Energy transfer process and evolution characteristics in impeller of contra-rotating axial fan

-

摘要:

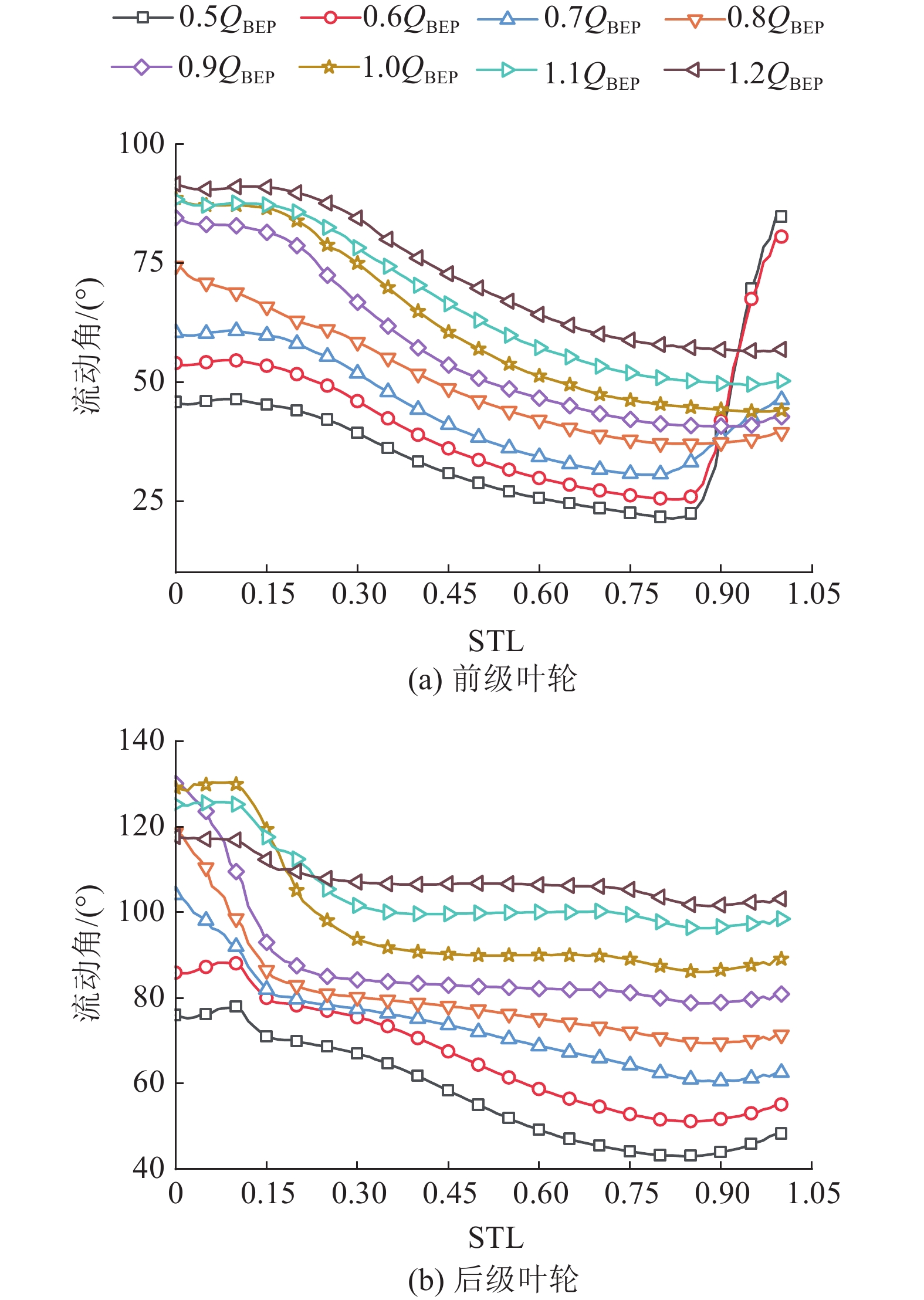

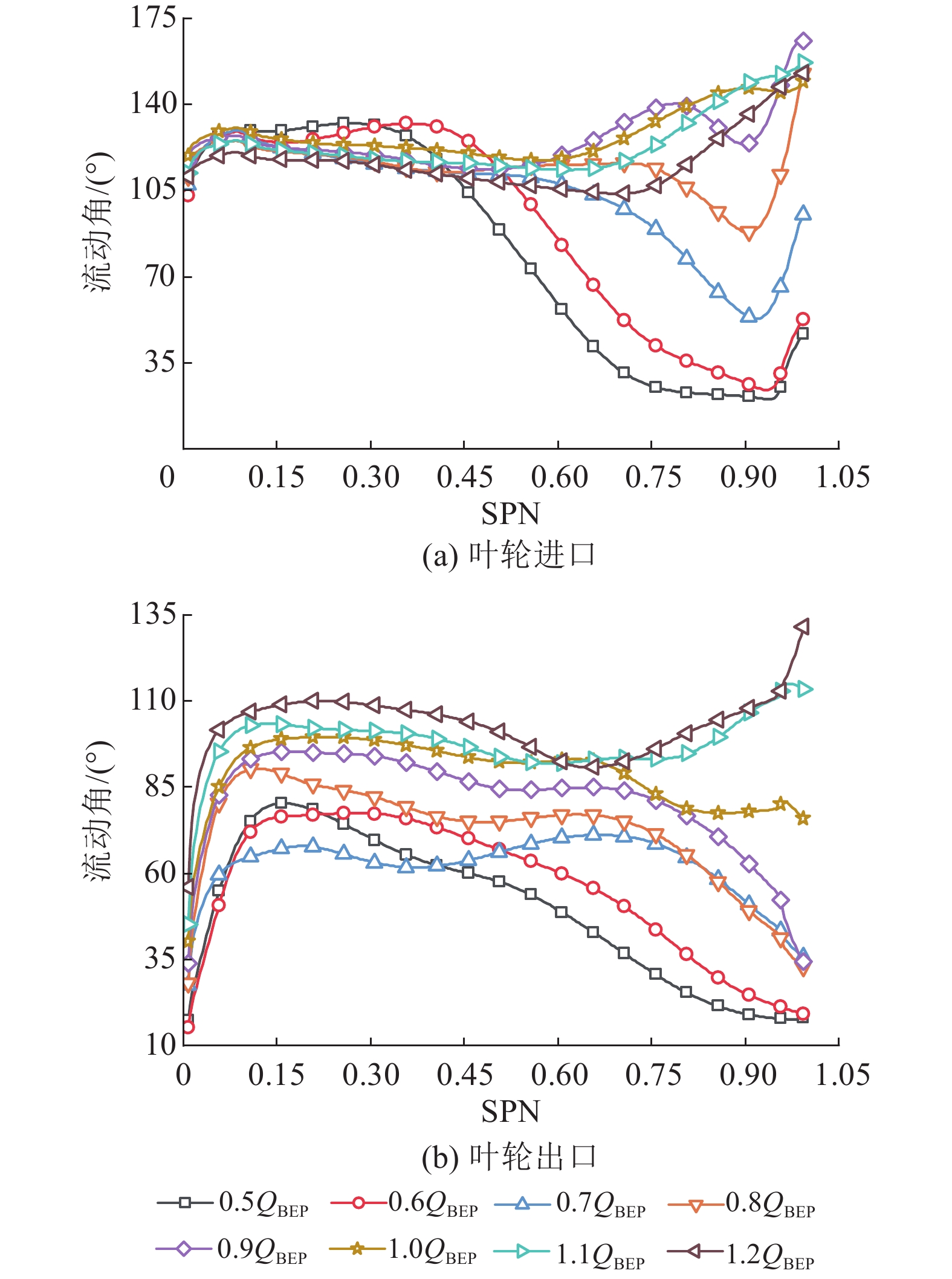

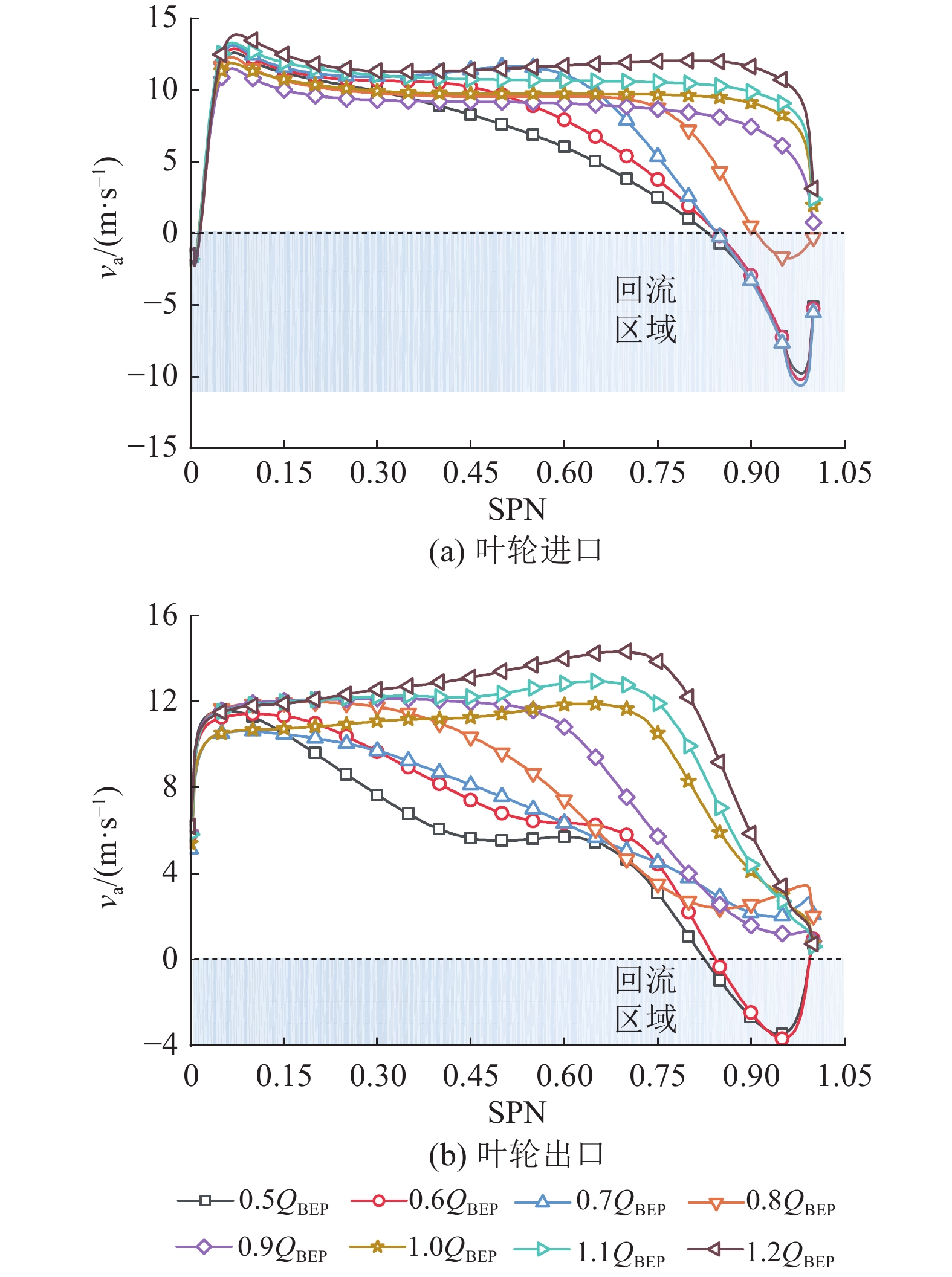

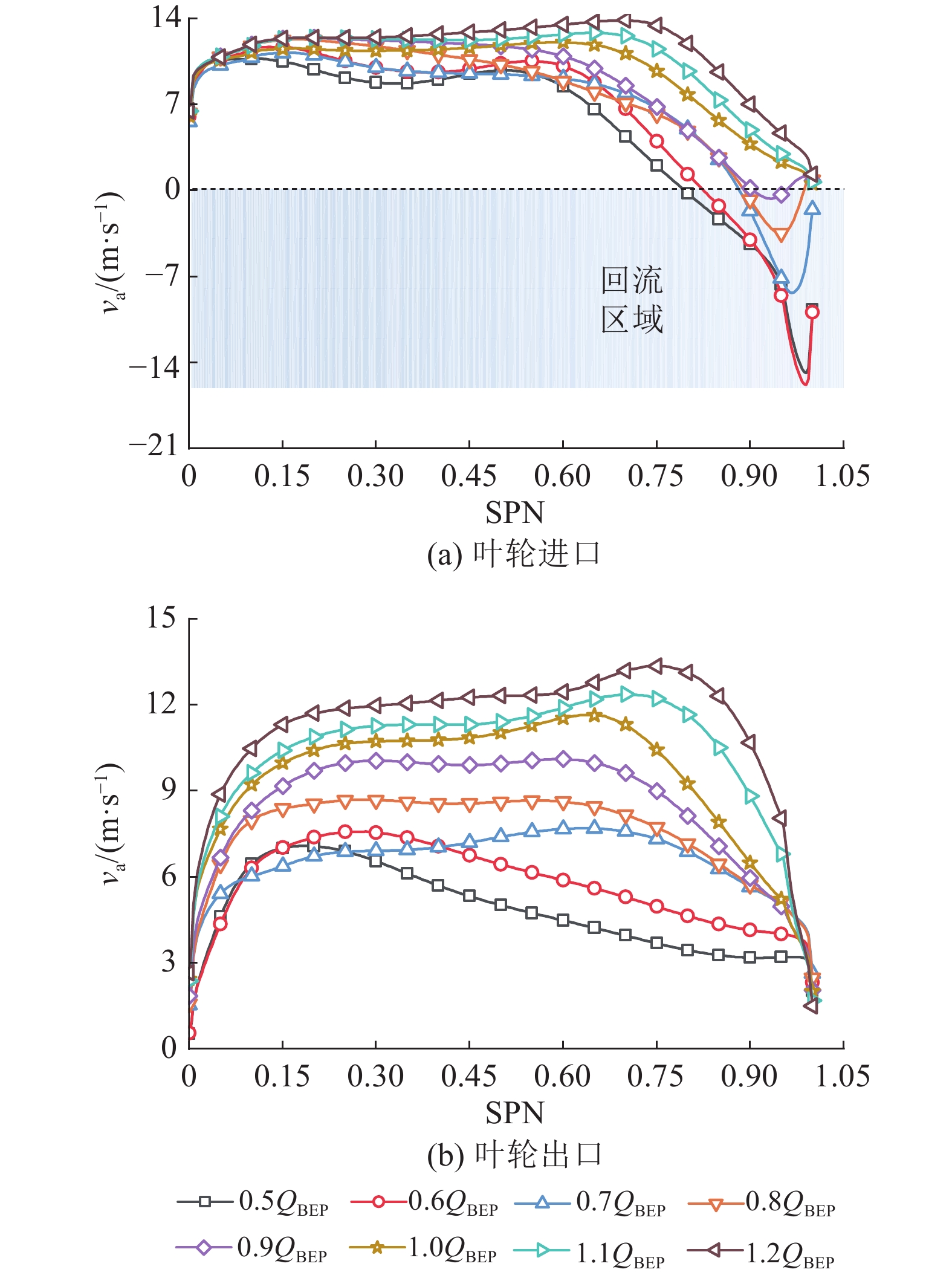

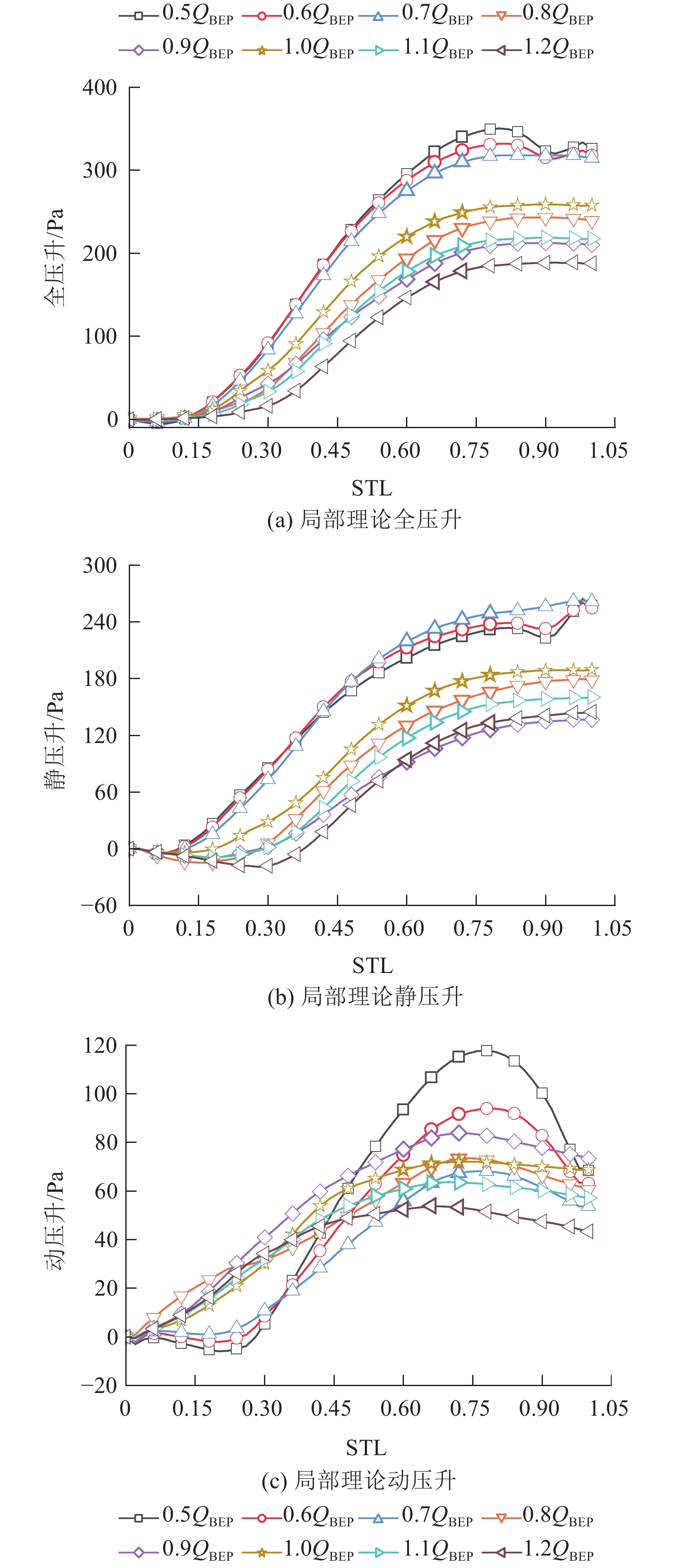

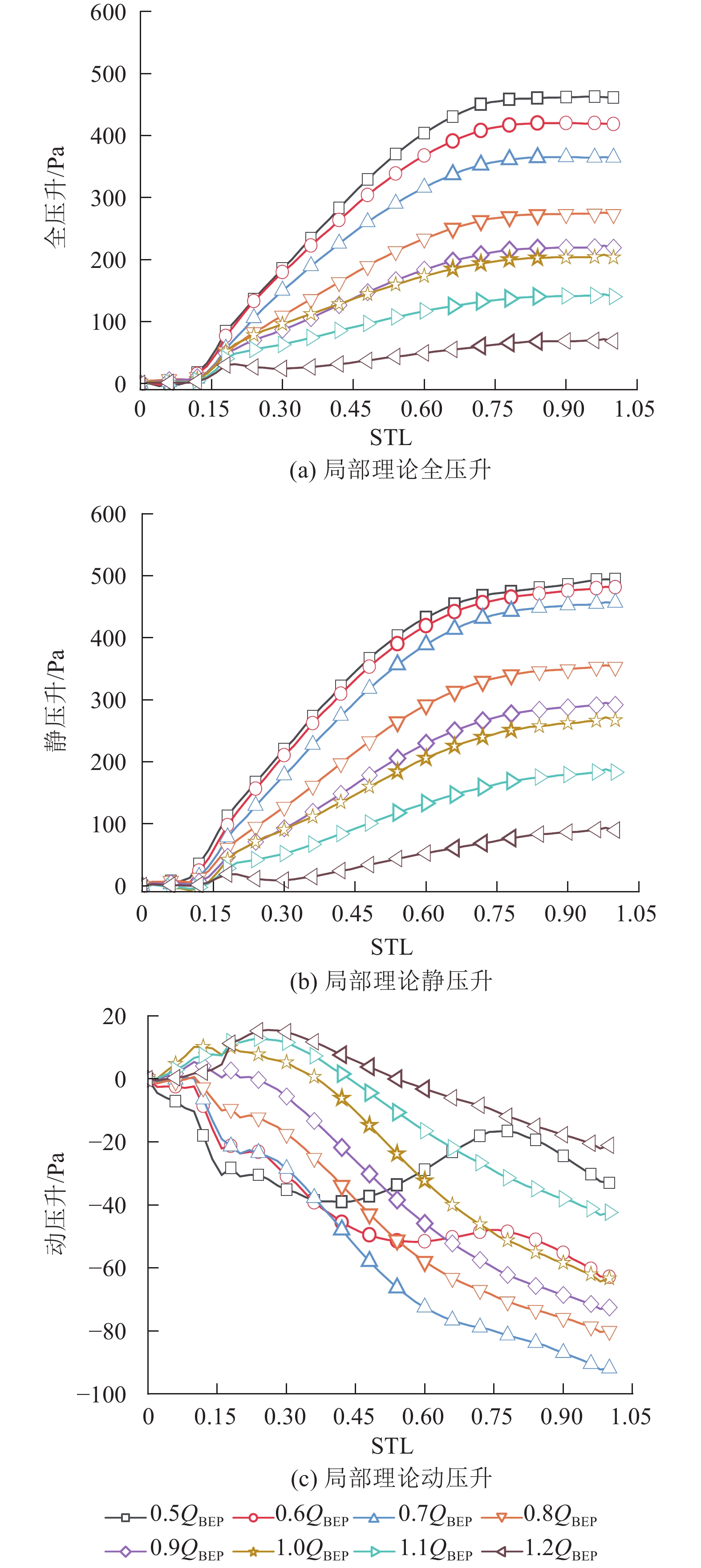

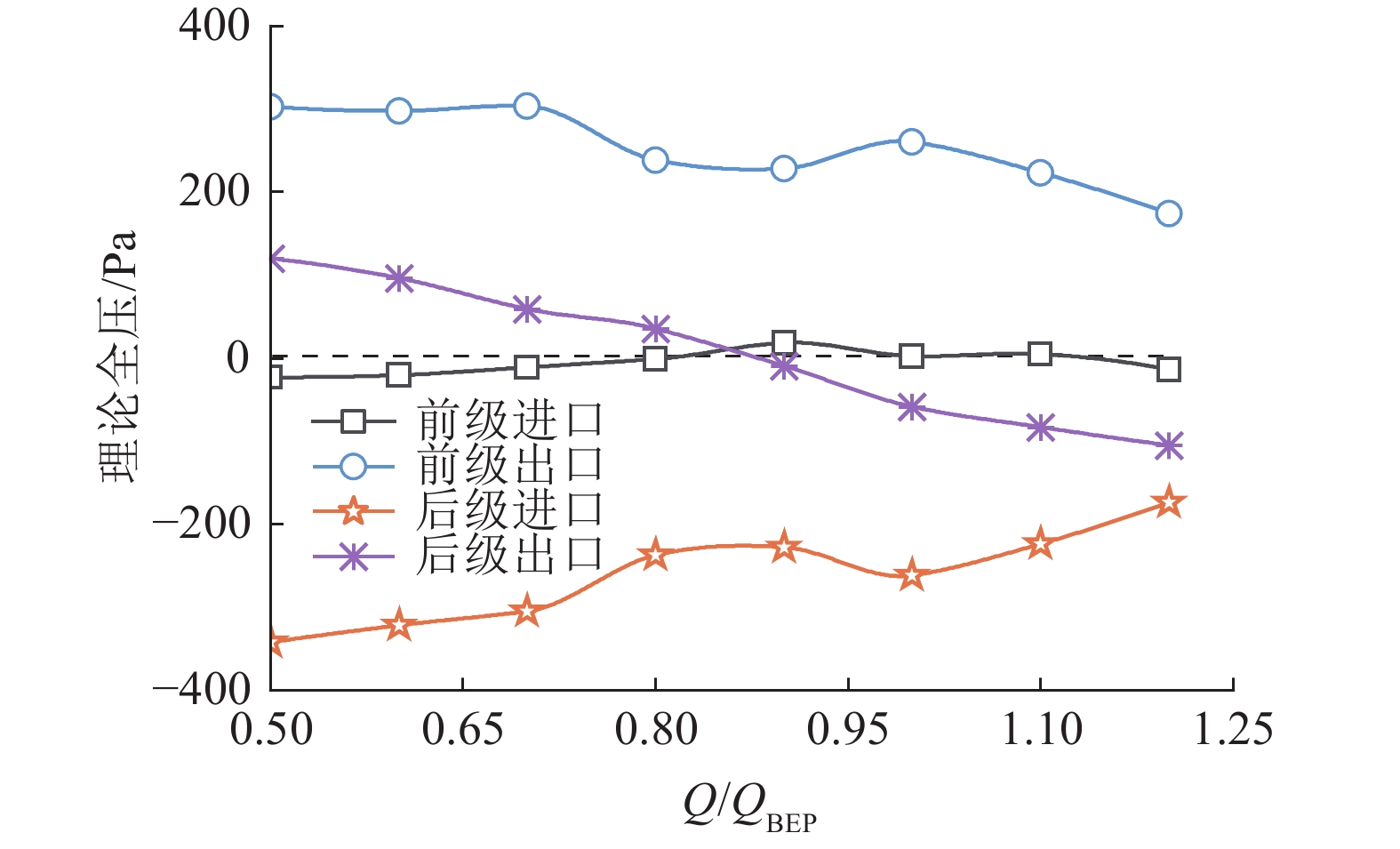

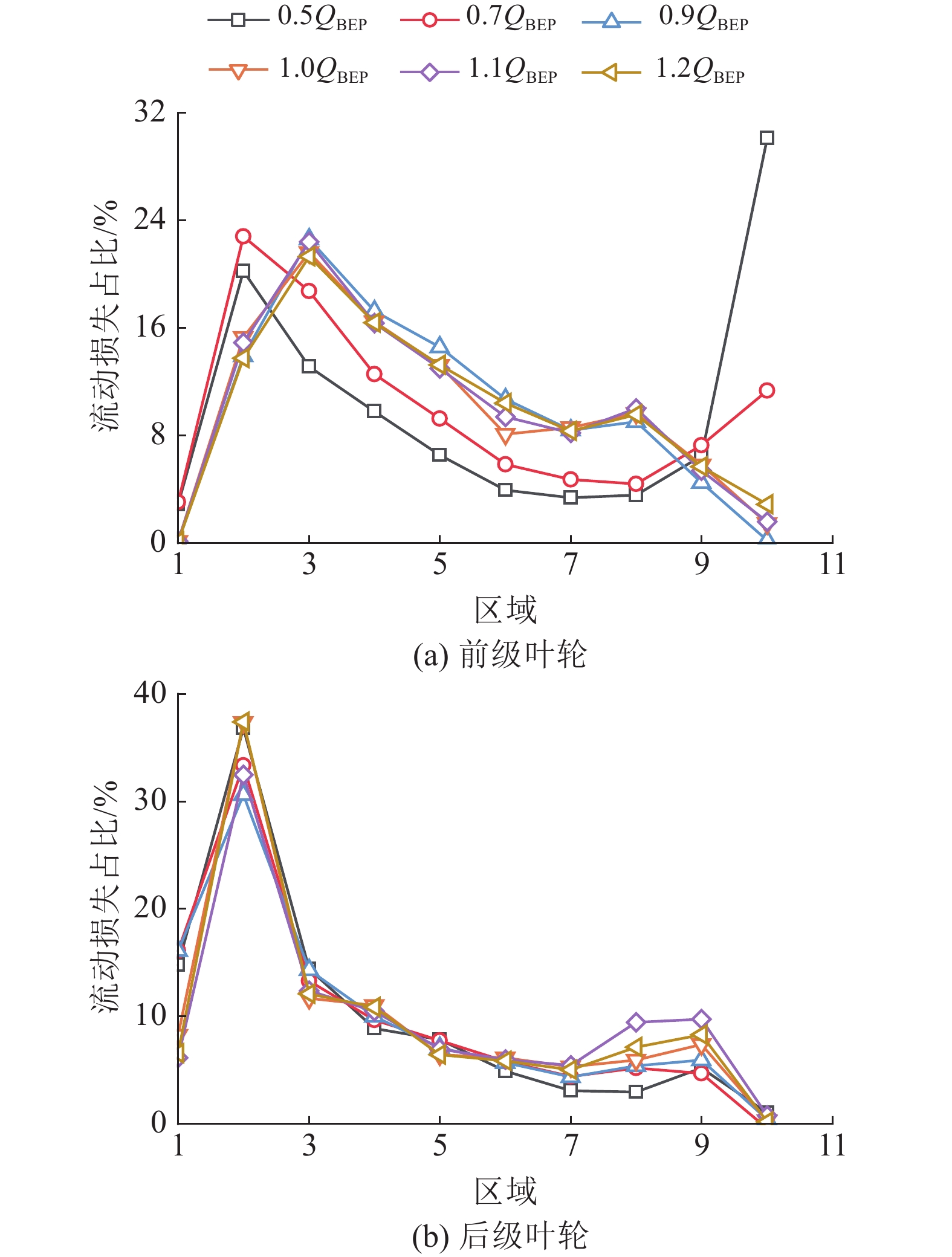

叶轮旋转将能量传递给风流,如何实现能量高效转化是工程领域内关键问题,掌握叶轮内能量传递过程是实现能量高效转化的前提与基础。为明确通风机叶轮内能量传递机理,以对旋轴流通风机为研究对象,采用数值模拟和试验方法获得了叶轮内部流场。基于叶轮机械能量转换理论,探明了叶轮内风流流动角、轴向速度和叶轮局部理论全压升等参数演变规律,揭示了叶轮内能量演变特性和流动损失过程。结果表明:当流量大于0.7 QBEP(QBEP为最高效率工况)时,前级叶轮效率明显高于后级,在最高效率工况,两级叶轮效率差值约26.5%,当流量等于1.22 QBEP时,效率差值高达66.6%,表明后级叶轮效率偏低是导致通风机整机效率降低的主因;在流动方向,后级叶轮流动损失集中在STL=0~0.3(STL为流动方向叶轮进口到出口的距离),降低该区域的流动损失是提升后级叶轮效率的关键;实际风流全压升曲线驼峰特性是叶轮理论全压升和流动损失共同作用的结果,但主要与前级叶轮出口和后级叶轮入口理论全压有关;流动角在叶展方向急剧减小或增大将引起轴向速度显著减小,进而导致前级叶轮进出口和后级叶轮进口在SPN=0.8~1.0产生回流(SPN为叶展方向轮毂至机壳的距离),最终影响叶轮内理论全压升的大小,因此流动角和轴向速度共同作用并改变叶轮内能量演变规律;两级叶轮局部理论全压升均在叶轮中部区域获得较大提升,而在叶轮进出口区域变化甚微,局部理论全压升增长率是决定叶轮理论全压升大小的关键因素。

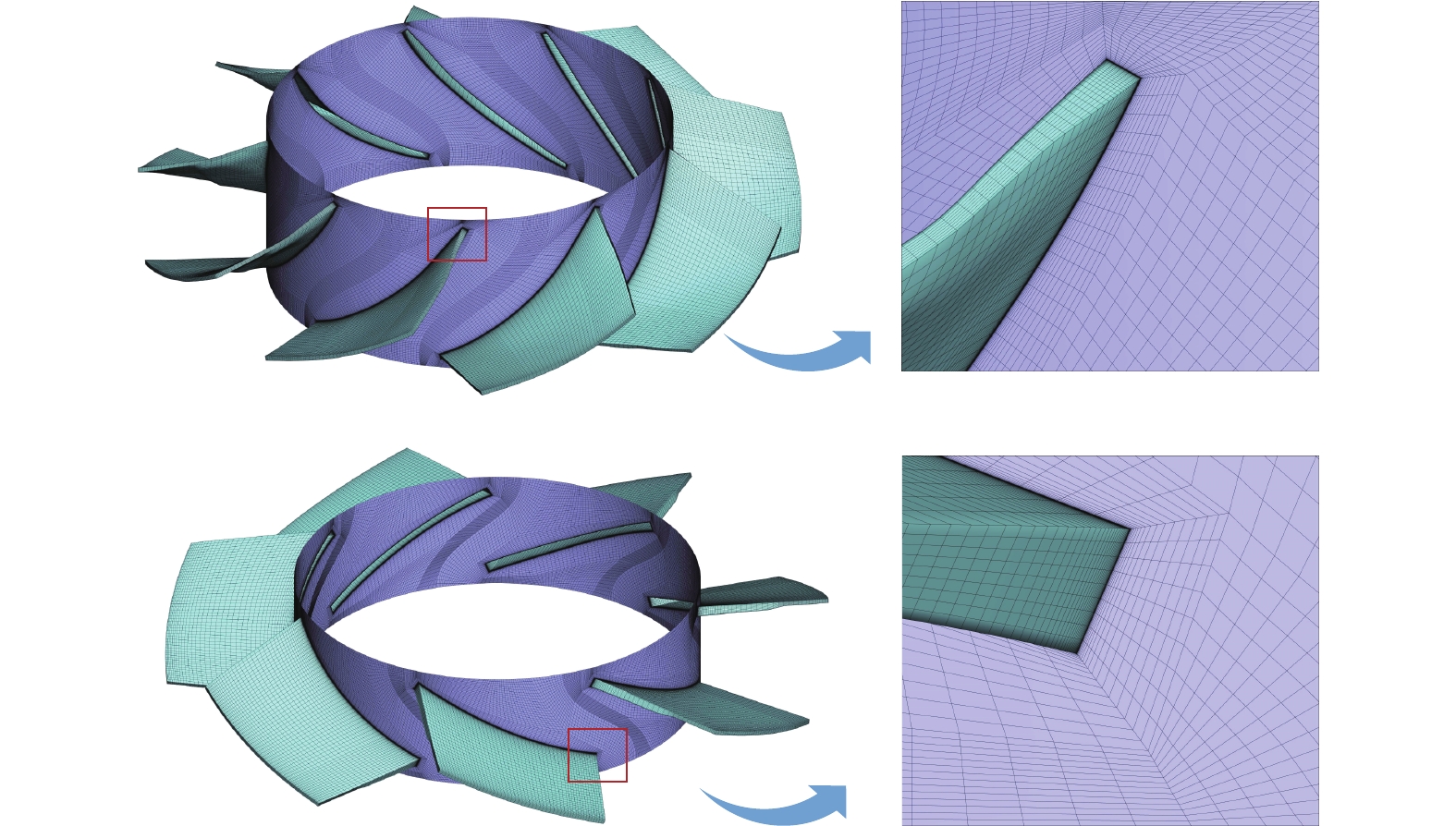

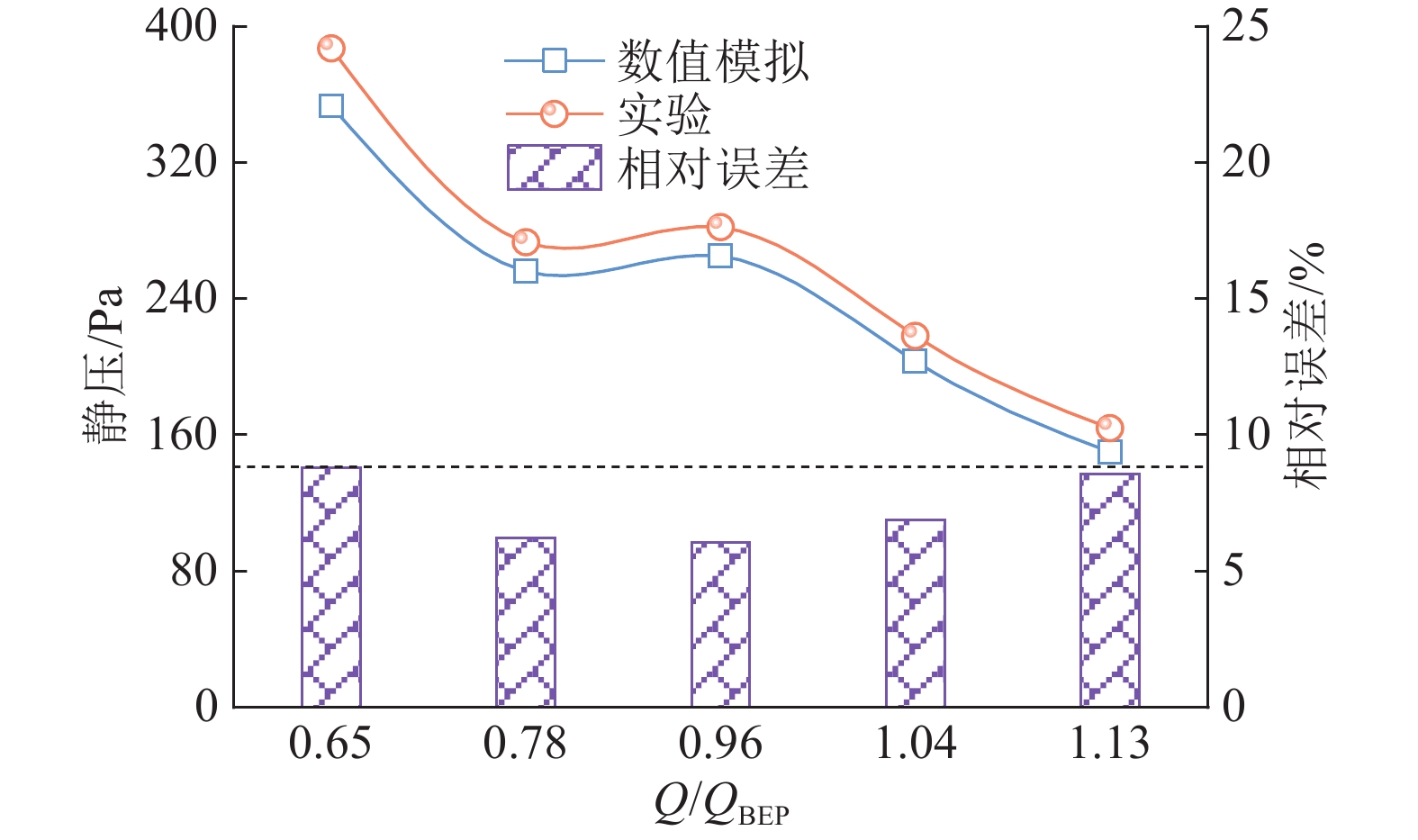

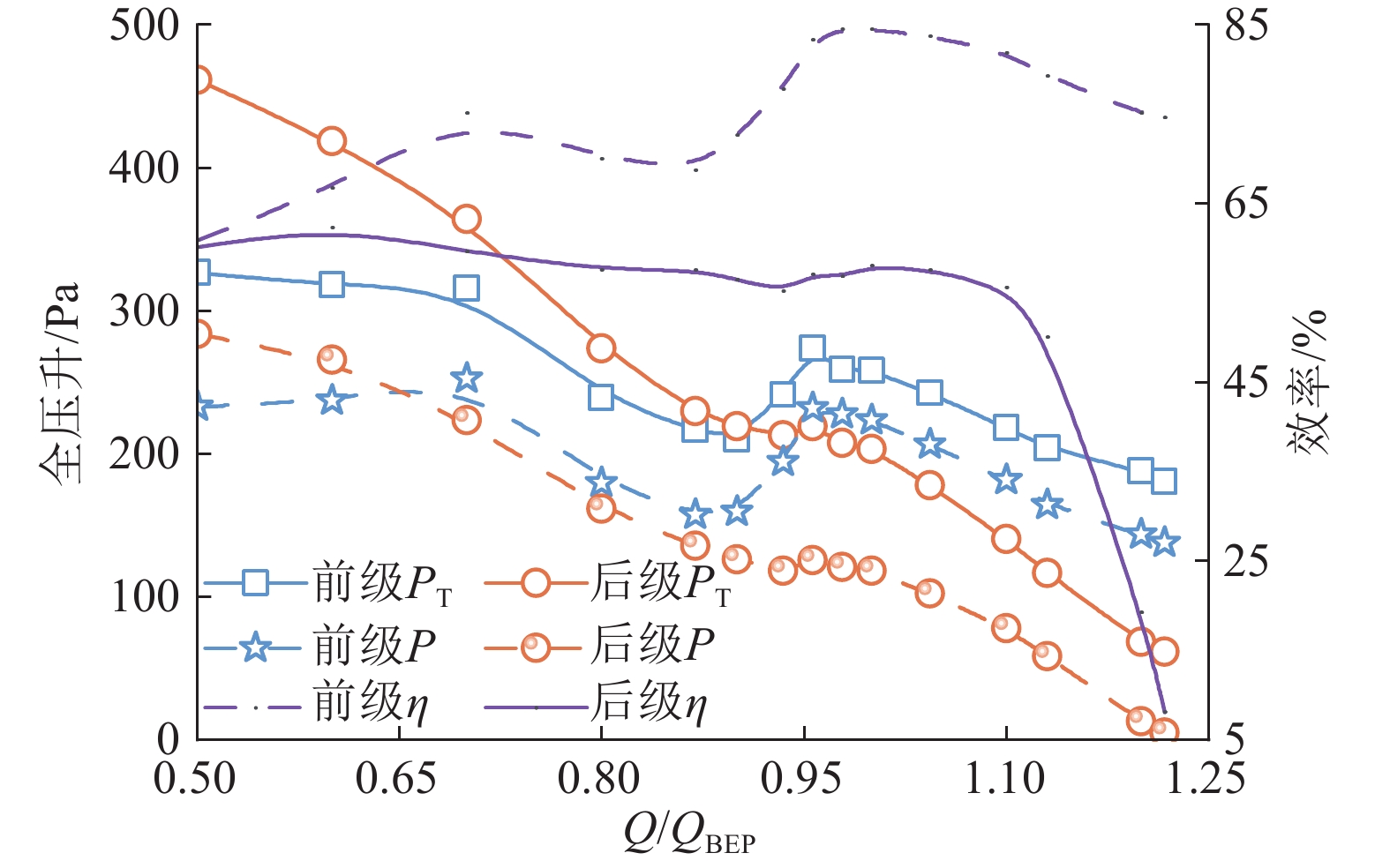

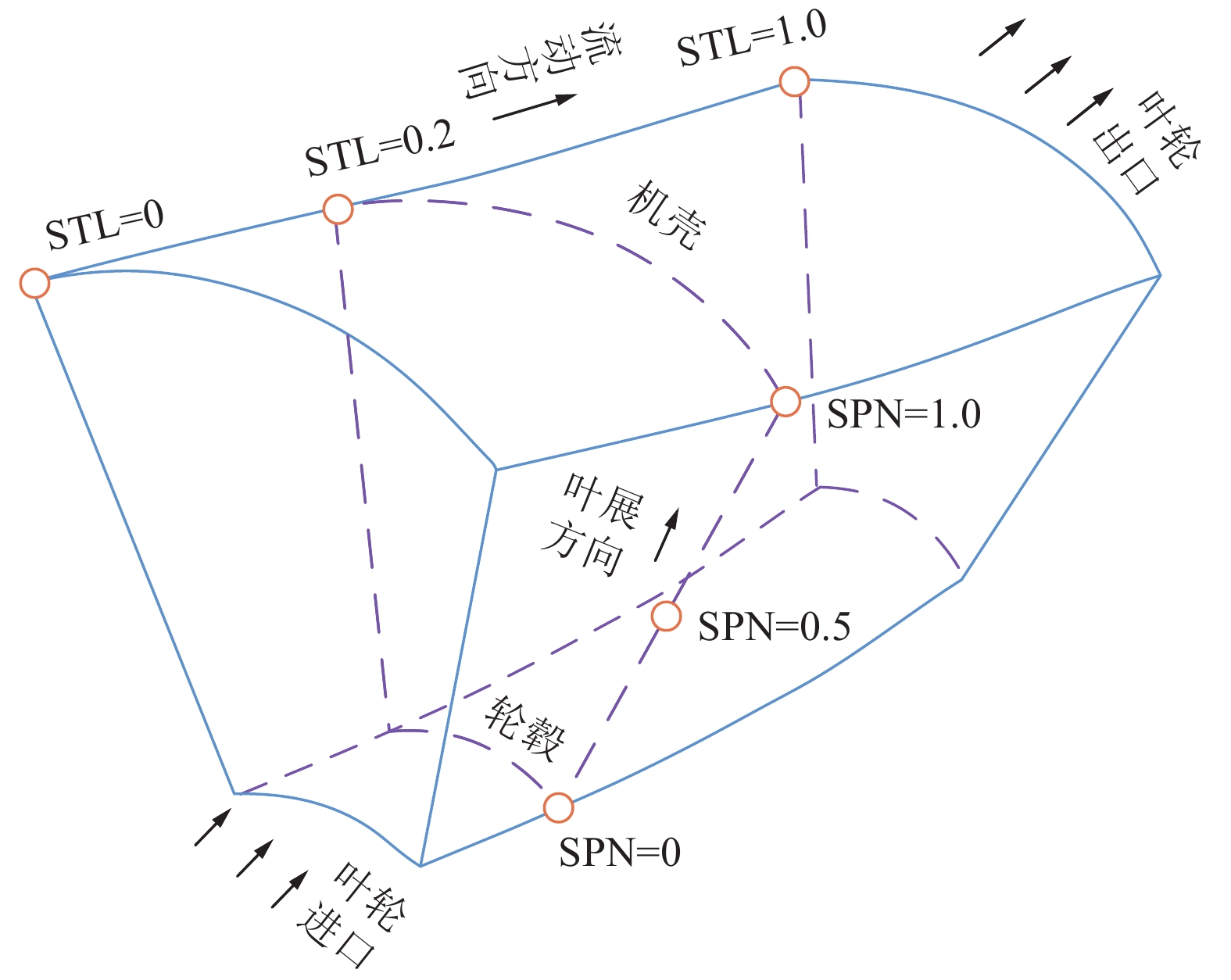

Abstract:Energy is transferred to the airflow during the rotation of impeller. In engineering, the efficient energy conversion is a key issue. Mastering the energy transfer process in impeller is the premise and basis for realizing efficient energy conversion. In order to clarify the energy transfer mechanism in impeller of contra-rotating axial fan, the internal flow field in impeller was obtained by numerical simulation and experiment. Based on the turbomachine energy conversion theory, the evolution characteristics of parameters such as flow angle, axial velocity and local theory total pressure rise were analyzed, and the laws of energy distribution and flow loss process in impeller were clarified. The results show that the efficiency of front impeller is significantly higher than that of the rear impeller when the flow rate is greater than 0.7 QBEP (QBEP is flow rate at the best efficiency point). When Q=1.0 QBEP, the efficiency difference between the two-stage impellers is about 26.5%, and the efficiency difference is as high as 66.6% when the flowrate increases to 1.22 QBEP, which indicate that the low efficiency of the rear impeller is the main reason for the efficiency reduction of the fan. In the streamwise location, the flow loss of the rear impeller is concentrated within STL=0−0.3 (STL represents the dimensionless distance from the inlet to outlet of the impeller in the flow direction), and reducing the flow loss in this region is the key to improve the efficiency of rear impeller. The hump characteristic of actual total pressure rise curve is the result of the combined effect of theory total pressure rise and flow loss, but mainly related to the theory total pressure rise at the outlet of front impeller and inlet of rear impeller. The sharp decrease or increase in flow angle at the spanwise direction is the main cause of a significant decrease in axial velocity, which in turn leads to backflow in the inlet and outlet of the front impeller and inlet of the rear impeller within SPN=0.8−1.0 (SPN represents the dimensionless distance from the hub to shroud of the impeller in the spanwise direction), and ultimately affects the theory total pressure rise in impeller. Therefore, the flow angle and axial velocity jointly affect the energy evolution law in impeller. The local theory total pressure rise is greatly improved in the middle region of the impeller, while the change in the inlet and outlet region is negligible. The significant increase growth rate of local theory total pressure rise is the key factor determining the theory total pressure rise of the impeller.

-

-

表 1 通风机主要参数

Table 1 Main parameters of fan

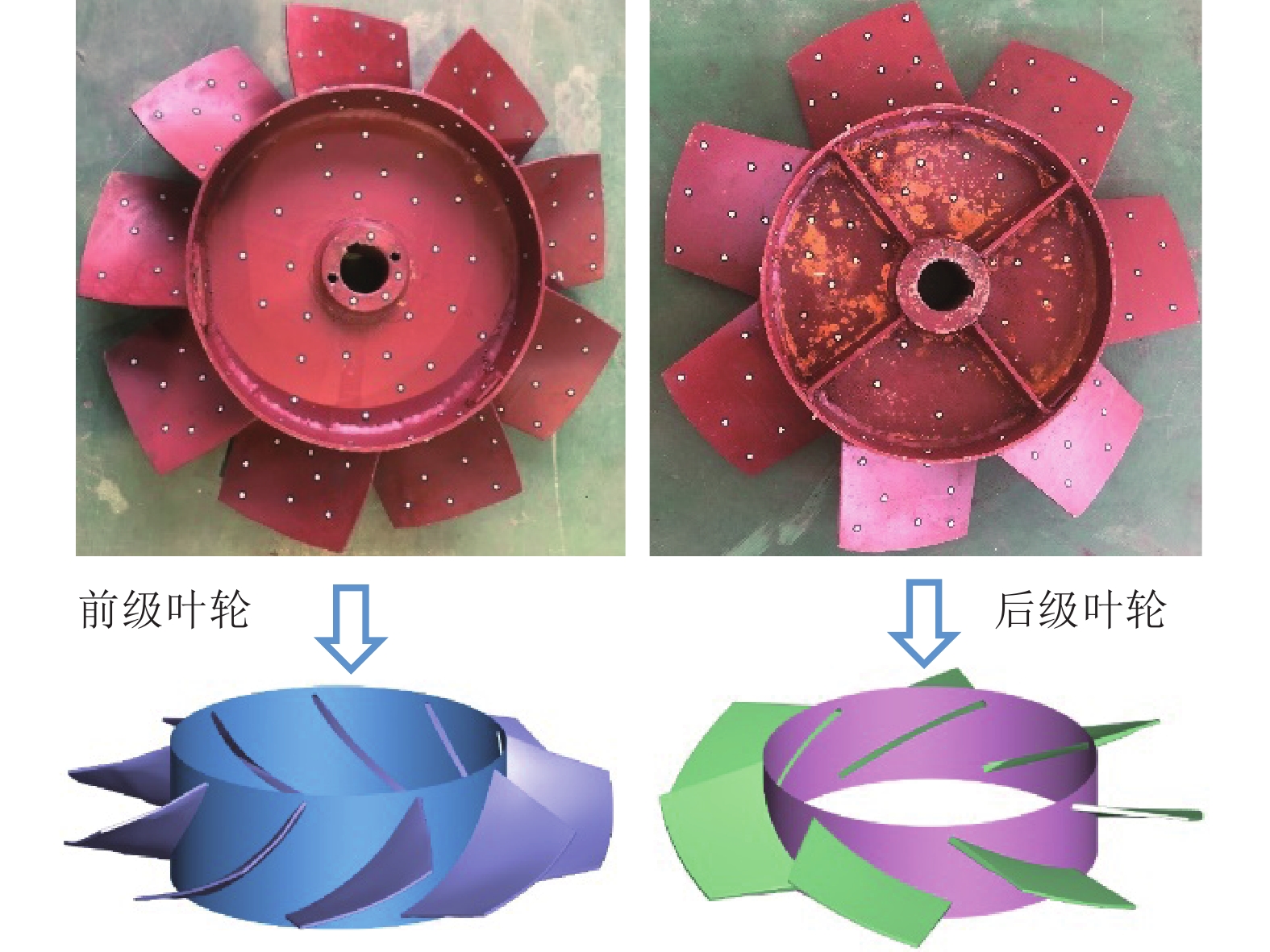

项目 参数 前级叶轮叶片数 9 后级叶轮叶片数 7 叶顶间隙/mm 5 前级叶轮转速/(r·min−1) 900 后级叶轮转速/(r·min−1) 900 叶轮直径/mm 620 轮毂直径/mm 380 -

[1] 周福宝,辛海会,魏连江,等. 矿井智能通风理论与技术研究进展[J]. 煤炭科学技术,2023,51(1):313−328. ZHOU Fubao,XIN Haihui,WEI Lianjiang,et al. Research progress of mine intelligent ventilation theory and technology[J]. Coal Science and Technology,2023,51(1):313−328.

[2] 张庆华,姚亚虎,赵吉玉. 我国矿井通风技术现状及智能化发展展望[J]. 煤炭科学技术,2020,48(2):97−103. ZHANG Qinghua,YAO Yahu,ZHAO Jiyu. Status of mine ventilation technology in China and prospects for intelligent development[J]. Coal Science and Technology,2020,48(2):97−103.

[3] 陈庆光,徐延辉,郭武,等. 轴向间距对FBCDZ-10-No20型对旋风机失速过程的影响[J]. 煤炭科学技术,2023,51(6):229−236. CHEN Qingguang,XU Yanhui,GUO Wu,et al. Influence of axial spacing on stall development of FBCDZ-10-No20 mode contra-rotating fan[J]. Coal Science and Technology,2023,51(6):229−236.

[4] AI Z J,QIN G L,LIN J X,et al. Variable-speed method for improving the performance of a mine counter-rotating fan[J]. Energy Science & Engineering,2020,8(7):2412−2425.

[5] HAO H Q,JIANG S G,WU Z Y,et al. Experimental study on precise control air quantity on demand by the cooperation of multiple main fans in mine[J]. Journal of Cleaner Production,2023,414:137626. doi: 10.1016/j.jclepro.2023.137626

[6] 孙晓波,孟大伟,杨小妮. 对旋风机电动机变极调速控制与节能分析[J]. 电机与控制学报,2019,23(11):60−66. SUN Xiaobo,MENG Dawei,YANG Xiaoni. Pole-changing control of motors and its energy saving of contra-rotating axial-flow fan[J]. Electric Machines and Control,2019,23(11):60−66.

[7] 陈世强,成剑林,冯进,等. 主扇扩散器出口速度分布的数值模拟与实验研究[J]. 中国安全科学学报,2008,18(8):32−36. doi: 10.3969/j.issn.1003-3033.2008.08.005 CHEN Shiqiang,CHENG Jianlin,FENG Jin,et al. Numerical simulation and experimental research on the velocity distribution in outlet of main fan diffusers[J]. China Safety Science Journal (CSSJ),2008,18(8):32−36. doi: 10.3969/j.issn.1003-3033.2008.08.005

[8] 金永平,刘德顺,文泽军. 矿用对旋式轴流通风机前后两级叶片弯掠参数优化设计[J]. 煤炭学报,2010,35(10):1754−1759. JIN Yongping,LIU Deshun,WEN Zejun. Optimization design for skew and sweep parameters of mine contra-rotating axial fan two-stage blades[J]. Journal of China Coal Society,2010,35(10):1754−1759.

[9] 孙文龙,方祥军. 对旋风机叶片造型优化对气动特性的影响[J]. 工程热物理学报,2018,39(6):1251−1257. SUN Wenlong,FANG Xiangjun. Influence of blade structure optimization on the aerodynamic characteristics for counter-rotating fan[J]. Journal of Engineering Thermophysics,2018,39(6):1251−1257.

[10] YE X M,ZHENG N,HU J M,et al. Numerical investigation of the benefits of serrated Gurney flaps on an axial flow fan[J]. Energy,2022,252:124072. doi: 10.1016/j.energy.2022.124072

[11] YE X M,ZHANG J K,LI C X. Effect of blade tip pattern on performance of a twin-stage variable-pitch axial fan[J]. Energy,2017,126:535−563. doi: 10.1016/j.energy.2017.03.057

[12] 杨天康,叶学民,林卿,等. 叶顶开槽:小翼结构对提升轴流风机性能影响的数值研究[J]. 热能动力工程,2023,38(7):36−43. YANG Tiankang,YE Xuemin,LIN Qing,et al. Numerical study on influence of blade tip slot-winglet pattern on performance improvement of an axial fan[J]. Journal of Engineering for Thermal Energy and Power,2023,38(7):36−43.

[13] 张永建,徐晓,陈庆光,等. 轴向间距对矿用对旋式通风机性能的影响[J]. 煤炭学报,2011,36(7):1217−1221. ZHANG Yongjian,XU Xiao,CHEN Qingguang,et al. Effects of axial gap on contra-rotating mine fan’s performance[J]. Journal of China Coal Society,2011,36(7):1217−1221.

[14] 陈世强,王海桥,杨超,等. 变频矿用主通风机流量比与功率比的非等比特性实验研究[J]. 湖南科技大学学报(自然科学版),2016,31(2):1−7. CHEN Shiqiang,WANG Haiqiao,YANG Chao,et al. Experimental investigation of a mine main fan with variable frequency adjustment and the non-equal law between flowrate-ratio and power-ratio[J]. Journal of Hunan University of Science & Technology (Natural Science Edition),2016,31(2):1−7.

[15] TIAN F,WANG H Q,CHEN S Q,et al. Energy efficiency overestimated by classic affinity laws:relation between volumetric flow rate and static pressure of an axial mine fan adjusted by a variable frequency driver[J]. Mining Technology,2019,128(3):186−191. doi: 10.1080/25726668.2019.1631623

[16] 温嘉斌,和海波. 对旋轴流通风机流场预测及两级电机功率匹配研究[J]. 电工技术学报,2015,30(1):105−111. doi: 10.3969/j.issn.1000-6753.2015.01.014 WEN Jiabin,HE Haibo. Flow field estimation of counter-rotating axial flow fan and power matching research of two motors[J]. Transactions of China Electrotechnical Society,2015,30(1):105−111. doi: 10.3969/j.issn.1000-6753.2015.01.014

[17] 陈庆光,邹璐瑶,李哲,等. 进气型式对压入式矿用对旋主通风机内部流动及性能的影响[J]. 煤炭工程,2020,52(4):171−176. CHEN Qingguang,ZOU Luyao,LI Zhe,et al. Effect of intake type on internal flow and performance of mining contra-rotating main fan for forced ventilation[J]. Coal Engineering,2020,52(4):171−176.

[18] 陈庆光,邹璐瑶,李哲,等. 畸变进气条件下压入式矿用对旋主通风机失速机理研究[J]. 机械科学与技术,2021,40(5):670−677. CHEN Qingguang,ZOU Luyao,LI Zhe,et al. Study on stall mechanism of mining contra-rotating main fan for forced type ventilation under distortion air intake condition[J]. Mechanical Science and Technology for Aerospace Engineering,2021,40(5):670−677.

[19] MANAS M P,PRADEEP A M. Influence of distorted inflows on the performance of a contra-rotating fan[J]. The Aeronautical Journal,2021,125(1286):702−719. doi: 10.1017/aer.2020.120

[20] SHIGEMITSU T,FUKUTOMI J,OKABE Y,et al. Performance and flow condition of contra-rotating small-sized axial fan at partial flow rate[J]. International Journal of Fluid Machinery and Systems,2010,3(4):271−278. doi: 10.5293/IJFMS.2010.3.4.271

[21] 艾子健,吴龙,高浩. 对旋风机两级叶轮等功率R2变转速试验研究[J]. 流体机械,2019,47(3):1−5. AI Zijian,WU Long,GAO Hao. Experimental study on the R2 speed matching with equal power for the two rotors of the counter-rotating fan[J]. Fluid Machinery,2019,47(3):1−5.

[22] JUNG J H,JOO W G. The effect of the entrance hub geometry on the efficiency in an axial flow fan[J]. International Journal of Refrigeration,2019,101:90−97. doi: 10.1016/j.ijrefrig.2019.02.026

[23] JUNG J H,JOO W G. Effect of tip clearance,winglets,and shroud height on the tip leakage in axial flow fans[J]. International Journal of Refrigeration,2018,93:195−204.

[24] TIAN C Y,LIU X M,WANG J H,et al. Effects of bionic blades inspired by the butterfly wing on the aerodynamic performance and noise of the axial flow fan used in air conditioner[J]. International Journal of Refrigeration,2022,140:17−28. doi: 10.1016/j.ijrefrig.2022.04.018

[25] WANG K,JU Y P,ZHANG C H. Aerodynamic optimization of forward-curved blade centrifugal fan characterized by inclining bionic volute tongue[J]. Structural and Multidisciplinary Optimization,2021,63(5):2493−2507. doi: 10.1007/s00158-020-02801-2

[26] WHITE F M. Fluid mechanics[M]. New York:McGraw-Hill,2011:764−766.

[27] MUNSON B R,DONALD F Y,OKIISHI T H,et al. Fundamentals of Fluid Mechanics[M]. Hoboken:John Wiley & Sons,2009:647−652.

-

期刊类型引用(23)

1. 郑斌,钱兆明,贾明滔,李邵东. 推覆构造条件下多种因素不同工况边坡稳定性研究. 中国矿业. 2025(01): 164-173 .  百度学术

百度学术

2. 李营作. 先锋露天煤矿软岩边坡稳定性分析及控制方案设计. 露天采矿技术. 2024(02): 102-105 .  百度学术

百度学术

3. 李美军. 新鑫露天煤矿边坡稳定性分析及建议. 山东煤炭科技. 2024(09): 164-168 .  百度学术

百度学术

4. 王振伟,成智强,夏宇飞. 基于FLAC3D不同含水工况下软岩边坡蠕变变形分析. 北方工业大学学报. 2024(05): 49-56 .  百度学术

百度学术

5. 屈晓明. 考虑参数敏感性的软弱基底排土场边坡稳定性建模分析. 矿产勘查. 2024(S2): 308-312 .  百度学术

百度学术

6. 王志修,秦秀山. 贯穿断层及隐伏巷道对某露天边坡稳定性影响数值模拟分析. 有色金属(矿山部分). 2023(01): 62-67 .  百度学术

百度学术

7. 李元浩,王振伟,韦永豪,郭海棣,林令鑫. 基于双向流固耦合的顺倾岩质边坡变形机理研究. 露天采矿技术. 2023(02): 61-64 .  百度学术

百度学术

8. 吕承贤,张东华. 石头梅一号露天煤矿顺层边坡稳定性评价及治理措施. 露天采矿技术. 2023(02): 46-49 .  百度学术

百度学术

9. 郭海建,成功. 基于三维数值模拟的黑山露天矿边坡形态优化. 露天采矿技术. 2023(02): 42-45+49 .  百度学术

百度学术

10. 张禹,刘宇,杨洋,杨国华,吕文伟,李广贺. 基于形态与支挡效应的露天矿到界边坡形态优化. 煤炭科学技术. 2023(04): 66-71 .  本站查看

本站查看

11. 屈晓明. 基于RBF神经网络的露天采石场边坡稳定性数值模拟. 水力发电. 2023(06): 34-38 .  百度学术

百度学术

12. 夏宇飞,王振伟,李元浩,郭海棣,黄科伟. 别斯库都克露天煤矿南帮顺层边坡稳定性分析. 露天采矿技术. 2023(03): 78-81 .  百度学术

百度学术

13. 张军文. 软土边坡开挖变形特征与临界破坏范围数值模拟. 能源与节能. 2023(07): 156-160 .  百度学术

百度学术

14. 李文尧,黄科伟,李营作,姜海涛,韦永豪. 顺倾多弱层复合边坡稳定性分析及参数优化. 露天采矿技术. 2023(04): 14-16+22 .  百度学术

百度学术

15. 黄亚军,景明,吕志强,徐啸川. 考虑软弱夹层蠕变特性的某矿山边坡稳定性研究. 有色金属(矿山部分). 2023(06): 94-101+127 .  百度学术

百度学术

16. 贺云,李爱兵,虎万杰. 含软弱夹层露采边坡稳定性分析与治理方案研究. 采矿技术. 2022(01): 54-57+61 .  百度学术

百度学术

17. Karimov Nodirbek. 复合顺倾弱层边坡变形破坏机理研究. 煤炭科技. 2022(01): 64-69 .  百度学术

百度学术

18. 李广贺,王东,曹兰柱,杨国华,魏宁. 露天煤矿顺倾软岩到界边坡空间形态优化. 安全与环境学报. 2022(02): 673-679 .  百度学术

百度学术

19. 王振伟,李斌,王智涛,董黎明,韦永豪,李营作. 伊敏露天矿弱层与正断层复合作用下顺倾边坡变形规律. 露天采矿技术. 2022(05): 24-27 .  百度学术

百度学术

20. 袁飞虎,朱显峰,陈德军,向小东,李伟. 多断层对露天矿高陡边坡稳定性的影响研究. 现代矿业. 2022(11): 82-88 .  百度学术

百度学术

21. 肖学沛,蒋锐. 某高速公路堑坡滑坡变形机制与稳定性分析. 地质灾害与环境保护. 2021(01): 42-48 .  百度学术

百度学术

22. 毛正君,毕银丽,李成,陈建平,孙魁,张瑾鸽,连海波,刘伟. 渭北石灰岩露天采区高陡边坡破坏模式及形态优化研究. 西北地质. 2021(04): 211-226 .  百度学术

百度学术

23. 刘月亭,吕文伟,张禹. 黑山露天矿底帮边坡留煤柱设计分析. 露天采矿技术. 2021(06): 93-95+99 .  百度学术

百度学术

其他类型引用(13)

下载:

下载: