Research on hole protection technology of screen pipe for hydraulic transportation and automatic butt joint in high position directional borehole

-

摘要:

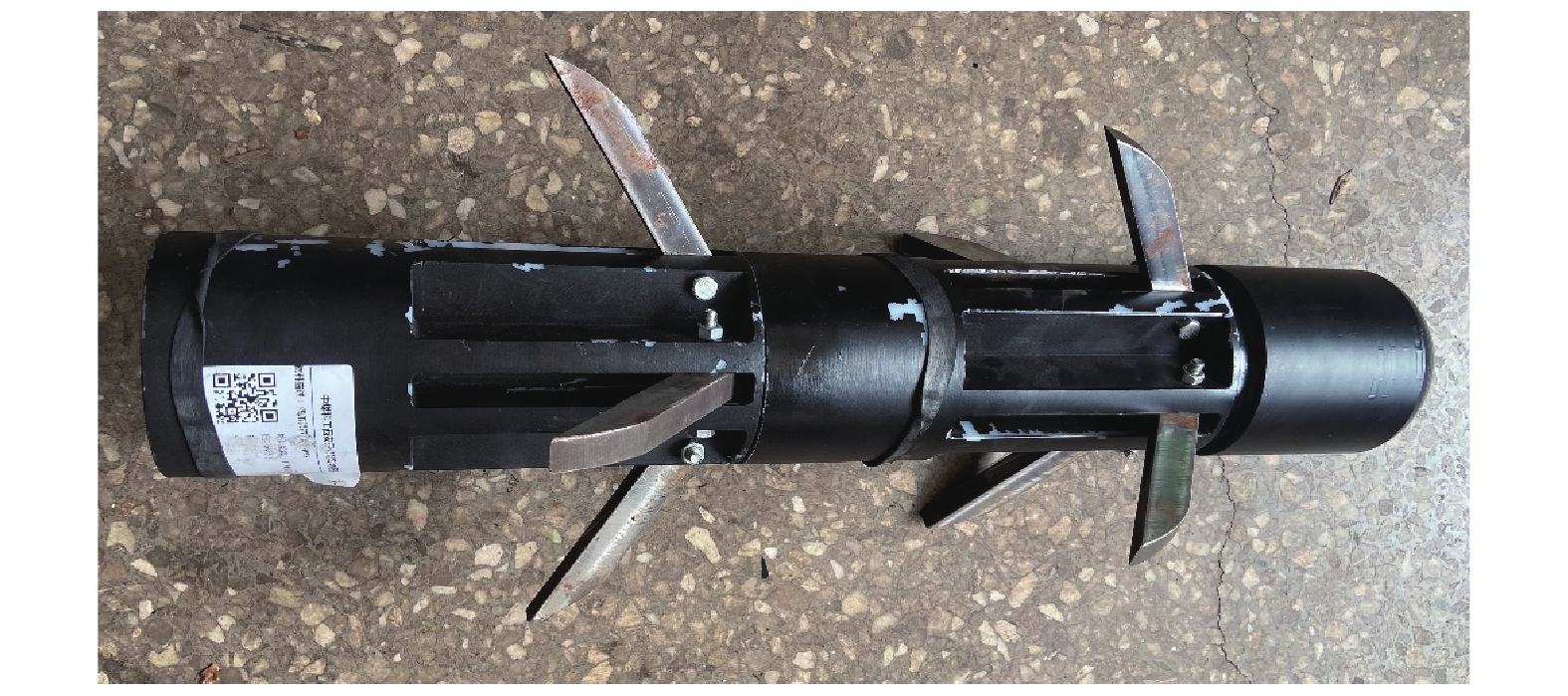

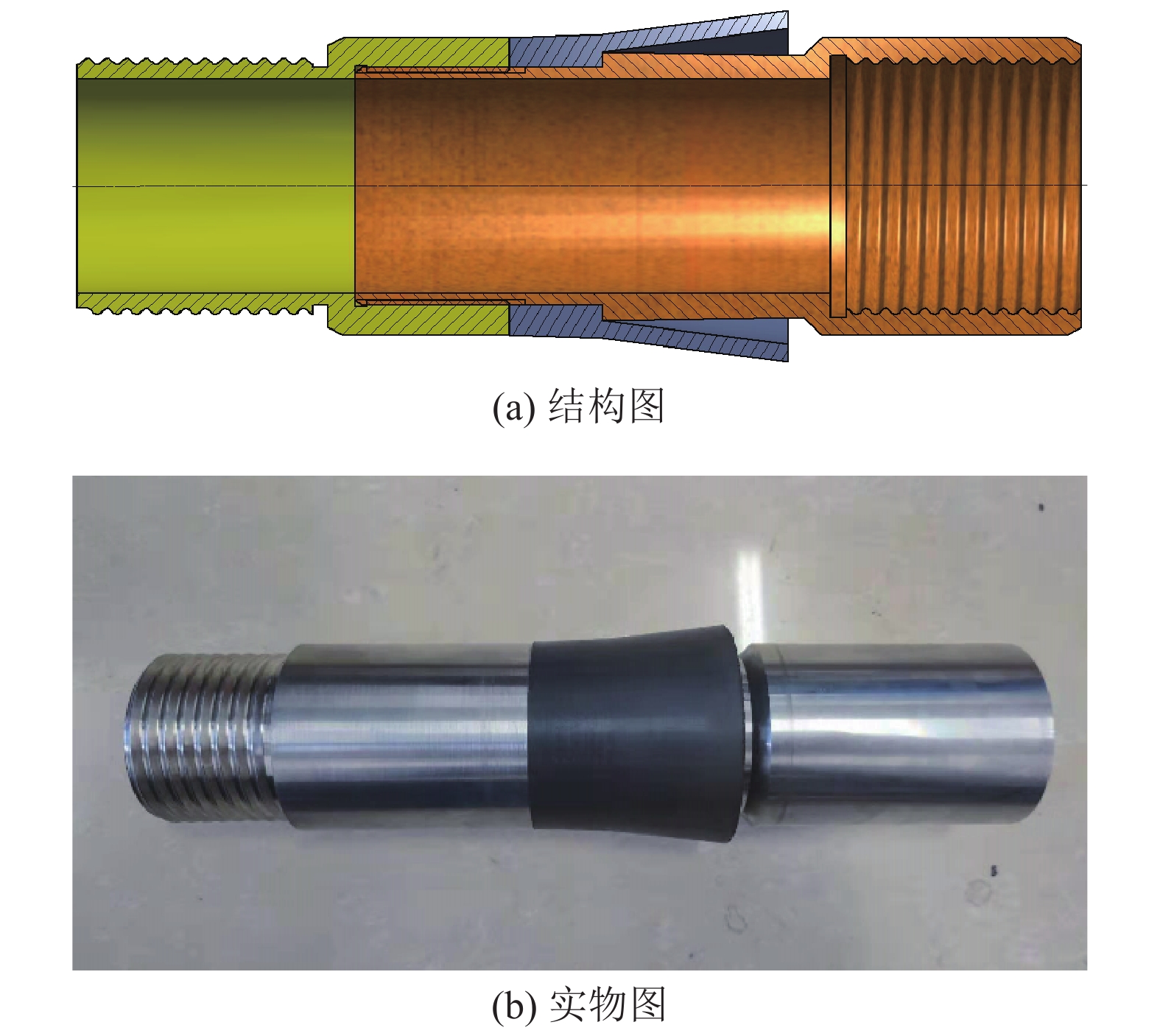

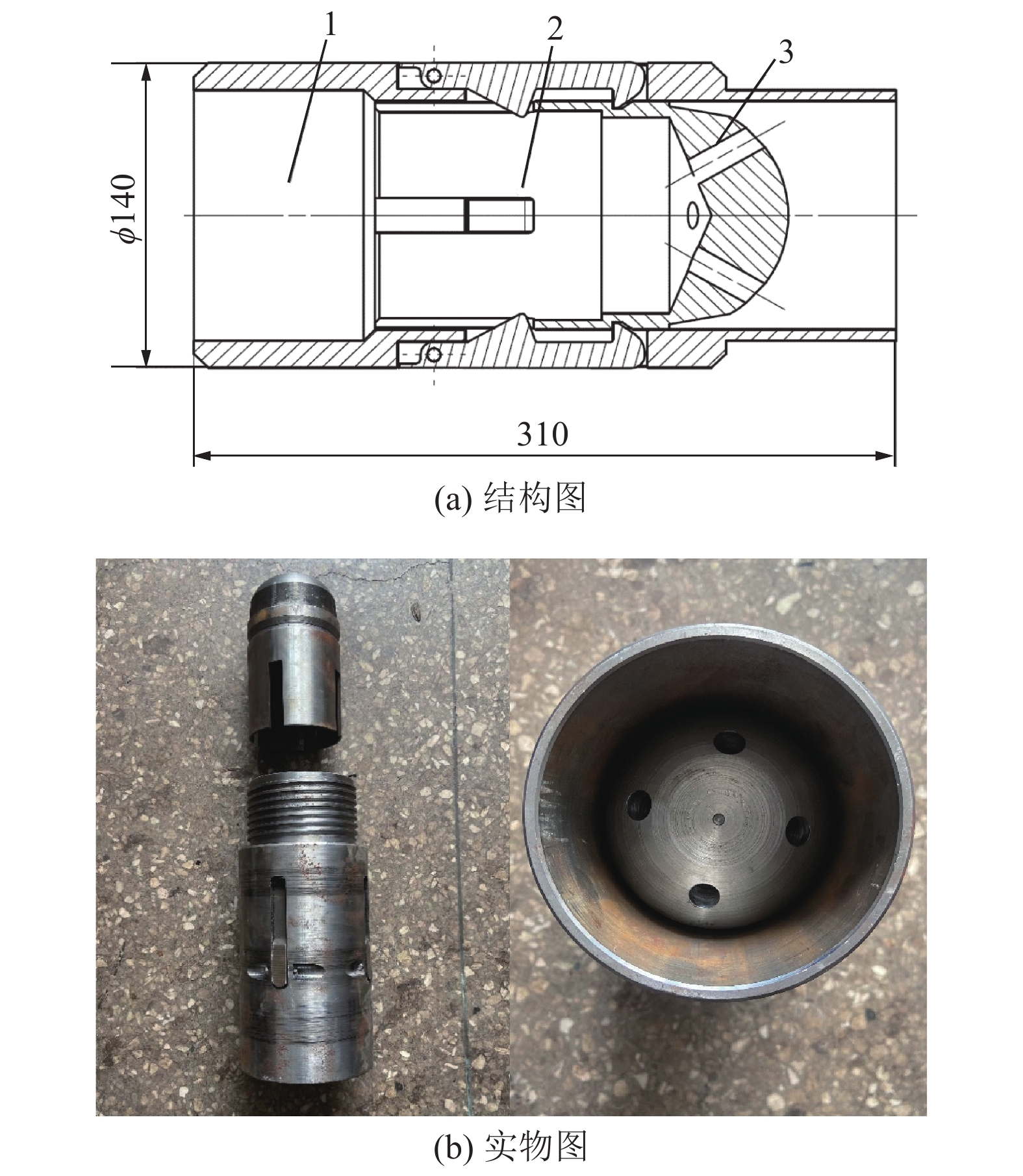

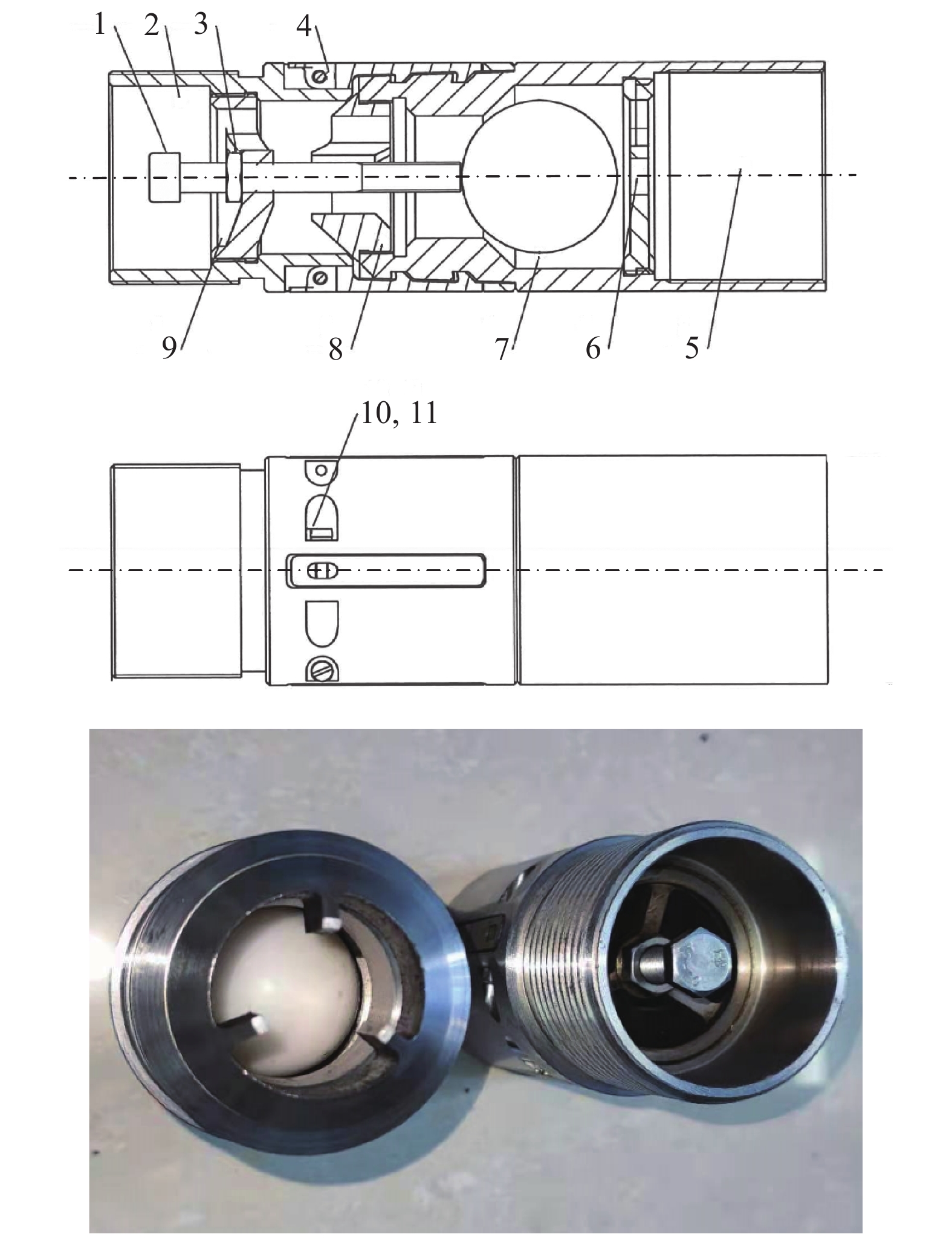

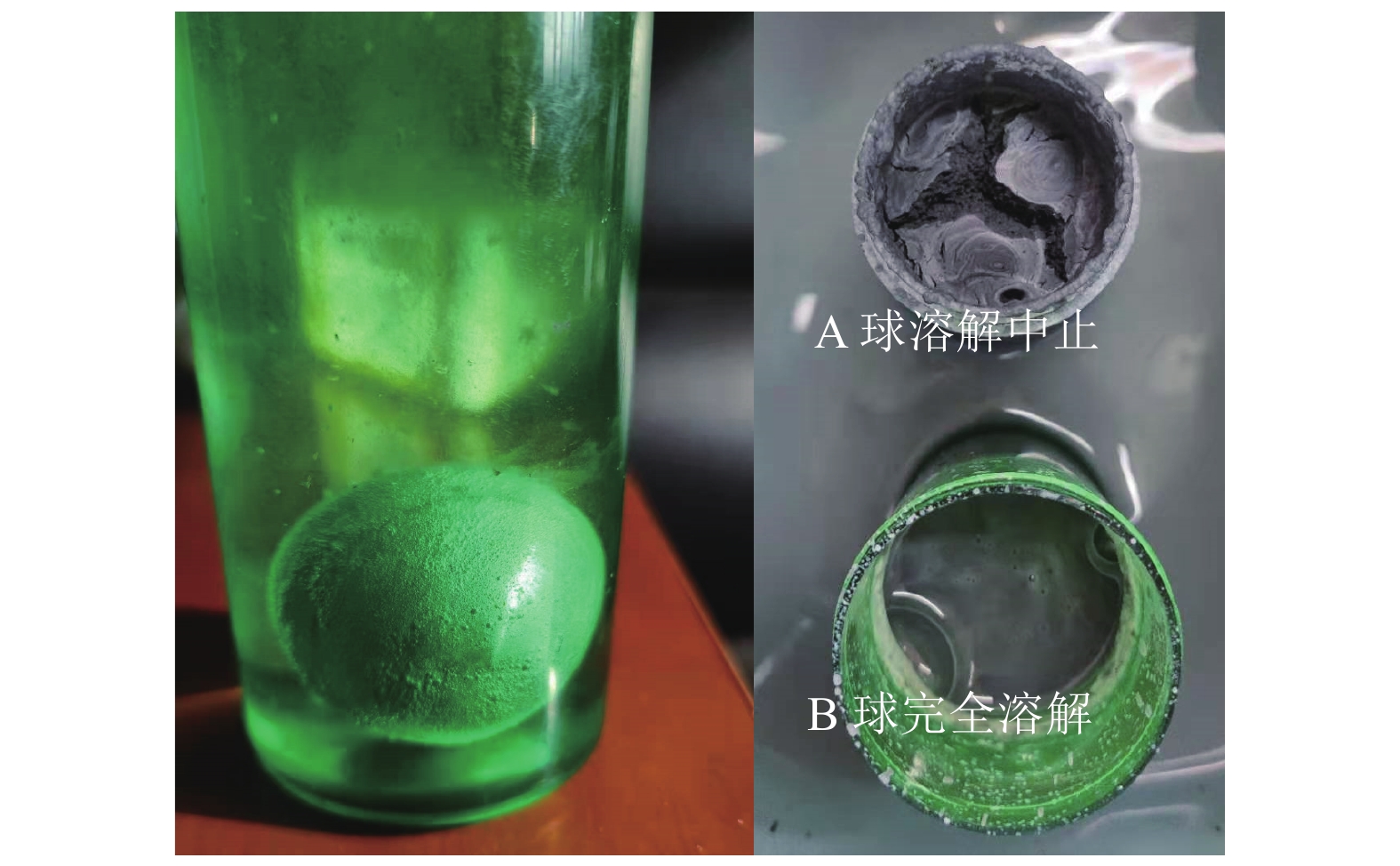

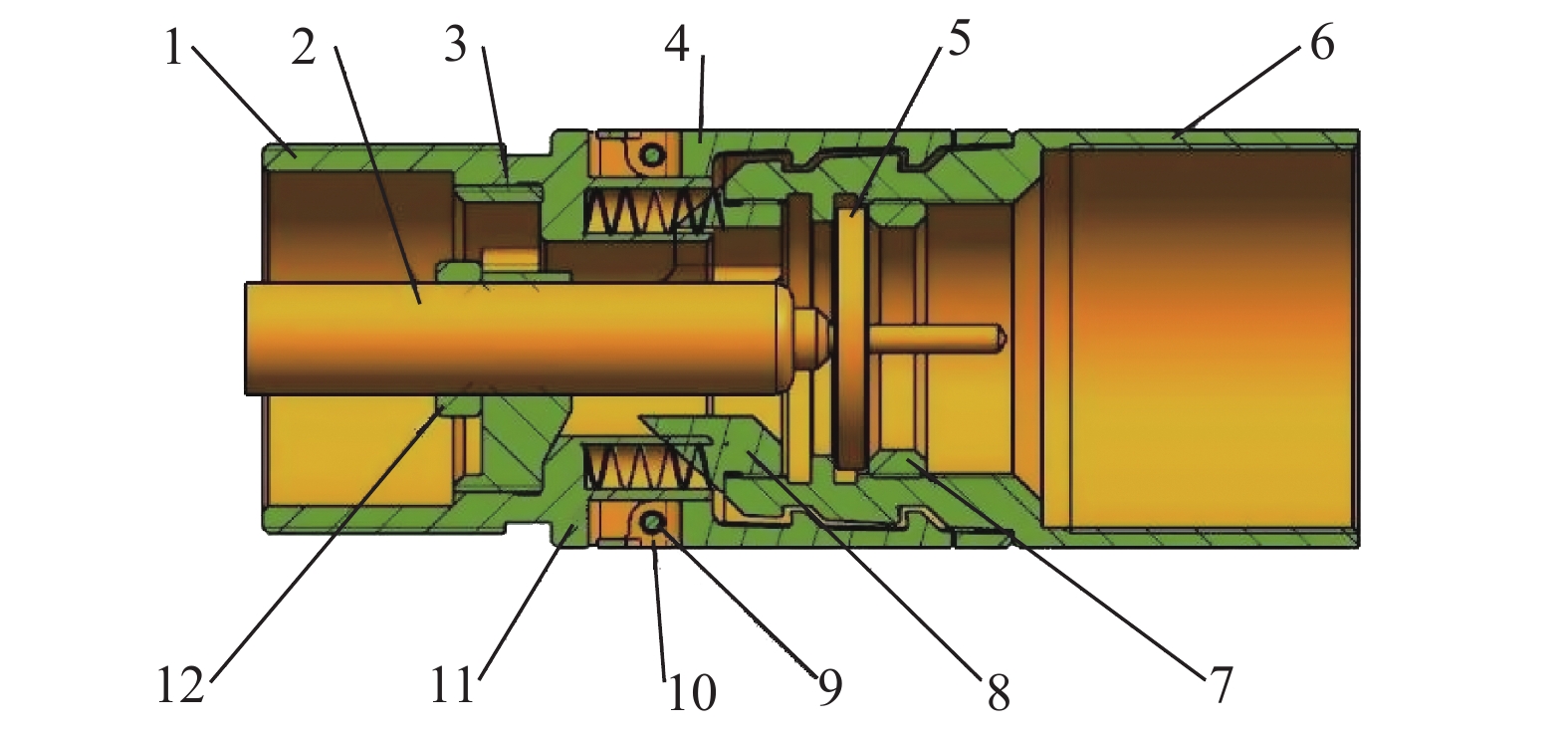

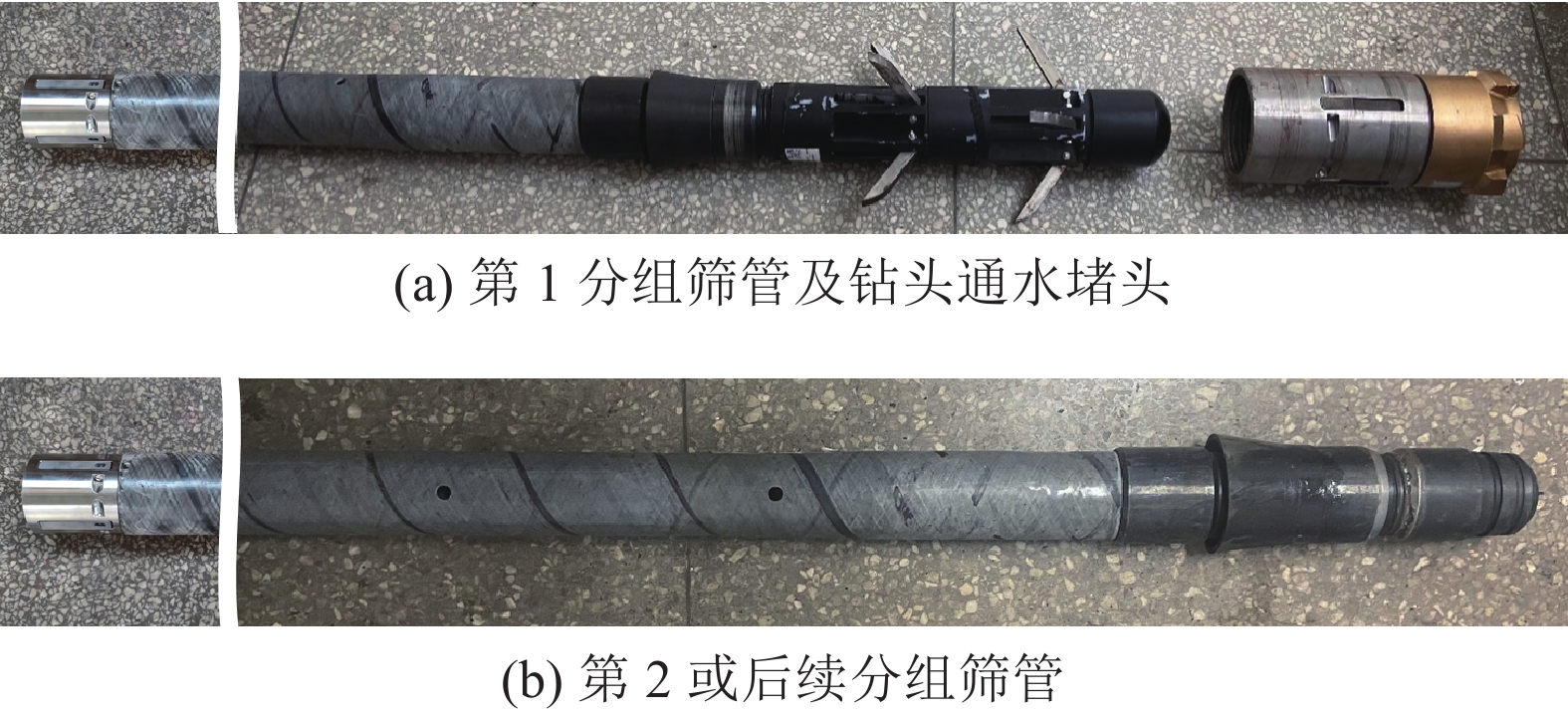

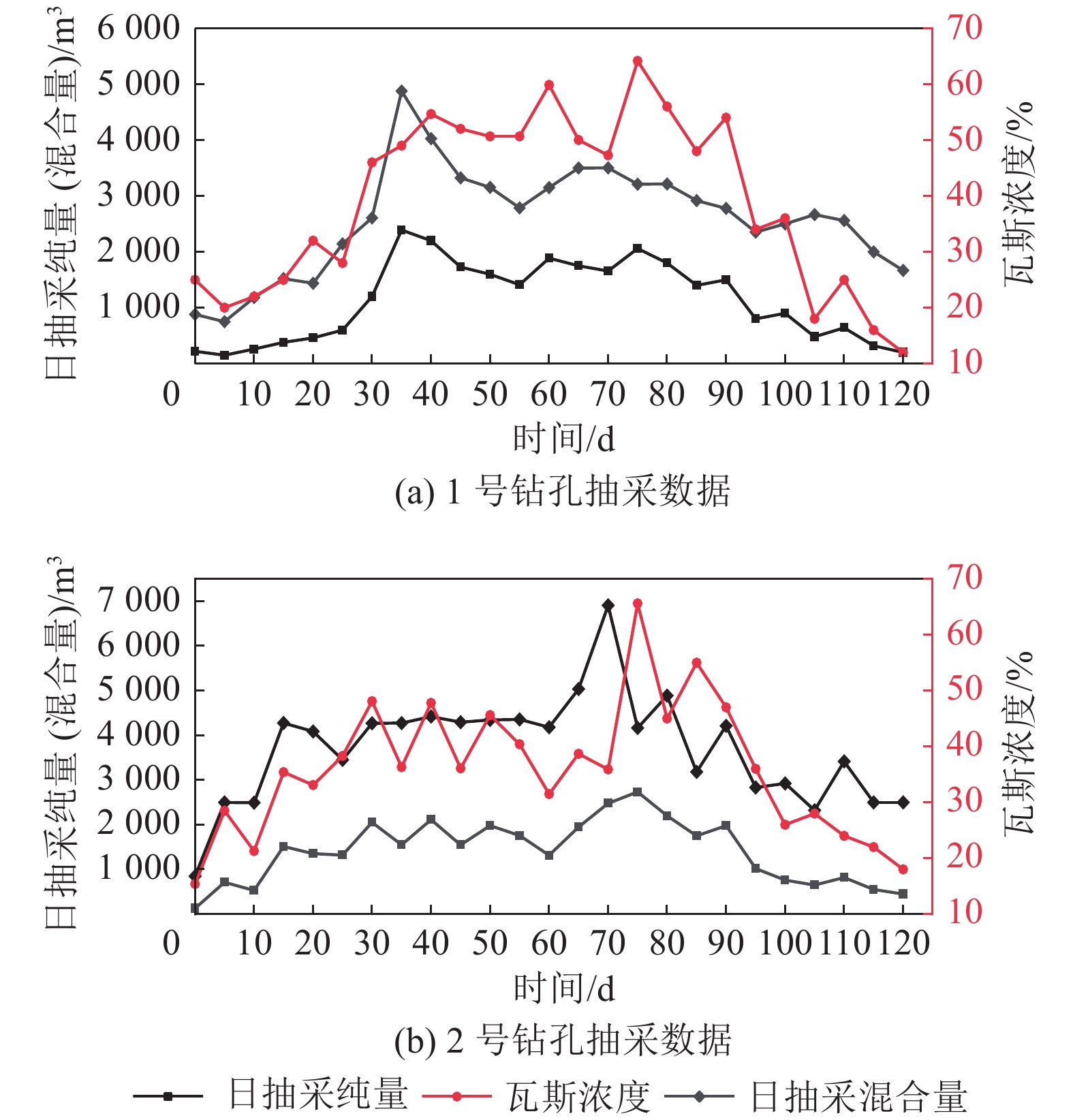

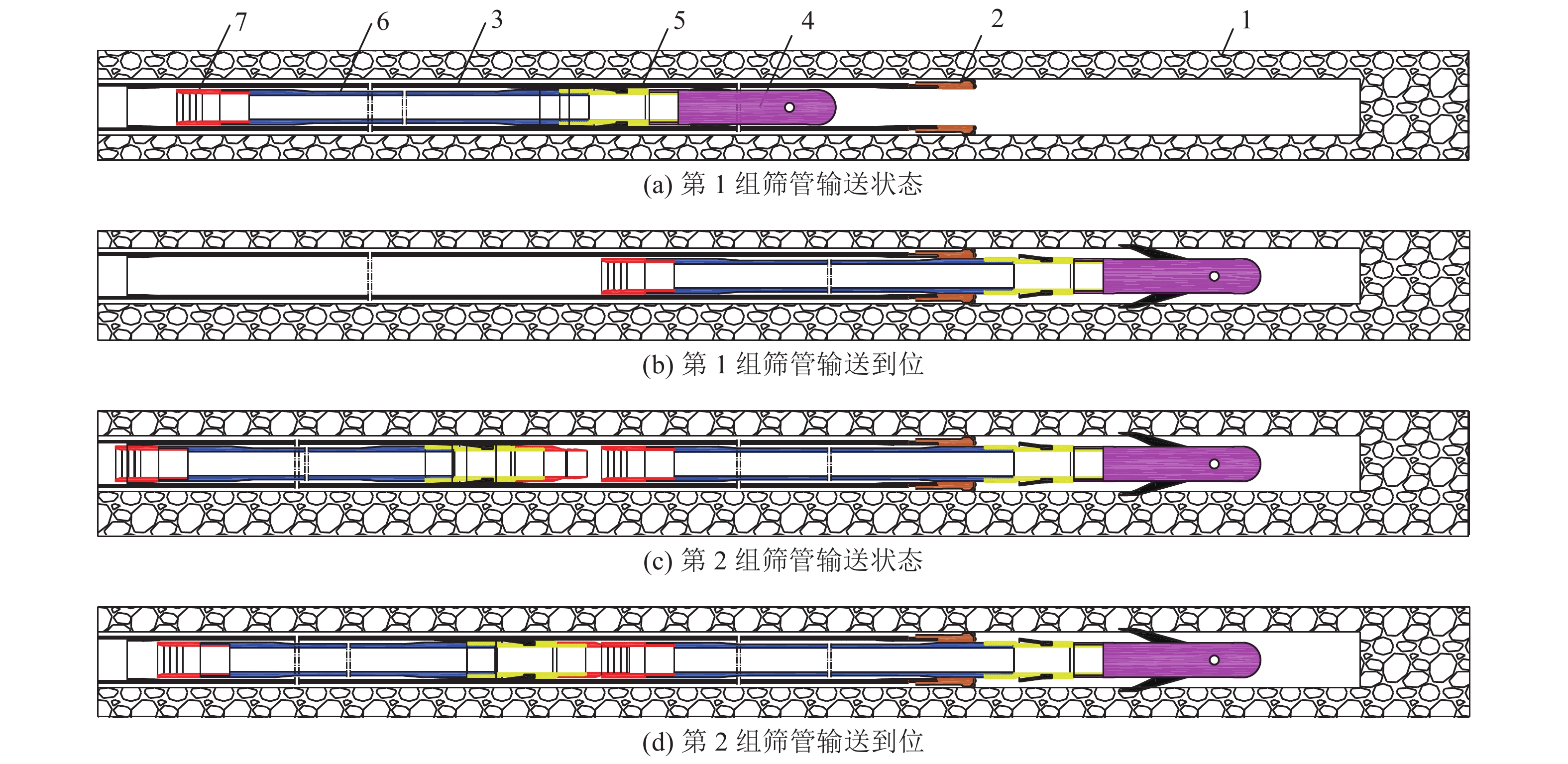

保障高位定向长钻孔在工作面回采过程中的稳定抽采是实现“以孔代巷”的前提,而采用筛管完孔是维持钻孔稳定的有效护孔措施。为了实现高位定向长钻孔全孔段筛管护孔的工程应用,开发了钻孔内水力输送分组筛管自主对接完孔工艺技术,配套研制了ø95 mm筛管悬挂装置、ø95 mm玻璃钢筛管、ø100 mm封堵短节、ø140 mm钻头通水堵头以及ø95 mm分组筛管对接装置,并在皖北矿区两个煤矿的不同工作面顶板高位钻孔进行了水力输送分组筛管完孔现场试验。试验结果表明:玻璃钢筛管质量轻推送阻力小,可在倾角17°~26°的钻孔内人工连接长100 mø95 mm玻璃钢分组筛管,分组筛管输送过程中水压为1.0~1.5 MPa,输送到位时水压降为0.5 MPa以下,在泵量200~390 L/min下,分组筛管水力平均输送速度可达150~260 m/min,试验期间分组筛管输送到位时泵压变化明显,前后两组筛管对接可靠,可有效实现到位报信,成功实现ø153 mm高位定向钻孔内ø95 mm筛管的全孔段护孔,2个钻孔的筛管水力输送试验深度分别达到501、522 m,工作面回采120 d累计抽采瓦斯纯量分别为139 945、176 139 m3。钻孔内水力输送对接筛管护孔技术为高位定向长钻孔全孔段大直径筛管护孔提供了可实现的技术解决方案,有助于保障高位定向长钻孔的瓦斯抽采效果,为煤矿井下“以孔代巷”的瓦斯治理模式革新提供技术支撑。

Abstract:Ensuring the stable extraction of high position directional long boreholes in the mining process of working face is the premise of realizing ' replacing the roadway with the boreholes', and the use of screen pipe completion is an effective hole protection measure to maintain the stability of boreholes. In order to realize the engineering application of full-hole segment screen pipe protection in high position directional borehole, the technology of automatic butt joint technology of grouping screen pipe for hydraulic transportation in the borehole has been developed, and the ø95 mm screen pipe Hanging unit, ø95 mm fiberglass screen pipe, ø100 mm water flow blocking short section, ø140 mm drilling bit plug with passable water and ø95 mm grouping screen pipe connecting device have been developed, In addition, the field test of hydraulic transportation grouping screen pipe hole completion was carried out in the high level boreholes of different working faces in two coal mines in the northern Anhui mining area. The test results show that the weight of the GRP screen pipe is light and the resistance to push is small. The ø95 mm GRP grouping screen pipe with a length of ø100 m can be manually connected in the borehole with an inclination of 17°−26°. The water pressure in the grouping screen pipe transportation process is about 1.0−1.5 MPa, and the water pressure drops below 0.5 MPa when it is transported in place. Under the pump capacity of 200-390 L/min, the average hydraulic transportation speed of the grouping screen pipe can reach 150-260 m/min. The pump pressure changes significantly when the grouping screen tube is transported in place during the test. The front and rear sets of screen pipes are connected reliably, which can effectively realize the message in place, and successfully achieve the full hole protection of ø95 mm screen pipes in the ø153 mm high position directional borehole. The hydraulic transportation test depth of screen pipes in the two boreholes reaches 501 and 522 m respectively and the cumulative pure gas extracted from the two boreholes in 120 d working face mining is 139 945 and 176 139 m3 respectively. The technology of screen pipe for hydraulic transportation and automatic butt joint in the borehole provides an achievable technical solution for the large-diameter screen pipe hole protection in the full-hole section of the high-position directional long borehole, helps to ensure the gas drainage effect of the high-position directional long borehole, and provides technical support for the innovation of the gas control mode of ‘replacing the roadway with the boreholes’ in the coal mine.

-

-

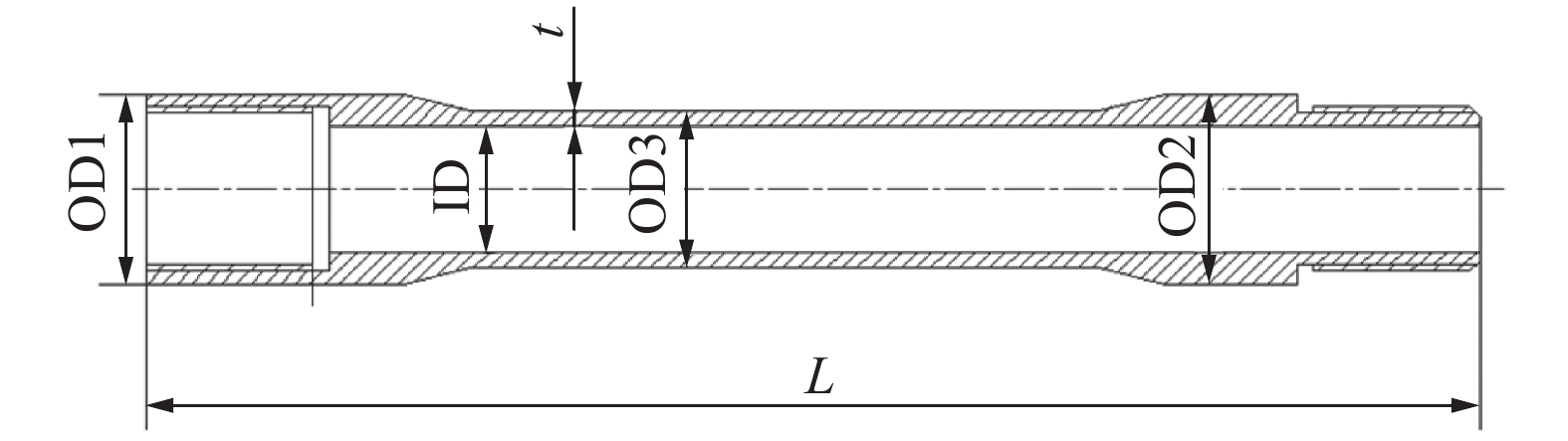

表 1 大直径玻璃钢筛管结构及性能参数

Table 1 Structure and performance parameters of large diameter GRP screen pipe

接头外径

OD1,OD2/mm内径

ID/mm壁厚

t/mm管体外径

OD3/mm长度L/mm 管身径向抗挤

压强度/MPa轴向拉力/kN 轴向压力/kN 抗扭强度/(N·m) 孔眼直径/mm 孔眼数量/个 95 76 5 86 3 081.2 ≥ 20 ≥ 25 ≥ 10 ≥ 2 000 14 30 表 2 试验钻孔设计及施工参数

Table 2 Test drilling design and construction parameters

孔号 开孔倾角/(°) 稳定岩层施工倾角/(°) 设计孔深/m 终孔孔深/m 终孔孔径/mm 终孔至煤顶垂直距离/m 1号 17 0.5 520 511 153 16 2号 26 1.0 600 607 153 65 表 3 玻璃钢筛管水力输送参数

Table 3 Hydraulic transport parameters for fiberglass screen pipes

钻孔号 筛管平均

重量/(N·m−1)筛管平均浮

重量/(N·m−1)筛管与钻杆

摩擦因数钻孔前100 m

平均倾角/(°)钻孔水平段

平均倾角/(°)孔底距孔口

垂距/m钻杆内径/mm 1号 25 11.3 0.25 12 0.5 46 103 2号 25 11.3 0.25 18 1.0 66 103 -

[1] 李树刚,杨二豪,林海飞,等. 深部开采卸压瓦斯精准抽采体系构建及实践[J]. 煤炭科学技术,2021,49(5):1−10. LI Shugang,YANG Erhao,LIN Haifei,et al. Construction and practice of accurate gas drainage system for pressure relief gas in deep mining[J]. Coal Science and Technology,2021,49(5):1−10.

[2] 张宇菲,郭家豪,安 晨,等. 高瓦斯矿井内错顶板瓦斯巷合理布设及应用[J]. 矿业科学学报,2018,3(1):29−38. ZHANG Yufei,GUO Jiahao,AN Chen,et al. Reasonable layout and application of inner dislocated gas roadway at the first mining working face with high gas mine[J]. Journal of Mining Science and Technology,2018,3(1):29−38.

[3] 周爱桃,张 蒙,王 凯,等. 布尔台矿综放工作面采空区瓦斯运移规律及瓦斯抽采优化研究[J]. 矿业科学学报,2020,5(3):291−301. ZHOU Aitao,ZHANG Meng,WANG Kai,et al. Research on gas migration law and gas drainage parameters optimization in goaf of fully mechanized caving face in Buertai coal mine[J]. Journal of Mining Science and Technology,2020,5(3):291−301.

[4] 林海飞,王 旭,徐培耘,等. 特厚煤层开采卸压瓦斯储集区演化特征分析及工程应用[J]. 煤炭科学技术,2023,51(2):173−182. LIN Haifei,WANG Xu,XU Peiyun,et al. Evolution characteristics analysis and engineering application of pressure-relieved gas reservoir in extra-thick coal seam mining[J]. Coal Science and Technology,2023,51(2):173−182.

[5] 刘 厅,林柏泉,赵 洋,等. 瓦斯非均衡赋存煤层精准冲孔增透技术及应用[J]. 煤炭科学技术,2023,51(2):217−231. LIU Ting,LIN Baiquan,ZHAO Yang,et al. Precise permeability enhancement technique with hydraulic flushing for coal seams with non-uniformly distributed gas[J]. Coal Science and Technology,2023,51(2):217−231.

[6] 孙荣军,魏 刚,吴 璋,等. 顶板近水平长钻孔替代闭式高抽巷进行瓦斯抽放的试验研究[J]. 煤田地质与勘探,2005,33(5):20−21. SUN Rongjun,WEI Gang,WU Zhang,et al. Experimental research on using approximate horizontal long-hole instead of closed high extracted roadway to drain gas[J]. Coal Geology & Exploration,2005,33(5):20−21.

[7] 李泉新,石智军,田宏亮,等. 我国煤矿区钻探技术装备研究进展[J]. 煤田地质与勘探,2019,47(2):1−6. LI Quanxin,SHI Zhijun,TIAN Hongliang,et al. Progress in the research on drilling technology and equipment in coal mining areas of China[J]. Coal Geology & Exploration,2019,47(2):1−6.

[8] 石智军,姚 克,姚宁平,等. 我国煤矿井下坑道钻探技术装备40年发展与展望[J]. 煤炭科学技术,2020,48(4):1−34. SHI Zhijun,YAO Ke,YAO Ningping,et al. 40 years of development and prospect on underground coal mine tunnel drilling technology and equipment in China[J]. Coal Science and Technology,2020,48(4):1−34.

[9] 姚宁平. 我国煤矿井下近水平定向钻进技术的发展[J]. 煤田地质与勘探,2008,36(4):81−83. YAO Ningping. Development trend of nearly horizontal directional drilling technology in coal mines of China[J]. Coal Geology & Exploration,2008,36(4):81−83.

[10] 童 碧,许 超,刘 飞,等. 淮南矿区瓦斯抽采中以孔代巷技术研究与工程实践[J]. 煤炭科学技术,2018,46(4):33−39. TONG Bi,XU Chao,LIU Fei,et al. Technology research on borehole in place of roadway and its engineering practice in gas drainage of Huainan Mining Area[J]. Coal Science and Technology,2018,46(4):33−39.

[11] 于士芹,杨宏民,鲁小凯,等. 王家岭煤矿高位定向长钻孔抽采顶板卸压瓦斯技术[J]. 河南理工大学学报:自然科学版,2018,37(4):31−36. YU Shiqin,YANG Hongmin,LU Xiaokai,et al. Technology of pressure-relief gas drainage by highly oriented level boreholes from roof fracture zone in Wangjialing coal mine[J]. Journal of Henan Polytechnic University( Natural Science),2018,37(4):31−36.

[12] 许 超,王 鲜,李泉新,等. 顾桥煤矿顶板复杂地层中高位定向钻孔成孔试验[J]. 煤田地质与勘探,2018,46(3):184−188. doi: 10.3969/j.issn.1001-1986.2018.03.031 XU Chao,WANG Xian,LI Quanxin,et al. Borehole-forming experiment of high level directional drilling in complex seam roof of Guqiao coal mine[J]. Coal Geology & Exploration,2018,46(3):184−188. doi: 10.3969/j.issn.1001-1986.2018.03.031

[13] 陈 涛. 煤巷底板防冲钻孔释能解危原理及参数优化[J]. 煤炭科学技术,2023,51(5):21−31. doi: 10.13199/j.cnki.cst.2021-0772 CHEN Tao. Danger-relief principle and parameter optimization of borehole energy relief for rock burst in coal road floor[J]. Coal Science and Technology,2023,51(5):21−31. doi: 10.13199/j.cnki.cst.2021-0772

[14] 李 平,童 碧,许 超. 顶板复杂地层高位定向钻孔成孔工艺研究[J]. 煤田地质与勘探,2018,46(4):197−201. LI Ping,TONG Bi,XU Chao. Study on hole-forming technology of high-level directional borehole in complicated roof strata[J]. Coal Geology & Exploration,2018,46(4):197−201.

[15] 石 浩. 大直径高位定向长钻孔瓦斯抽采技术及应用[J]. 煤炭科学技术,2018,46(10):195−200. SHI Hao. Gas drainage technology and its application of large diameter and high directional long drilling[J]. Coal Science and Technology,2018,46(10):195−200.

[16] 赵耀江,郭海东,袁胜军. 综采面顶板走向大直径长钻孔瓦斯抽采技术参数的研究[J]. 太原理工大学学报,2009,40(1):74−77. ZHAO Yaojiang,GUO Haidong,YUAN Shengjun. The study on the key gas drainage technique by long & large diameter roof bore holes in fully mechanized face[J]. Journal of Taiyuan University of Technology,2009,40(1):74−77.

[17] 郝世俊,段会军,莫海涛,等. 大直径高位定向长钻孔瓦斯抽采技术及实践[J]. 煤田地质与勘探,2020,48(6):243−248. doi: 10.3969/j.issn.1001-1986.2020.06.032 HAO Shijun,DUAN Huijun,MO Haitao,et al. Gas drainage technology and practicean alysis of large diameter high position directional long borehole[J]. Coal Geology & Exploration,2020,48(6):243−248. doi: 10.3969/j.issn.1001-1986.2020.06.032

[18] 童 碧. 复杂顶板高位定向长钻孔全程下筛管技术实践[J]. 煤矿安全,2021,52(9):85−89. TONG Bi. Technical practice of running screen in the whole process for high level directional drilling of complex roof[J]. Safety in Coal Mines,2021,52(9):85−89.

[19] 司原龙. 顶板定向长钻孔全孔下筛管技术的应用[J]. 现代矿业,2019,35(8):52−54. SI Yuanlong. Application of screen technology under directional long hole drilling in roof[J]. Modern Mining,2019,35(8):52−54.

[20] 赵亮宏. 全程筛管护孔技术在高位瓦斯抽采钻孔中的应用[J]. 现代矿业,2020,36(2):110−112. ZHAO Lianghong. Application of whole-process screen pipe hole protection in highly-located gas drainage borehole[J]. Modern Mining,2020,36(2):110−112.

下载:

下载: