Evolution laws and control technology of near and far stress field in hard roof mining roadway

-

摘要:

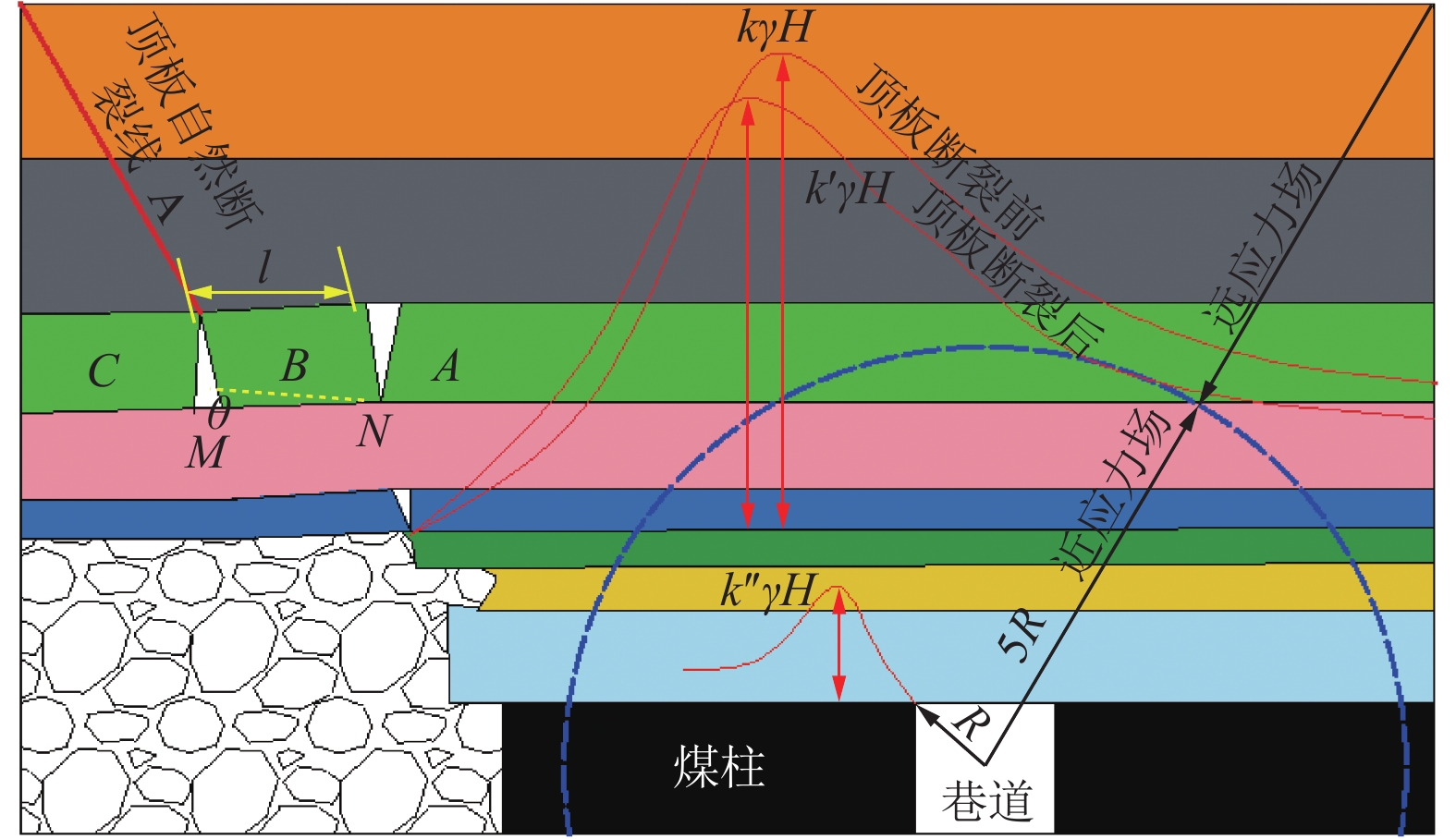

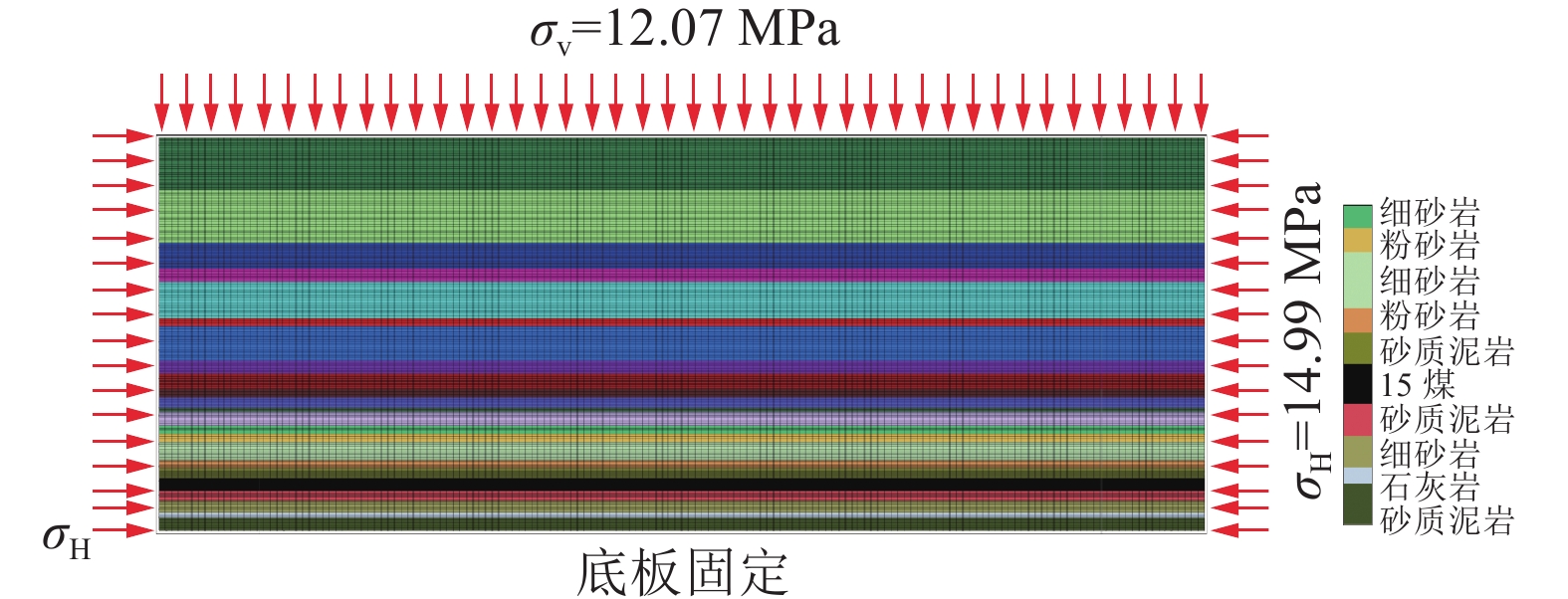

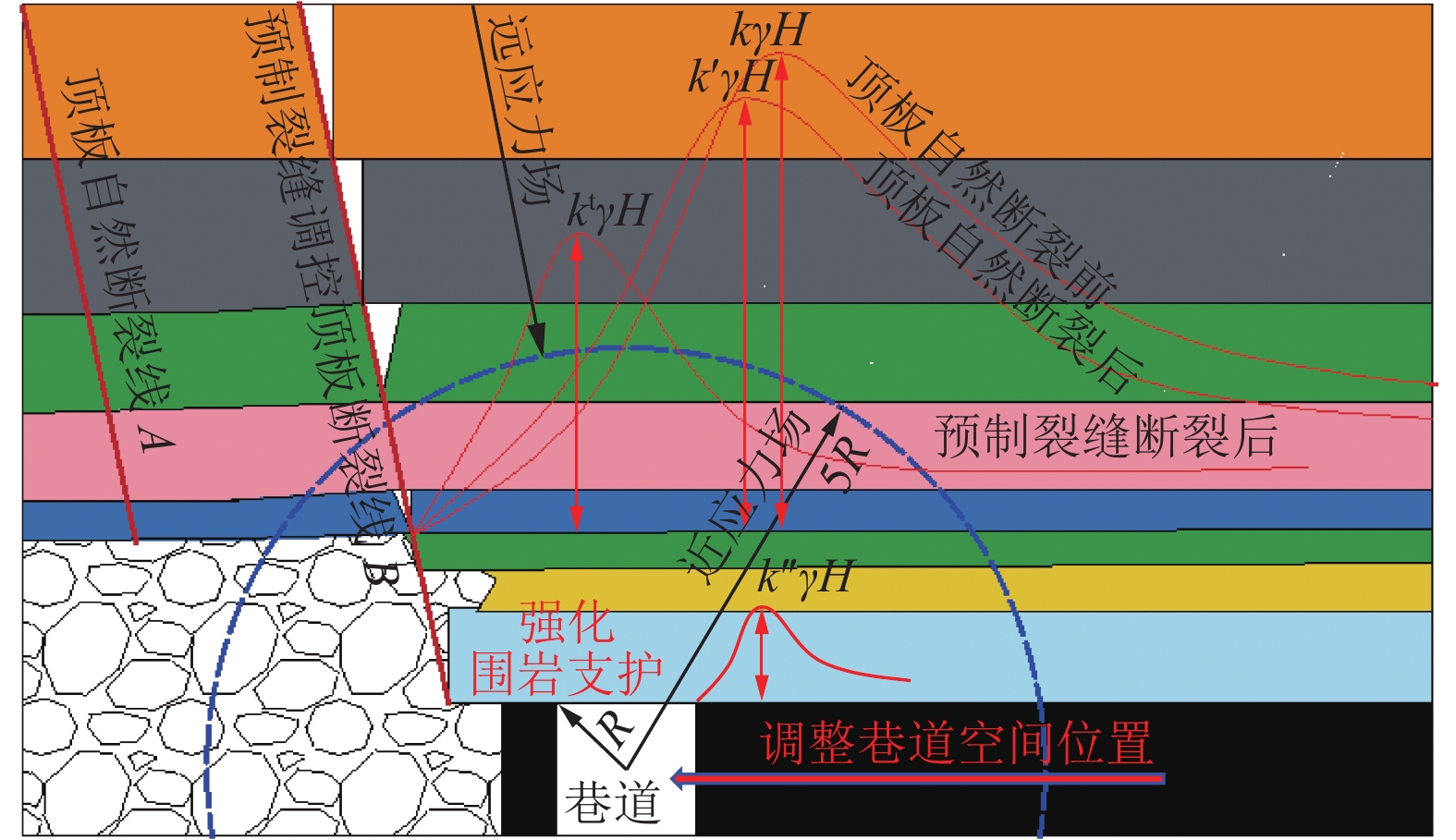

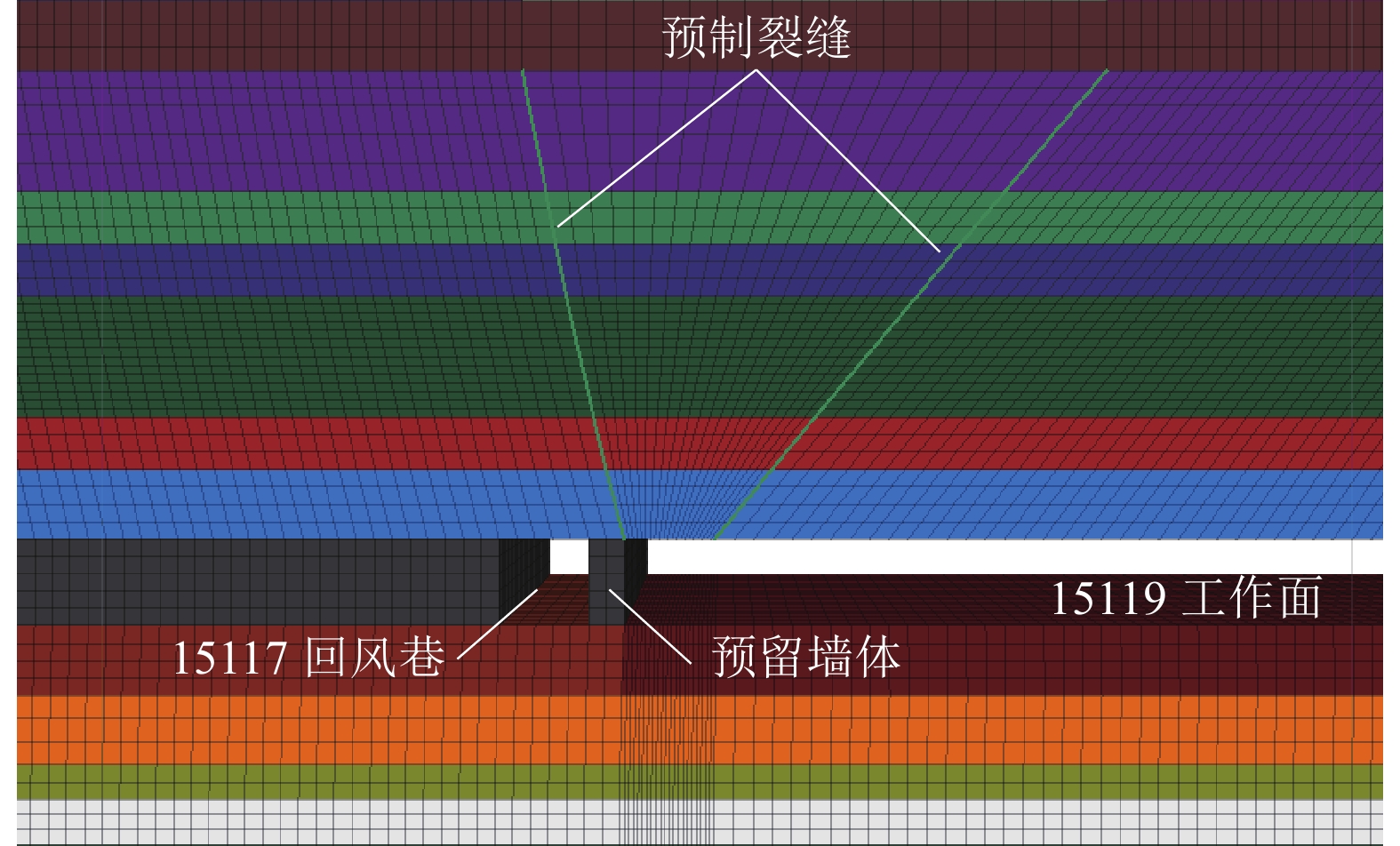

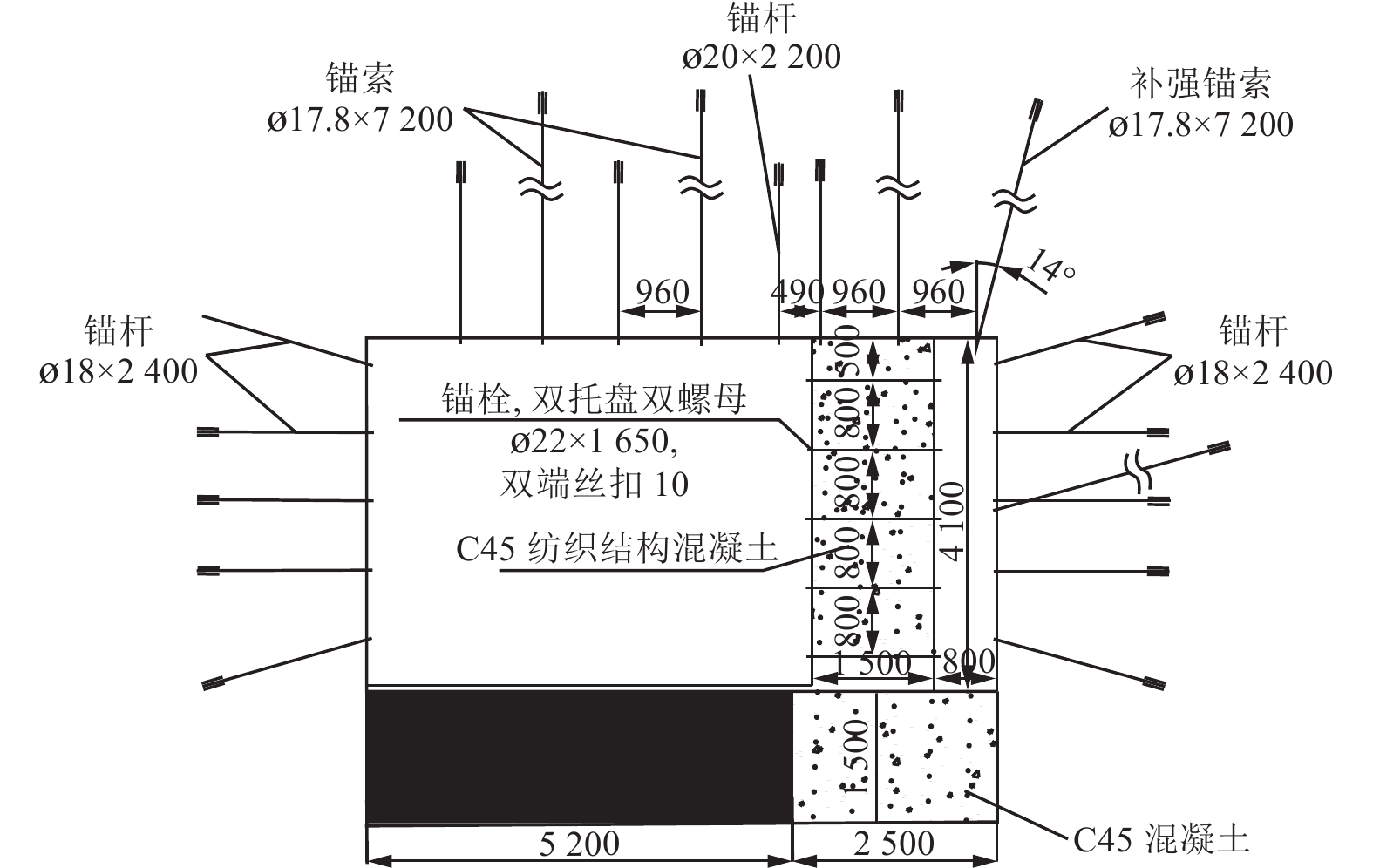

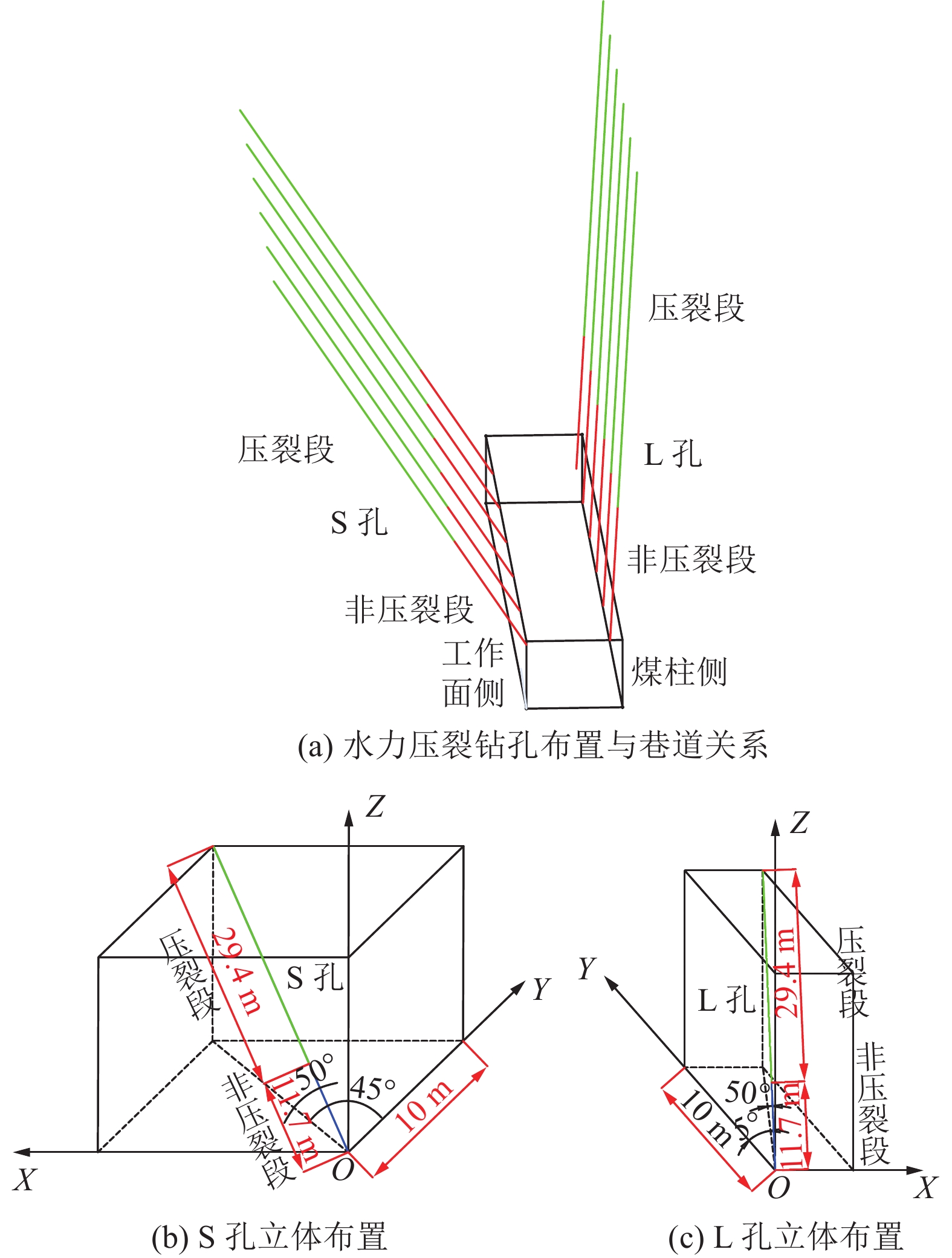

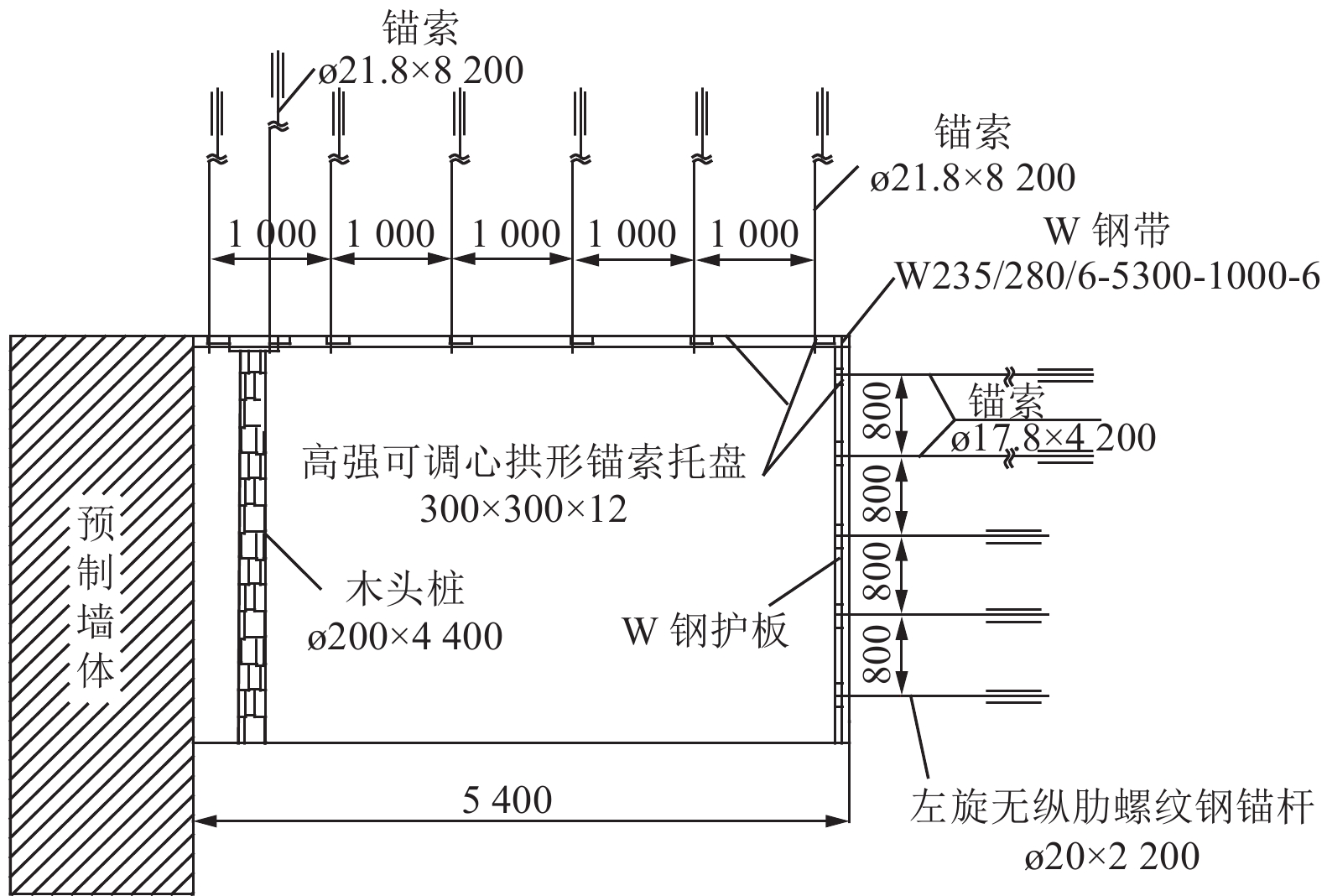

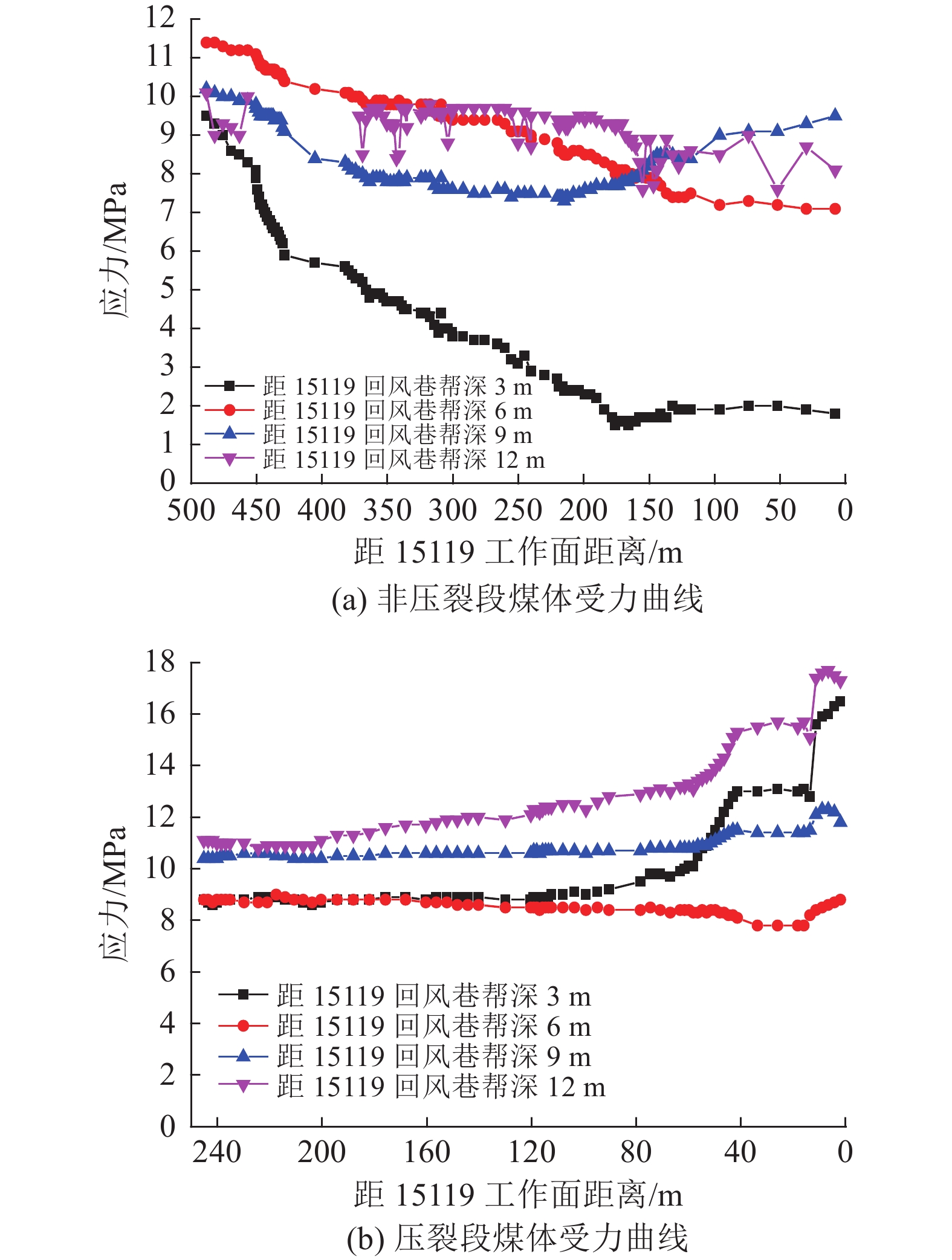

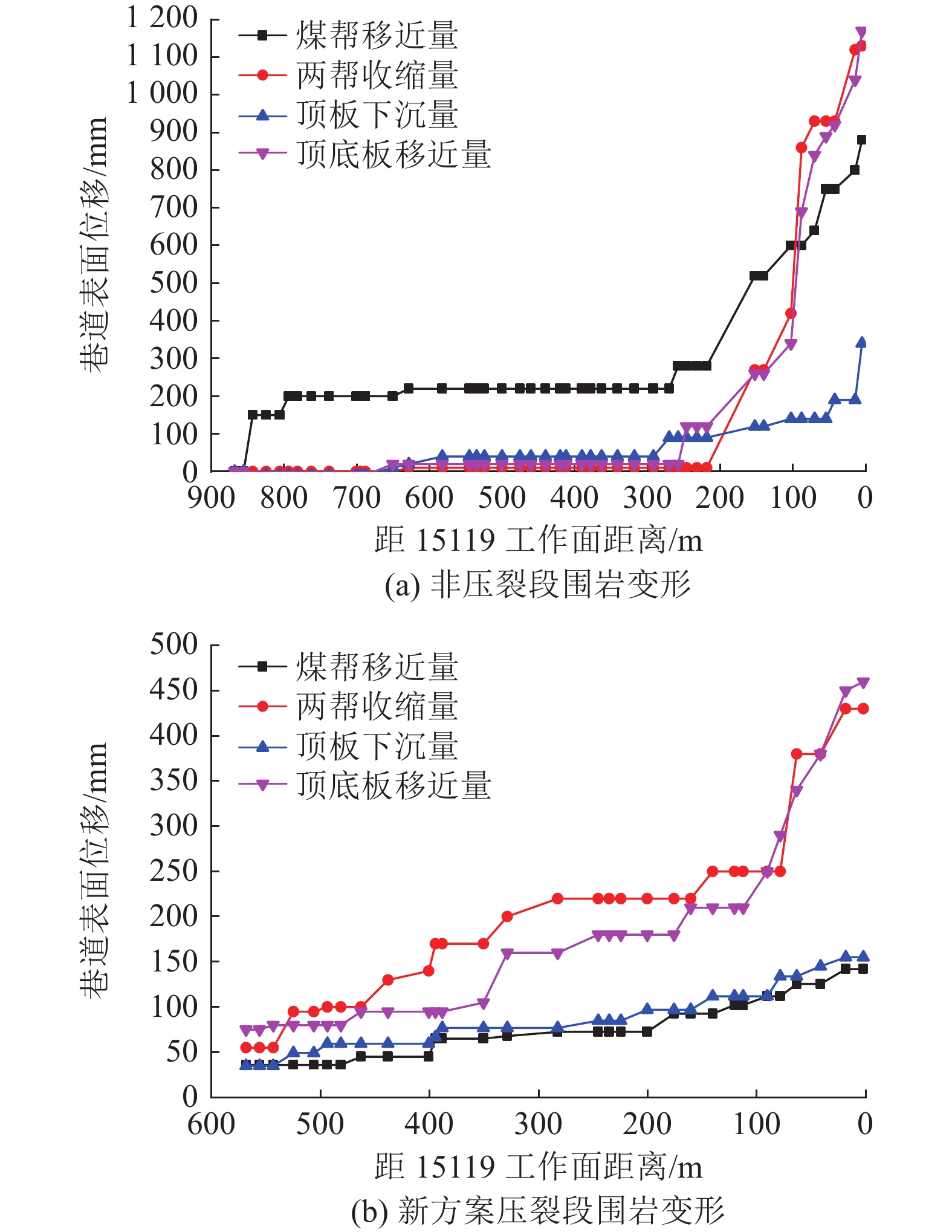

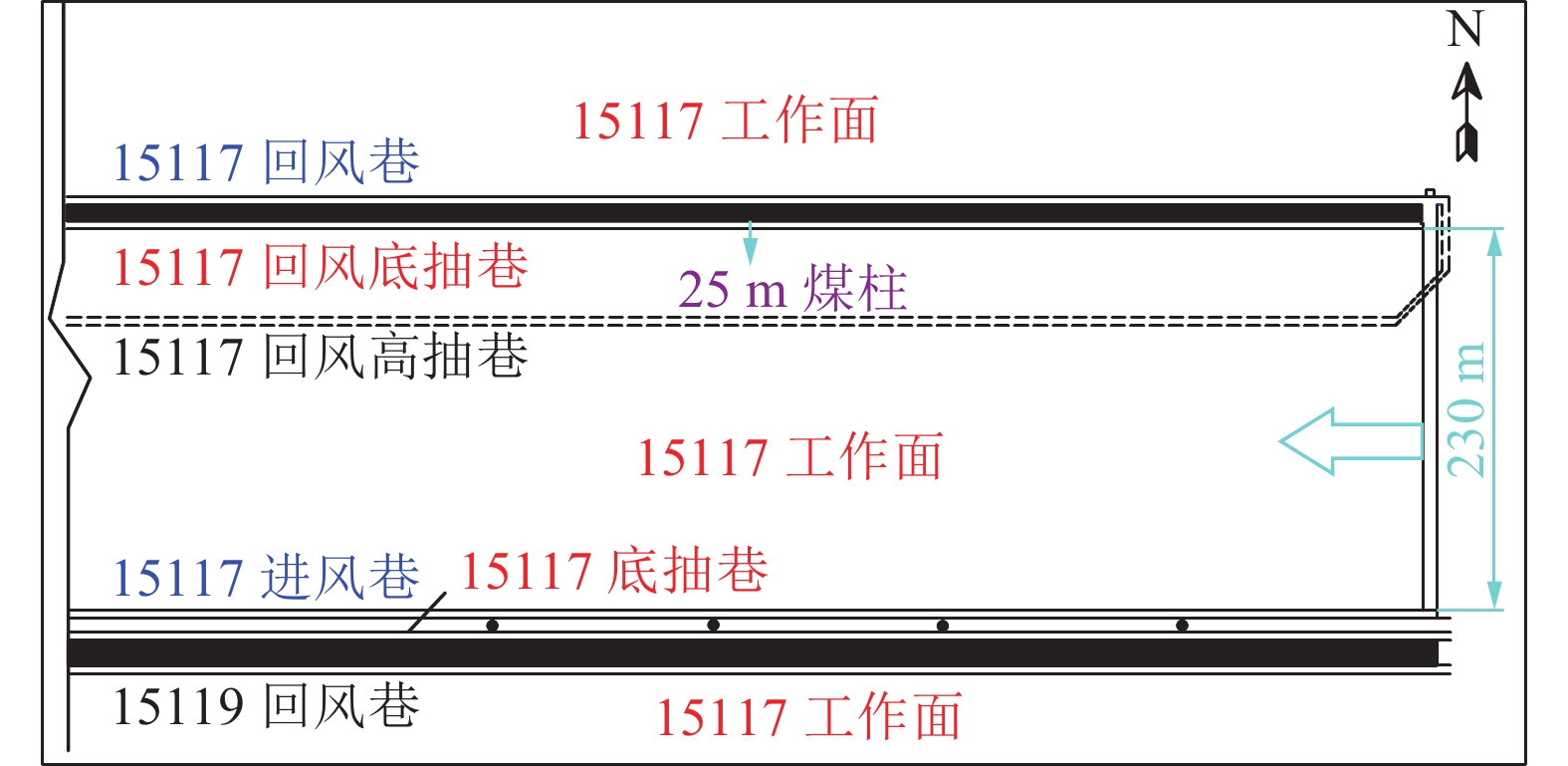

针对坚硬顶板强动压巷道围岩变形破坏难控制的问题,以寺家庄15119回风巷为工程背景,采用理论分析、现场实测、数值模拟与工业试验的综合研究方法,研究了坚硬顶板回采巷道远近应力场演化规律及调控技术。研究表明:15119回风巷在留设25 m煤柱时由于坚硬顶板难垮落造成远场应力集中,且在演化过程中加剧了巷道围岩近场应力环境恶化,这是致使该类巷道围岩变形破坏的问题所在。巷道围岩远近应力场存在紧密的相互作用关系,远场的应力能够引起近场应力范围和大小的变化,从而对巷道围岩的变形与破坏时效及范围产生影响。基于此,提出了巷道围岩的远场与近场应力场调控原理,即在通过工程干预手段有效地调控远近应力场的分布、传导途径及其相互作用,以此实现围岩应力环境的优化和巷道稳定性的增强。依据该原理,提出了“无煤柱留墙掘巷+切顶卸压+强力支护”远近应力场调控技术方案,新方案先调整15119回风巷至邻近15117工作面1.5 m处的低应力区,然后在15117进风巷顶板水压裂预制裂缝卸压调控远场应力分布与传播途径,最后强化15119回风巷围岩支护,优化近场应力环境。工业性试验表明:新方案能够有效减弱远场应力对近场应力的叠加作用,新方案中压裂对应的15119回风巷顶底板移近量最大460 mm,两帮收缩量最大为430 mm,断面收缩率降低了26.1%。巷道围岩远近场应力调控方案取得了良好的控制效果,可为类似巷道提供理论依据与技术参考。

Abstract:In response to the challenge of controlling deformation and damage in hard roof strong mining roadways, the study, taking the 15119 return airway of Sijiazhuang as an engineering background, employs a comprehensive research methodology combining theoretical analysis, field measurements, numerical simulations, and industrial experiments to investigate the evolution patterns of stress fields in hard roof mining roadways at various distances and the corresponding control techniques.Research indicates that when a 25-meter coal pillar is retained in the mining area of 15119 Hui Feng Lane, the difficulty in collapsing the hard roof causes stress concentration at a distance. Furthermore, this condition exacerbates the deterioration of the near-field stress environment surrounding the roadway during its evolution, which is the underlying issue leading to deformation and failure of the roadway’s surrounding rock.The stress fields of the surrounding rock in roadways exhibit a close interaction; fluctuations in the distant stress field can induce changes in the range and magnitude of the local stress field, thereby affecting the deformation and failure timing and extent of the roadway surrounding rock.Based on this understanding, the principle of regulating both the distant and local stress fields of roadway surrounding rock has been proposed. This involves the effective reallocation of the distribution and transmission pathways of the stress fields through engineering interventions, thereby optimizing the stress environment of the surrounding rock and enhancing the stability of the roadway. Based on the principle, the “pillarless mining with retained wall + roof cutting for pressure relief + enhanced support” method has been proposed to regulate the stress fields both in proximity and at a distance. The new strategy initially adjusts the low-stress zone near the 15119 return airway to 1.5 meters from the adjacent 15117 working face. Subsequently, hydraulic fracturing is utilized to create predetermined fractures in the roof of the 15117 intake airway, thereby controlling the distribution and propagation paths of the far-field stress. Finally, the support for the surrounding rock of the 15119 return airway is strengthened to optimize the near-field stress environment.Industrial trials of the new scheme indicate its efficacy in mitigating the impact of far-field stress on near-field stress. The maximum convergence of the roof and floor in the 15119 return airway, associated with the hydraulic fracturing of the new scheme, is 460 mm, and the maximum rib convergence is 430 mm, resulting in a 26.1% reduction in cross-sectional shrinkage rate. Consequently, the rock surrounding the gallery’s stress control scheme for both far-field and near-field has been proven effective, providing a theoretical basis and technical reference for similar galleries.

-

-

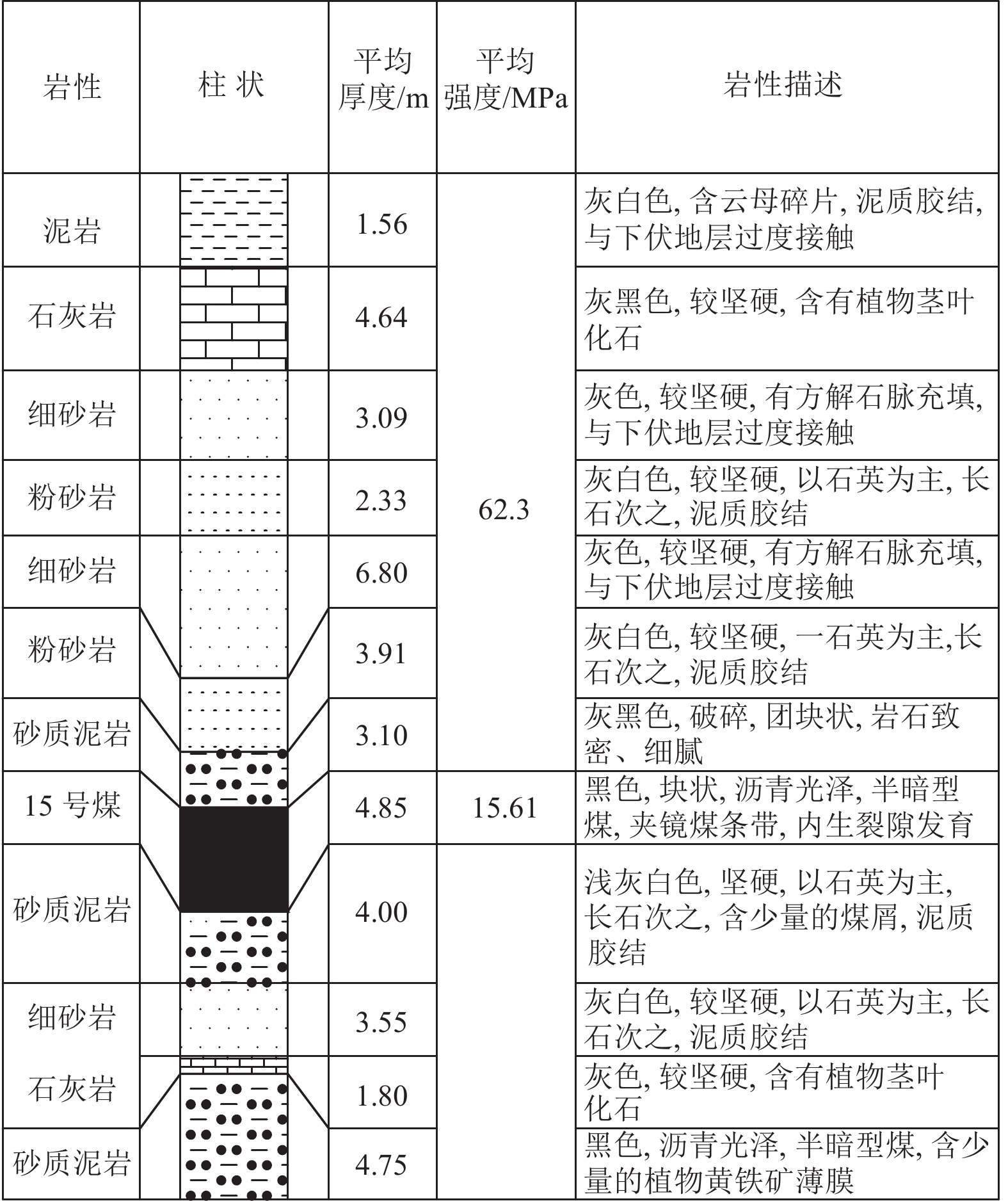

表 1 数值模拟的岩层力学参数

Table 1 Rock mechanics parameters of numerical simulation

岩层 弹性模量/GPa 剪切模量/GPa 抗压强度/MPa 抗拉强度/MPa 黏聚力/MPa 内摩擦角/(°) 密度/(kg·m−3) 粉砂岩 19.50 8.10 52.90 1.84 2.75 38 2460 砂质泥岩 5.40 2.30 41.52 0.75 2.16 36 2510 泥岩 2.60 1.00 41.07 0.60 1.30 25 2567 15号煤 5.30 2.00 15.61 0.15 1.25 32 1380 泥质粉砂岩 100 3.80 56.80 1.60 1.70 28 2400 细砂岩 4.01 1.60 68.83 1.00 2.00 35 2540 石灰岩 11.00 4.53 86.00 3.20 11.40 38 2800 -

[1] 蔡巧玉. 黄炳香:凝思聚力破解坚硬顶板的及时可控放顶难题[J]. 科学中国人,2020,6(8):62−63. CAI Qiaoyu. Huang Bingxiang: Concentrate on solving the problem of timely and controllable caving of hard roof[J]. Scientific Chinese,2020,6(8):62−63.

[2] 袁亮. 我国煤矿安全发展战略研究[J]. 中国煤炭,2021,47(6):1−6. YUAN Liang. Study on the development strategy of coal mine safety in China[J]. China Coal,2021,47(6):1−6.

[3] 康红普. 我国煤矿巷道围岩控制技术发展70年及展望[J]. 岩石力学与工程学报,2021,40(1):1−30. KANG Hongpu. Seventy years development and prospects of strata control technologies for coal mine roadways in China[J]. Chinese Journal of Rock Mechanics and Engineering,2021,40(1):1−30.

[4] 朱珍,张科学,何满潮,等. 无煤柱无掘巷开采自成巷道围岩结构控制及工程应用[J]. 煤炭学报,2018,43(S1):52−60. [5] 侯朝炯,王襄禹,柏建彪,等. 深部巷道围岩稳定性控制的基本理论与技术研究[J]. 中国矿业大学学报,2021,50(1):1−12. HOU Chaojiong,WANG Xiangyu,BAI Jianbiao,et al. Basic theory and technology study of stability control for surrounding rock in deep roadway[J]. Journal of China University of Mining & Technology,2021,50(1):1−12.

[6] 张红军,李海燕,张太平,等. 深部软岩巷道高预应力增阻大变形锚杆研究及工程应用[J]. 煤炭学报,2019,44(2):409−418. ZHANG Hongjun,LI Haiyan,ZHANG Taiping,et al. Research and engineering application of high pre-stressed resistance enhancement large deformation bolt in deep soft rock roadway[J]. Journal of China Coal Society,2019,44(2):409−418.

[7] 侯朝炯,李学华. 综放沿空掘巷围岩大、小结构的稳定性原理[J]. 煤炭学报,2001,26(1):1−7. doi: 10.3321/j.issn:0253-9993.2001.01.001 HOU Chaojiong,LI Xuehua. Stability principle of big and small structures of rock surrounding roadwaydriven along goaf in fully mechanized top coal caving face[J]. Journal of China Coal Society,2001,26(1):1−7. doi: 10.3321/j.issn:0253-9993.2001.01.001

[8] 钱鸣高,石平五,许家林. 矿山压力与岩层控制[M]. 2版. 徐州:中国矿业大学出版社,2010. [9] 郑西贵,姚志刚,张农. 掘采全过程沿空掘巷小煤柱应力分布研究[J]. 采矿与安全工程学报,2012,29(4):459−465. ZHENG Xigui,YAO Zhigang,ZHANG Nong. Stress distribution of coal pillar with gob-side entry driving in the process of excavation & mining[J]. Journal of Mining & Safety Engineering,2012,29(4):459−465.

[10] 韩承强,张开智,徐小兵,等. 区段小煤柱破坏规律及合理尺寸研究[J]. 采矿与安全工程学报,2007,24(3):370−373. doi: 10.3969/j.issn.1673-3363.2007.03.026 HAN Chengqiang,ZHANG Kaizhi,XU Xiaobing,et al. Study on failure regularity and reasonable dimension of district sublevel small coal pillar[J]. Journal of Mining & Safety Engineering,2007,24(3):370−373. doi: 10.3969/j.issn.1673-3363.2007.03.026

[11] 屠世浩,白庆升,屠洪盛. 浅埋煤层综采面护巷煤柱尺寸和布置方案优化[J]. 采矿与安全工程学报,2011,28(4):505−510. doi: 10.3969/j.issn.1673-3363.2011.04.002 TU Shihao,BAI Qingsheng,TU Hongsheng. Pillar size determination and panel layout optimization for fully mechanized faces in shallow seams[J]. Journal of Mining & Safety Engineering,2011,28(4):505−510. doi: 10.3969/j.issn.1673-3363.2011.04.002

[12] 张自政,柏建彪,王襄禹,等. 我国沿空留巷围岩控制技术研究进展与展望[J]. 煤炭学报,2023,48(11):3979−4000. ZHANG Zizheng,BAI Jianbiao,WANG Xiangyu,et al. Review and development of surrounding rock control technology for gob-side entry retaining in China[J]. Journal of China Coal Society,2023,48(11):3979−4000.

[13] 郑西贵,张农,袁亮,等. 无煤柱分阶段沿空留巷煤与瓦斯共采方法与应用[J]. 中国矿业大学学报,2012,41(3):390−396. ZHENG Xigui,ZHANG Nong,YUAN Liang,et al. Method and application of simultaneous pillar-less coal mining and gas extraction by staged gob-side entry retaining[J]. Journal of China University of Mining & Technology,2012,41(3):390−396.

[14] 王襄禹,张科学,赵锋,等. 煤柱下煤层巷道围岩变形破坏机理[J]. 煤炭技术,2017,36(1):1−3. WANG Xiangyu,ZHANG Kexue,ZHAO Feng,et al. Mechanism of surrounding rock deformation and failure in seam roadway under barrier pillar[J]. Coal Technology,2017,36(1):1−3.

[15] 康红普,王金华. 煤巷锚杆支护理论与成套技术[M]. 北京:煤炭工业出版社,2007. [16] 何满潮,马资敏,郭志飚,等. 深部中厚煤层切顶留巷关键技术参数研究[J]. 中国矿业大学学报,2018,47(3):468−477. HE Manchao,MA Zimin,GUO Zhibiao,et al. Key parameters of the gob-side entry retaining formed by roof cutting and pressure release in deep medium-thickness coal seams[J]. Journal of China University of Mining & Technology,2018,47(3):468−477.

[17] 冯彦军,康红普. 定向水力压裂控制煤矿坚硬难垮顶板试验[J]. 岩石力学与工程学报,2012,31(6):1148−1155. doi: 10.3969/j.issn.1000-6915.2012.06.008 FENG Yanjun,KANG Hongpu. Test on hard and stable roof control by means of directional hydraulic fracturing in coal mine[J]. Chinese Journal of Rock Mechanics and Engineering,2012,31(6):1148−1155. doi: 10.3969/j.issn.1000-6915.2012.06.008

[18] 康红普,姜鹏飞,冯彦军,等. 煤矿巷道围岩卸压技术及应用[J]. 煤炭科学技术,2022,50(6):1−15. KANG Hongpu,JIANG Pengfei,FENG Yanjun,et al. Destressing technology for rock around coal mine roadways and its applications[J]. Coal Science and Technology,2022,50(6):1−15.

[19] 孙利辉,杨贤达,张海洋,等. 强动压松软煤层巷道煤帮变形破坏特征及锚注加固试验研究[J]. 采矿与安全工程学报,2019,36(2):232−239. SUN Lihui,YANG Xianda,ZHANG Haiyang,et al. Experimental research on characteristics of deformation and failure of roadway ribs in soft coal seams under strong dynamic pressure and bolt-grouting reinforcement[J]. Journal of Mining & Safety Engineering,2019,36(2):232−239.

[20] 肖同强,支光辉,张治高. 深部构造区域地应力分布与巷道稳定关系研究[J]. 采矿与安全工程学报,2013,30(5):659−664. XIAO Tongqiang,ZHI Guanghui,ZHANG Zhigao. Relationship between ground stress distribution and roadway stability in deep tectonic region[J]. Journal of Mining & Safety Engineering,2013,30(5):659−664.

[21] 姚强岭,李英虎,夏泽,等. 基于有效锚固层厚度的煤系巷道顶板叠加梁支护理论及应用[J]. 煤炭学报,2022,47(2):672−682. YAO Qiangling,LI Yinghu,XIA Ze,et al. Theory and application of roof superimposed beam support of coal roadway based on effective anchorage layer thickness[J]. Journal of China Coal Society,2022,47(2):672−682.

[22] 张百胜,王朋飞,崔守清,等. 大采高小煤柱沿空掘巷切顶卸压围岩控制技术[J]. 煤炭学报,2021,46(7):2254−2267. ZHANG Baisheng,WANG Pengfei,CUI Shouqing,et al. Mechanism and surrounding rock control of roadway driving along gob in shallow-buried,large mining height and small coal pillars by roof cutting[J]. Journal of China Coal Society,2021,46(7):2254−2267.

[23] 吴少康,张俊文,徐佑林,等. 煤层群采动下围岩应力演化规律及协同控制技术研究[J]. 煤炭科学技术,2024,52(3):24−37. doi: 10.12438/cst.2023-0515 WU Shaokang,ZHANG Junwen,XU Youlin,et al. Study on the stress evolution law of surrounding rock and cooperative control technology in coal seam group mining[J]. Coal Science and Technology,2024,52(3):24−37. doi: 10.12438/cst.2023-0515

-

期刊类型引用(8)

1. 陈泽民,李振雷,钟涛平,宋大钊,刘旭东,胡旭聪. 急倾斜特厚煤层防冲开采方法数值模拟研究. 煤矿安全. 2025(01): 117-127 .  百度学术

百度学术

2. 侯挺,聂谦,薛兴伟. 弱化转移高水平应力技术在巷道修护中的研究与应用. 山东煤炭科技. 2025(01): 12-16 .  百度学术

百度学术

3. 陈学亚,张宁波,刘立明,陈宝宝,付世雄. 遗留煤柱扰动下薄间距动压巷道压裂卸压护巷技术研究. 煤炭工程. 2025(01): 42-51 .  百度学术

百度学术

4. 郭争利,杨真. 水力压裂防治强矿压机理及卸压护巷技术研究. 山西冶金. 2025(01): 204-206 .  百度学术

百度学术

5. 龚惠春,夏广宁,杨生龙,刘鹏,杨龙. 深埋工作面回采巷道复合顶板水压致裂技术应用. 陕西煤炭. 2024(08): 90-94+140 .  百度学术

百度学术

6. 赵会波. 水力压裂裂缝开裂压力影响因素分析及应用. 煤炭工程. 2024(09): 127-135 .  百度学术

百度学术

7. 聂嘉汾,张海东. 不同切顶角度下临空巷道围岩力学响应特征及控制效果. 山西煤炭. 2024(04): 120-127 .  百度学术

百度学术

8. 曹沛沛. 水力切顶卸压在动压巷道围岩控制中应用. 内蒙古煤炭经济. 2024(24): 160-162 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: