Rapid support technology and engineering application of roadway reconstruction high strength bearing structure in coal mine

-

摘要:

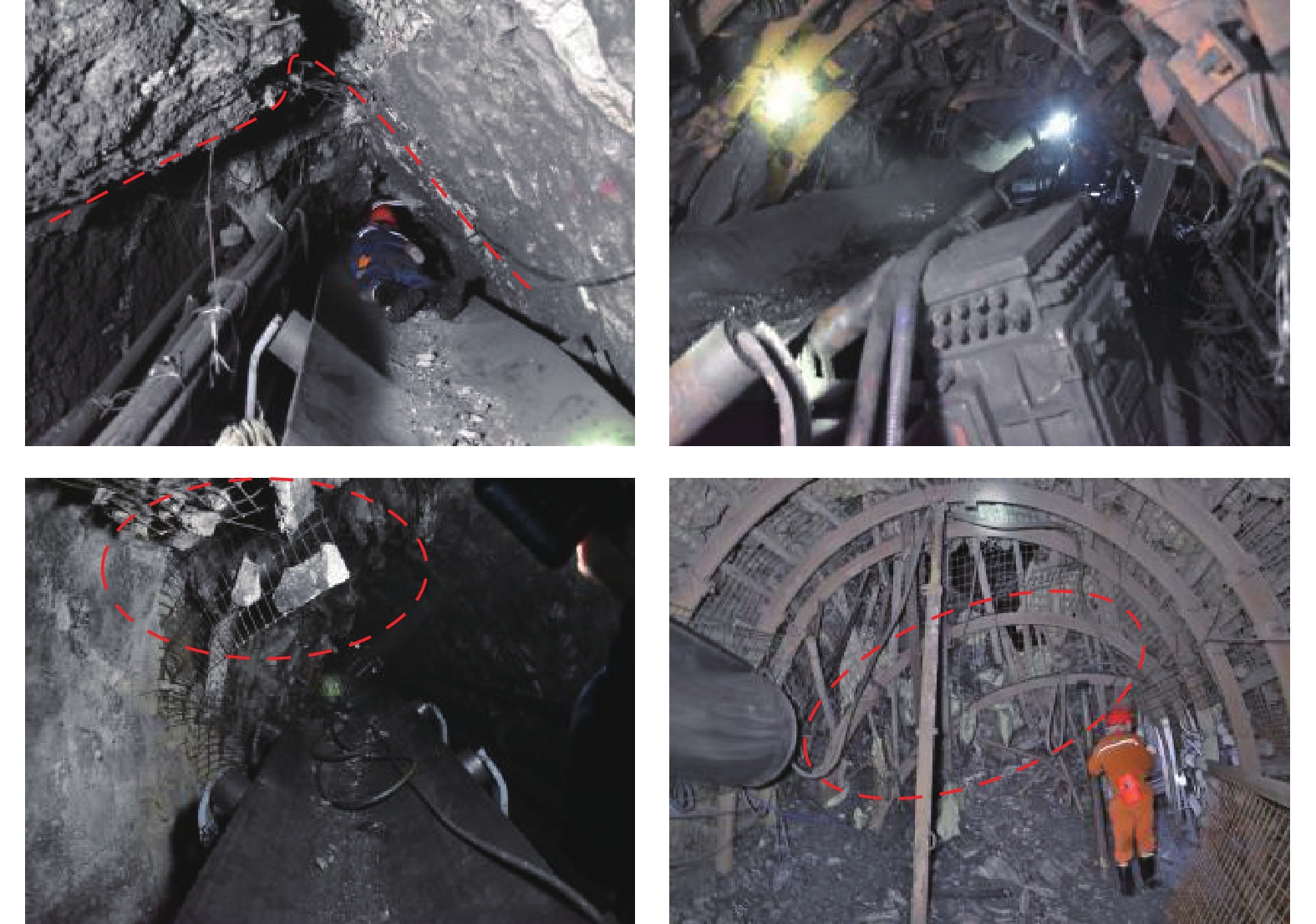

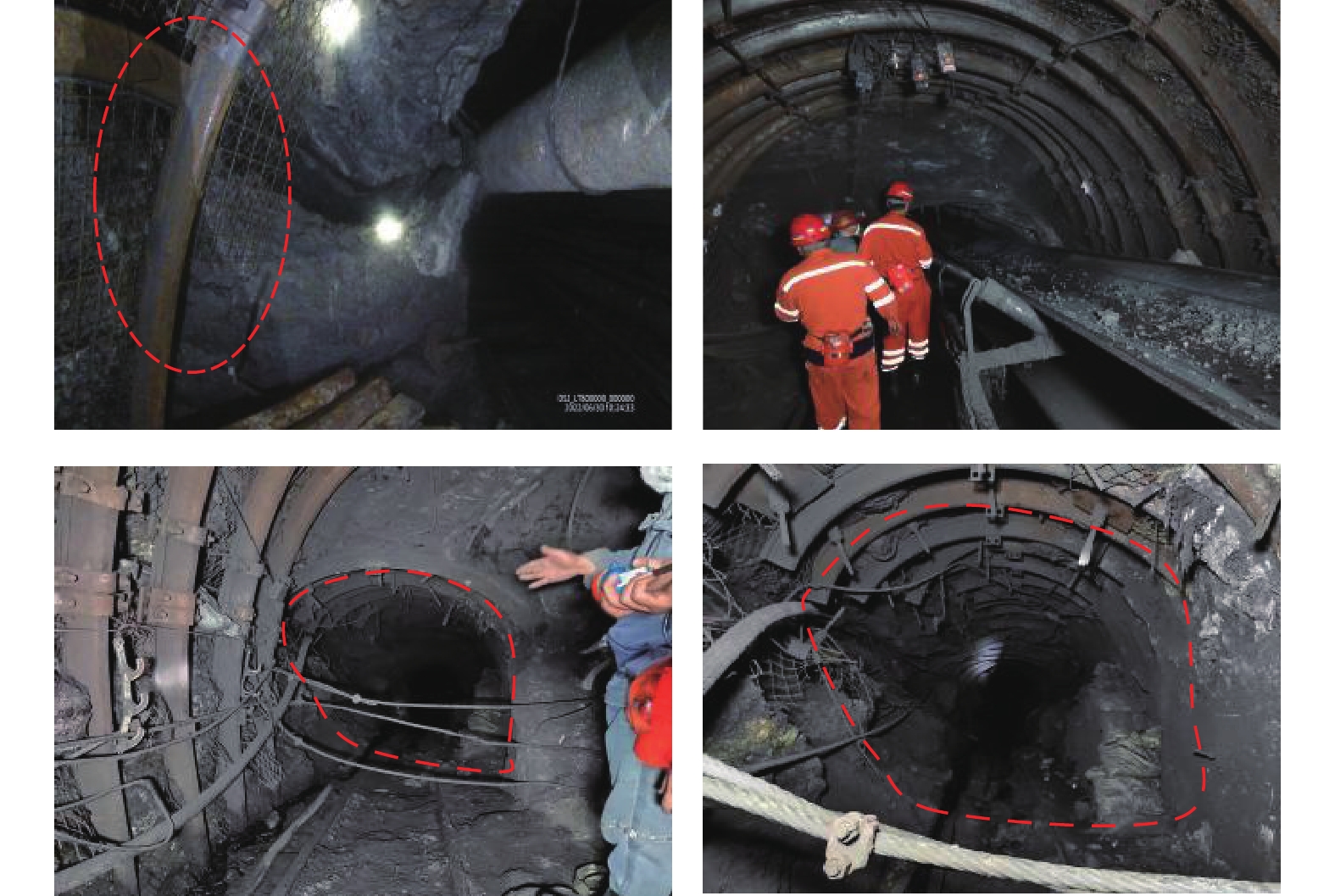

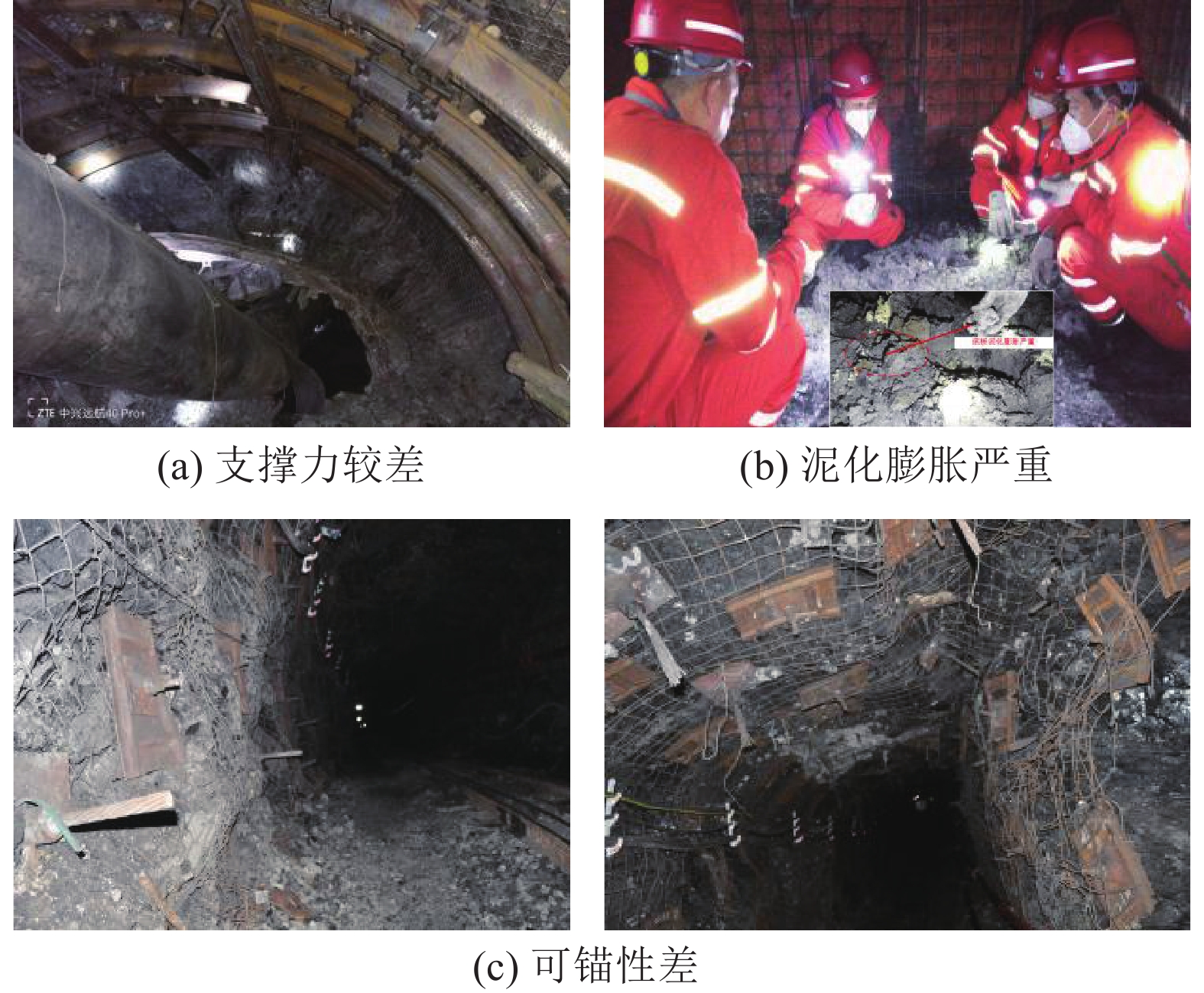

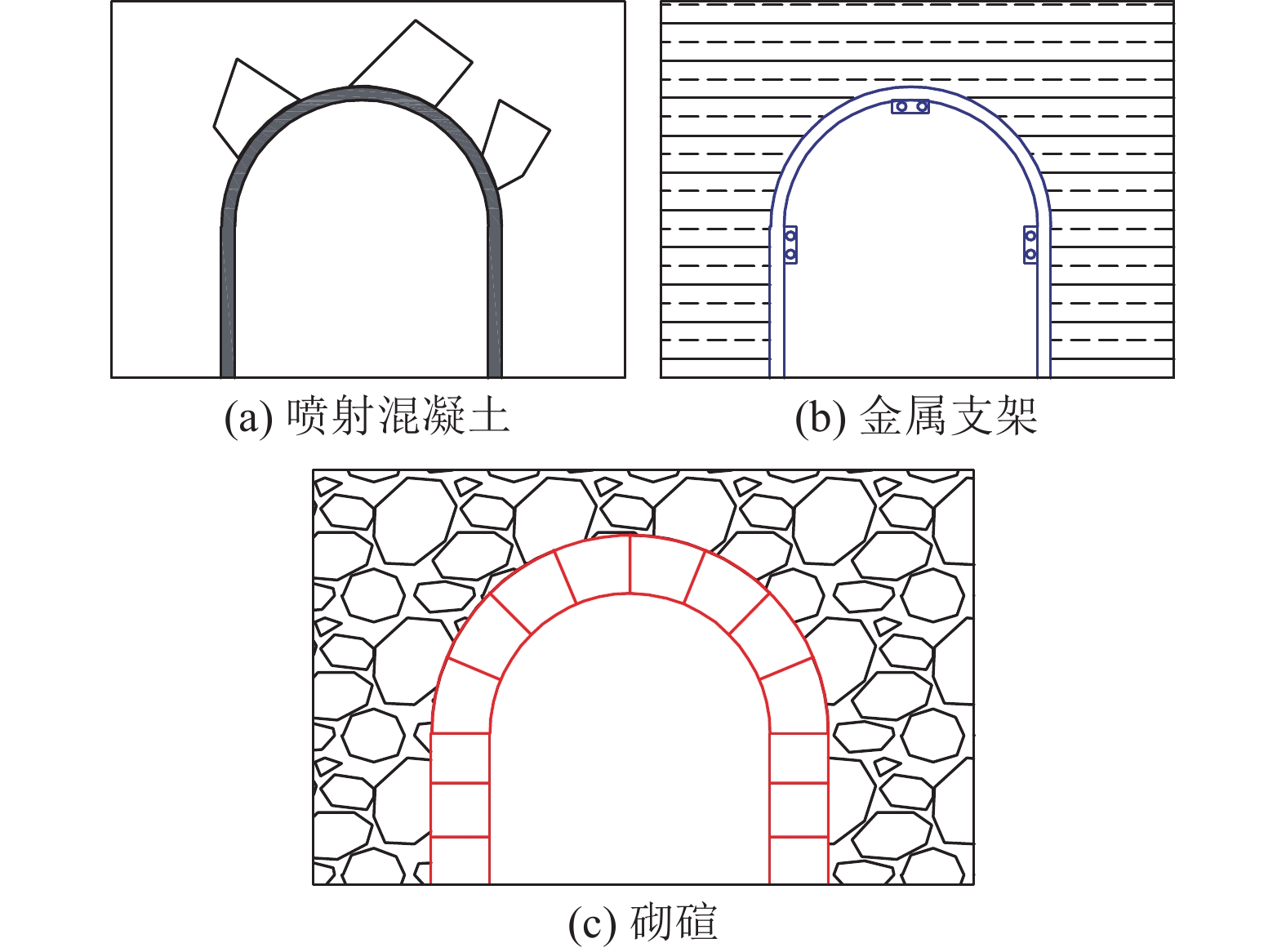

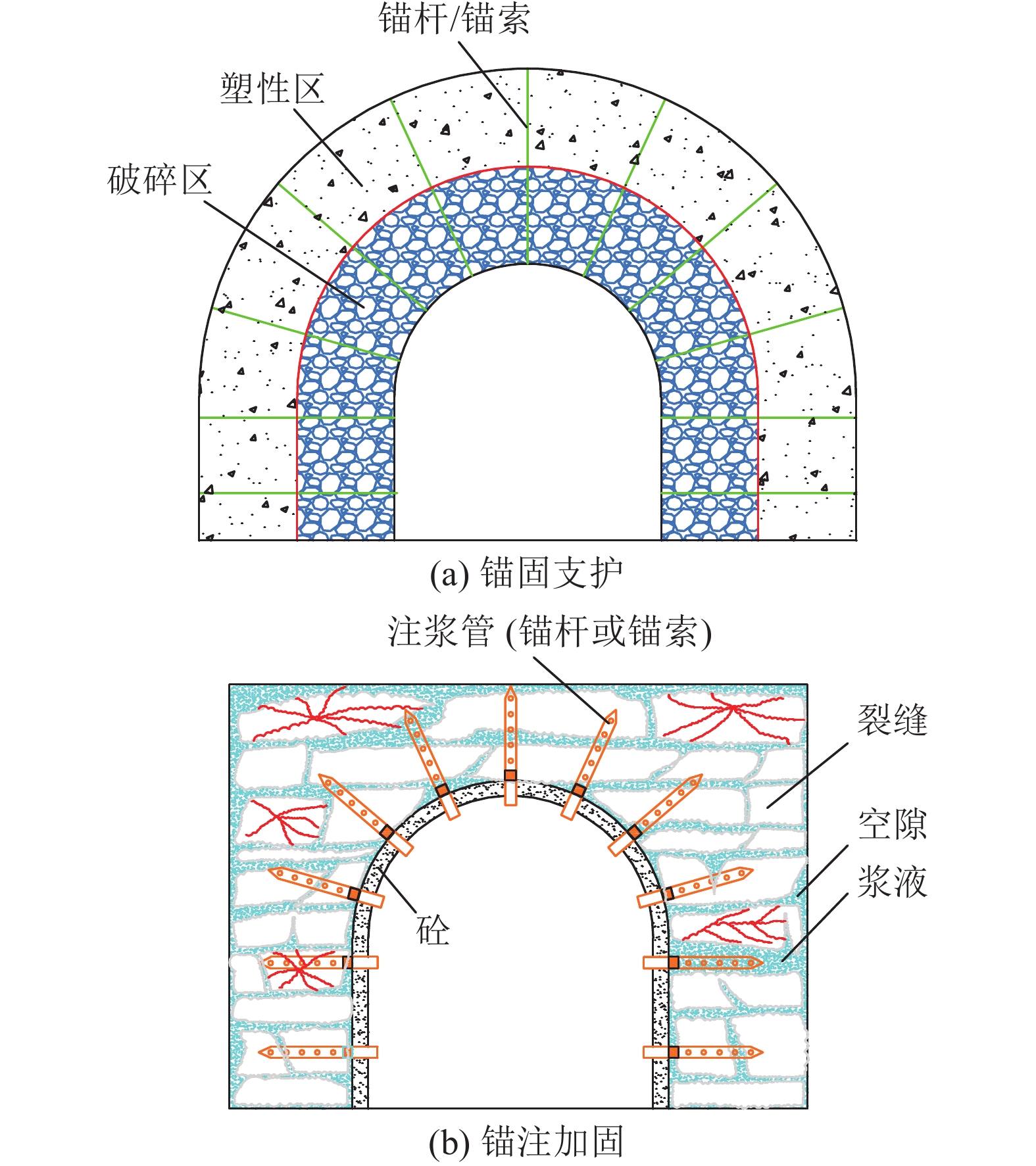

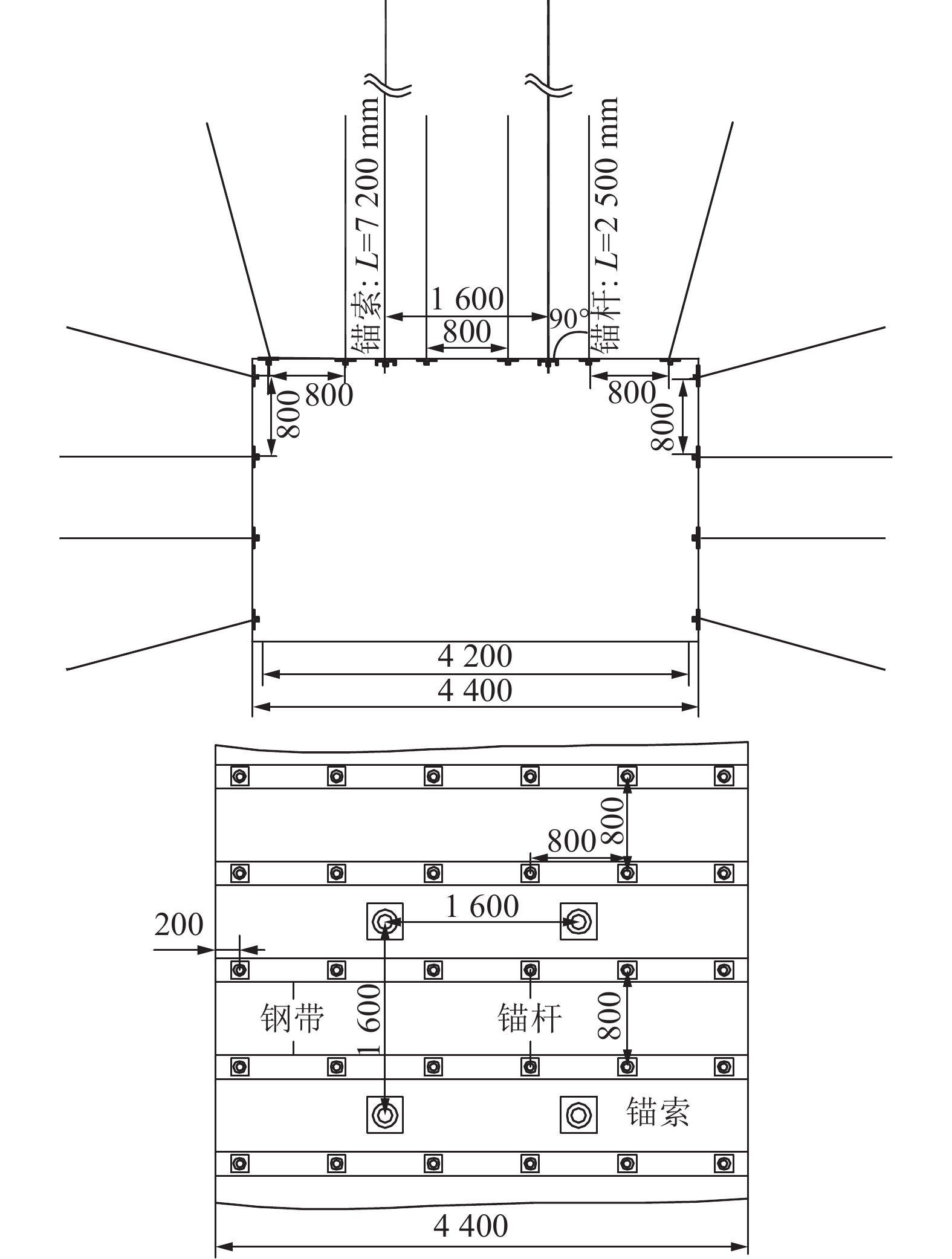

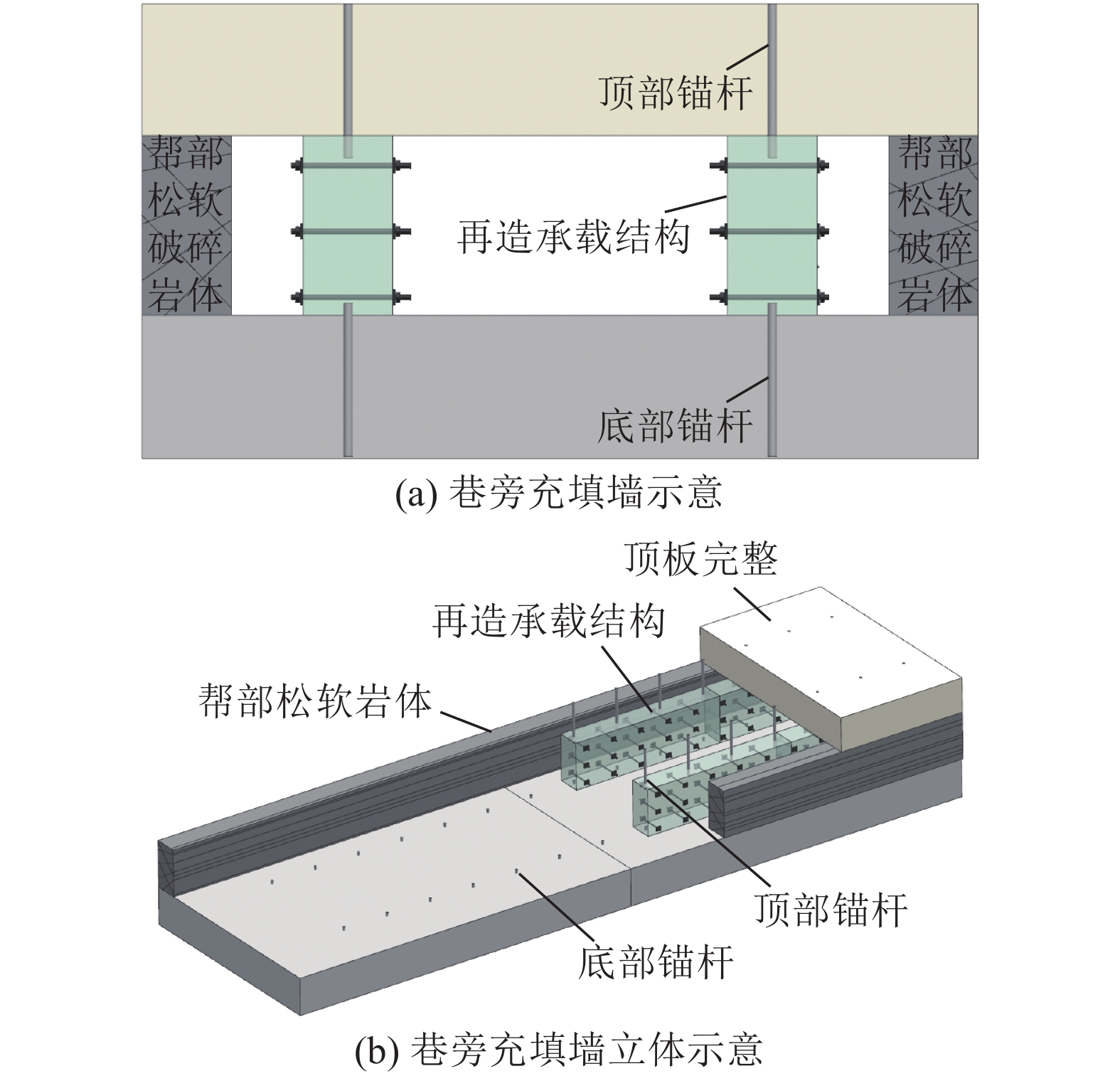

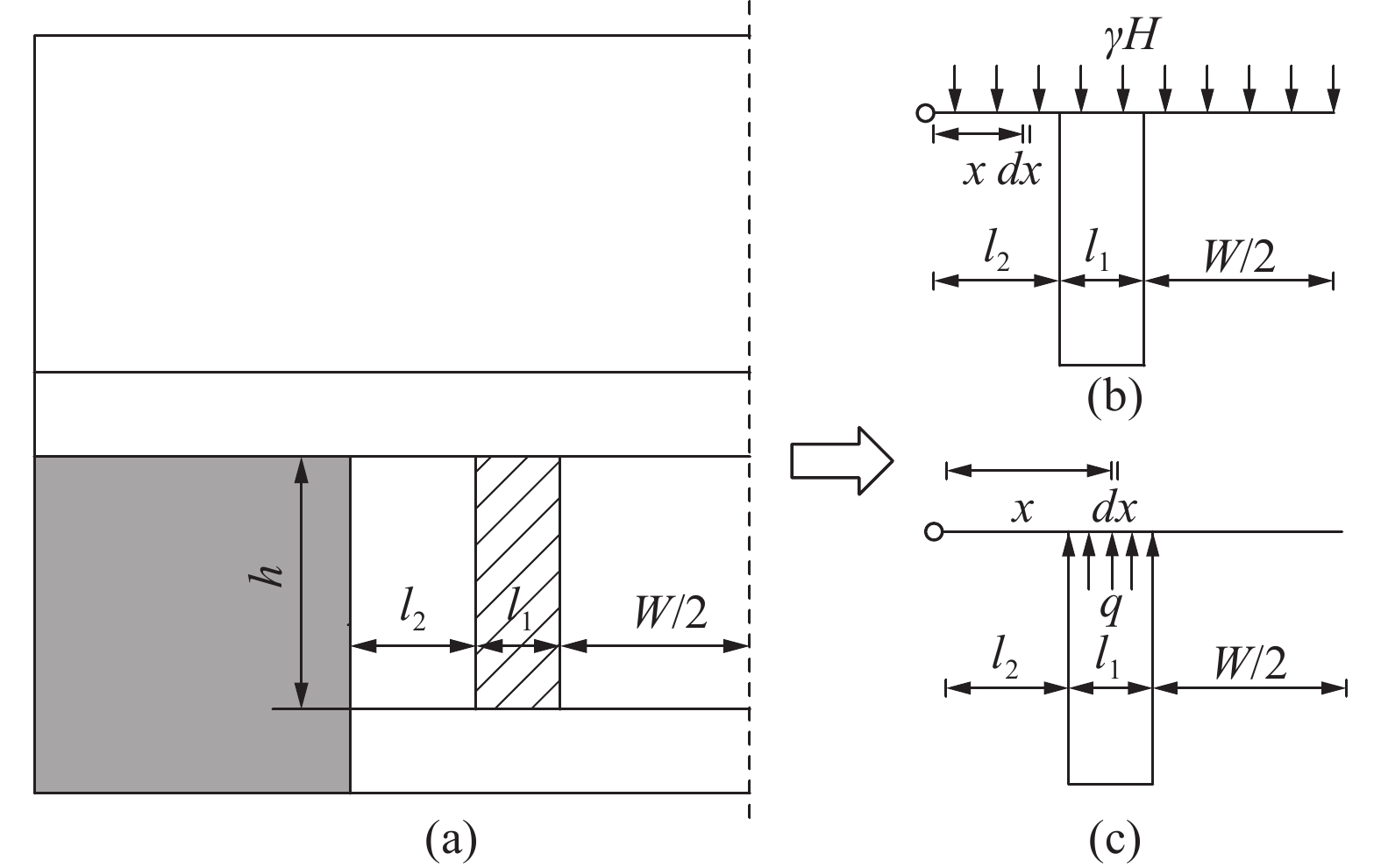

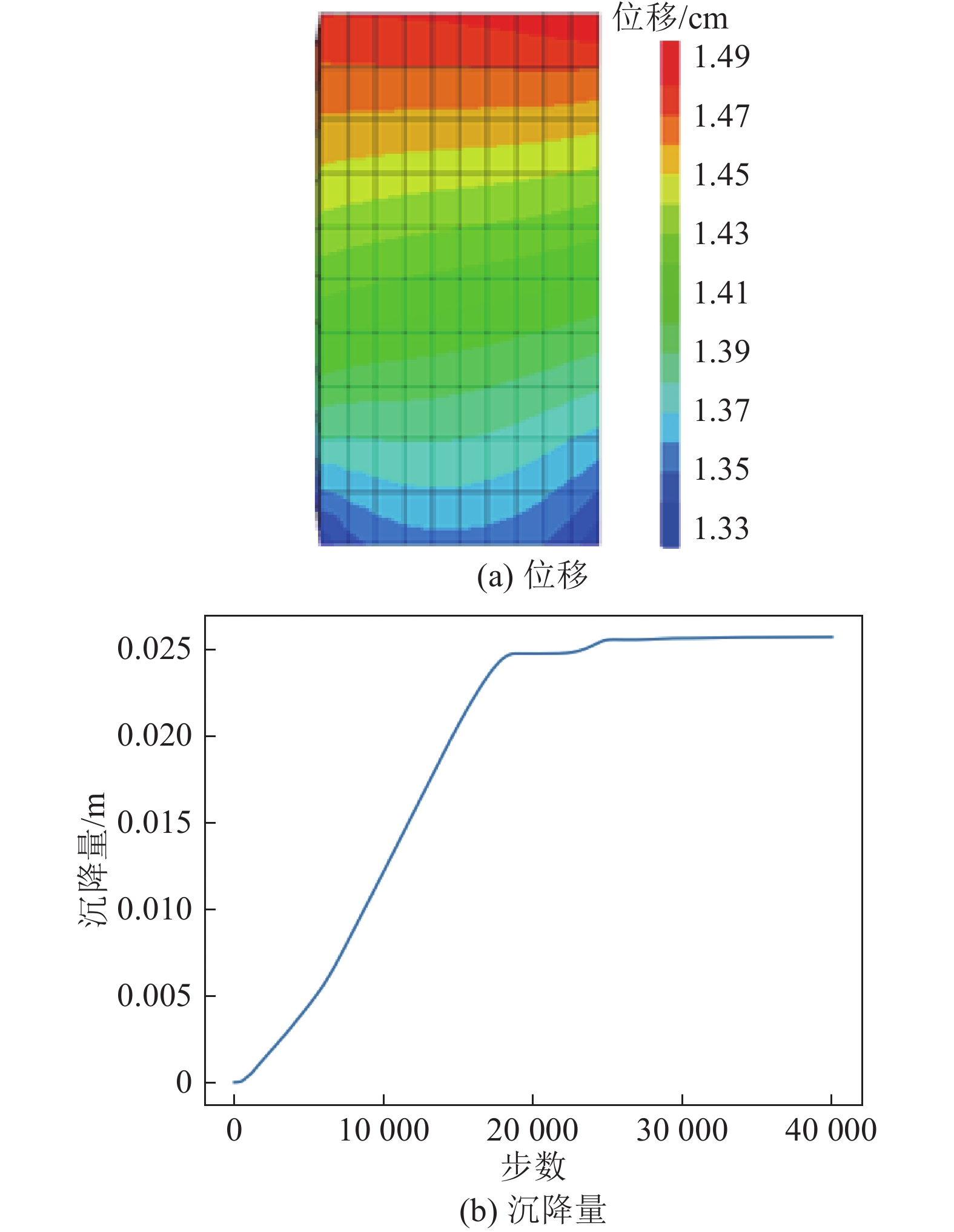

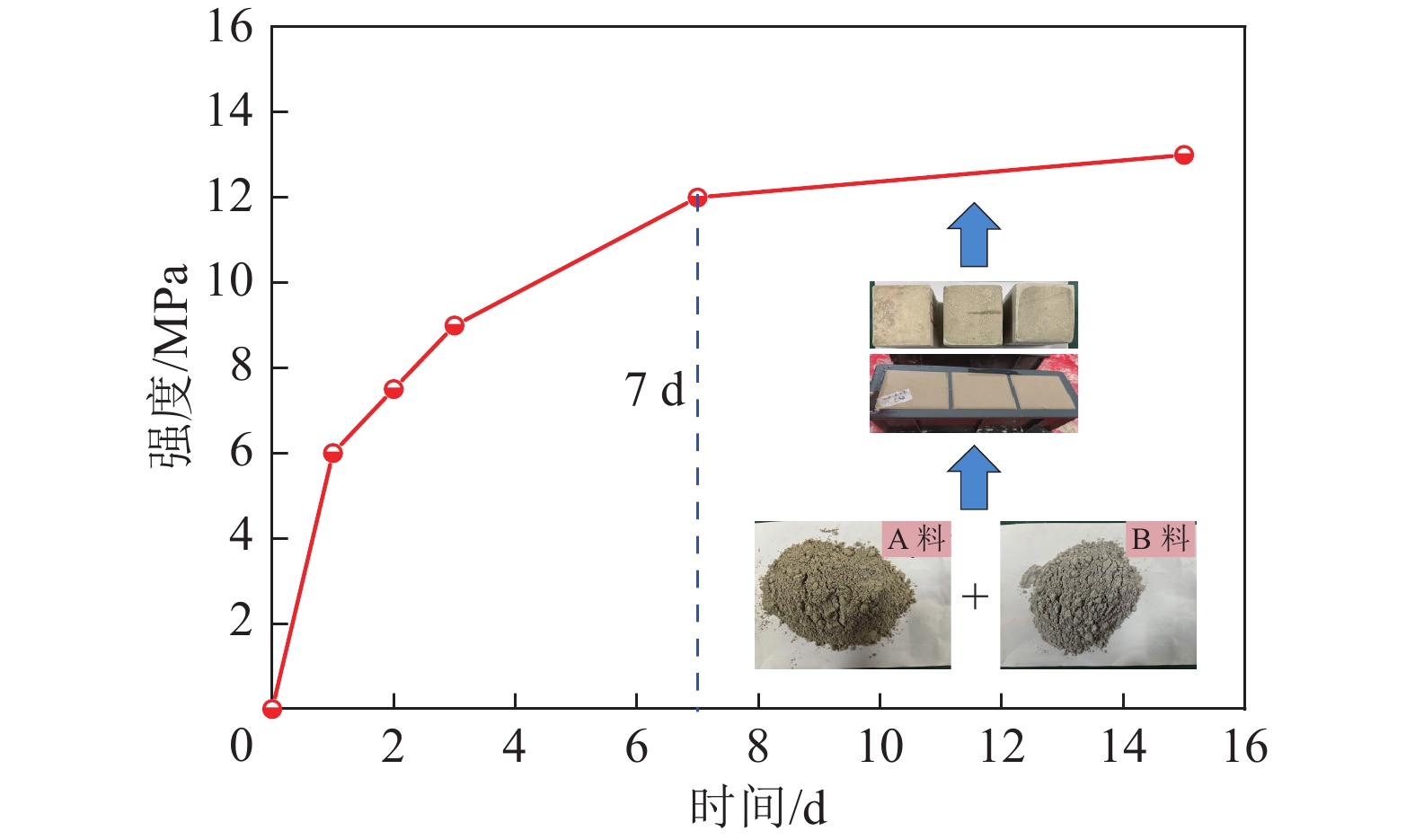

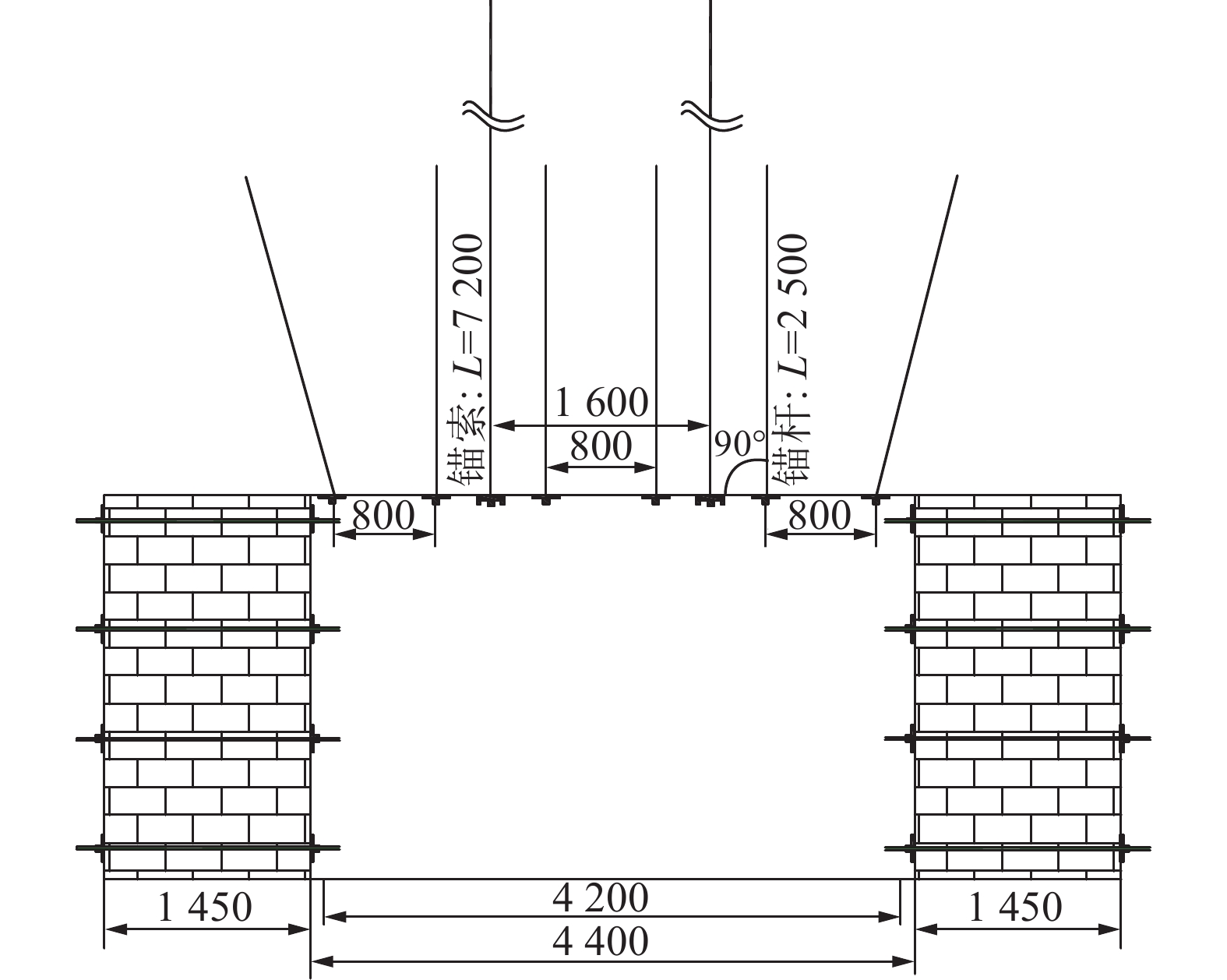

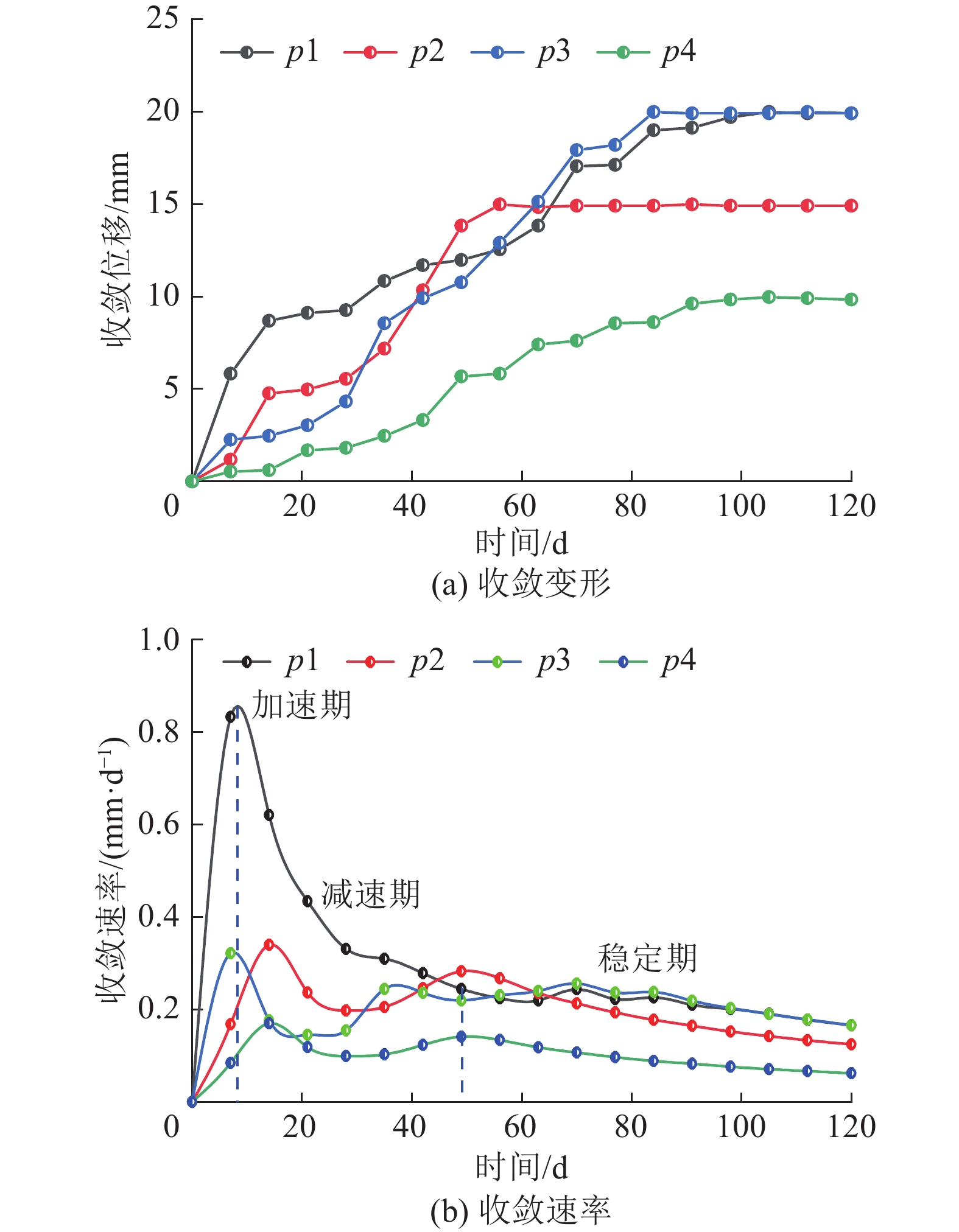

针对松软、破碎围岩巷道可锚性差、受强动压和强构造应力影响等问题,开展了大量现场调研并归纳分析了3种典型煤矿巷道围岩大变形和围岩控制难题;在分析现有支护技术和理论基础上,提出再造高强度承载结构快速支护技术思路和再造方法。以贵州龙宝煤矿11205运输下山为工程背景,分析其变形破坏原因,结合实际设计出对破碎围岩进行置换加卸压的联合支护方法,理论上建立巷旁充填墙承载力学模型,分析了巷旁充填墙的承载强度,确定了巷旁充填墙的强度与巷道围岩的可适性及有效性。结合FLAC3D数值模拟与Python脚本编程语言,实现飞蛾火焰优化算法,确定最优的破碎围岩巷道的置换参数(墙体厚度和卸压区宽度)。研发了高强度高韧性充填支护新材料。通过对软弱墙体进行置换再造,让巷道顶板、充填体和底板重新构成一个整体承载结构。井下工业性试验结果表明,对巷道软弱岩体进行置换再造后,巷道顶板、充填体和底板所构成的新结构可实现整体承载,充分发挥了围岩自身承载能力和抵抗变形能力,围岩变形趋于平稳,收敛速率基本都小于0.2 mm/d,无明显变形,且数值模拟计算结果与工程实践监测较为吻合,表明巷旁充填置换支护方案对松软破碎围岩巷道控制有较好的效果。最后,对深入研究再造承载结构快速支护技术进行了展望。

Abstract:In response to the technical challenges of supporting tunnels in loose and fragmented surrounding rock with poor anchorage, strong dynamic pressure, and strong structural stress influences, extensive on-site surveys were conducted, and several typical problems of large deformation in coal mine tunnel surrounding rock and difficulty in rock control were summarized and analyzed. Based on the analysis of existing support technologies and theoretical foundations, a concept and method for the rapid support technology of reconstructing high-strength load-bearing structures were proposed. Taking the 11205 down-hill transport tunnel at Longbao Coal Mine in Guizhou as an engineering background, the causes of deformation and failure were analyzed. A combined support method of displacement and unloading for fragmented surrounding rock was designed in practice. The design plan and optimal parameter calculations for the roadside backfill wall were carried out, and a mechanical model for the load-bearing capacity of the roadside backfill wall was theoretically established. Its load-bearing strength was analyzed to determine the strength of the wall and its suitability and effectiveness with the surrounding rock of the tunnel. By integrating the FLAC3D numerical simulation software and the Python scripting language, the moth-flame optimization algorithm was applied to determine the optimal displacement parameters for the fragmented rock tunnel (wall thickness and unloading zone width). A new material for high-strength, high-toughness backfill support was developed. By displacing and reconstructing the weak wall body, the tunnel roof, backfill, and floor were reconstituted into an integral load-bearing structure. Industrial-scale trial results underground showed that after reconstructing the weak rock body of the tunnel, the new structure consisting of the roof, backfill, and floor fully utilized the surrounding rock’s own load-bearing capacity and resistance to deformation. The rock deformation stabilized, the convergence rate was generally less than 0.2 mm/d, with no significant deformation, and the results of the numerical simulation calculations were consistent with the engineering practice monitoring, indicating that the roadside backfill displacement support scheme has a good effect on controlling tunnels in loose and fragmented surrounding rock. This can provide a theoretical basis for the support and strength parameters of roadside backfill. Finally, the paper looked forward to deeper research into the technology of rapid support for reconstructed load-bearing structures.

-

-

表 1 岩土体和巷旁充填墙的力学参数

Table 1 Mechanical parameters of rock and soil mass and roadside backfill wall

岩性 密度/(kg·m−3) 体积模量/GPa 剪切模量/GPa 黏聚力/MPa 内摩擦角/(°) 抗拉强度/MPa 岩土体 2500 11.18 11.90 0.71 20 0.55 巷旁充填墙 2800 22.00 22.00 60.00 50 40.00 -

[1] 何满潮,高尔新. 软岩巷道耦合支护力学原理及其应用[J]. 水文地质工程,1998(2):1−4. HE Manchao,GAO Erxin. Principle and application of coupling support mechanics of soft rock roadway[J]. Hydrogeology Engineering,1998(2):1−4.

[2] 康红普. 我国煤矿巷道锚杆支护技术发展60年及展望[J]. 中国矿业大学学报,2016,45(6):1071−1081. KANG Hongpu. 60 years of development and prospect of coal mine roadway bolt support technology in China[J]. Journal of China University of Mining and Technology,2016,45(6):1071−1081.

[3] 康红普,姜鹏飞,黄炳香,等. 煤矿千米深井巷道围岩支护-改性-卸压协同控制技术[J]. 煤炭学报,2020,45(3):845−864. KANG Hongpu,JIANG Pengfei,HUANG Bingxiang,et al. Collaborative control technology of surrounding rock support-modification-pressure relief in coal mine thousand-meter deep shaft roadway[J]. Journal of China Coal Society,2020,45(3):845−864.

[4] 侯朝炯. 深部巷道围岩控制的关键技术研究[J]. 中国矿业大学学报,2017,46(5):881−889. HOU Chaojiong. Research on key technologies of surrounding rock control in deep roadway[J]. Journal of China University of Mining and Technology,2017,46(5):881−889.

[5] 赵光明,彭 瑞,孟祥瑞,等. 软岩巷道开挖−支护过程承载结构稳定性分析[J]. 中国矿业大学学报,2017,46(4):792−802. ZHAO Guangming,PENG Rui,MENG Xiangrui,et al. Stability analysis of bearing structure in excavation-support process of soft rock roadway[J]. Journal of China University of Mining and Technology,2017,46(4):792−802.

[6] 左建平,洪紫杰,于美鲁,等. 破碎围岩梯度支护模型及分级控制研究[J]. 中国矿业大学学报,2022,51(2):221−231. ZUO Jianping,HONG Zijie,YU Meilu,et al. Research on gradient support model and grading control of broken surrounding rock[J]. Journal of China University of Mining and Technology,2022,51(2):221−231.

[7] 龙景奎. 深部巷道围岩协同锚固机理[J]. 采矿与安全工程学报,2016,33(1):19−26. LONG Jingkui. Cooperative anchoring mechanism of surrounding rock in deep roadway[J]. Journal of Mining & Safety Engineering,2016,33(1):19−26.

[8] 靖洪文,赵振龙,吴疆宇. 基于多源信息表征的深部巷道围岩结构灾变演化机理[J]. 煤炭学报,2023,48(1):163−176. JING Hongwen,ZHAO Zhenlong,WU Jiangyu. Catastrophe evolution mechanism of surrounding rock structure in deep roadway based on multi-source information representation[J]. Journal of China Coal Society,2023,48(1):163−176.

[9] 王襄禹,柏建彪,陈 勇,等. 软岩巷道锚注结构承载特性的时变规律与初步应用[J]. 岩土工程学报,2013,35(3):469−475. WANG Xiangyu,BAI Jianbiao,CHEN Yong,et al. Time-varying law and preliminary application of bearing characteristics of anchored structures in soft rock roadway[J]. Chinese Journal of Geotechnical Engineering,2013,35(3):469−475.

[10] 康红普,冯志强. 煤矿巷道围岩注浆加固技术的现状与发展趋势[J]. 煤矿开采,2013,18(3):1−7. KANG Hongpu,FENG Zhiqiang. Current situation and development trend of surrounding rock grouting reinforcement technology in coal mine roadway[J]. Coal Mining,2013,18(3):1−7.

[11] 张庆松,张连震,刘人太,等. 基于“浆–土”界面应力耦合效应的劈裂注浆理论研究[J]. 岩土工程学报,2016,38(2):323−330. ZHANG Qingsong,ZHANG Lianzhen,LIU Rentai,et al. Theoretical study on splitting grouting based on stress coupling effect at “slurry-soil” interface[J]. Chinese Journal of Geotechnical Engineering,2016,38(2):323−330.

[12] 张振峰,康红普,姜志云,等. 千米深井巷道高压劈裂注浆改性技术研发与实践[J]. 煤炭学报,2020,45(3):972−981. ZHANG Zhenfeng,KANG Hongpu,JIANG Zhiyun,et al. Study and application of high-pressure splitting grouting modification technology in coalmine with depth more than 1000m[J]. Journal of China Coal Society,2020,45(3):972−981.

[13] 康红普,姜鹏飞,冯彦军,等. 煤矿巷道围岩卸压技术及应用[J]. 煤炭科学技术,2022,50(6):1-15. KANG Hongpu,JIANG Pengfei,FENG Yanjun,et al. Destressing technology for rock around coal mine roadways and its applications [J].Coal Science and Technology,2022,50(6):1-15.

[14] 吴拥政,付玉凯,何 杰,等. 深部冲击地压巷道“卸压-支护-防护”协同防控原理与技术[J]. 煤炭学报,2021,46(1):132−144. WU Yongzheng,FU Yukai,HE Jie,et al. Principle and technology of “pressure relief-support-protection” collaborative prevention and control of deep impact ground pressure roadway[J]. Journal of China Coal Society,2021,46(1):132−144.

[15] 徐佑林,刘德成,吴旭坤,等. 强动压“三软”煤层巷道“卸-转-固”围岩控制技术[J]. 煤炭科学技术,2021,49(2):30−37. XU Youlin, LIU Decheng, WU Xukun et al. Control technology of "unloading, turning and fixing" surrounding rock in roadway of "three soft" coal seam under strong dynamic pressure[J]. Coal Science and Technology,2021,49(2):30−37.

[16] 董方庭,宋宏伟,郭志宏,等. 巷道围岩松动圈支护理论[J]. 煤炭学报,1994,19(1):21−32. DONG Fangting,SONG Hongwei,GUO Zhihong,et al. Roadway support theory based on broken rock zone[J]. Journal of China Coal Society,1994,19(1):21−32.

[17] 侯朝炯,王襄禹,柏建彪,等. 深部巷道围岩稳定性控制的基本理论与技术研究[J]. 中国矿业大学学报,2021,50(1):1−12. HOU Chaojiong,WANG Xiangyu,BAI Jianbiao,et al. Research on basic theory and technology of stability control of surrounding rock in deep roadway[J]. Journal of China University of Mining and Technology,2021,50(1):1−12.

[18] 姜鹏飞. 千米深井巷道围岩支护−改性−卸压协同控制原理及技术[D]. 北京:煤炭科学研究总院,2020. JIANG Pengfei. Cooperative control principle and technology of surrounding rock support-modification-pressure relief of kilometer deep shaft roadway[D]. Beijing :Chinese Institute of Coal Science,2020.

[19] 程利兴. 千米深井巷道围岩水力压裂应力转移机理研究及应用[D]. 北京:中国矿业大学(北京),2021. CHENG Lixing. Research and application of hydraulic fracturing stress transfer mechanism of surrounding rock in thousand-meter deep well roadway[D]. Beijing :China University of Mining and Technology−Beijing,2021.

[20] 陈晓翔,勾攀峰,范增哲,等. 深井高应力高突区域回采巷道变形特征及控制[J]. 采矿与安全工程学报,2013,30(3):363−368. CHEN Xiaoxiang,GOU Panfeng,FAN Zengzhe,et al. Deformation characteristics and control of mining roadway in deep well high stress and high protrusion area[J]. Journal of Mining & Safety Engineering,2013,30(3):363−368.

[21] 余伟健,王卫军,黄文忠,等. 高应力软岩巷道变形与破坏机制及返修控制技术[J]. 煤炭学报,2014,39(4):614−623. YU Weijian,WANG Weijun,HUANG Wenzhong,et al. Deformation and failure mechanism and rework control technology of high-stress soft rock roadway[J]. Journal of China Coal Society,2014,39(4):614−623.

[22] 靖洪文,尹 乾,朱 栋,等. 深部巷道围岩锚固结构失稳破坏全过程试验研究[J]. 煤炭学报,2020,45(3):889−901. JING Hongwen,YIN Qian,ZHU Dong,et al. Experimental study on the whole process of instability and failure of anchorage structure of surrounding rock in deep roadway[J]. Journal of China Coal Society,2020,45(3):889−901.

[23] 侯朝炯. 巷道围岩控制[M]. 徐州:中国矿业大学出版社,2013:288–390. HOU Chaojiong. Ground control of roadways[M]. Xuzhou:China University of Mining and Technology Press,2013:288–390.

[24] 张俊文. 深部大规模松软围岩巷道破坏分区理论分析[J]. 中国矿业大学学报,2017,46(2):292−299. ZHANG Junwen. Theoretical analysis of failure zoning of deep large-scale loose and soft surrounding rock roadway[J]. Journal of China University of Mining and Technology,2017,46(2):292−299.

[25] WU Shaokang,ZHANG Junwen,SONG Zhixiang,et al. Review of the development status of rock burst disaster prevention system in China[J]. Journal of Central South University,2023,30(11):3763−3789. doi: 10.1007/s11771-023-5478-2

[26] 康红普. 我国煤矿巷道围岩控制技术发展70年及展望[J]. 岩石力学与工程学报,2021,40(1):1−30. KANG Hongpu. 70 years and prospect of roadway surrounding rock control technology in China[J]. Chinese Journal of Rock Mechanics and Engineering,2021,40(1):1−30.

[27] MIRJALILI S. Moth-flame optimization algorithm:a novel nature-inspired heuristic paradigm. Knowledge-based systems,2015,89:228−249.

[28] GU X,LI J,XU X,et al. Optimization of slurry circulating pump combination based on moths to flame algorithm[J]. Journal of Engineering for Thermal Energy and Power ,2021,36(6):44−50.

-

期刊类型引用(8)

1. 张傲天. 厚硬煤层综放开采预裂技术研究. 凿岩机械气动工具. 2025(01): 116-118 .  百度学术

百度学术

2. 郭伟. 大采高工作面厚硬顶板预裂技术研究. 凿岩机械气动工具. 2025(01): 113-115 .  百度学术

百度学术

3. 马洪飞,底俊臣,王国牛,牛延汀,李书宾. 西庞井9303工作面厚硬顶板切顶卸压技术研究. 煤炭技术. 2025(03): 13-17 .  百度学术

百度学术

4. 张丁丁. 智能化综采工作面切顶卸压沿空留巷技术研究. 能源与节能. 2025(03): 182-184+266 .  百度学术

百度学术

5. 吴衡. 新田煤矿1901工作面沿空留巷支护设计. 能源与节能. 2025(03): 282-284 .  百度学术

百度学术

6. 张进波. 铝基高固水巷旁充填沿空留巷技术研究与应用. 煤. 2024(11): 29-33+48 .  百度学术

百度学术

7. 王世宇,张昌锁,王凯飞,张胜利. 地面深孔水压爆破弱化厚硬顶板技术研究. 山东科技大学学报(自然科学版). 2024(05): 1-12 .  百度学术

百度学术

8. 孟国龙. 某深部煤层综采工作面切顶卸压留巷技术研究. 现代矿业. 2024(12): 48-51+59 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: