Characterization of fissure distribution of overburden rock under roof cutting and entry retaining based on key strata theory

-

摘要:

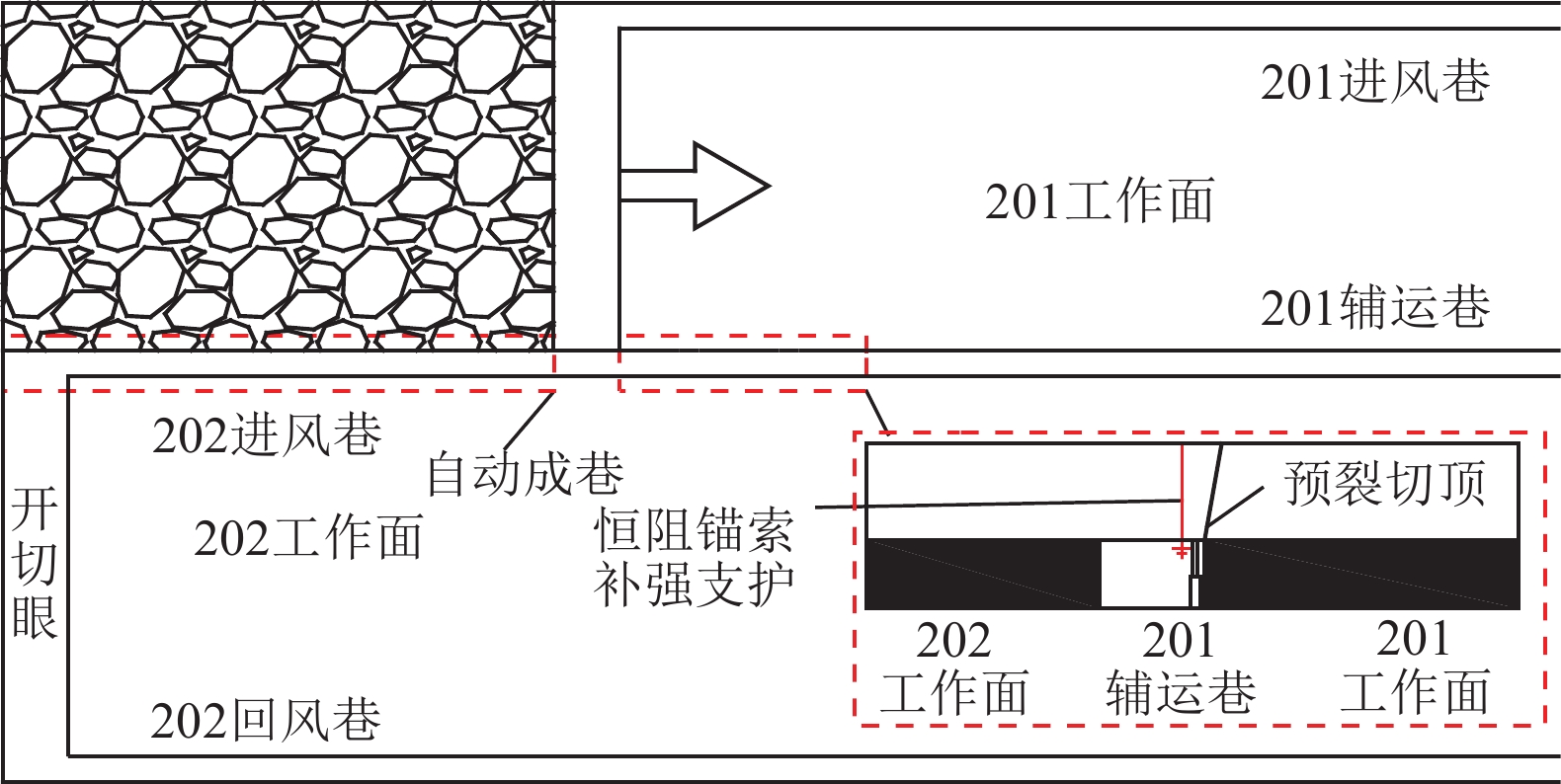

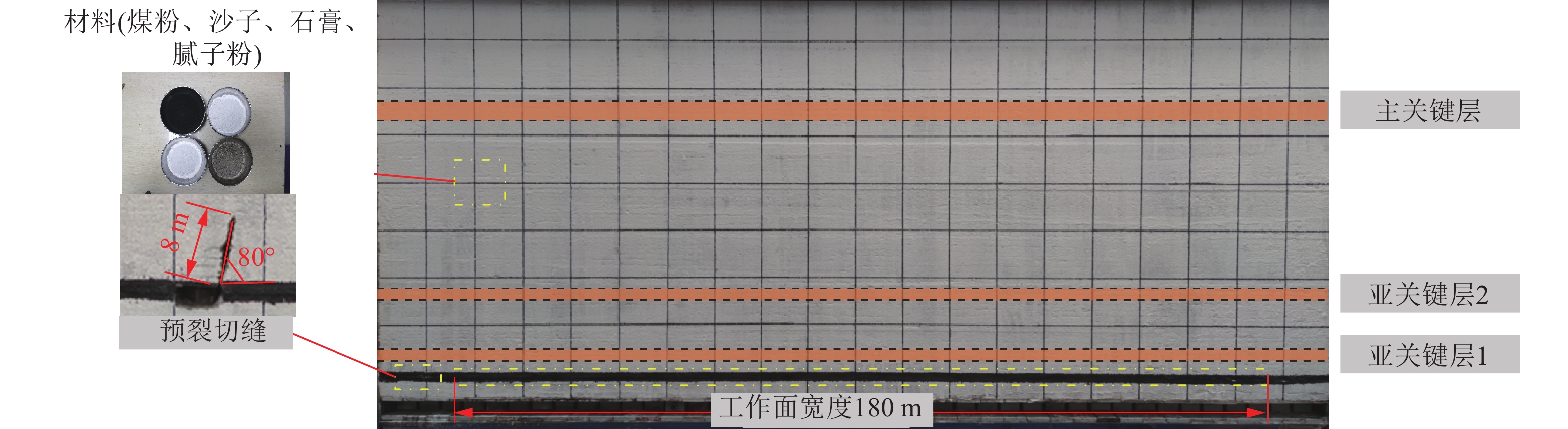

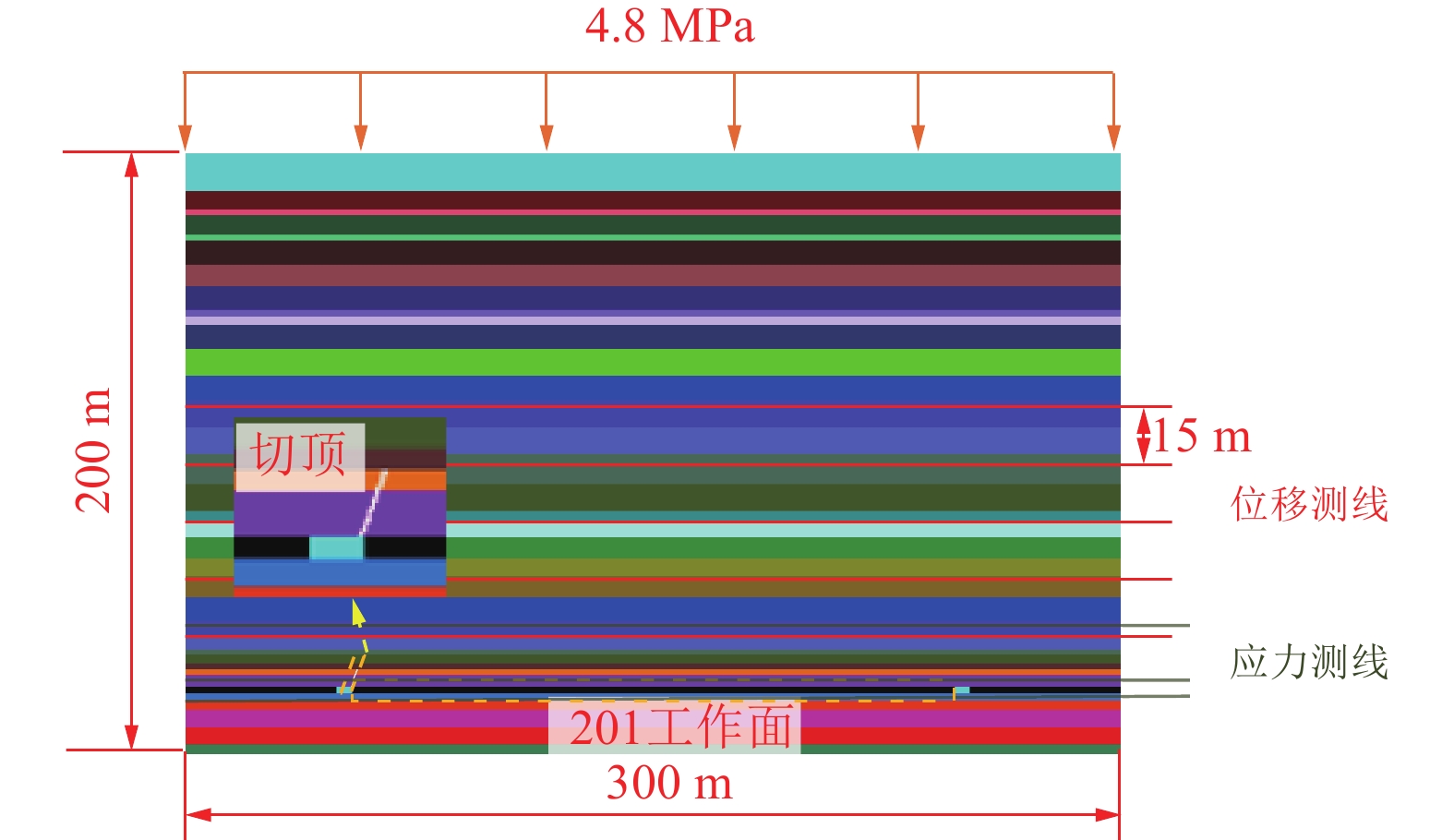

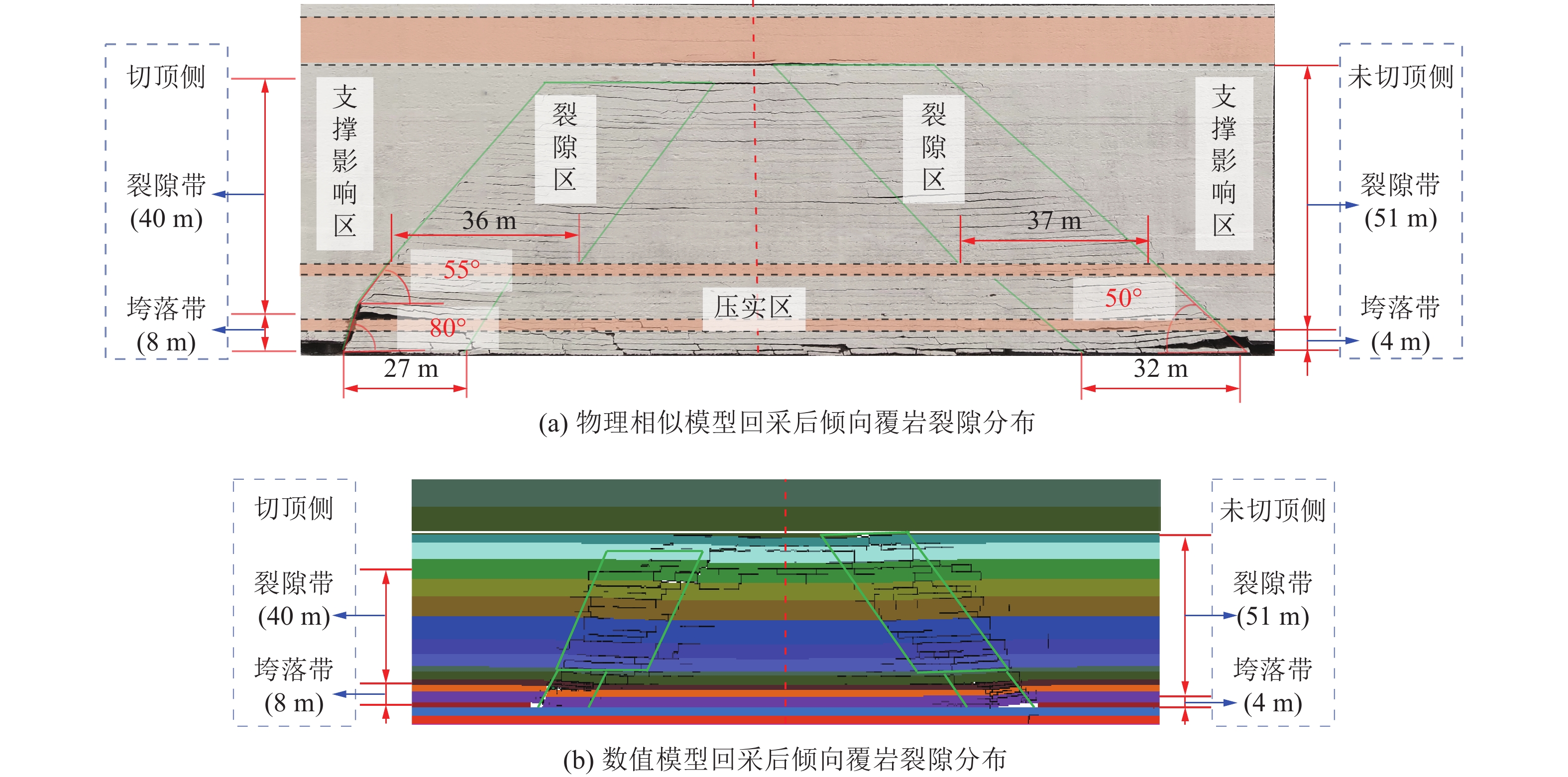

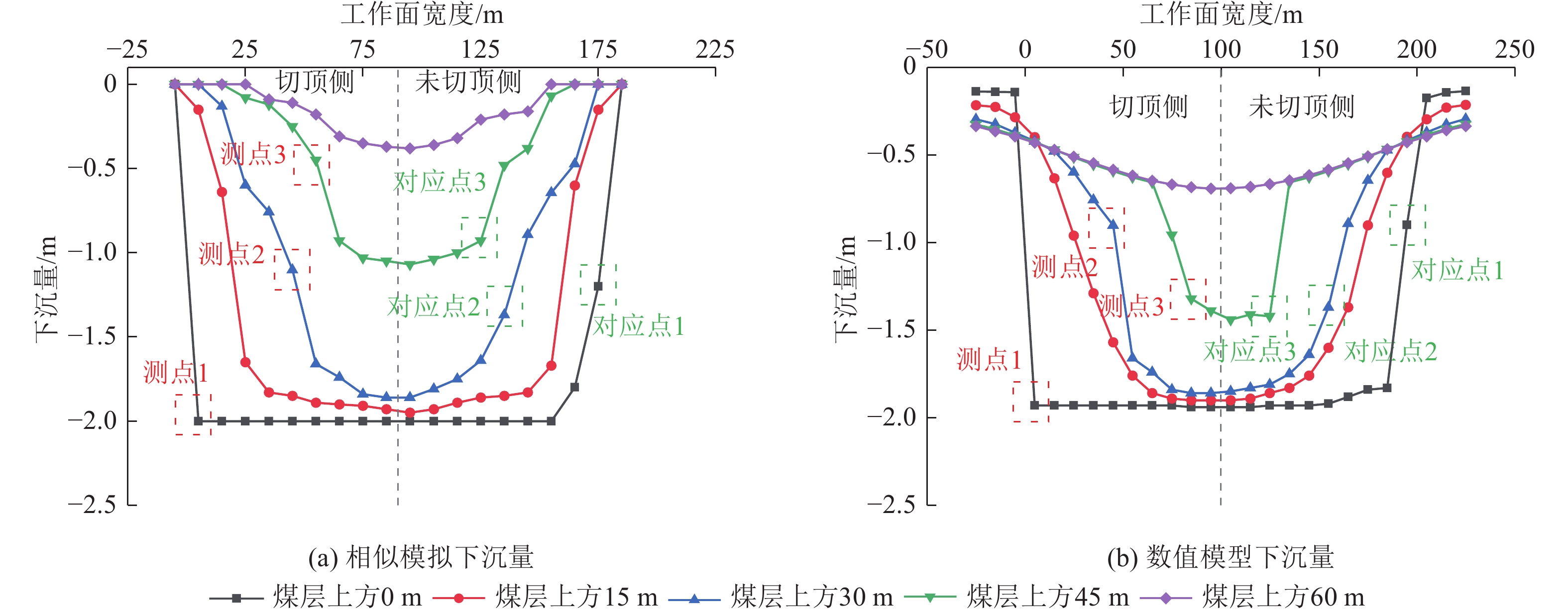

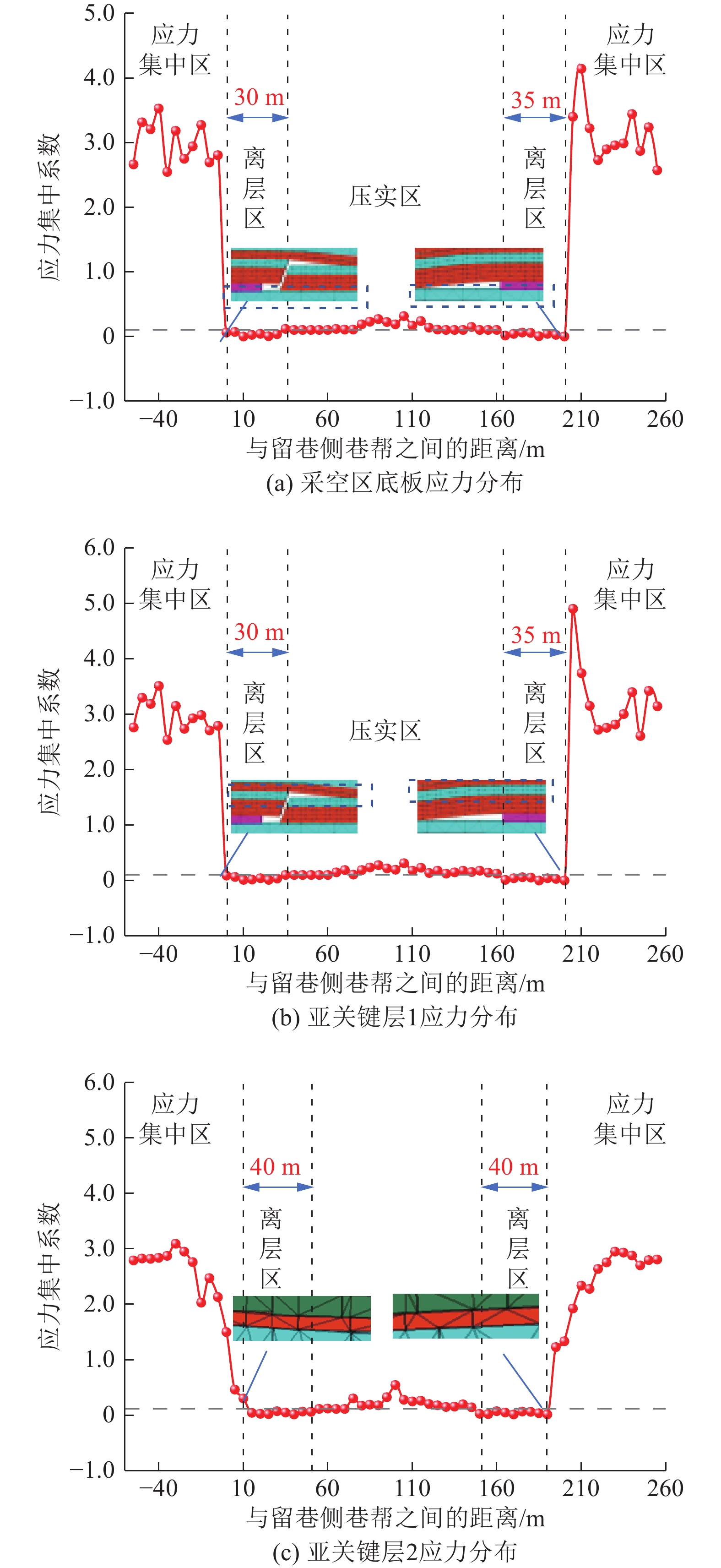

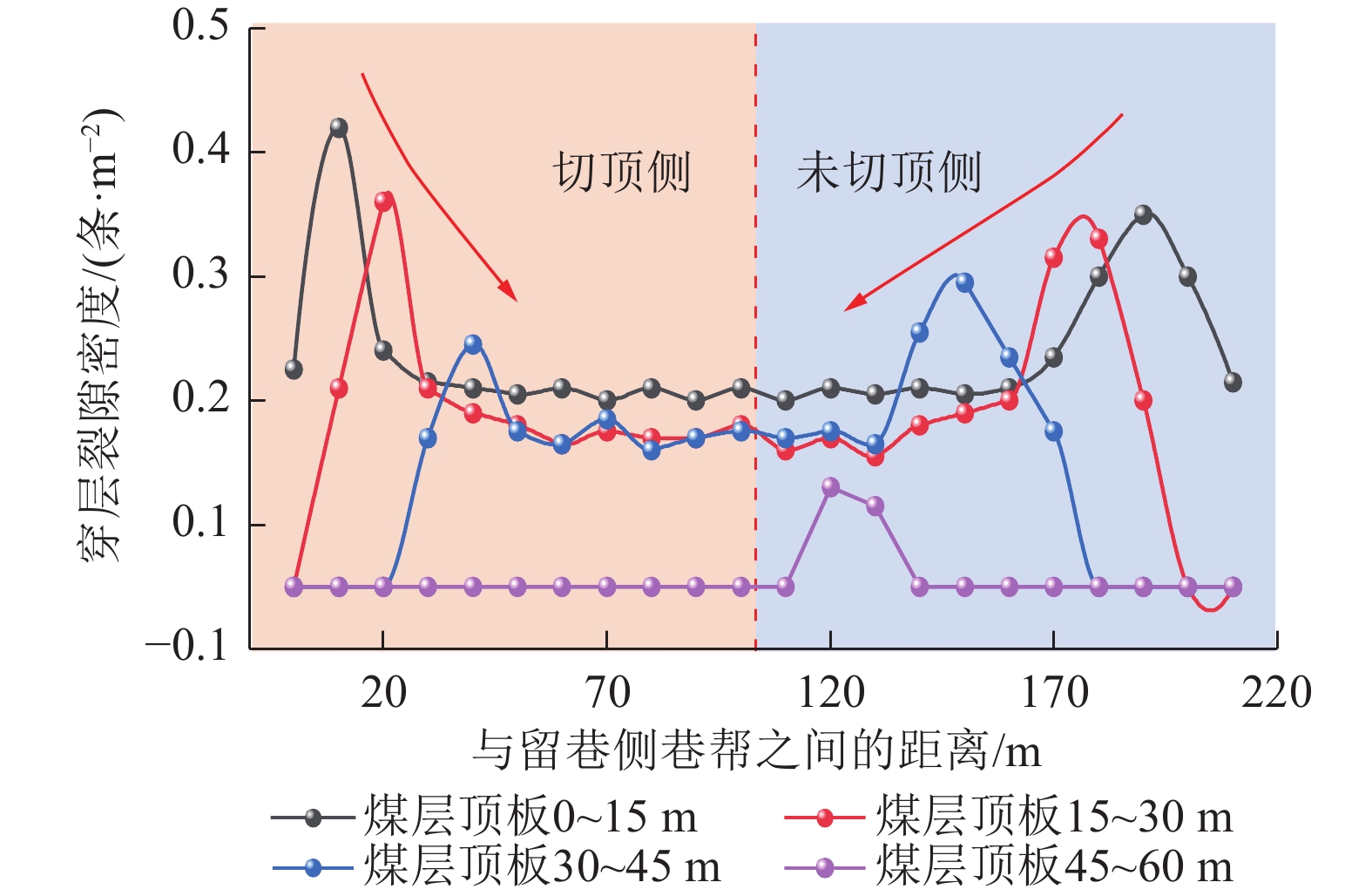

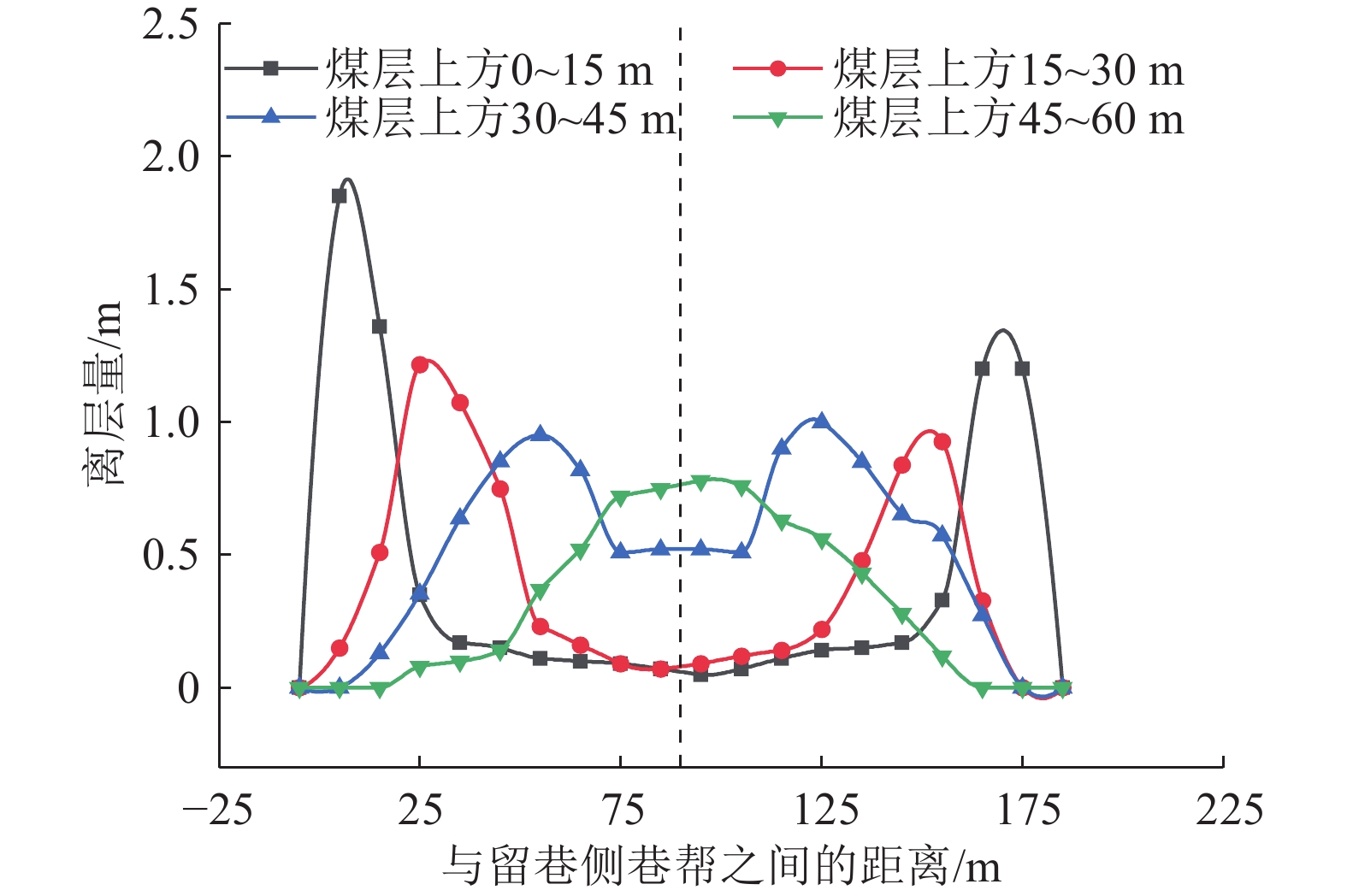

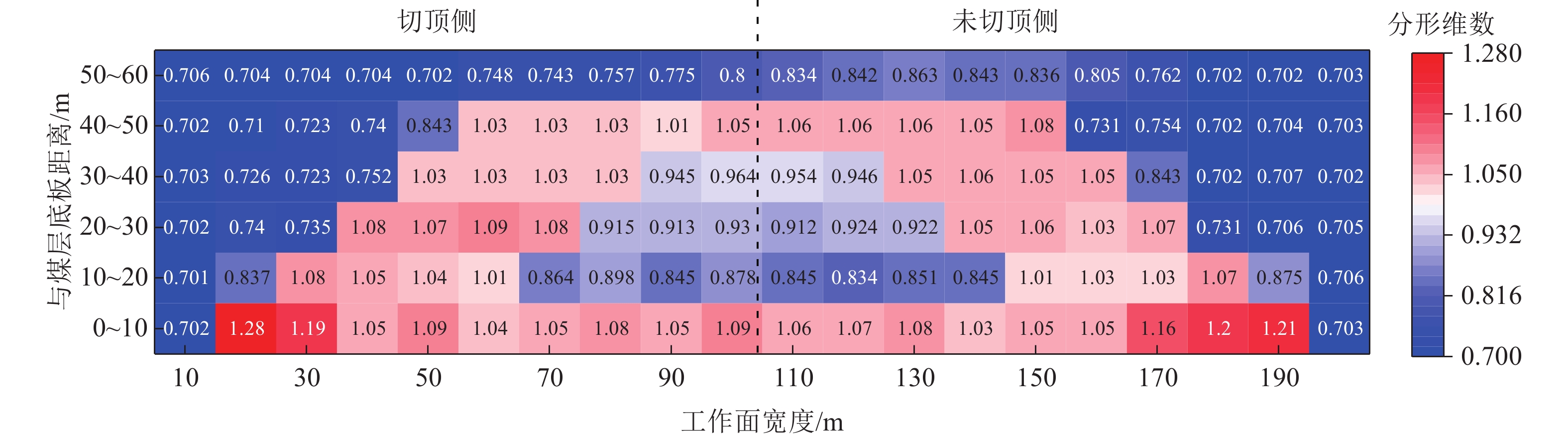

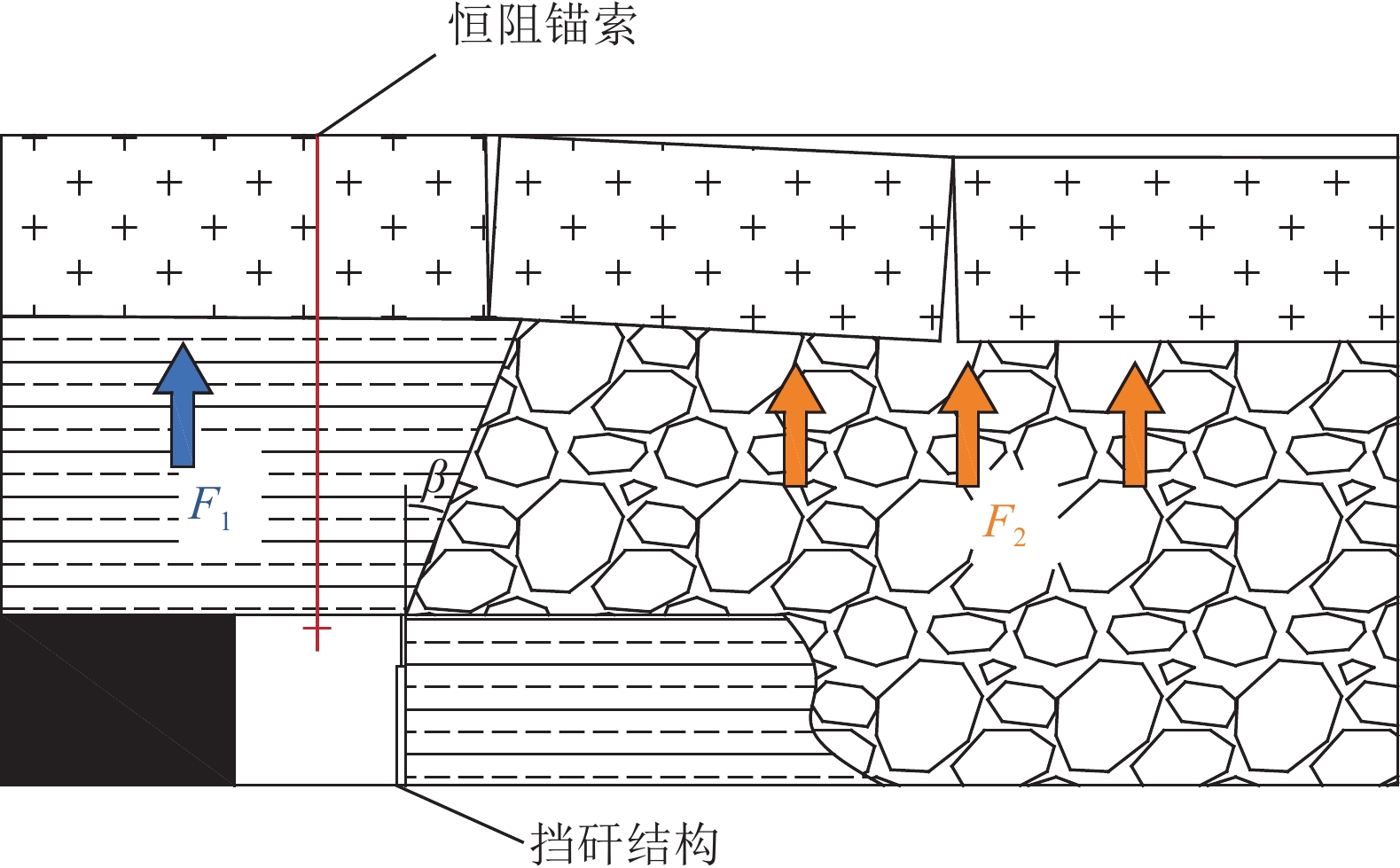

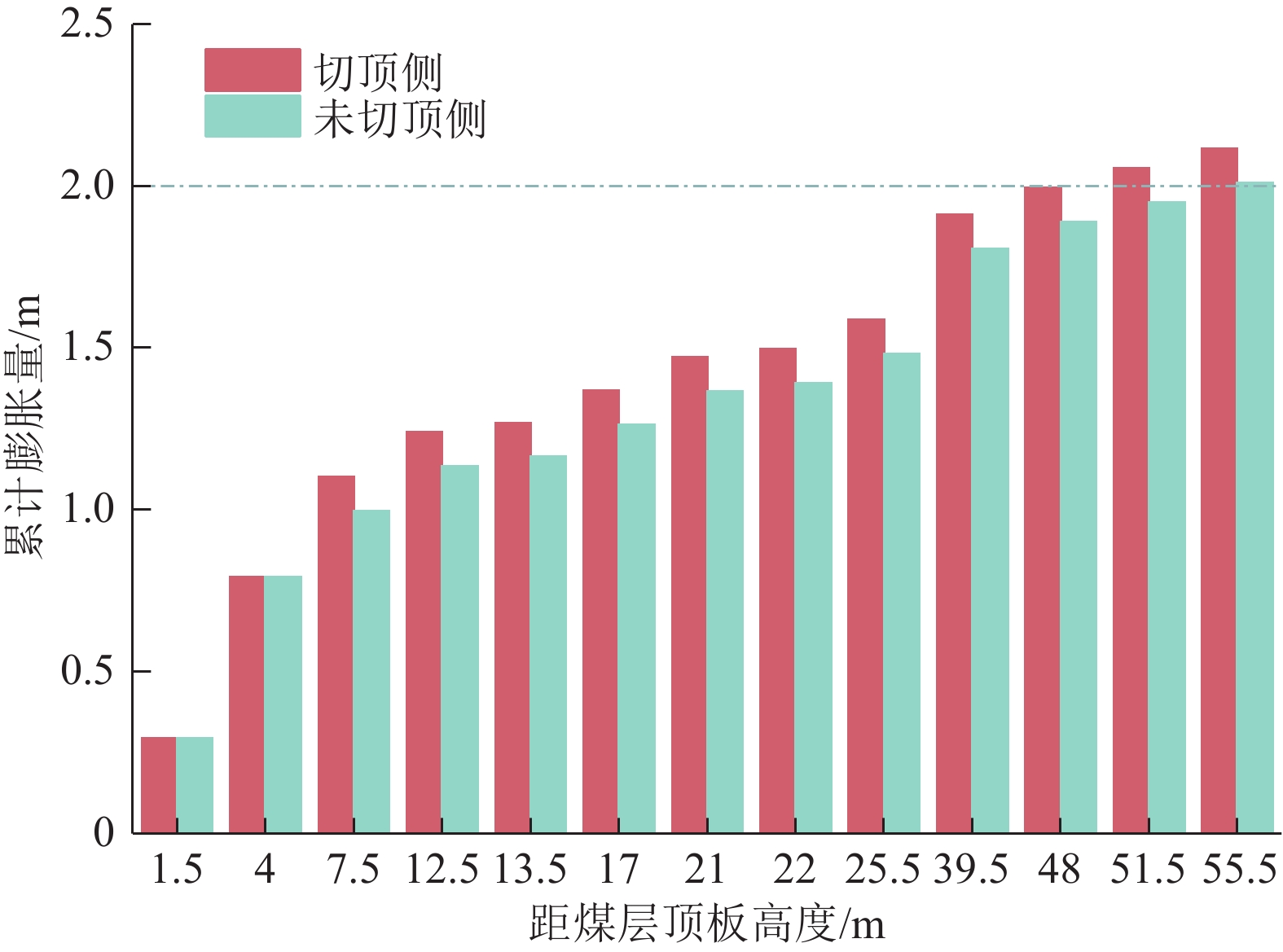

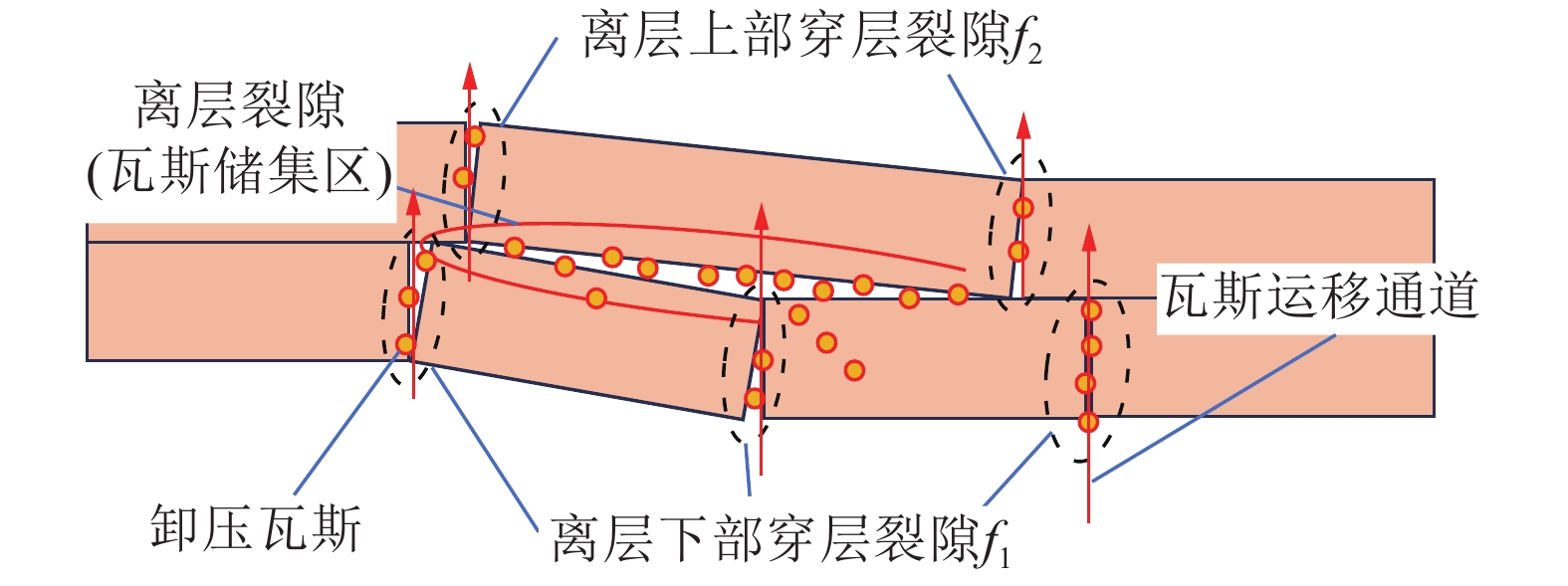

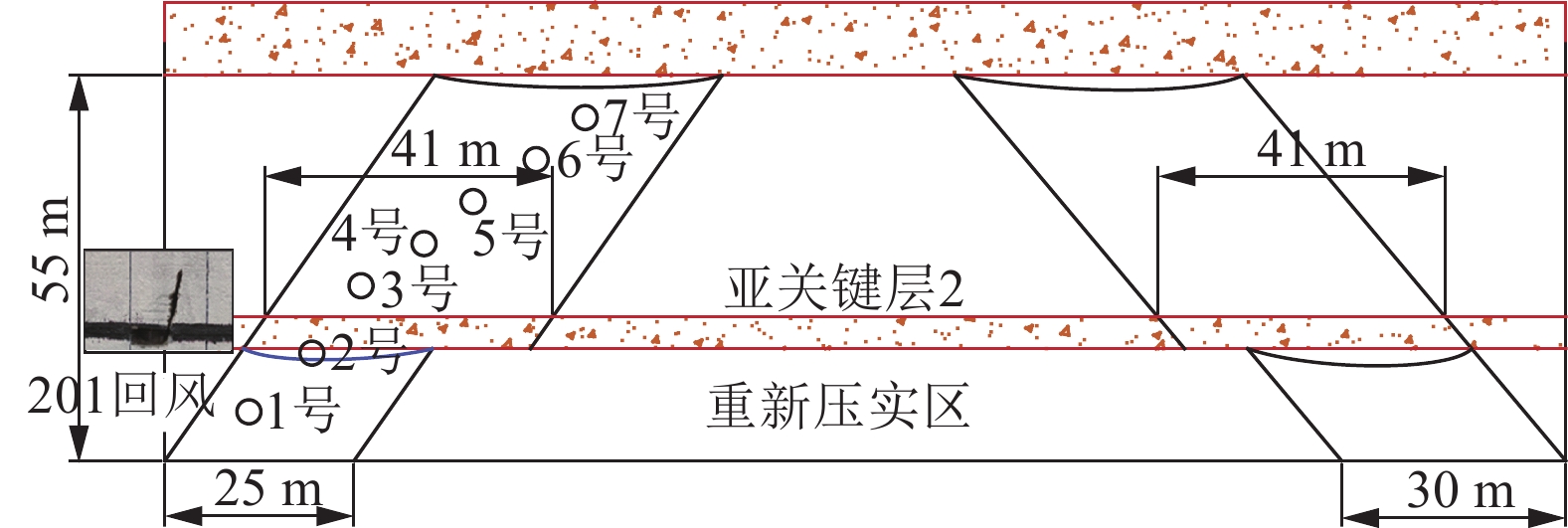

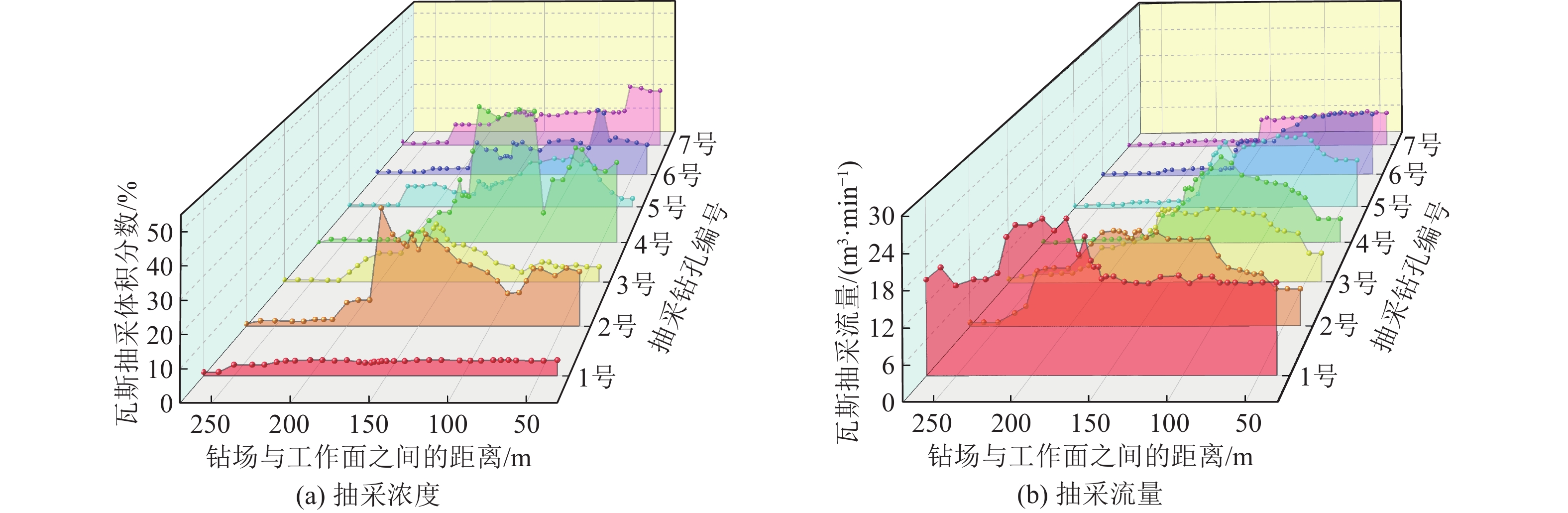

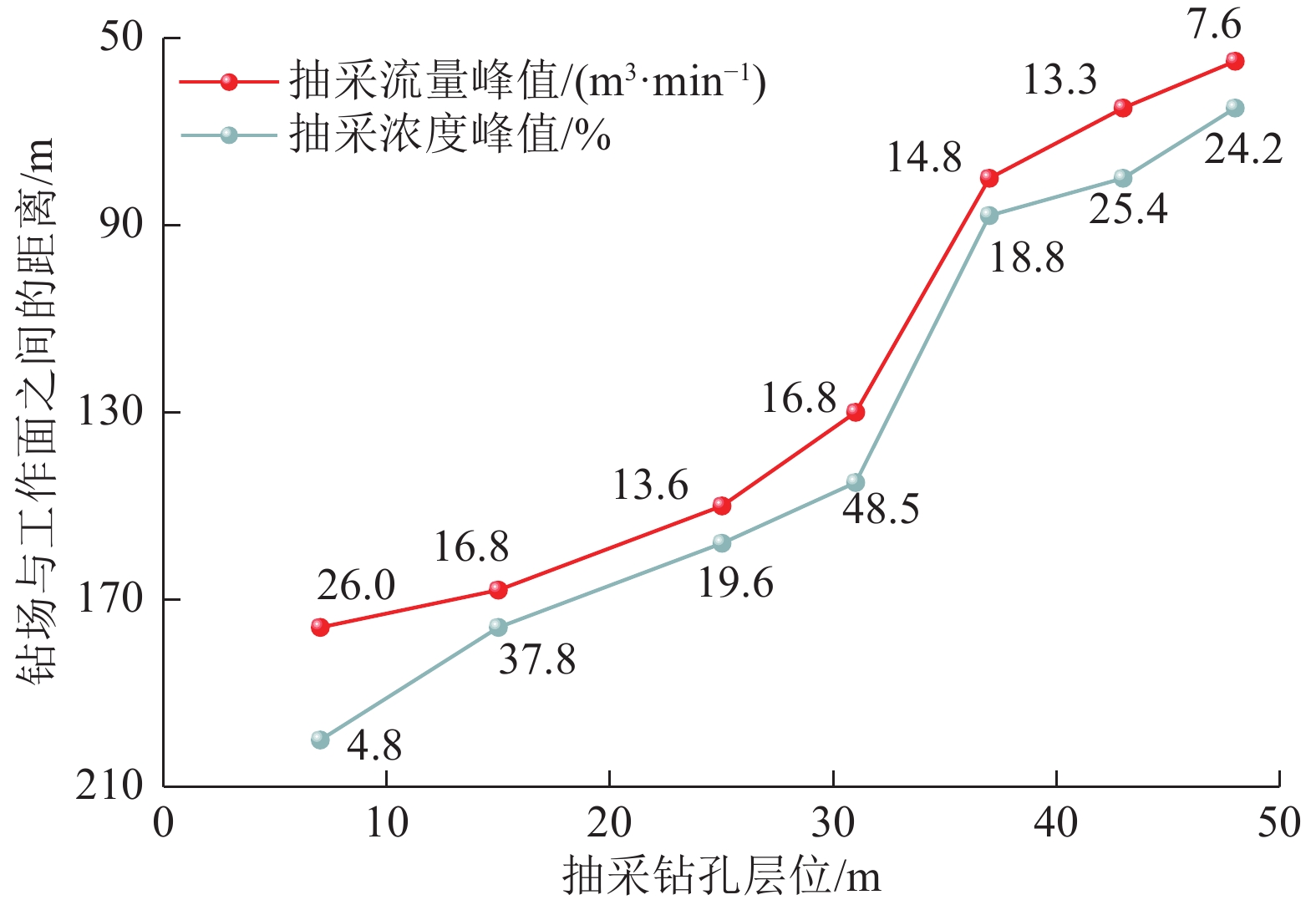

针对切顶留巷工艺使得切顶侧采空区覆岩裂隙分布改变的问题,采用物理相似模拟与数值模拟相结合的手段分析了切顶留巷工艺下采空区应力分布、覆岩运移和采动裂隙分布规律。在此基础上,基于关键层理论与采动覆岩卸荷膨胀累积效应,探讨了切顶与未切顶侧覆岩裂隙发育高度和离层裂隙区宽度的变化,分析了不同层位定向卸压瓦斯抽采钻孔抽采效果,验证和反演了切顶留巷工艺下覆岩裂隙分布规律。研究结果表明:切顶留巷工艺能有效降低切顶侧顶底板的应力集中,但应力仍会向煤岩深部传递;切顶使得垮落岩层厚度与顶板破断形式发生改变,导致裂隙带发育高度、亚关键层控制范围内离层裂隙区宽度产生变化;切顶侧端头垮落带高度为未切顶侧的2倍,裂隙带高度为未切顶侧的0.87倍,在裂隙带中下部,切顶侧的离层量和穿层裂隙数量均大于未切顶侧;切顶侧在煤层顶板8~30 m范围内裂隙发育量随距离增大而增大,在30~48 m范围内随距离增大而减小,裂隙主要分布于裂隙带中下部;不同层位抽采钻孔瓦斯浓度和流量的“错峰”验证了上述研究结论。研究结果对高瓦斯矿井切顶留巷工艺下卸压瓦斯治理具有一定参考价值。

Abstract:Aiming at the problem of changing the distribution of overburden fissures in the overhead mining area due to the cutting and retaining roadway process, the stress distribution, overburden transport and mining fissure distribution law in the mining zone under the roof cutting and retaining roadway process were analyzed by means of a combination of physical similarity simulation and numerical simulation. On this basis, based on the key strata theory and the cumulative effect of unloading and expansion of mining overburden, the changes in the height of overburden fissure development and the width of fissure zones on the roof cutting and un-cutting sides were investigated, the extraction effect of the directional unloading gas extraction boreholes in different strata was analyzed, and the overburden fissure distribution law under the roof cutting and retaining roadway process was verified and inverted. The results shown that, the roof cutting and retaining roadway process can effectively reduce the stress concentration of the top and bottom plates on the roof cutting side, but the stress will still be transferred to the deeper part of coal. Roof cutting caused changes in the thickness of the collapsed rock layer and the form of roof breakage, which led to the changes in the height of the fissure zone development, and the width of the off-strata fissure zones within the sub-critical strata control range. The height of the collapsed zone on the roof cutting side was twice as much as that on the un-cutting side, and the height of the fissure zone was 0.87 times as much as that on the un-cutting side. In the middle and lower part of the fissure zone, the amount of off- strata and the number of penetrating fissures on the cut top side are larger than those on the uncut top side; the amount of fissure development on the roof cutting side were larger than those on the un-cutting side. The amount of fissure development on the coal seam roof of roof cutting side increased with the increasing distance in the range of 8−30 m, and decreased with the increasing distance in the range of 30−48 m, The fissures were mainly distributed in the middle and lower part of the fissure zone. The “staggered” gas concentration and flow rate of the extraction boreholes in different layers validated the above conclusions. The study results have certain reference value for the decompression gas management in high gas mines under the process of roof cutting and retaining roadway.

-

-

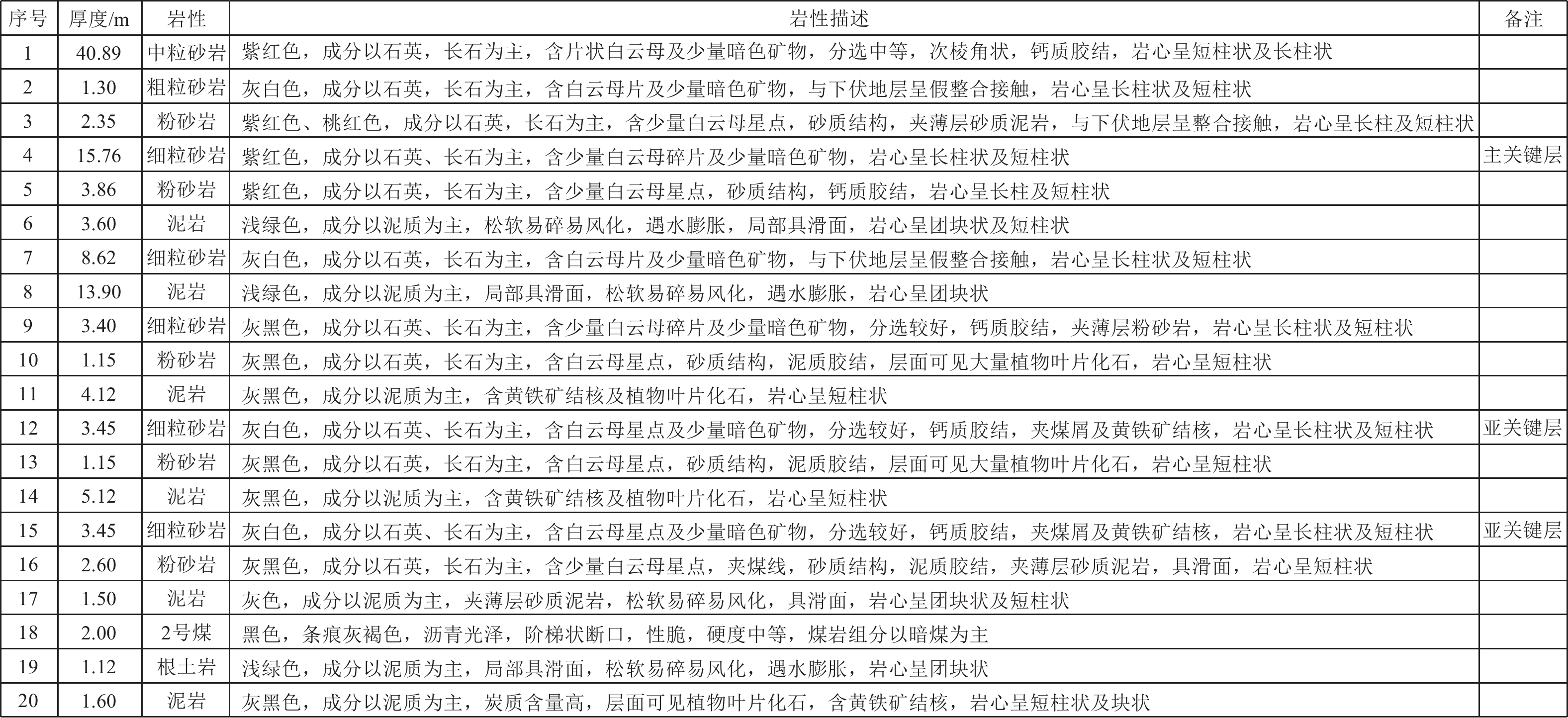

表 1 模拟试验材料配比

Table 1 Simulated test material ratios

序号 岩性 模型

厚/cm沙子

质量/g石膏

质量/g腻子粉

质量/g煤粉

质量/g1 中粒砂岩 10.0 4480 580 1350 0 2 粗粒砂岩 1.5 5120 510 770 0 3 粉砂岩 2.5 4480 768 1150 0 4 细粒砂岩 16.0 5120 380 900 0 5 粉砂岩 4.0 4480 390 1540 0 6 泥岩 3.5 5120 380 900 0 7 细粒砂岩 8.5 4480 768 1150 0 8 泥岩 14.0 5120 380 900 0 9 细粒砂岩 3.5 4480 768 1150 0 10 粉砂岩 1.0 4480 390 1540 0 11 泥岩 4.0 5120 380 900 0 12 细粒砂岩 3.5 4480 768 1150 0 13 粉砂岩 1.0 4480 390 1540 0 14 泥岩 5.0 5120 380 900 0 15 细粒砂岩 3.5 4480 768 1150 0 16 粉砂岩 2.5 4480 390 1540 0 17 泥岩 1.5 5120 380 900 0 18 2号煤 2.0 2880 130 510 2880 19 根土岩 1.0 5120 510 770 0 20 泥岩 1.5 5120 380 900 0 表 2 不同层位覆岩力学参数

Table 2 Physical and mechanical parameters of different layers of overburden rock formation

岩层 初始切线模量/GPa 初始碎胀系数(切顶侧) 初始碎胀系数(未切顶侧) 容重/(N·m−3) 弹性模量/GPa 厚度/m 泥岩 0.53 1.200 1.200 26250 5.4 1.5 粉砂岩 1.46 1.200 1.200 23970 10.2 2.5 细粒砂岩 1.39 1.100 1.060 25210 10.5 3.5 泥岩 0.53 1.030 1.030 26250 5.4 5.0 粉砂岩 1.46 1.029 1.029 23970 10.2 1.0 细粒砂岩 1.39 1.029 1.029 25210 10.5 3.5 泥岩 0.53 1.028 1.028 26250 5.4 4.0 粉砂岩 1.46 1.026 1.026 23970 10.2 1.0 细粒砂岩 1.39 1.026 1.026 25210 10.5 3.5 泥岩 0.53 1.025 1.025 26250 5.4 14.0 细粒砂岩 1.39 1.010 1.010 25210 10.5 8.5 泥岩 0.53 1.018 1.018 26250 5.4 3.5 粉砂岩 1.46 1.015 1.015 23970 10.2 4.0 细粒砂岩 1.39 1.000 1.000 25210 10.5 16.0 表 3 覆岩离层区宽度分布

Table 3 Distribution of widths of overburden outcrop zones

岩层 岩性 控制范围/m 切顶侧/m 未切顶侧/m 亚关键层1 细粒砂岩 4~16 25 30 亚关键层2 细粒砂岩 16~55 41 41 表 4 定向钻孔施工参数

Table 4 Directional drilling construction parameters

钻孔

编号开孔倾角/

(°)距帮距离/

m距顶距离/

m过渡段

长度/m钻孔

长度/m1 10 12 7 97 317 2 15 21 15 109 329 3 18 28 25 118 338 4 18 37 31 127 347 5 18 44 37 157 377 6 20 53 43 172 392 7 20 60 48 184 404 -

[1] 袁 亮. 我国煤炭主体能源安全高质量发展的理论技术思考[J]. 中国科学院院刊,2023,38(1):11−22. YUAN Liang. Theory and technology considerations on high-quality development of coal main energy security in China[J]. Bulletin of Chinese Academy of Sciences,2023,38(1):11−22.

[2] 何满潮,陈上元,郭志飚,等. 切顶卸压沿空留巷围岩结构控制及其工程应用[J]. 中国矿业大学学报,2017,46(5):959−969. HE Manchao,CHEN Shangyuan,GUO Zhibiao,et al. Control of surrounding rock structure for gob-side entry retaining by cutting roof to release pressure and its engineering application[J]. Journal of China University of Mining & Technology,2017,46(5):959−969.

[3] 许家林,钱鸣高. 地面钻井抽放上覆远距离卸压煤层气试验研究[J]. 中国矿业大学学报,2000,29(1):78−81. doi: 10.3321/j.issn:1000-1964.2000.01.020 XU Jialin,QIAN Minggao. Study on drainage of relieved m ethane from overlying coal seam far away from the protective seam by surface well[J]. Journal of China University of Mining & Technology,2000,29(1):78−81. doi: 10.3321/j.issn:1000-1964.2000.01.020

[4] 钱鸣高,许家林. 覆岩采动裂隙分布的“O”形圈特征研究[J]. 煤炭学报,1998,23(5):20−23. QIAN Minggao,XU Jialin. Study on the “O-shape” circle distribution characteristics of mining-induced fractures in the overlaying strata[J]. Journal of China Coal Society,1998,23(5):20−23.

[5] 袁 亮. 低透高瓦斯煤层群安全开采关键技术研究[J]. 岩石力学与工程学报,2008,27(7):1370−1379. doi: 10.3321/j.issn:1000-6915.2008.07.009 YUAN Liang. Key technique of safe mining in low permeability and methane-rich seam group[J]. Chinese Journal of Rock Mechanics and Engineering,2008,27(7):1370−1379. doi: 10.3321/j.issn:1000-6915.2008.07.009

[6] 袁 亮. 低透气煤层群首采关键层卸压开采采空侧瓦斯分布特征与抽采技术[J]. 煤炭学报,2008,33(12):1362−1367. doi: 10.3321/j.issn:0253-9993.2008.12.007 YUAN Liang. Gas distribution of the mined-out side and extraction technology of first mined key seam relief-mining in gassy multi-seams of low permeability[J]. Journal of China Coal Society,2008,33(12):1362−1367. doi: 10.3321/j.issn:0253-9993.2008.12.007

[7] 李树刚,林海飞,赵鹏翔,等. 采动裂隙椭抛带动态演化及煤与甲烷共采[J]. 煤炭学报,2014,39(8):1455−1462. LI Shugang,LIN Haifei,ZHAO Pengxiang,et al. Dynamic evolution of mining fissure elliptic paraboloid zone and extraction coal and gas[J]. Journal of China Coal Society,2014,39(8):1455−1462.

[8] 丁 洋,朱 冰,李树刚,等. 高突矿井采空区卸压瓦斯精准辨识及高效抽采[J]. 煤炭学报,2021,46(11):3565−3577. DING Yang,ZHU Bing,LI Shugang,et al. Accurate identification and efficient drainage of relieved methane in goaf of high outburst mine[J]. Journal of China Coal Society,2021,46(11):3565−3577.

[9] 李树刚,杨二豪,林海飞,等. 深部开采卸压瓦斯精准抽采体系构建及实践[J]. 煤炭科学技术,2021,49(5):1−10. LI Shugang,YANG Erhao,LIN Haifei,et al. Construction and practice of accurate gas drainage system for pressure relief gas in deep mining[J]. Coal Science and Technology,2021,49(5):1−10.

[10] 李树刚,刘李东,赵鹏翔,等. 综采工作面覆岩压实区裂隙动态演化规律影响因素分析[J]. 煤炭科学技术,2022,50(1):95−104. doi: 10.3969/j.issn.0253-2336.2022.1.mtkxjs202201008 LI Shugang,LIU Lidong,ZHAO Pengxiang,et al. Analysis and application of fracture evolution law of overburden compacted area on fully-mechanized mining face under multiple factors[J]. Coal Science and Technology,2022,50(1):95−104. doi: 10.3969/j.issn.0253-2336.2022.1.mtkxjs202201008

[11] MOHAMMAD Rezaei,MOHAMMAD Farouq Hossaini,ABBAS Majdi. A time-independent energy model to determine the height of destressed zone above the mined panel in longwall coal mining[J]. Tunnelling and Underground Space Technology incorporating Trenchless Technology Research,2015,47:81−92.

[12] ABBAS Majdi,FERRI P. Hassani,MEHDI Yousef Nasiri. Prediction of the height of destressed zone above the mined panel roof in longwall coal mining[J]. International Journal of Coal Geology,2012,98:62−72.

[13] 王 旭,尹尚先,徐 斌,等. 综采工作条件下覆岩导水裂隙带高度预测模型优化[J]. 煤炭科学技术,2023,51(S1):284−297. doi: 10.12438/cst.2022-1530 WANG Xu,YIN Shangxian,XU Bin,et al. Study on height optimization prediction model of overburden water-conducting fracture zone under fully mechanized mining[J]. Coal Science and Technology,2023,51(S1):284−297. doi: 10.12438/cst.2022-1530

[14] 王 炯,朱道勇,宫伟力,等. 切顶卸压自动成巷岩层运动规律物理模拟实验[J]. 岩石力学与工程学报,2018,37(11):2536−2547. WANG Jiong,ZHU Daoyong,GONG Weili,et al. Physical simulation experiment on the movement of rock strata upon automatic roadway forming by roof cutting and pressure releasing[J]. Chinese Journal of Rock Mechanics and Engineering,2018,37(11):2536−2547.

[15] 刘红威,赵阳升,REN Tingxiang,等. 切顶成巷条件下采空区覆岩破坏与裂隙发育特征[J]. 中国矿业大学学报,2022,51(1):77−89. LIU Hongwei,ZHAO Yangsheng,REN Tingxiang,et al. Characteristics of overburden failure and facture development in gob of mining with gob-side entry formed by cutting roof[J]. Journal of China University of Mining & Technology,2022,51(1):77−89.

[16] 高建良,孙望望. J型通风工作面采空区漏风与瓦斯浓度分布规律研究[J]. 煤炭工程,2018,50(1):132−136. doi: 10.11799/ce201801036 GAO Jianliang,SUN Wangwang. Study on air leakage and gas concentration distribution law in working face goaf with J type ventilation system[J]. Coal Engineering,2018,50(1):132−136. doi: 10.11799/ce201801036

[17] 高建良,李炫烨. 尾巷风量对“J”型通风工作面漏风及瓦斯分布的影响[J]. 煤矿安全,2017,48(8):166−169. GAO Jianliang,LI Xuanye. Effect of air volume in tail gateway on air leakage and gas distribution in“J”type ventilation working face[J]. Safety in Coal Mines,2017,48(8):166−169.

[18] 郭明杰,郭文兵,赵高博,等. 长壁开采覆岩内水平定向长钻孔位置特征与卸压瓦斯抽采机理[J]. 煤炭学报,2023,48(10):3750−3765. GUO Mingjie,GUO Wenbing,ZHAO Gaobo,et al. Position characteristics of horizontal-directional long boreholes in overlying strata and drainage mechanism of pressure-relief gas in longwall mining[J]. Journal of China Coal Society,2023,48(10):3750−3765.

[19] 孙晓明,刘 鑫,梁广峰,等. 薄煤层切顶卸压沿空留巷关键参数研究[J]. 岩石力学与工程学报,2014,33(7):1449−1456. SUN Xiaoming,LIU Xin,LIANG Guangfeng,et al. Key parameters of gob-side entry retaining formed by roof cut and pressure releasing in thin coal seams[J]. Chinese Journal of Rock Mechanics and Engineering,2014,33(7):1449−1456.

[20] 张庆贺,袁 亮,王汉鹏,等. 煤与瓦斯突出物理模拟相似准则建立与分析[J]. 煤炭学报,2016,41(11):2773−2779. ZHANG Qinghe,YUAN Liang,WANG Hanpeng,et al. Establishment and analysis of similarity criteria for physical simulation of coal and gas outburst[J]. Journal of China Coal Society,2016,41(11):2773−2779.

[21] 赵鹏翔,王 超,李树刚,等. 巨厚煤层综放开采上覆临近采空区裂隙二次演化特征分析[J]. 采矿与安全工程学报,2022,39(1):13−24. ZHAO Pengxiang,WANG Chao,LI Shugang,et al. Secondary evolution characteristics of fractures in overburden adjacent goafs during fully mechanized caving of extremely thick coal seams[J]. Journal of Mining and Safety Engineering,2022,39(1):13−24.

[22] 魏江波,王双明,宋世杰,等. 浅埋煤层过沟开采覆岩裂隙与地表裂缝演化规律数值模拟[J]. 煤田地质与勘探,2022,50(10):67−75. WEI Jiangbo,WANG Shuangming,SONG Shijie,et al. Numerical simulation on evolution law of overburden fractures and surface cracks in crossing ditch mining of shallow coal seam[J]. Coal Geology & Exploration,2022,50(10):67−75.

[23] 来兴平,张旭东,单鹏飞,等. 厚松散层下三软煤层开采覆岩导水裂隙发育规律[J]. 岩石力学与工程学报,2021,40(9):1739−1750. LAI Xingping,ZHANG Xudong,SHAN Pengfei,et al. Study on development law of water-conducting fractures in overlying strata of three soft coal seam mining under thick loose layers[J]. Chinese Journal of Rock Mechanics and Engineering,2021,40(9):1739−1750.

[24] 李春元,张 勇,张国军,等. 深部开采动力扰动下底板应力演化及裂隙扩展机制[J]. 岩土工程学报,2018,40(11):2031−2040. LI Chunyuan,ZHANG Yong,ZHANG Guojun,et al. Crack propagation mechanisms and stress evolution of floor under dynamic disturbance in deep coal mining[J]. Chinese Journal of Geotechnical Engineering,2018,40(11):2031−2040.

[25] 徐 超,王 凯,郭 琳,等. 采动覆岩裂隙与渗流分形演化规律及工程应用[J]. 岩石力学与工程学报,2022,41(12):2389−2403. XU Chao,WANG Kai,GUO Lin,et al. Fractal evolution law of overlying rock fracture and seepage caused by mining and its engineering application[J]. Chinese Journal of Rock Mechanics and Engineering,2022,41(12):2389−2403.

[26] 许家林,秦 伟,陈晓军,等. 采动覆岩卸荷膨胀累积效应的影响因素[J]. 煤炭学报,2022,47(1):115−127. XU Jialin,QIN Wei,CHEN Xiaojun,et al. Influencing factors of accumulative effect of overburden strata expansion induced by stress relief[J]. Journal of China Coal Society,2022,47(1):115−127.

[27] 何满潮,高玉兵,盖秋凯,等. 无煤柱自成巷力学原理及其工法[J]. 煤炭科学技术,2023,51(1):19−30. HE Manchao,GAO Yubing,GAI Qiukai,et al. Mechanical principle and mining methods of automagical entry formation without coal pillars[J]. Coal Science and Technology,2023,51(1):19−30.

[28] 黄志安,童海方,张英华,等. 采空区上覆岩层“三带”的界定准则和仿真确定[J]. 北京科技大学学报,2006,28(7):609−612. HUANG Zhian,TONG Haifang,ZHANG Yinghua,et al. Dividing guideline and emulating determination of “three zones” of the depressing zones overlying a goaf[J]. Journal of University of Science and Technology Beijing,2006,28(7):609−612.

[29] 胡国忠,李 康,许家林,等. 覆岩采动裂隙空间形态反演方法及在瓦斯抽采中的应用[J]. 煤炭学报,2023,48(2):750−762. HU Guozhong,LI Kang,XU Jialin,et al. Spatial morphology inversion method of mining-induced fractures of overburden and its application in gas drainage[J]. Journal of China Coal Society,2023,48(2):750−762.

[30] 王泓博,张 勇,庞义辉,等. 基于地表点下沉阶段特征的覆岩裂隙带高度演化[J]. 中国矿业大学学报,2022,51(1):24−34. WANG Hongbo,ZHANG Yong,PANG Yihui,et al. Evolution of the height of overburden fractured zone based on stage characteristics of surface subsidence[J]. Journal of China University of Mining & Technology,2022,51(1):24−34.

[31] 赵鹏翔,张文进,李树刚,等. 高瓦斯厚煤层综采工作面推进速度影响下的瓦斯运–储区交叉融合机理[J]. 煤炭学报,2023,48(9):3405−3419. ZHAO Pengxiang,ZHANG Wenjin,LI Shugang,et al. Mechanism of cross-fusion in gas transportation-storage area in fully mechanized mining face of high gas thick coal seam under different advancing speeds[J]. Journal of China Coal Society,2023,48(9):3405−3419.

[32] 林海飞,王 旭,徐培耘,等. 特厚煤层开采卸压瓦斯储集区演化特征分析及工程应用[J]. 煤炭科学技术,2023,51(2):173−182. LIN Haifei,WANG Xu,XU Peiyun,et al. Evolution characteristics analysis and engineering application of pressure-relieved gas reservoir in extra-thick coal seam mining[J]. Coal Science and Technology,2023,51(2):173−182.

下载:

下载: