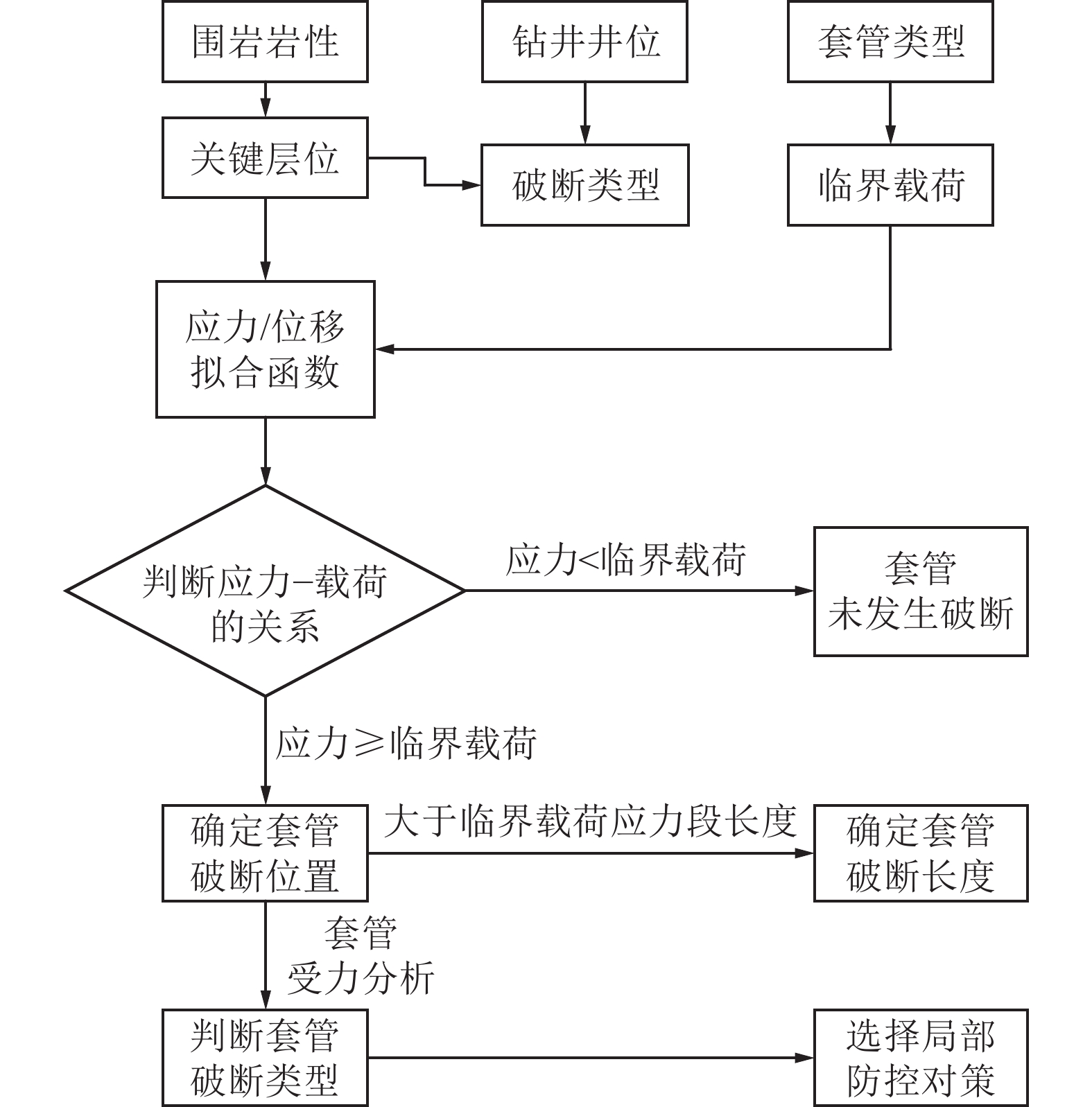

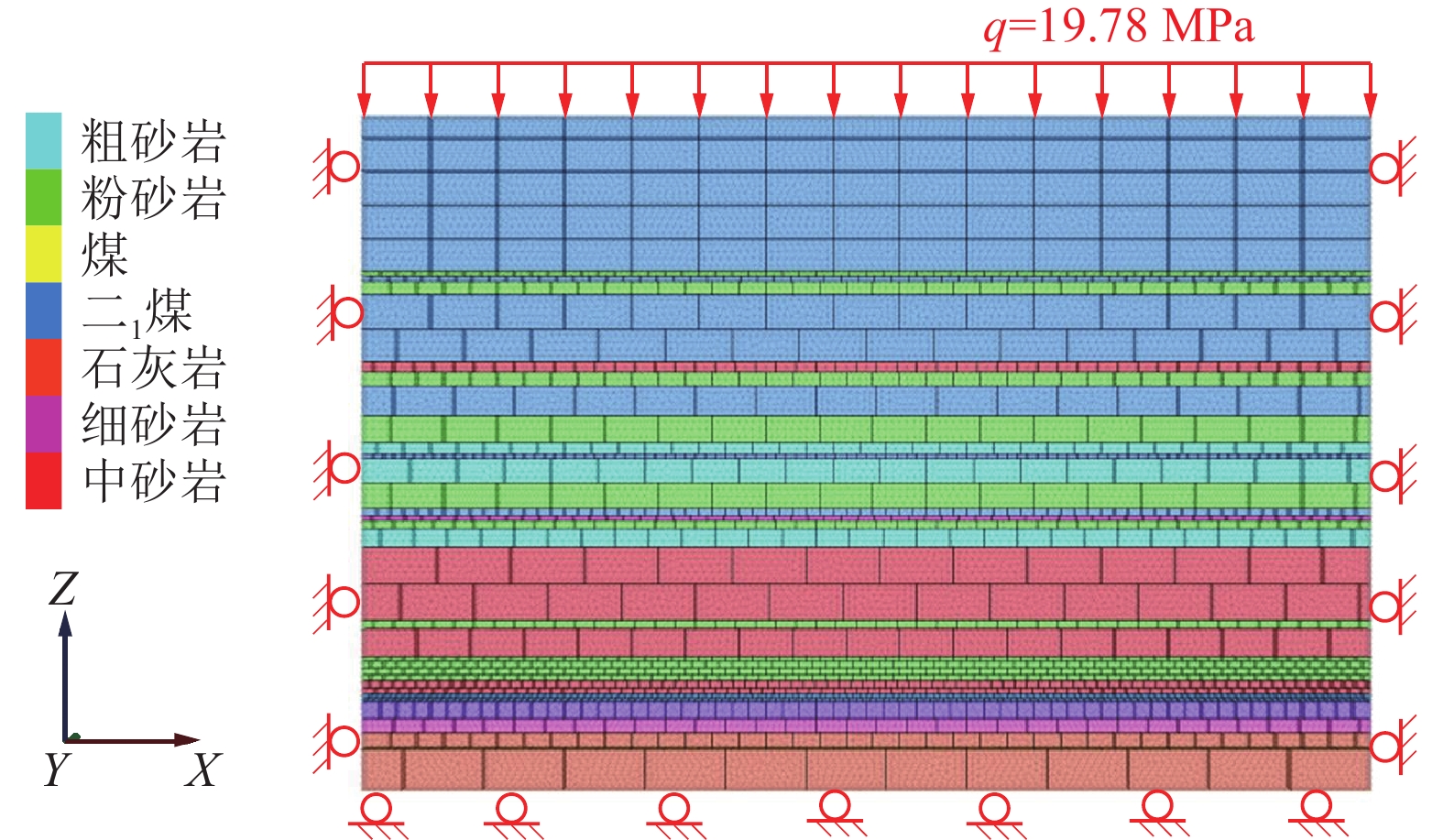

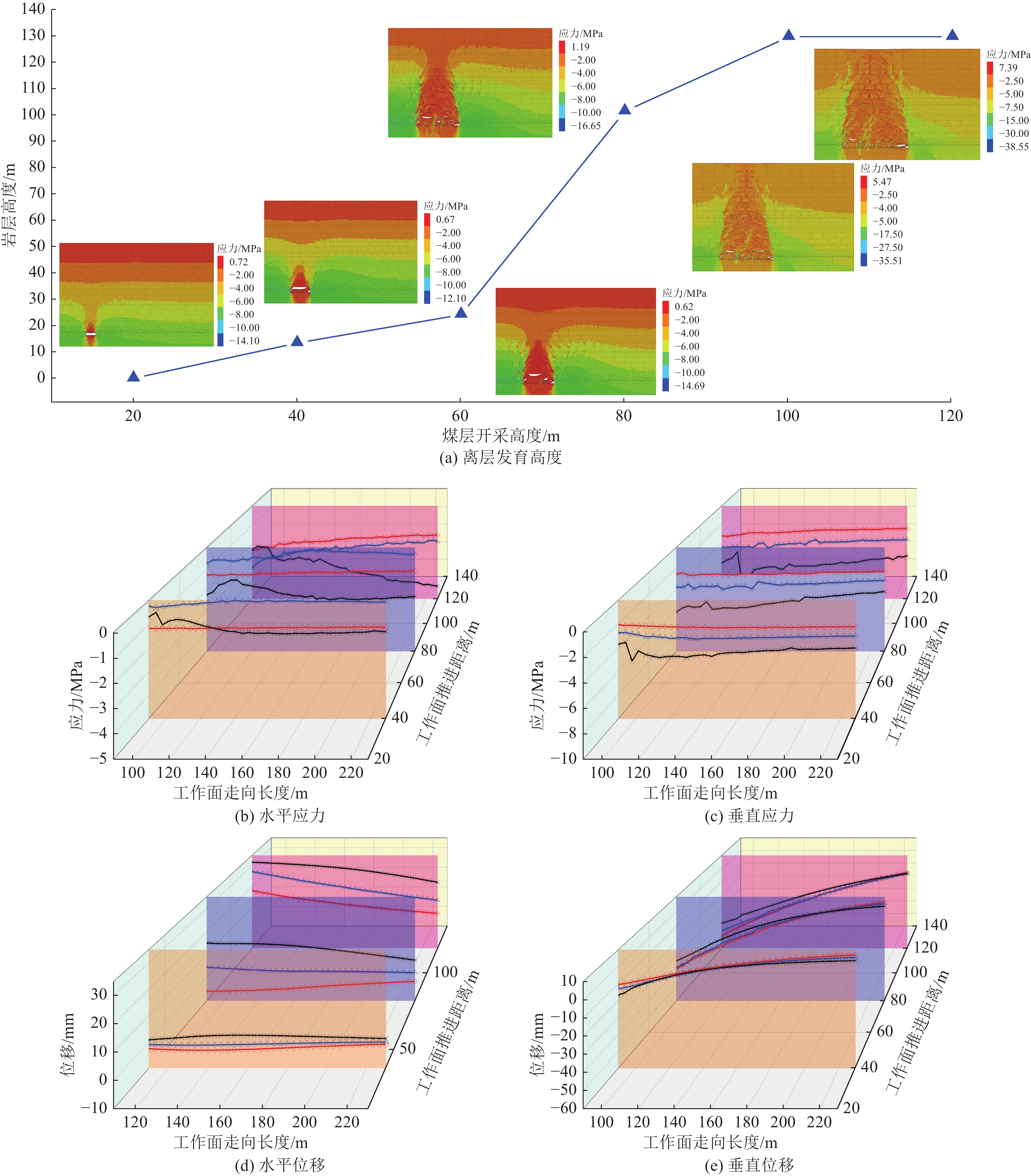

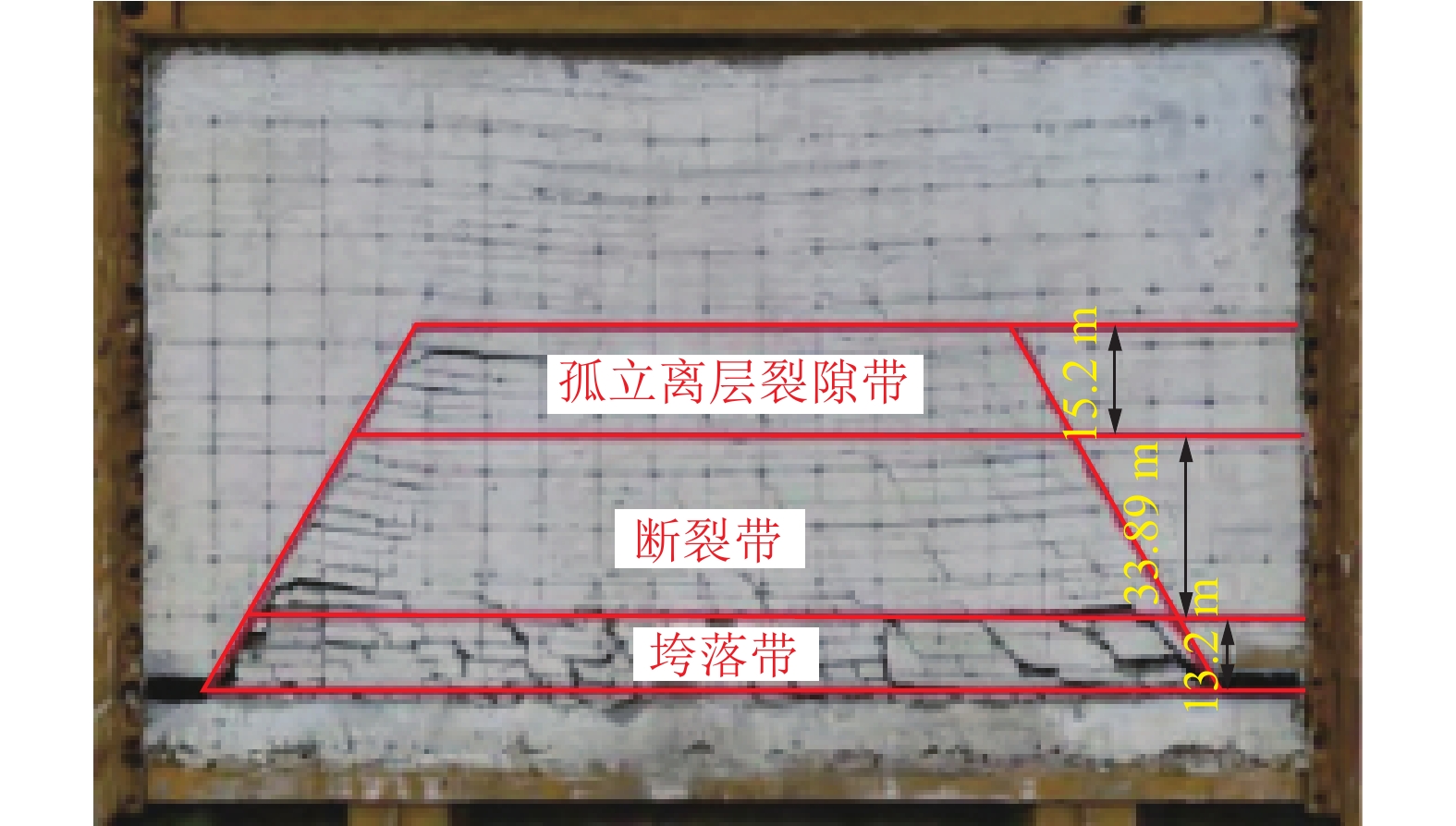

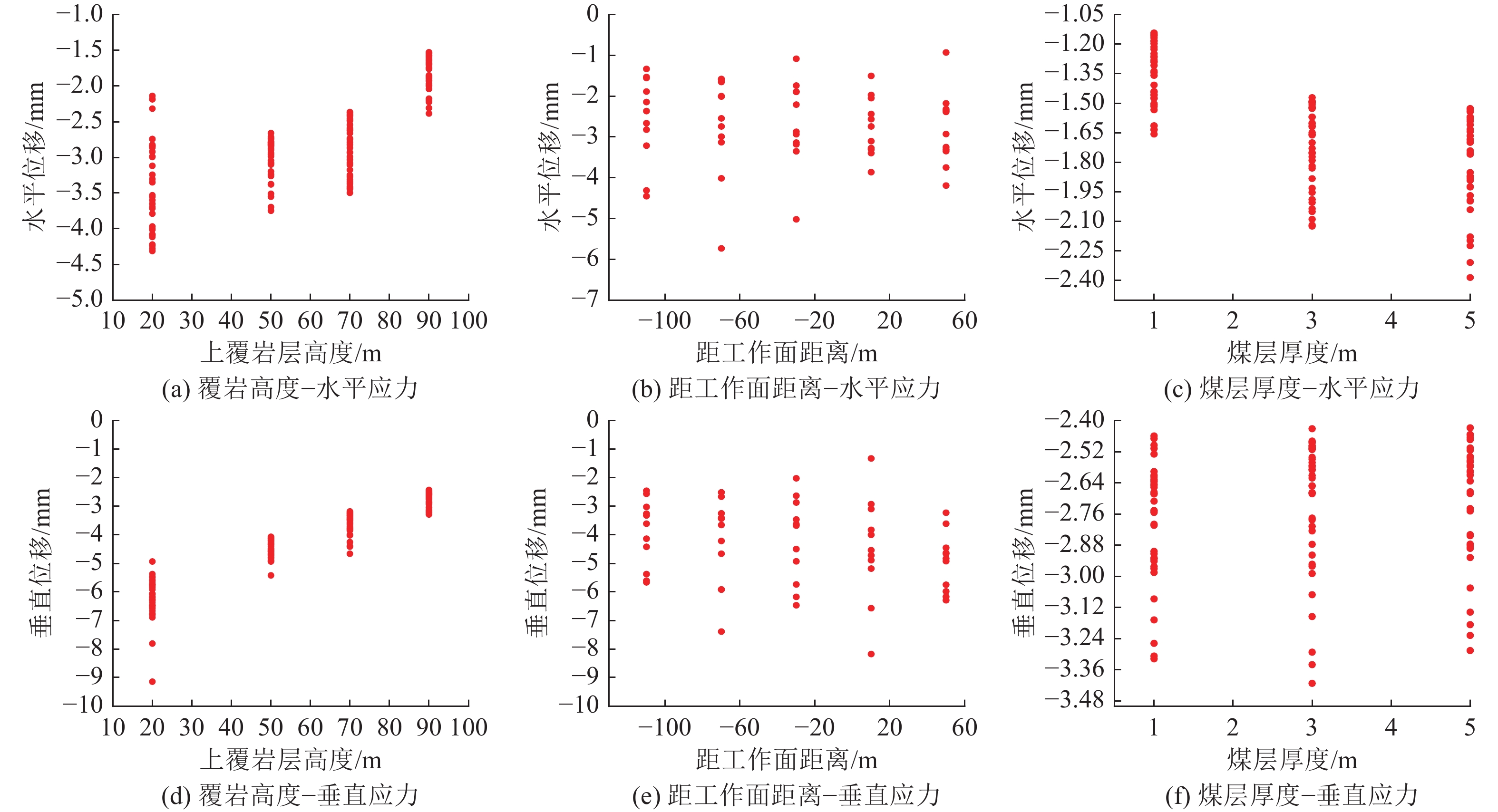

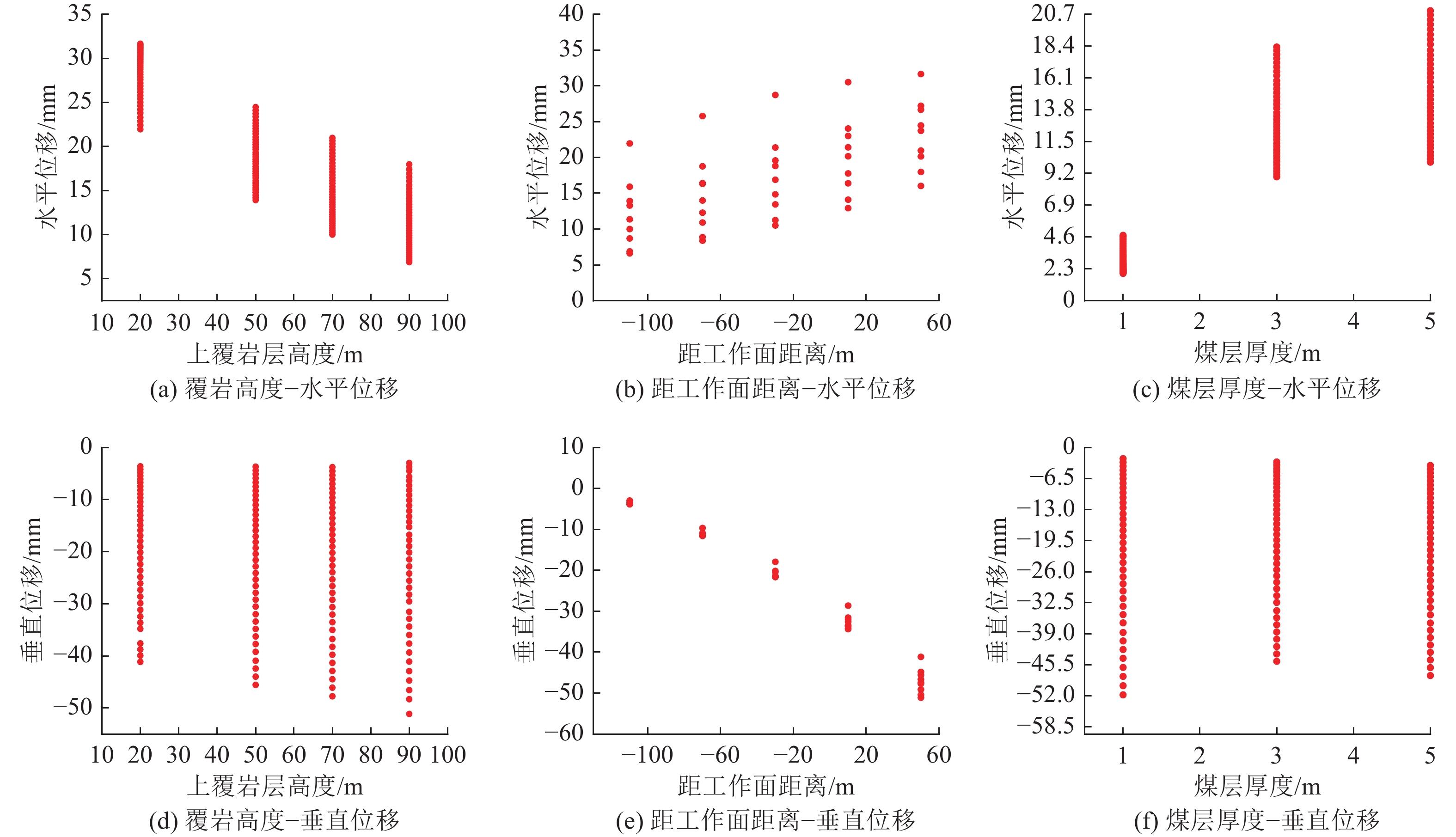

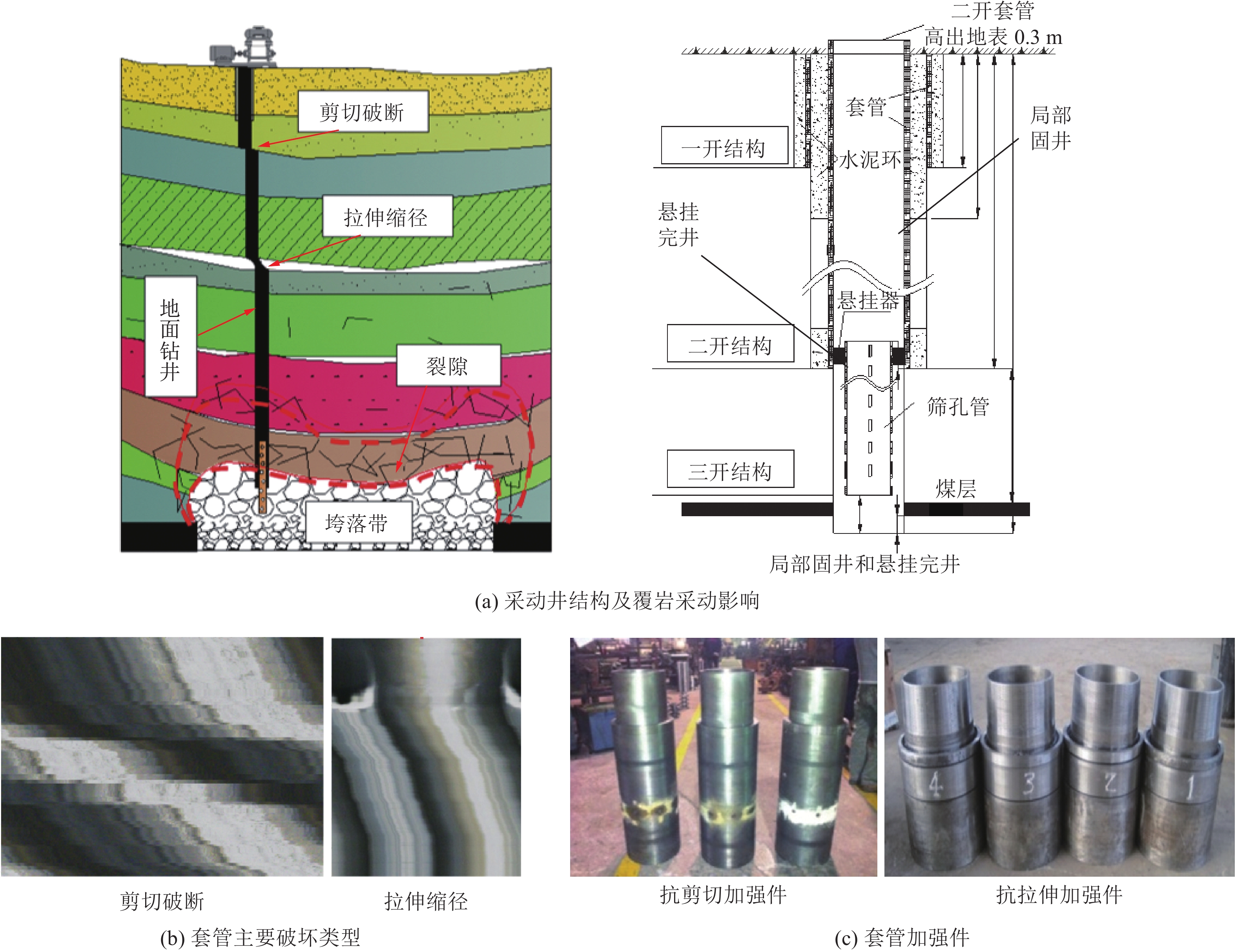

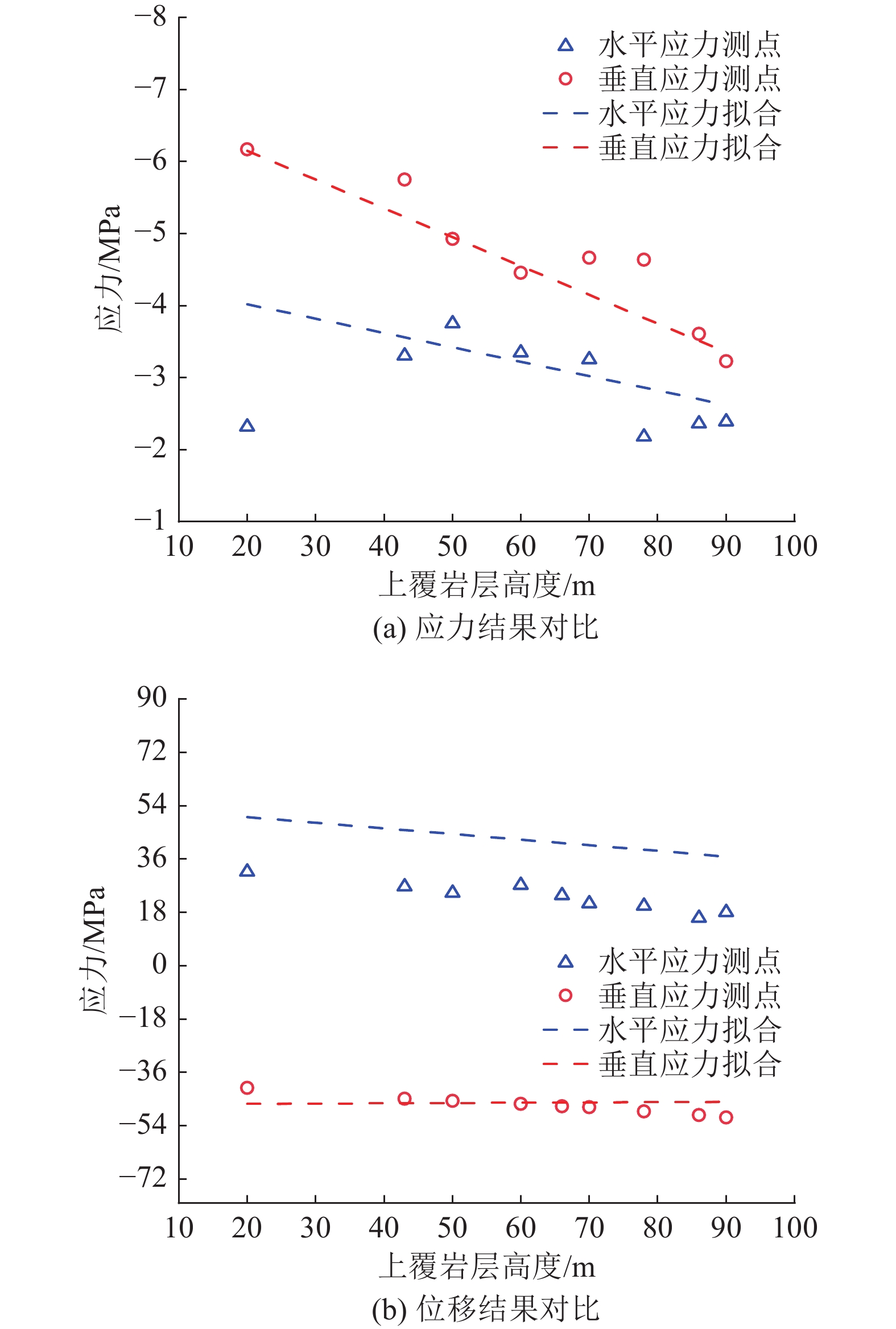

准确确定出煤矿采动井套管破断特征并提出相应的防控对策,能为井筒长期稳定提供重要保障。以平顶山矿区的二1煤层及上覆岩层为研究对象,采用理论计算与数值模拟软件模拟方法,确定出上覆岩层离层段应力和位移分布规律,分析了上覆岩层高度、距工作面水平距离与应力、位移的相关性,拟合出上覆岩层高度、距工作面水平距离与应力、位移的关系式;根据研究区采动井的实际开发经验,确定出最佳布井区域下的套管主要破断类型,结合常用套管力学参数,得出“两场”演化下的套管破断位置及长度等特征;对常用的采动井局部防护技术进行总结,并提出对应的防控对策。结果表明:工作面推进过程中,上覆岩层应力呈现出“波动−线性降低”的变化规律,位移呈现出“几乎未发生变化−类双曲线型”的变化规律。最佳布井区域下的采动井套管主要以拉伸缩径和剪切破断为主,选择施加套管加强件对采动井套管进行加固。研究区地面采动井三开段采用N80套管时,需在煤层上部46 m亚关键层处、54 m软硬互层处分别加设抗拉伸套管加强件和抗剪切加强件;采用P110套管时,需在煤层上部46 m亚关键层处加设抗拉伸加强件。建议研究区地面采动井三开段均采用P110套管,增加采动井的井筒稳定性。该研究成果为平顶山矿区及相似条件下采动井预防套管破断提供了理论指导。

Abstract:Accurately determining the casing breakage characteristics in mining wells and proposing corresponding preventive and control measures can provide an important guarantee for the long-term stability of the wellbore. Taking the No. 21 coal seam and overlying strata in the Pingdingshan mining area as the research object, theoretical calculations and numerical simulation were used to determine the stress and displacement distribution law of separation section in the overlying strata. The correlation between the height of the overlying strata, the horizontal distance from the working face and stress and displacement were analyzed, and the relationship between the height of the overlying strata, the horizontal distance from the working face and the stress and displacement were fitted. Based on the actual development experience of mining wells in the research area, the main types of casing breakage in the optimal well layout area were determined. Combined with the commonly used casing mechanical parameters, the casing breakage location and length under the “two field” evolution were characterized. The commonly used local protection technologies for mining wells was summarized and the corresponding preventive and control measures were proposed. The results shown that, in the process of working face advancement, the stress of the overlying strata shown a change pattern of from fluctuation to linear decrease, and the displacement shown a change pattern of from almost unchanged to hyperbolic type. The casing in the optimal well layout area was mainly characterized by tensile shrinkage and shear fracture, and the casing reinforcement was applied to reinforce the casing in mining well. When N80 casing was used in the third section of the ground mining well in the research area, it was necessary to install anti- tensile and shear casing reinforcement in the upper 46 m of the coal seam at the sub-critical layer and in the upper 54 m of the coal seam at the soft/hard interlayer. When P110 casing was used, it is necessary to install anti-tensile reinforcement in the upper 46 m of the coal seam at the sub-critical layer. It is recommended to use P110 casing for all three sections of the surface mining wells in the research area to increase the wellbore stability in mining well. The research achievement can provide theoretical guidance for preventing casing breakage in the Pingdingshan mine and mining wells under similar conditions.

-

-

表 1 关键层位置计算所需基本参数及计算结果

Table 1 Basic parameters and calculated results of key layer location calculation

层号 岩性 计算参数 计算结果 层位

判识层厚/

m弹性模量/

GPa体积力/

(kN·m3)抗拉强度/

MPan层硬岩累计载荷/

MPa破断距/

m周期来压步距/

m24 砂质泥岩 45.75 6.5 25.48 1.5 19.78 73.40 — 硬层3 23 粉砂岩 1.37 20 25.28 2.8 — — — — 22 粉砂岩 1.37 20 25.3 2.8 — — — — 21 砂质泥岩 1.61 6.5 25.5 1.5 — — — 软硬互层4 20 粉砂岩 3.87 20 25.3 2.8 — — — 19 砂质泥岩 20.07 6.5 25.5 1.5 — — — — 18 中砂岩 3.09 20 24.1 2.8 — — — 软硬互层3 17 泥岩 4.14 4.17 24.5 0.8 — — — 16 砂质泥岩 8.84 6.5 25.5 1.5 — — — — 15 粉砂岩 8.08 20 25.3 2.8 — — — — 14 粗砂岩 3.29 9 24.5 2.8 — — — — 13 砂质泥岩 1.44 6.5 25.5 1.5 — — — 软硬互层2 12 粗砂岩 7.20 9 24.5 2.8 — — — 11 粉砂岩 7.82 20 25.3 2.8 — — — — 10 砂质泥岩 2.00 6.5 25.5 1.5 — — — 软硬互层1 9 细砂岩 1.53 29 24.6 2.8 — — — 8 粉砂岩 2.4 20 25.3 2.8 — — — — 7 粗砂岩 5.43 9 24.5 2.8 — — — 6 中砂岩 21.87 20 24.1 2.8 2.30 71.29 — 硬层2 5 粉砂岩 2.54 20 25.3 2.8 — — — — 4 中砂岩 8.27 20 24.1 2.8 0.46 43.84 — 硬层1 3 粉砂岩 7.19 20 25.3 2.8 0.18 39.89 16.29 基本顶 2 中砂岩 3.98 20 24.1 1.5 — — — 直接顶 1 砂质泥岩 2.24 6.5 25.5 1.5 — — — 直接顶 0 二1煤 5.04 1.3 15.7 0.21 — — — — 表 2 模型的块体力学和节理力学参数

Table 2 Block mechanics and joint mechanics parameters of model

岩性 块体力学参数 节理力学参数 密度/

(kg·m−3)弹性模量/

GPa泊松比 体积模量/

GPa剪切模量/

GPa法向刚度/

(N·m−1)切向刚度/

(N·m−1)内摩擦角/(°) 黏聚力/

MPa煤 1457 1.3 0.30 1.1 0.5 7.5×1010 0.01×1010 22.1 1 泥岩 2670 4.17 0.34 4.3 1.6 10.5×1010 0.8×1010 32.1 3.05 砂质泥岩 2340 6.5 0.32 6.0 2.5 4.8×1010 0.1×1010 24.9 4.2 细砂岩 2680 29 0.26 20.1 11.5 6.84×1010 1.8×1010 30 2 中砂岩 2460 20 0.23 12.3 8.1 4.46×1010 2.6×1010 26 3.8 粉砂岩 2680 20 0.31 17.5 7.6 1.38×1010 0.7×1010 30 8.95 粗砂岩 3300 9 0.32 8.3 3.4 4.46×1010 2.6×1010 36 2.8 表 3 采动井套管破断类型

Table 3 Types of casing breakage in mining wells

破断类型 破断示意 主要作用力 破坏原理 弯曲破断

垂直/斜向外力作用 套管所受的垂直/斜向外力的受力点不在井套管的中心线上,导致套管发生弯曲变形,变形超过其强度极限后发生破断 压缩破断

压力作用 套管在受到上覆岩层或其他物体的压力作用时,受力面积较小,易发生套管压缩破断 拉伸破断

拉伸力作用 套管在受到拉伸力作用时,发生拉伸变形,变形超过其强度极限时,会发生破断 剪切破断

剪切力作用 套管在受到岩体滑移所造成的水平或倾斜方向的剪切力作用时,发生横向错位,当横向位移量超过套管极限时,发生套管错断 表 4 煤矿采动井常用套管临界载荷

Table 4 Critical load of commonly used casings in coal mining wells

序号 钢级 外径/mm 壁厚/mm 径厚比 临界均匀

载荷/MPa最小非均匀

临界载荷/MPa最大非均匀

临界载荷/MPa套管线重/(kg·m−1) 抗拉强度/kN 1 N80 139.7 7.72 18.10 43.3 2.165 5.4125 25.3 1766 2 N80 139.7 9.17 15.23 60.9 3.045 7.6125 29.8 2073 3 N80 139.7 10.54 13.25 76.9 3.845 9.6125 34.2 2358 4 P110 139.7 7.72 18.10 51.5 2.575 6.4375 25.3 2429 5 P110 139.7 9.17 15.23 76.5 3.825 9.5625 29.8 2851 6 P110 139.7 10.54 13.25 100.2 5.010 12.525 0 34.2 3243 表 5 采动井局部防护技术的技术原理及应用范围

Table 5 Technical principles and application scope of local protection technology for mining wells

技术理念 关键技术 技术原理 应用范围 避 布井位置优选技术 选取能够兼顾地面井结构稳定区与裂隙空间发育

的区域为最优布井区域通过优化布井位置减少套管变形破坏,当地层应力变化较大时,难以保障套管的稳定性 让 局部固井技术 采用局部固井技术,为地面井下端岩层“让”出移

动空间适用于岩层采动影响较小的层位,当岩层位移超过环空距离时,增稳效果较差 防 局部防护技术 在套管高危位置上安设防护装置,提高套管抗性 施工简便、增稳成本低,但需要根据套管高危位置的受力情况选取相应的防护装置 疏 悬挂完井技术 优化三开筛管尺寸,提高筛管抗性和抽采透气效果 适用于生产过程中存在筛管段泥沙堵孔现象的区域 表 6 套管加强件的位置与长度

Table 6 Location and length of casing reinforcement

覆岩 高度/m 距工作面距离/m 水平应力/MPa 垂直应力/MPa 水平位移/mm 垂直位移/mm 横向滑移量/m 离层量/m 套管类型 加强件类型 硬层1 13.41 120.00 −4.95 −5.70 29.94 −61.95 — 0.04 N80 — P110 — 硬层2 46.09 120.00 −3.97 −4.13 22.92 −63.38 — 0.12 N80 抗拉伸加强件 P110 抗拉伸加强件 硬层3 129.64 120.00 −1.46 −0.12 4.95 −67.06 — 0.24 N80 — P110 — 软硬互层1 53.92 120.00 −3.74 −3.75 21.23 −63.73 0.09 — N80 抗剪切加强件 P110 — 软硬互层2 72.47 120.00 −3.18 −2.86 17.24 −64.55 0.22 — N80 — P110 — 软硬互层3 94.12 120.00 −2.53 −1.82 12.59 −65.50 0.19 — N80 — P110 — 软硬互层4 121.42 120.00 −1.71 −0.51 6.72 −66.70 0.14 — N80 — P110 — -

[1] 郝登云,崔千里,何 杰,等. 锚杆锚索支护巷道层状顶板变形特征及离层监测研究[J]. 煤炭学报,2017,42(S1):43−50. HAO Dengyun,CUI Qianli,HE Jie, et al. Deformation characteristics and separation monitoring of layered roof roadway supported with bolts and cables[J]. Journal of China Coal Society,2017,42(S1):43−50.

[2] 程敬义,万志军,PENG Syd S,等. 基于海量矿压监测数据的采场支架与顶板状态智能感知技术[J]. 煤炭学报,2020,45(6):2090−2103. CHENG Jingyi,WAN Zhijun,PENG Syd S,et al. Technology of intelligent sensing of longwall shield supports status and roof strata based on massive shield pressure monitoring data[J]. Journal of China Coal Society,2020,45(6):2090−2103.

[3] 谢正正,张 农,王 朋,等. 长期载荷作用下柔性锚杆力学特性及工程应用[J]. 煤炭学报,2020,45(9):3096−3106. XIE Zhengzheng,ZHANG Nong,WANG Peng,et al. Mechanical characteristics and field application of flexible bolt under long-term load[J]. Journal of China Coal Society,2020,45(9):3096−3106.

[4] 王宴滨,曾 静,高德利. 环空带压对深水水下井口疲劳损伤的影响规律[J]. 天然气工业,2020,40(12):116−123. WANG Yanbin,ZENG Jing,GAO Deli. Effect of annular pressure on the fatigue damage of deepwater subsea wellheads[J]. Natural Gas Industry,2020,40(12):116−123.

[5] 王黎松,高宝奎,胡天祥,等. 考虑材料非线性的环空增压预测模型[J]. 石油学报,2020,41(2):235−243. WANG Lisong,GAO Baokui,HU Tianxiang,et al. A prediction model of annular pressure build-up considering material nonlinearity[J]. Acta Petrolei Sinica,2020,41(2):235−243.

[6] 王海柱,石鲁杰,郑 永,等. 基于组合体力学模型的固井水泥石封隔能力分析[J]. 东北大学学报(自然科学版),2020,41(9):1334−1340. WANG Haizhu,SHI Lujie,ZHENG Yong,et al. Sealing capacity analysis of cement sheath based on combined mechanical model[J]. Journal of Northeastern University(Natural Science),2020,41(9):1334−1340.

[7] 刘 强,申照熙,李东风,等. 钛合金油套管抗挤毁性能计算与实验[J]. 天然气工业,2020,40(10):94−101. LIU Qiang,SHEN Zhaoxi,LI Dongfeng,et al. Calculation and experimental studies on the collapse strength of titanium alloy tubing and casing[J]. Natural Gas Industry,2020,40(10):94−101.

[8] 樊金杰,郭锦棠,肖明明,等. 核壳型丁苯胶乳的制备及其对油井水泥石性能的影响[J]. 化工进展,2018,37(12):4845−4852. FAN Jinjie,GUO Jintang,XIAO Mingming,et al. Preparation of styrene-butadiene latex with core-shell structure and effect on oil well cement[J]. Chemical Industry and Engineering Progress,2018,37(12):4845−4852.

[9] 郭辛阳,宋雨媛,步玉环,等. 基于损伤力学变内压条件下水泥环密封完整性模拟[J]. 石油学报,2020,41(11):1425−1433. GUO Xinyang,SONG Yuyuan,BU Yuhuan,et al. Simulation of seal integrity of cement sheath under variable internal casing pressure based on damage mechanics[J]. Acta Petrolei Sinica,2020,41(11):1425−1433.

[10] 孙海涛,郑颖人,胡千庭,等. 地面钻井套管耦合变形作用机理[J]. 煤炭学报,2011,36(5):823−829. SUN Haitao,ZHENG Yingren,HU Qianting,et al. Surface borehole casing coupling deformation mechanism[J]. Journal of China Coal Society,2011,36(5):823−829.

[11] 于秋鸽, 张华兴, 邓伟男, 等. 采动影响下断层面离层空间产生及其对开采空间传递作用分析[J]. 煤炭学报, 2018, 43(12): 3286−3292. YU Qiuge, ZHANG Huaxing, DENG Weinan, et al. Analysis of fault separation generation and its increasing effect on mining zone.[J]. Journal of China Coal Society, 2018, 43(12): 3286−3292.

[12] 杨 鹏,杨伟峰,张鑫全,等. 基于信息熵的采动覆岩应力动态演化与水害辨识[J]. 煤炭学报,2021,46(9):3006−3014. YANG Peng,YANG Weifeng,ZHANG Xinquan,et al. Dynamic evolution of overlying strata stress induced by mining and mine water disaster identification based on information entropy[J]. Journal of China Coal Society,2021,46(9):3006−3014.

[13] 柴 敬,杨玉玉,欧阳一博,等. 采场覆岩变形破坏模拟试验的光测方法对比[J]. 煤炭学报,2021,46(1):154−163. CHAI Jing,YANG Yuyu,OUYANG Yibo,et al. Comparison of optical measurement methods for deformation and failure simulation test of overburden in working face[J]. Journal of China Coal Society,2021,46(1):154−163.

[14] 许家林,秦 伟,轩大洋,等. 采动覆岩卸荷膨胀累积效应[J]. 煤炭学报,2020,45(1):35−43. XU Jialin,QIN Wei,XUAN Dayang,et al. Accumulative effect of overburden strata expansion induced by stress relief[J]. Journal of China Coal Society,2020,45(1):35−43.

[15] 梁 涛, 刘晓丽, 王思敬. 采动裂隙扩展规律及渗透特性分形研究[J]. 煤炭学报, 2019, 44(12): 3729−3739. LIANG Tao, LIU Xiaoli, WANG Sijing. Fractal study on the crack network evolution and permeability change in mining rock mass.[J]. Journal of China Coal Society, 2019, 44(12): 3729−3739.

[16] 张 鑫,乔 伟,雷利剑,等. 综放开采覆岩离层形成机理[J]. 煤炭学报,2016,41(S2):342−349. ZHANG Xin,QIAO Wei,LEI Lijian,et al. Formation mechanism of overburden bed separation in fully mechanized top-coal caving[J]. Journal of China Coal Society,2016,41(S2):342−349.

[17] 牛宏伟,高 峰,韩进利,等. 巨厚砂岩下厚煤层采动覆岩离层形成机理与探测[J]. 煤矿安全,2020,51(11):150−154. NIU Hongwei,GAO Feng,HAN Jinli,et al. Formation mechanism and detection method of overburden abscission layer in mining coal seam under thick sandstone[J]. Safety in Coal Mines,2020,51(11):150−154.

[18] 林海飞, 李树刚, 成连华, 等. 基于薄板理论的采场覆岩关键层的判别方法[J]. 煤炭学报, 2008, 33(10): 1081−1085. LIN Haifei, LI Shugang, CHENG Lianhua, et al. Key layer distinguishing method of overlying strata based on the thin slab theory.[J]. Journal of China Coal Society, 2008, 33(10): 1081−1085.

[19] 赵雁海,周晨华,张 新,等. 浅埋单一关键层断裂覆岩压力成拱效应及分布特征[J]. 煤炭学报,2020,45(S1):1−11. ZHAO Yanhai,ZHOU Chenhua,ZHANG Xin,et al. The pressure arching effect and distribution characteristics of fractured strata of single key layer under shallow buried condition[J]. Journal of China Coal Society,2020,45(S1):1−11.

[20] 杨兆彪,王家琛,杨彦群,等. 废弃工作面遗留煤层气扰动储层空间划分:以屯兰煤矿12501工作面为例[J]. 煤炭科学技术,2023,51(2):243−255. YANG Zhaobiao,WANG Jiachen,YANG Yanqun,et al. Spatial division of abandoned mine methane reservoir:taking 12501 working face of Tunlan Coal Mine as an example[J]. Coal Science and Technology,2023,51(2):243−255.

[21] 郑俊德,张艳秋,王文军,等. 非均匀载荷下套管强度的计算[J]. 石油学报,1998,19(1):129−133,10. ZHENG Junde,ZHANG Yanqiu,WANG Wenjun,et al. Calculation of casing strength under non-uniform load[J]. Acta Petrollei Sinica,1998,19(1):129−133,10.

[22] 林元华,邓宽海,曾德智,等. 套管在单轴压缩载荷下的失效规律[J]. 天然气工业,2016,36(1):99−105. LIN Yuanhua,DENG Kuanhai,ZENG Dezhi,et al. Casing failure laws under uniaxial compressive load[J]. Natural Gas Industry,2016,36(1):99−105.

[23] 孙东玲,付军辉,孙海涛,等. 采动区瓦斯地面井破断防护研究及应用[J]. 煤炭科学技术,2018,46(6):17−23. SUN Dongling,FU Junhui,SUN Haitao,et al. Study and application of gas surface well broken protection in mining area[J]. Coal Science and Technology,2018,46(6):17−23.

下载:

下载: