Study on the permeability model and in-situ testing of coal seams using repeatedinjection pressure drop method

-

摘要:

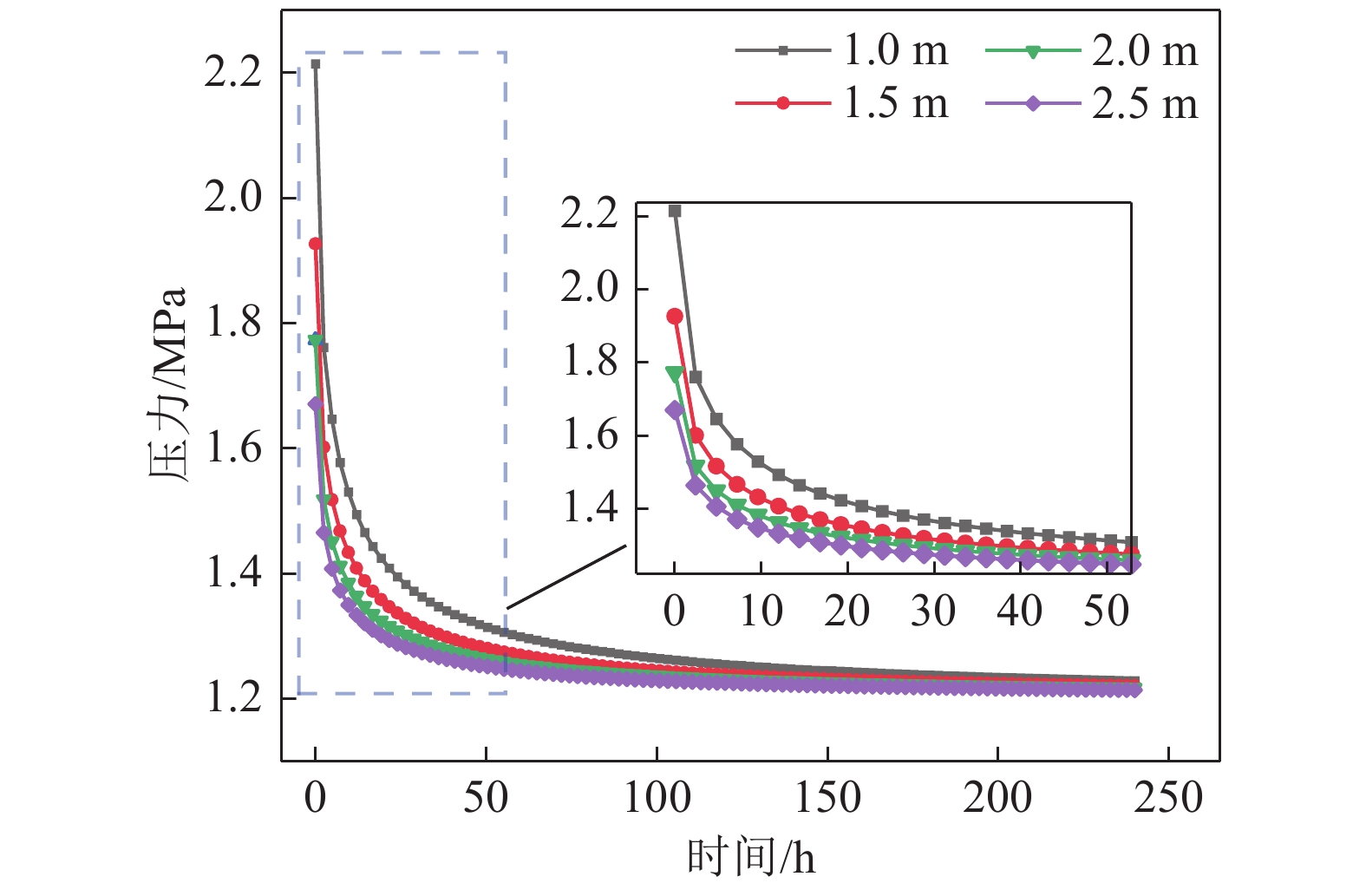

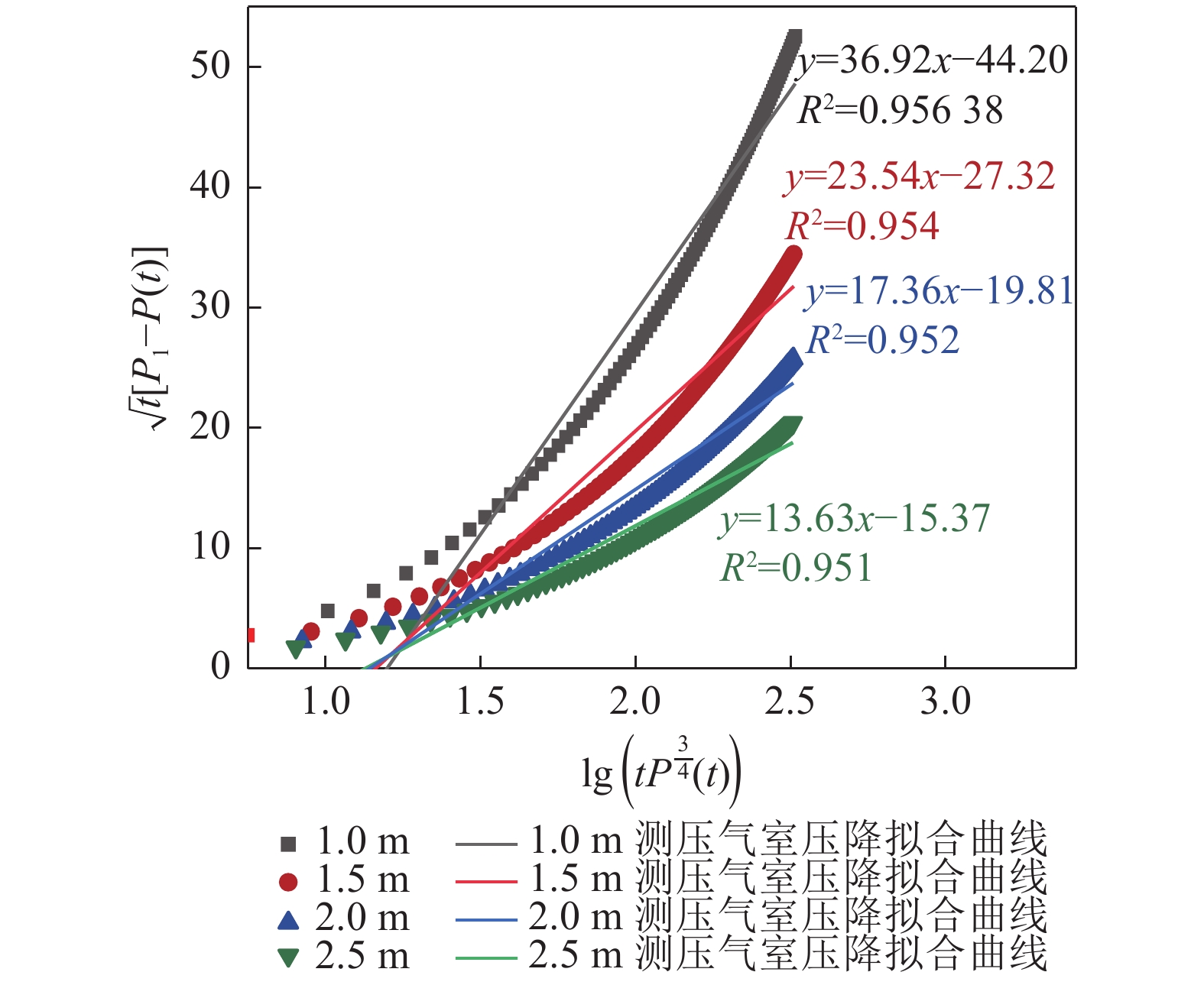

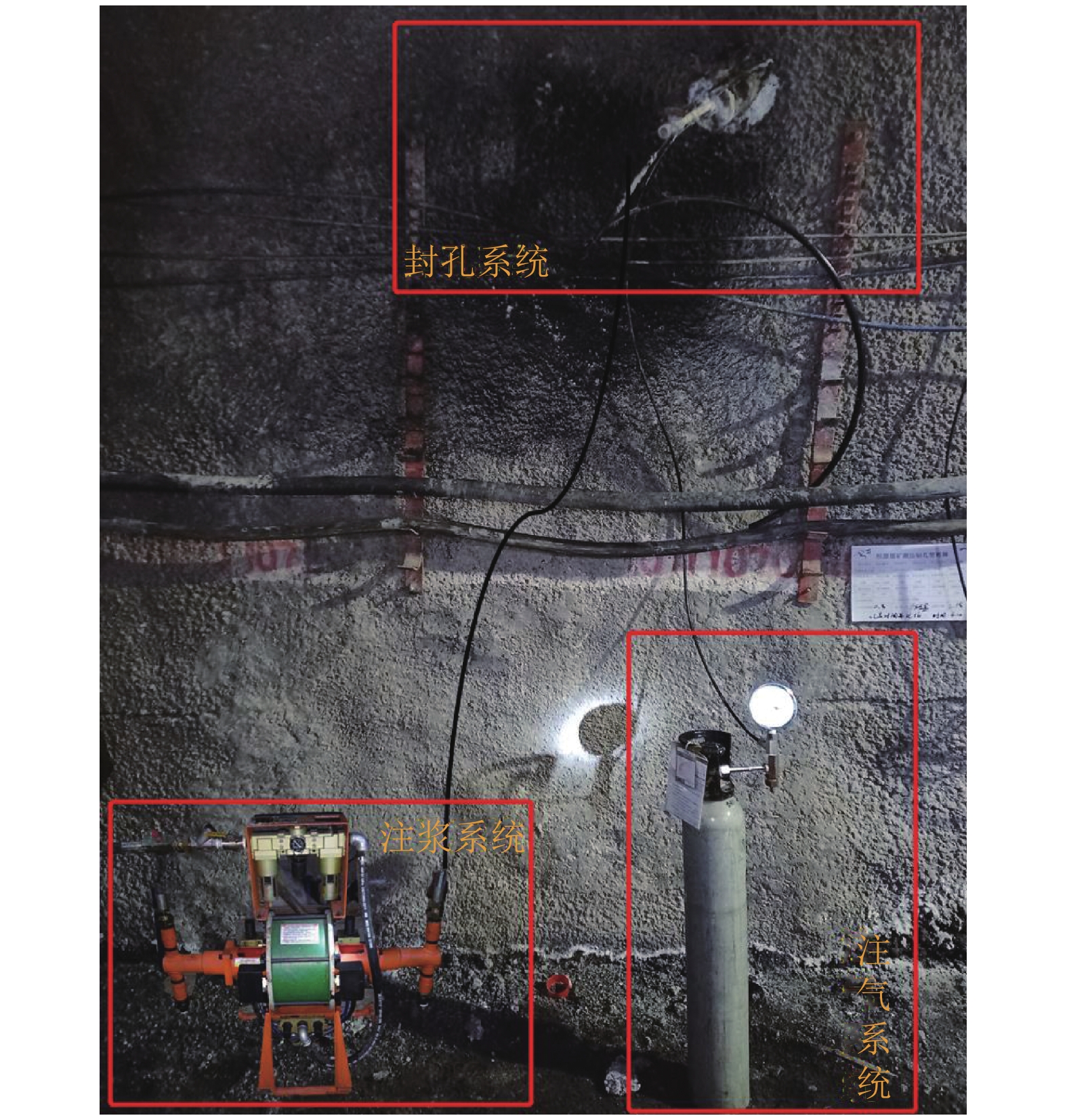

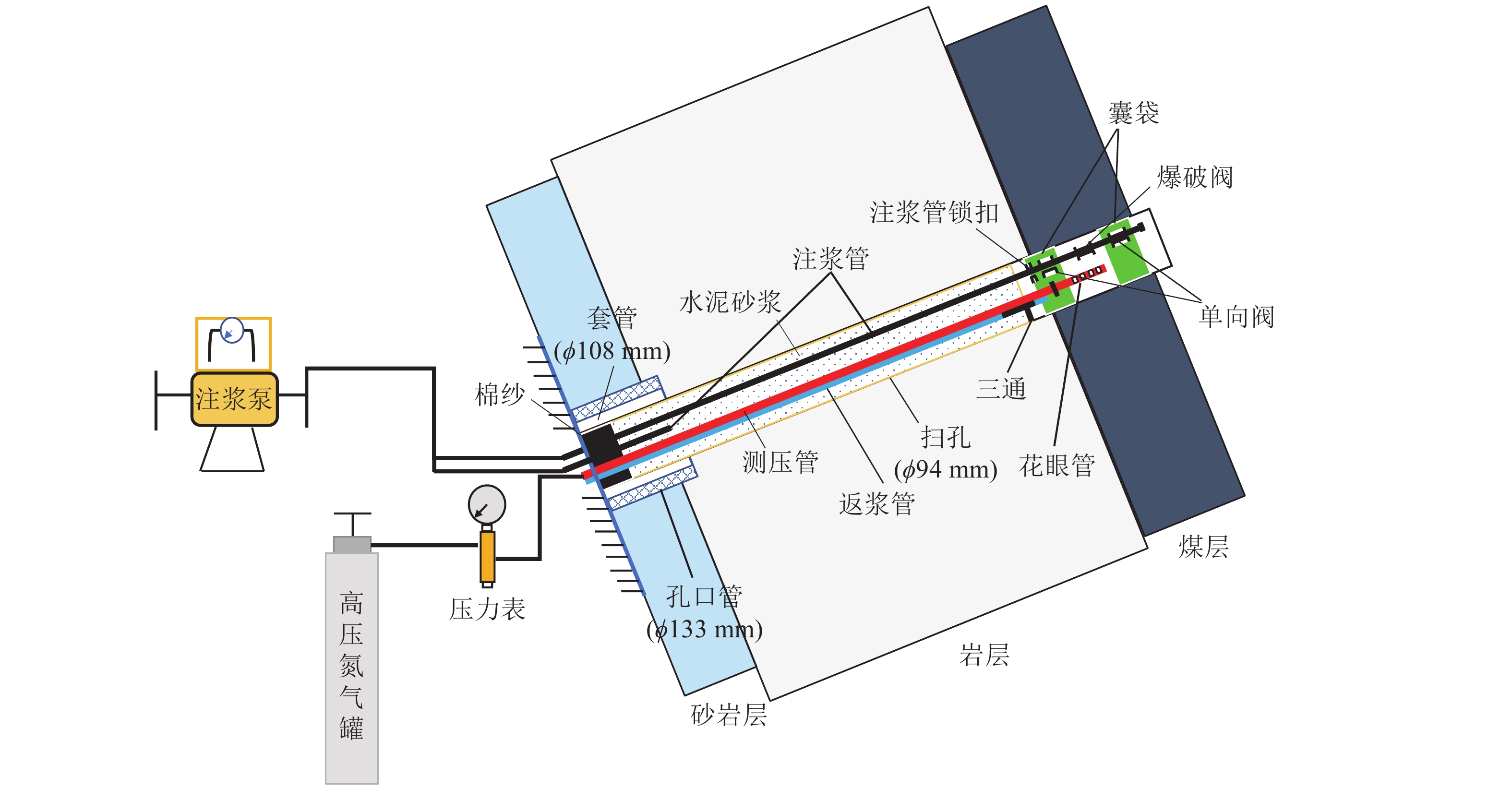

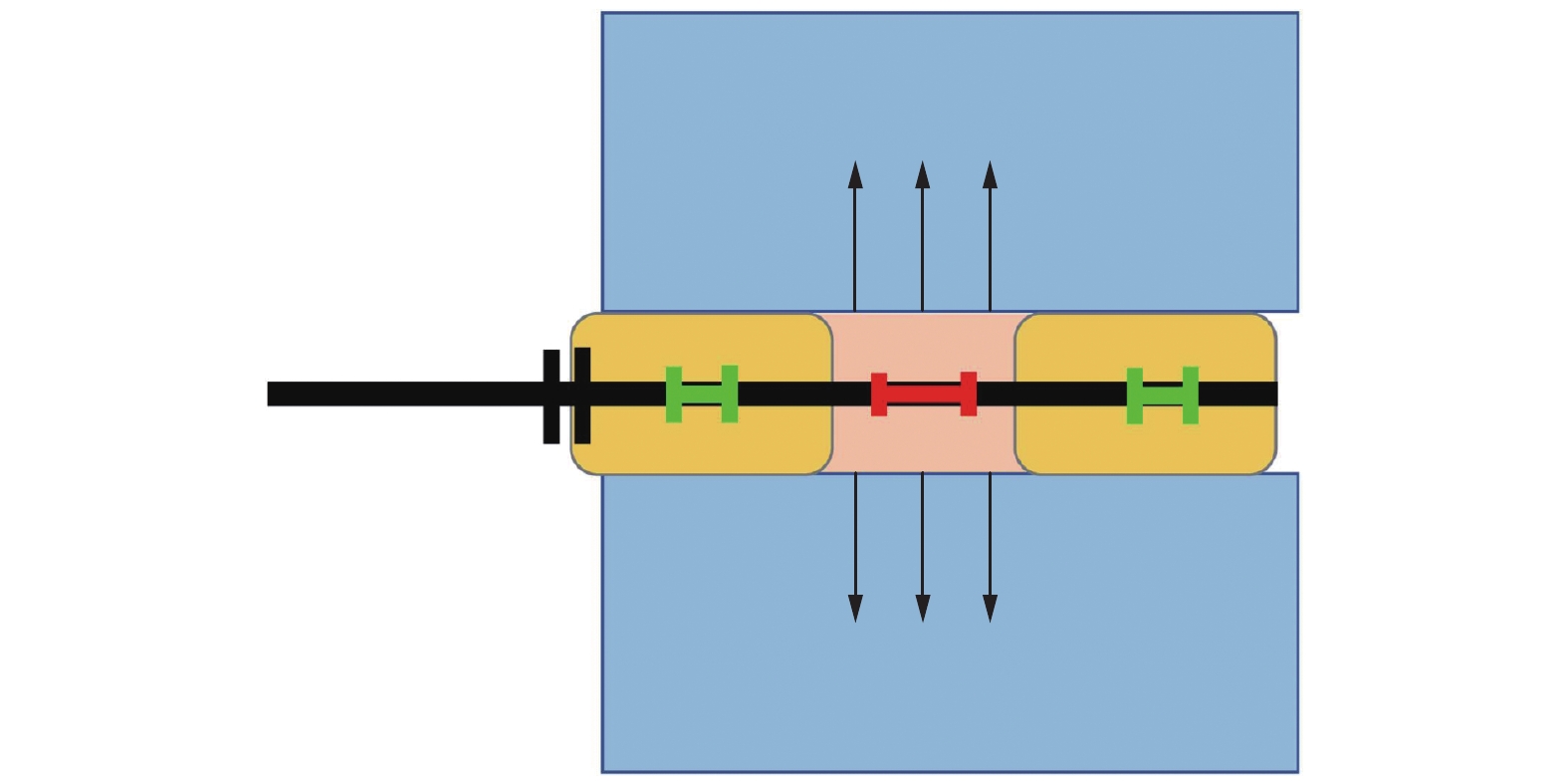

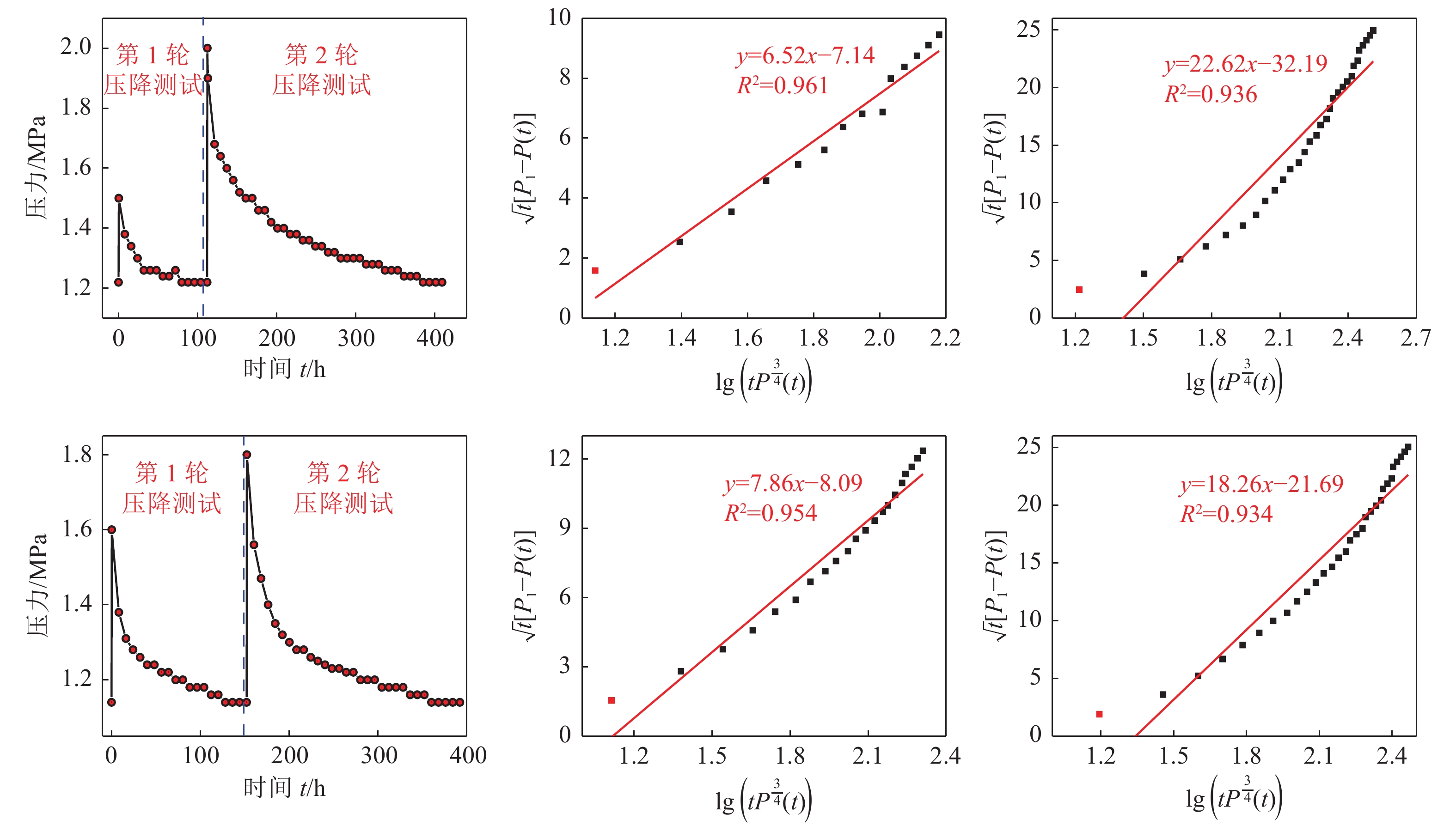

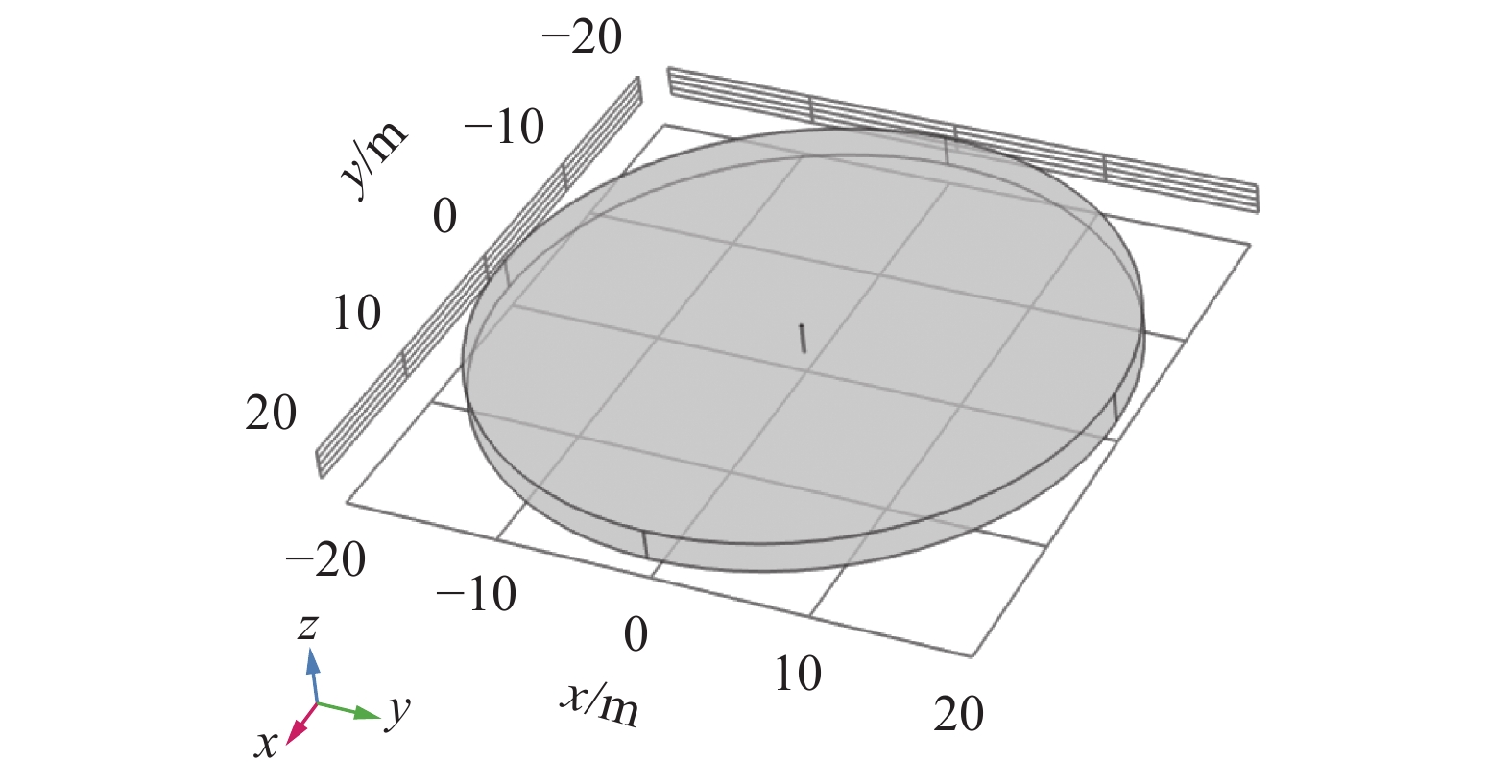

煤层渗透率作为衡量瓦斯渗流与抽采难易程度的重要指标,对其进行准确测定具有重要意义。针对现有方法计算渗透率测试周期长、结果不稳定、模型不完善等问题,研究煤层渗透率的快速准确测定方法及相应的计算模型。基于煤层中气体径向不稳定流控制方程,结合不同压差下气体在煤层中的体积流量方程,建立可利用全区间压降数据测定煤层渗透率的注气压降计算模型。应用COMSOL数值模拟软件的达西渗流模块对模型进行求解,针对现场工程设计中可对压降曲线产生影响的测压气室长度进行单变量处理,根据模拟结果分析钻孔的测压气室长度可设计为2.0 m。根据数值模拟结果进行现场布置,搭建井下重复注气压降试验系统,结合煤层瓦斯赋存条件和巷道条件施工两组穿层钻孔,对2个测点分别注入两次高于煤层瓦斯压力的补偿气体进行渗透率原位测试,测试周期分别约为6 d和17 d,第2轮测试的注气压力高于第1轮。结合理论推导验证了注气压降过程中煤层瓦斯的雷诺数均处于线性达西渗流段,瓦斯在煤层中的渗流符合达西定律,满足计算模型的假设。与传统煤层渗透率计算方法进行了比较,结果表明:本方法和径向流量法的计算结果基本一致,可以满足实际工程需要。重复注气压降法的测试结果稳定可靠,具备快速测定的优点。

Abstract:Permeability of coal seams is an important indicator for assessing the difficulty of gas seepage and extraction, and its accurate determination holds significant significance. In light of the existing issues with long testing cycles, unstable results, and imperfect models, this research focuses on developing a rapid and accurate method for determining coal seam permeability and the corresponding computational model. Based on the radial unsteady-state gas flow control equation within coal seams and the volume flow equation for gas under different pressure differentials within the coal seam, we have established an injection pressure drop calculation model that utilizes the entire pressure drop dataset for measuring coal seam permeability. The COMSOL numerical simulation software, equipped with the Darcy flow module, is employed to solve the model. To address variables affecting the pressure drop curve in field engineering design, a univariate analysis of the length of the pressure measuring gas chamber is conducted. According to simulation results, the gas chamber length for pressure measurement in boreholes can be designed as 2.0 meters. Field arrangements are made based on the numerical simulation results, and an underground repeated gas injection pressure drop test system is established. This system, in conjunction with coal seam gas occurrence conditions and tunnel conditions, facilitates the drilling of two cross-seam boreholes for each of the two test points. These boreholes are injected with compensatory gas twice, each time exceeding the coal seam gas pressure, to conduct in-situ permeability tests. The testing periods are approximately 6 days and 17 days for the first and second rounds, respectively, with the second round having higher injection pressures. Combined with theoretical derivation, it was verified that the Reynolds numbers of coal seam gas remained within the linear Darcy flow regime during the gas injection pressure drop process, and gas flow within the coal seam adheres to Darcy's law, thus satisfying the assumptions of the calculation model. When compared to traditional methods for calculating coal seam permeability, the results indicate that this method aligns closely with the radial flow rate method, effectively meeting the requirements of practical engineering applications. The testing results of the repeated gas injection pressure drop method are stable and reliable, offering the advantage of rapid determination.

-

-

表 1 基础参数设置

Table 1 Basic parameter settings

类型 参数 数值 C1号 C2号 现场设置参数 钻孔半径/m 0.047 0.047 钻孔长度/m 33 26 封孔长度/m 30 23 见煤长度/m 3.0 2.5 煤层基础参数 初始孔隙率/% 0.04 瓦斯动力学黏度系数/(Pa·s) 1.08×10−5 煤层温度/K 298 煤的视密度/(kg·m−3) 1350 初始瓦斯压力/MPa 1.20 1.14 瓦斯含量/(m3·t−1) 9.51 10.65 初始渗透率/10−18 m2 2.27 3.85 Langmuir常数(压力)/MPa 1.02 1.64 Langmuir常数(极限吸附量)/(m3·t−1) 26.88 39.26 瓦斯含量系数/(m3·(m3·MPa0.5)−1) 12.17 13.96 表 2 不同长度测压气室测得的煤层渗透率

Table 2 Permeability of coal seams measured with different lengths of compressed air chambers

测压气室

长度/m煤层瓦斯

压力/MPa注气后

压力/MPa测定渗透

率/10−18 m2模型设置渗

透率/m21.0 1.20 2.23 0.525 1.0 1.5 1.94 0.767 2.0 1.78 0.944 2.5 1.67 1.072 表 4 煤层基础参数

Table 4 Basic parameters of coal seams

钻孔编号 初始瓦斯

压力/MPa瓦斯含量系数/

(m3·(m3·MPa0.5)−1)钻孔半

径/m排放时

间/d钻孔流量/

(m3·d−1)C1号 1.20 12.17 0.047 13.7 0.51 C2号 1.14 13.96 0.047 10.8 0.64 表 3 重复注气压降法计算的煤层渗透率

Table 3 Calculation of coal seam permeability using repeated injection pressure drop method

钻孔编号 煤层瓦斯压力/MPa 注气压力/MPa 煤层渗透率/10−18 m2 C1号 1.20 1.5 2.124 2.0 0.941 C2号 1.14 1.6 3.680 1.8 1.248 表 5 重复注气压降法与径向流量法计算的煤层渗透率值

Table 5 Coal seam permeability values calculated by repeated injection pressure drop method and radial flow rate method

钻孔编号 渗透率/10−18 m2 重复注气压降法 径向流量法 C1号 2.124 2.271 0.941 C2号 3.680 3.850 1.248 -

[1] 李波波,王 斌,杨 康,等. 煤岩孔裂隙结构分形特征及渗透率模型研究[J]. 煤炭科学技术,2021,49(2):226−231. LI Bobo,WANG Bin,YANG Kang,et al. Study on fractal characteristics of coal and rock pore fissure structure and permeability model[J]. Coal Science and Technology,2021,49(2):226−231.

[2] 尧春洪,李波波,高 政,等. 孔隙压力升降条件下煤岩双孔隙渗透率模型研究[J]. 煤炭科学技术,2022,50(11):116−121. YAO Chunhong,LI Bobo,GAO Zheng,et al. Study on dual pore permeability model of coal under the conditions of pore pressure increasing and decreasing[J]. Coal Science and Technology,2022,50(11):116−121.

[3] 蒋长宝,余 塘,段敏克,等. 瓦斯压力和应力对裂隙影响下的渗透率模型研究[J]. 煤炭科学技术,2021,49(2):115−121. JIANG Changbao,YU Tang,DUAN Minke,et al. Study on permeability model under the influence of gas pressure and stress on fracture[J]. Coal Science and Technology,2021,49(2):115−121.

[4] 徐 超,李小芳,陈晴晴,等. 基于非线性渗透率模型的高抽巷精准抽采参数优化[J]. 煤炭科学技术,2021,49(5):100−109. XU Chao,LI Xiaofang,CHEN Qingqing,et al. Optimization of precise extraction parameters in high-drainage roadway based on nonlinear permeability model[J]. Coal Science and Technology,2021,49(5):100−109.

[5] 李 伟,钟 艺,郭敬杰,等. 不同类型煤颗粒侧限压缩变形破碎特性试验研究[J]. 煤炭科学技术,2022,50(2):163−170. LI Wei,ZHONG Yi,GUO Jingjie,et al. Experimental study on confined compression deformation and breakage characteristics for different types of coal particles[J]. Coal Science and Technology,2022,50(2):163−170.

[6] 傅雪海,许行行,王 强,等. 煤层气异常成分的界定、分布及其成因研究进展[J]. 煤炭科学技术,2023,51(1):343−352. FU Xuehai,XU Hanghang,WANG Qiang,et al. Review of research on definition, distribution and causes of abnormal coalbed methane composition[J]. Coal Science and Technology,2023,51(1):343−352.

[7] 切尔诺夫O N,罗赞采夫E C. 瓦斯突出危险煤层井田的准备[M]. 北京:煤炭工业出版社,1980. [8] 周世宁. 煤层瓦斯赋存与流动理论[M]. 北京:煤炭工业出版社,1997:11–17. [9] 蒋承林. 煤层透气性系数测定方法的研究[J]. 中国矿业学院学报,1988,13(2):80−86. JIANG Chenglin. Study on measurement method of permeability coefficient of coal seam[J]. Journal of China University of Mining and Technology,1988,13(2):80−86.

[10] 刘明举,何学秋. 煤层透气性系数的优化计算方法[J]. 煤炭学报,2004,29(1):74−77. LIU Mingju,HE Xueqiu. Optimistic calculation method of gas seepage coefficients[J]. Journal of China Coal Society,2004,29(1):74−77.

[11] 刘能强. 实用现代试井解释方法(第五版)[M]. 北京:石油工业出版社,2008:28–35. [12] 阿曼纳特U. 乔德瑞. 油井试井手册[M]. 北京:石油工业出版社,2008:238–239. [13] 周世宁. 从钻孔瓦斯压力上升曲线计算煤层透气系数的方法[J]. 中国矿业学院学报,1982(3):8−15. ZHOU Shining. Calculation of gas permeability coefficient of coal seams by means of the curve of rising gas pressure in boreholes[J]. Journal of China University of Mining & Technology,1982(3):8−15.

[14] 刘明举,陈 亮,曾昭友. 基于压力恢复曲线的富水煤层瓦斯测压结果修正[J]. 煤炭科学技术,2013,41(7):71−74. LIU Mingju,CHEN Liang,ZENG Zhaoyou. Correction on pressure measured results of watery seam gas based on pressure recovered curve[J]. Coal Science and Technology,2013,41(7):71−74.

[15] 王国际,岑培山,田坤云,等. 上倾角含水瓦斯压力测压孔压力恢复曲线分析[J]. 煤炭科学技术,2010,38(3):52−54. WANG Guoji,CEN Peishan,TIAN Kunyun,et al. Analysis on pressure recovery curve of water bearing gas pressure measuring borehole with upward inclination[J]. Coal Science and Technology,2010,38(3):52−54.

[16] 邹永洺. 煤层瓦斯压力快速测定技术应用研究[J]. 煤矿安全,2019,50(4):138−141. ZOU Yongming. Application research on rapid determination technology of coal seam gas pressure[J]. Safety in Coal Mines,2019,50(4):138−141.

[17] 煤炭科学研究院抚顺研究所,焦作矿务局研究所. 应用压力恢复曲线测定煤层瓦斯渗流参数[J]. 煤矿安全,1986,17(12):1−6. Fushun Research Institute of Coal Science RESEARCH Institute,Jiaozuo Mining Bureau RESEARCH Institute. Application of pressure recovery curve to determine gas seepage parameters in coal seams[J]. Safety in Coal Mines,1986,17(12):1−6.

[18] 雷文杰,雷建伟,杨宏民,等. 钻孔瓦斯压力恢复法求解煤层透气性系数[J]. 煤田地质与勘探,2017,45(6):28−33. LEI Wenjie,LEI Jianwei,YANG Hongmin,et al. Borehole gas pressure build-up to evaluate the permeability of coal seam[J]. Coal Geology & Exploration,2017,45(6):28−33.

[19] 傅永帅. 基于压力恢复曲线测定煤层瓦斯参数研究[J]. 煤炭技术,2018,37(2):181−183. FU Yongshuai. Study on gas parameters of coal seam based on pressure recovery curve[J]. Coal Technology,2018,37(2):181−183.

[20] 陶云奇,闫本正,刘 东. 煤矿井下煤层渗透率直接测定方法研究及应用[J]. 煤矿安全,2018,49(3):140−143,147. TAO Yunqi,YAN Benzheng,LIU Dong. Study and application of direct determination method in coal seam permeability of coal mine[J]. Safety in Coal Mines,2018,49(3):140−143,147.

[21] 王剑英. 寺家庄井田8号煤层气储层物性特征研究[J]. 煤,2019,28(11):5−8,80. WANG Jianying. Physical properties characteristics of the no. 8 coalbed methane reservoirs in Sijiazhuang minefield[J]. Coal,2019,28(11):5−8,80.

[22] 关金锋,王永周,马静驰,等. 古汉山矿二1煤层渗透性优势方位及对瓦斯抽采的影响[J]. 煤矿安全,2019,50(6):185−187,191. GUAN Jinfeng,WANG Yongzhou,MA Jingchi,et al. Dominant permeability direction and its influence on gas drainage of Ⅱ1 coal seam in guhanshan coal mine[J]. Safety in Coal Mines,2019,50(6):185−187,191.

[23] 郝家兴,刘 垒,王彦敏. 压力恢复曲线测定煤层瓦斯赋存参数的试验研究[J]. 内蒙古煤炭经济,2020(14):64−65. HAO Jiaxing,LIU Lei,WANG Yanmin. Experimental study on the measurement of coal seam gas storage parameters by pressure recovery curve[J]. Inner Mongolia Coal Economy,2020(14):64−65.

[24] 唐建新,鲁思佳,袁 芳,等. 极近距离煤层开采围岩应力及煤体渗透率演化规律[J]. 矿业研究与开发,2023,43(3):160−165. TANG Jianxin,LU Sijia,YUAN Fang,et al. Evolution law of surrounding rock stress and coal permeability in very close coal seam mining[J]. Mining Research and Development,2023,43(3):160−165.

[25] YU P,LIU Y T,WANG J,et al. A new fracture permeability model:influence of surrounding rocks and matrix pressure[J]. Journal of Petroleum Science and Engineering,2020,193:107320. doi: 10.1016/j.petrol.2020.107320

[26] 周 睿,闫斌移. 穿层钻孔径向流场瓦斯流量推算煤层瓦斯压力方法研究[J]. 岩石力学与工程学报,2016,35(S1):3147−3152. ZHOU Rui,YAN Binyi. Research on calculating gas pressure with gas flow in crossing borehole[J]. Chinese Journal of Rock Mechanics and Engineering,2016,35(S1):3147−3152.

[27] 陈元千. 油气藏工程常用公式的单位变换[J]. 油气井测试,2011,20(1):1−9. CHEN Yuanqian. Unit conversion of often-used formulas in petroleum reservoir engineering[J]. Well Testing,2011,20(1):1−9.

[28] 游继军,蒋承林,汤海林. 主动式测压瓦斯压降曲线的影响因素分析[J]. 煤矿安全,2012,43(12):154−156. YOU Jijun,JIANG Chenglin,TANG Hailin. Analysis on influence factors for gas pressure decline curve of active pressure measurement[J]. Safety in Coal Mines,2012,43(12):154−156.

[29] 孙东坡. 水力学[M]. 郑州:郑州大学出版社,2007:187. [30] SCHROT B M,KLAVE G T,SCHUTTENHELM R T. Surface and subsurface expressions of gas seepage to the seabed[J]. Ex-amples from the Southern North Sea Marine and Petroleum Geology,2005,22(4):499−515.

[31] BROWN A. Evaluation of possible gas microseepage mecha-nisms[J]. AAPG Bulletin,2000,84(11):1775−1789.

[32] SASSEN R,MILKOV A V,De FREITAS D A. Gas venting and gas hydrate stability in the Northwestern Gulf of Mexico Slope:Significance to Sediment Deformation[A]//Proceedings of the Annual Offshore Technology Conference[C]. Houston:Offshore Technology Conference,2002:377–383.

[33] KLUSMAN R W. Detailed compositional analysis of gas seep-age at the National Carbon Storage TEST Site,TEAPOT Dome,Wyoming,USA[J]. Applied Geochemistry,2006,21(9):1498−1521. doi: 10.1016/j.apgeochem.2006.06.009

[34] VINSOT A,APPELO C J,CAILTEAU C. CO2 data on gas and pore water sampled in situ in the Opalinus Clay at the Mont Terri rock laboratory[J]. Physics and Chemistry of the Earth,2008,33(1):54−60.

[35] 马跃龙,林柏泉. 煤层透气性系数的测定及其分析[J]. 辽宁工程技术大学学报(自然科学版),1998(3):240−243. MA Yaolong,LIN Baiquan. The determination and analysis of permeability coefficient in coal seam[J]. Journal of Liaoning Technical University(Natural Science),1998(3):240−243.

-

期刊类型引用(1)

1. 王磊,钟浩,范浩,邹鹏,商瑞豪,晋康. 循环荷载下含瓦斯煤力学特性及应变场演化规律研究. 煤炭科学技术. 2024(06): 90-101 .  本站查看

本站查看

其他类型引用(0)

下载:

下载: