Virtual debugging method of hydraulic support group following machine process based on digital twin

-

摘要:

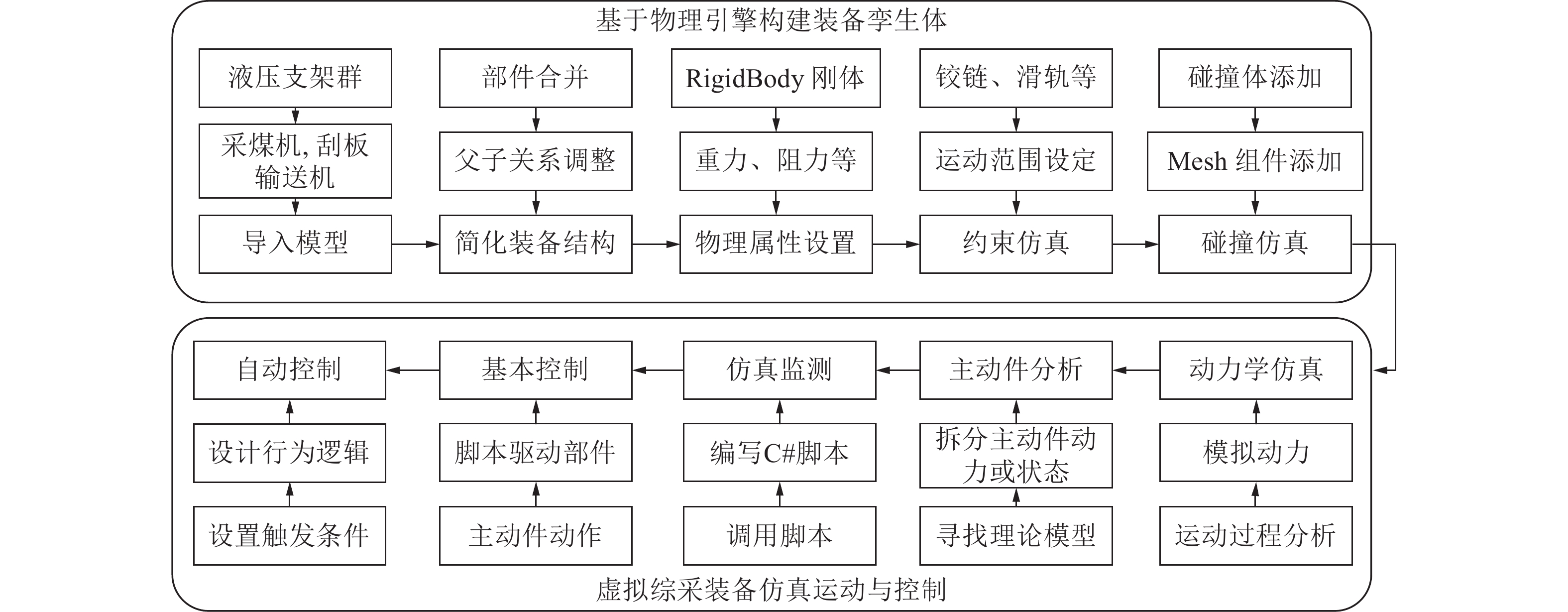

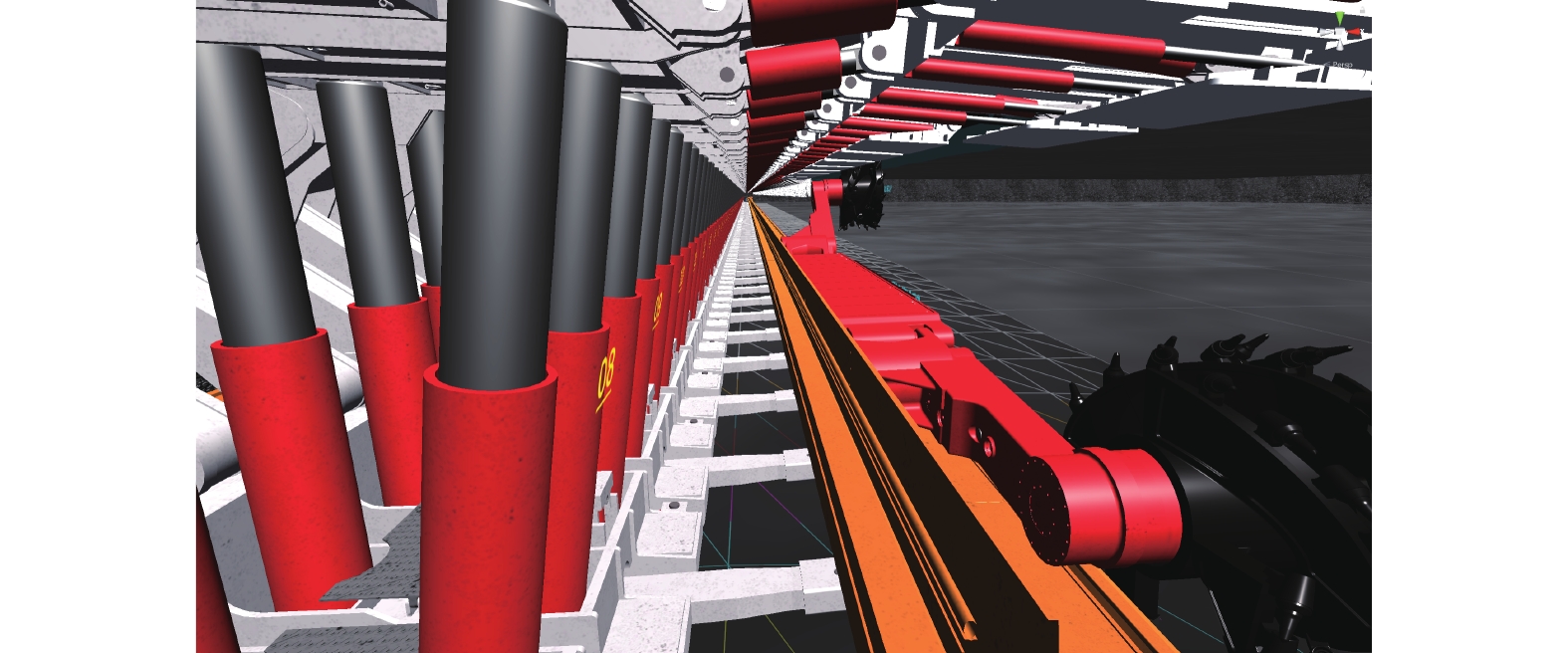

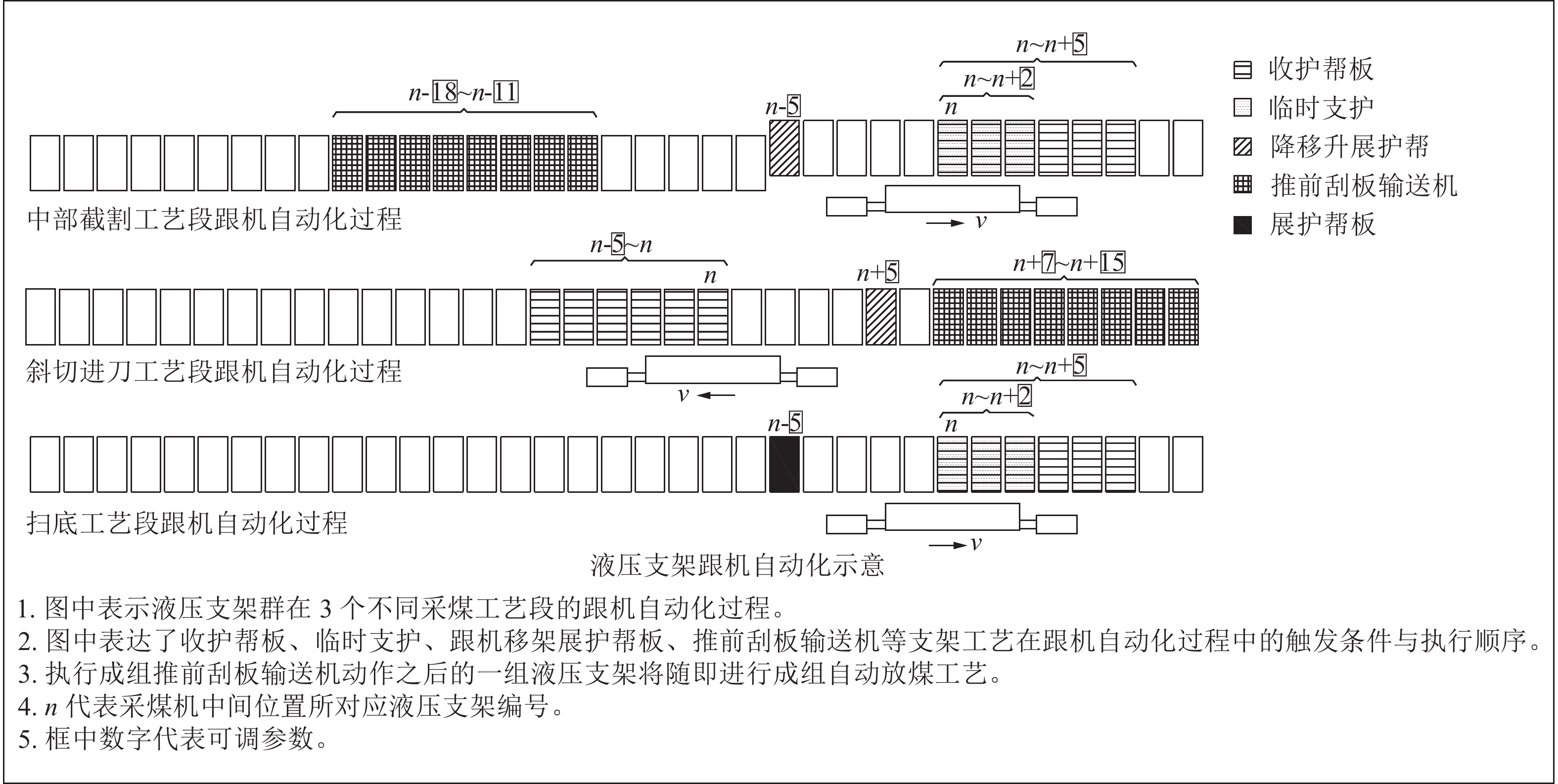

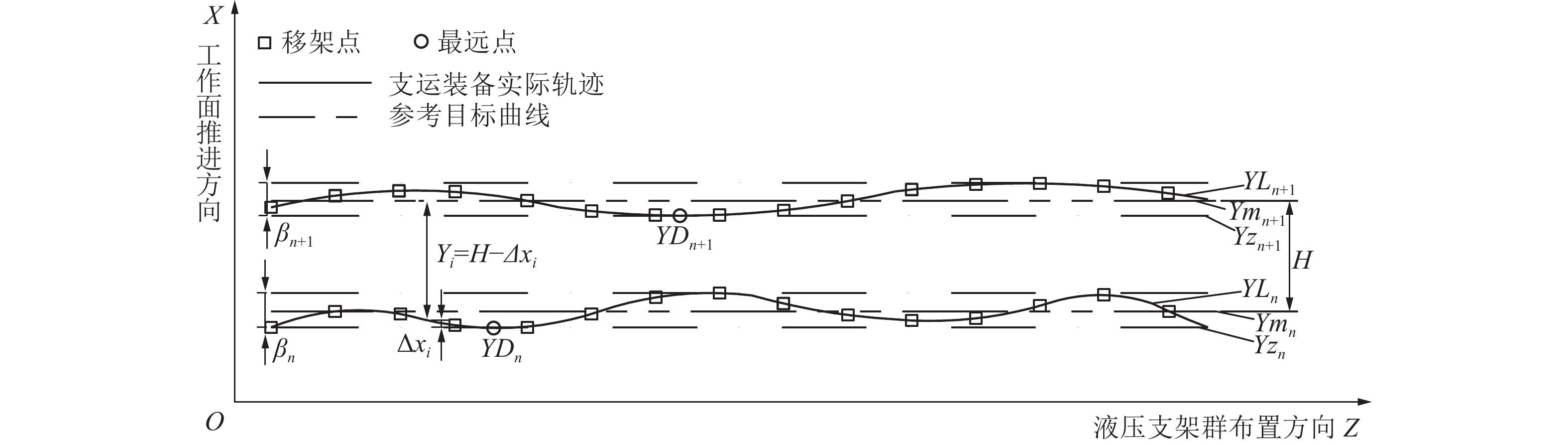

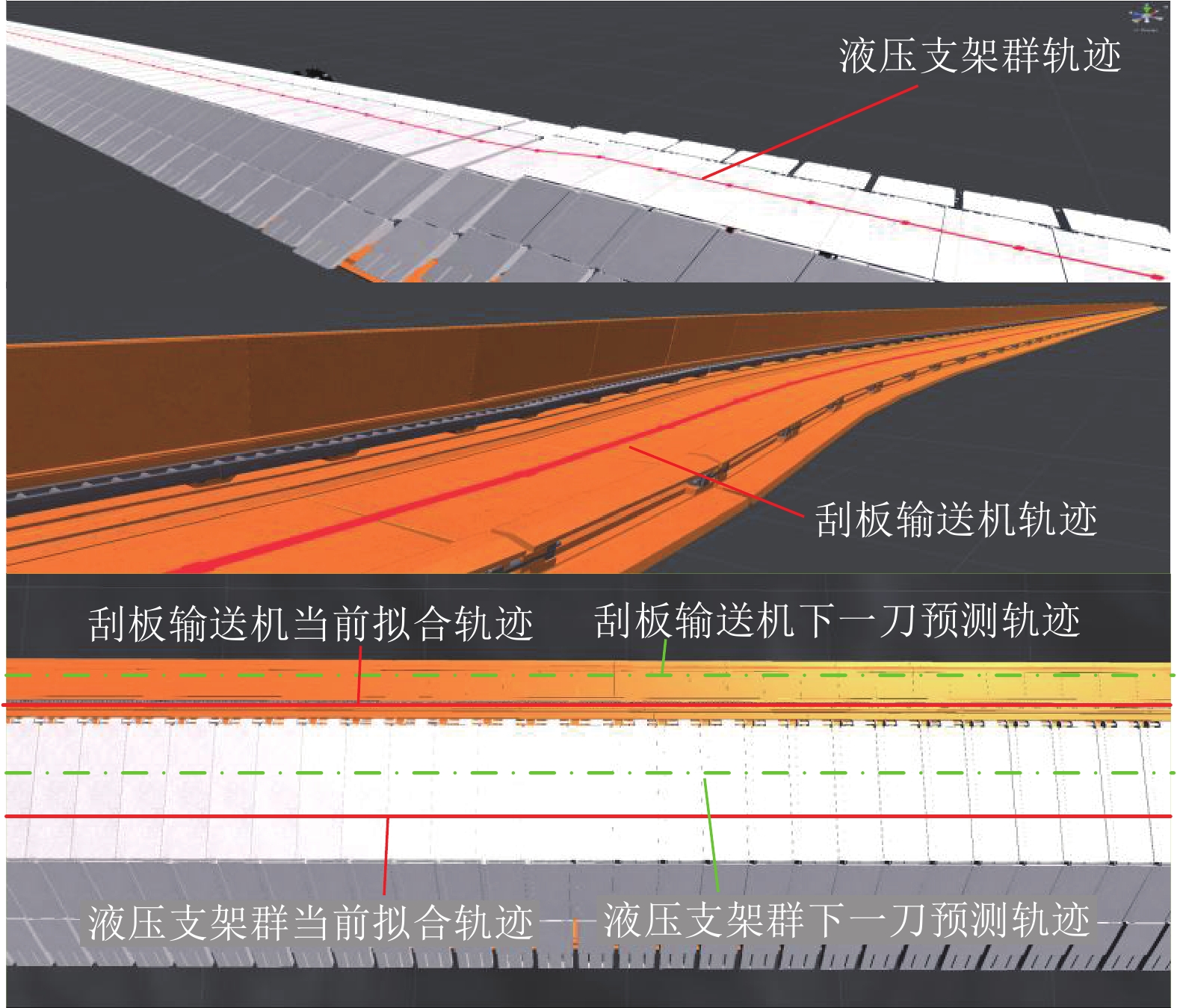

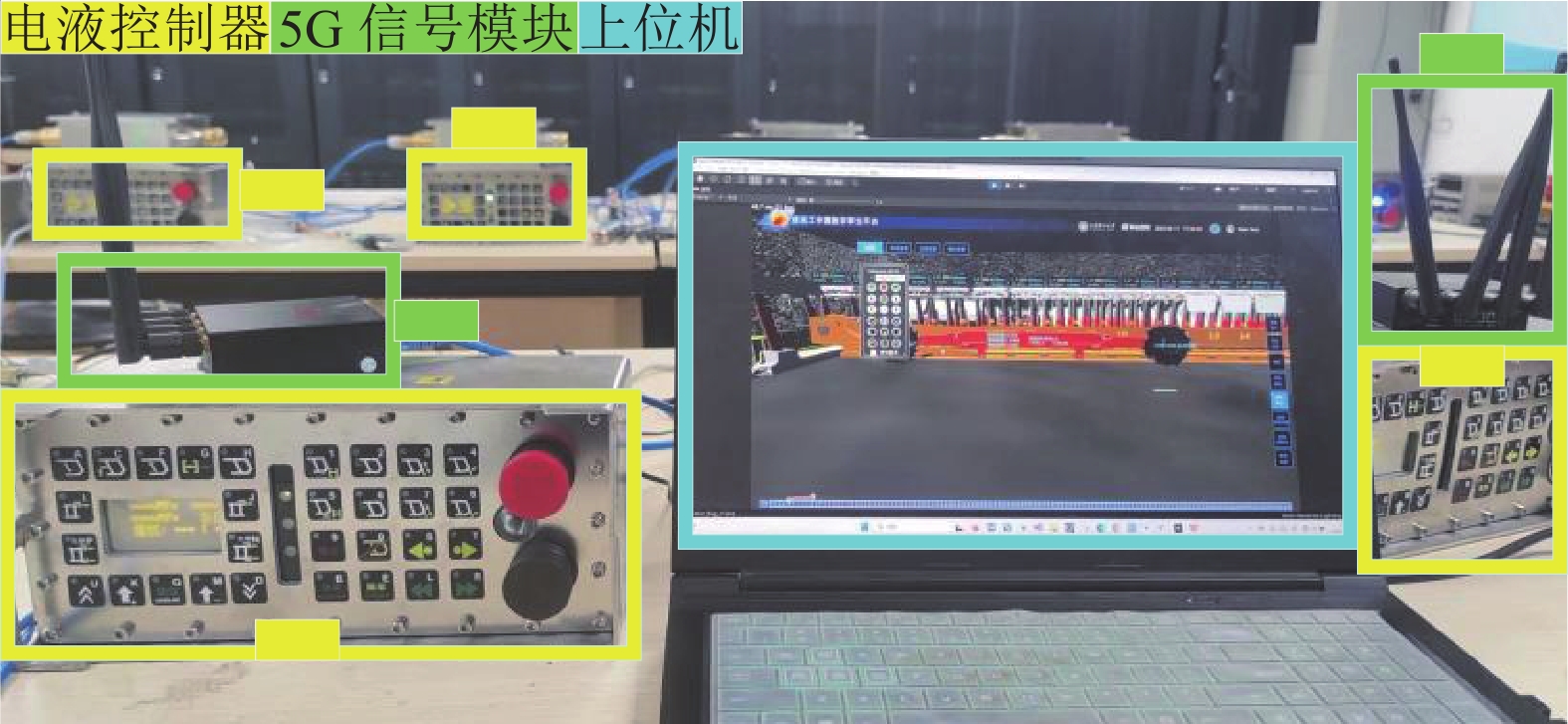

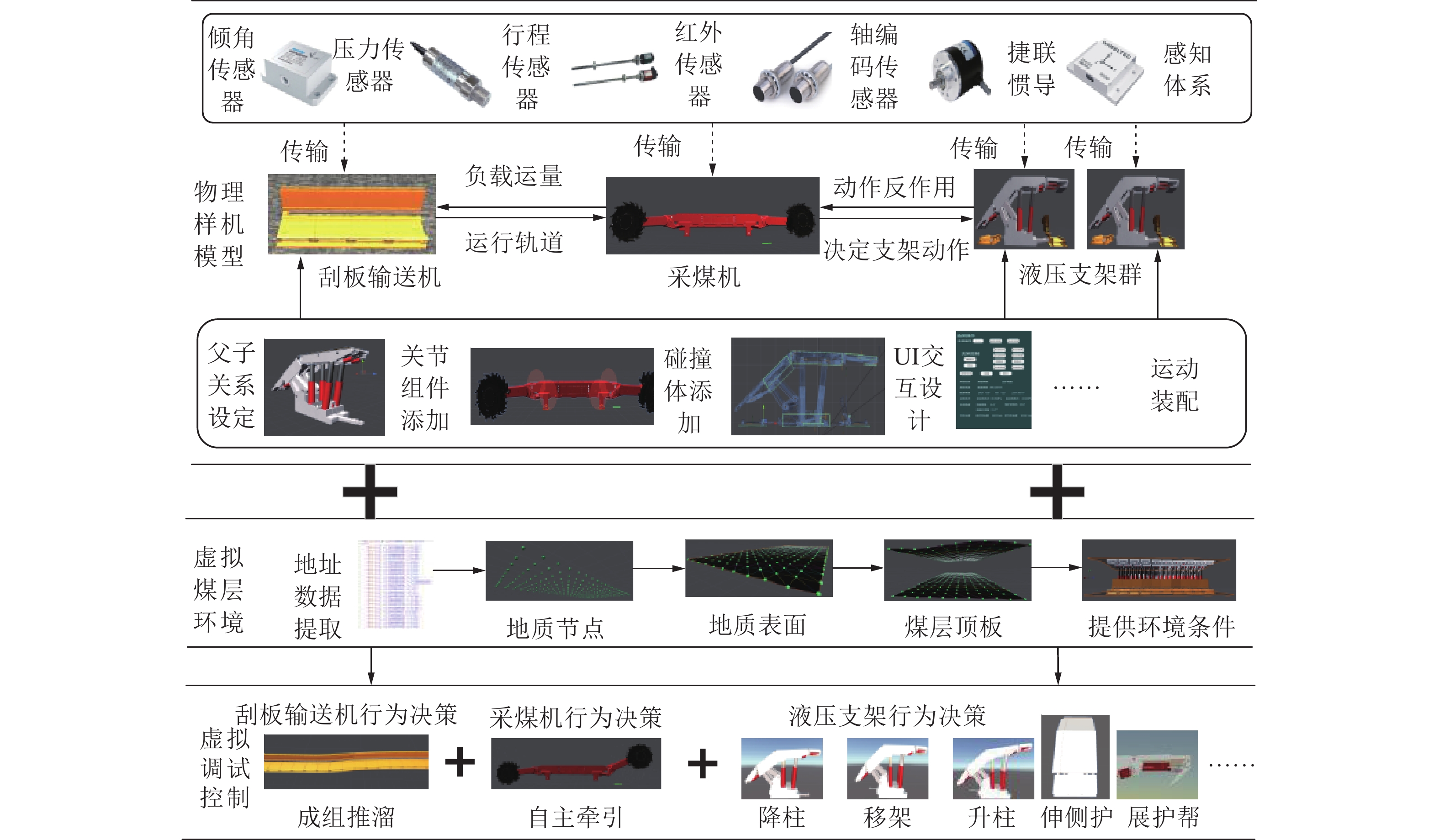

针对物理综采工作面“三机”跟机自动化工艺参数调试周期长,费用成本高,以及工作环境搭建困难等问题,基于数字孪生技术,研究了液压支架群跟机行为工艺虚拟调试关键技术。首先基于现代建模技术构建了1∶1构综采“三机”孪生体,利用虚拟现实引擎对综采“三机”运动单元进行了虚拟重构和虚拟仿真;然后基于现代设计理论,依据“三机”协同原则实现了跟机自动化过程中的不同参数配置,建立了采煤工艺的支架行为工艺决策模型和支运装备直线度协同控制模型,并在虚拟场景中对决策模型进行预演;最后利用TCP协议建立了虚实交互通道,通过半实物仿真试验对决策模型进行了验证。结果表明:虚拟场景在执行采煤工艺时可对物理工作面场景进行精准复现,通过支架群行为决策模型可提前对液压支架工艺行为进行决策规划,通过反向控制试验可对支架控制器进行实时虚实交互,有望克服井下调试环境阻碍,对综采“三机”电液控程序的合理制定与修正提供参考价值。

Abstract:In view of the problems such as long period of automatic process parameter debugging, high cost and difficult construction of working environment, the key technology of virtual process debugging of hydraulic support group process is studied based on digital twin technology. Firstly, based on modern modeling technology, a 1∶1 twin of three fully-mechanized mining machines was constructed, and virtual reconstruction and simulation of the three mechanized mining machines were carried out by virtual reality engine. Then, based on the modern design theory and the principle of three-machine collaboration, different parameters in the automatic process of the following machine are configured, and the decision-making model of the support behavior of the coal mining process is established, and the decision-making model is rehearsed in the virtual scene. Finally, the virtual and real interaction channel is established by TCP protocol, and the decision model is verified by semi-physical simulation experiment. The results show that the virtual scene can accurately reproduce the physical working face scene in the implementation of coal mining technology, the support group behavior decision model can be used to make decision planning of the hydraulic support process behavior in advance, and the real-time virtual-real interaction of the support controller can be carried out through the reverse control experiment. It is expected to overcome the obstacles of underground commissioning environment and provide useful reference value for the reasonable formulation and revision of hydraulic control program of the third mechanized mining machine.

-

-

表 1 工作面设备配置

Table 1 Equipment configuration of fully-mechanized mining face

装备类型 型号 数量 端头支架 ZTZ20000/28.5/42 1 过渡支架(机头) ZF13000/27.5/42H 5 过渡支架(机尾) ZF13000/27.5/42H 4 中部支架 ZF15000/27.5/42 108 前部刮板输送机 JTAFC1050 1 后部刮板输送机 JTAFC1050 1 转载机 JBSL600 1 破碎机 JCRSH400 1 带式输送机 DSJ140/3×630 1 采煤机 Eickhoff SL-500 1 表 2 采煤工艺流程

Table 2 Coal mining process flow

工艺序号 执行工艺 工艺序号 执行工艺 01 (一刀开始)采煤机行走 07 采煤机前后滚筒下放 02 后滚筒后1~2支

架降移升08 采煤机来回扫地2~3次 03 执行降移升后,伸缩梁伸

且打开护帮板09 斜切进刀割三角煤(留出刮板输送机空间) 04 成组推刮板输送机

(后滚筒超过约10台支架)10 采煤机前后滚筒下放 05 成组放煤(成组推刮板

输送机后的支架)11 采煤机来回扫地2~3次 06 采煤机行至支架尾部 12 调整前后滚筒高度(准备下一刀) 表 3 液压支架动作时间符号

Table 3 Hydraulic support action time symbol

动作 符号 动作 符号 液压支架收护帮 $ {t_1} $ 液压支架升柱 $ {t_5} $ 液压支架伸缩梁伸出 $ {t_2} $ 液压支架展护帮 $ {t_6} $ 液压支架降柱 $ {t_3} $ 液压支架成组推刮板输送机 $ {t_7} $ 液压支架拉架 $ {t_4} $ — — 表 4 采煤机速度为$ 4\;{\mathrm{m}}/\min $支架工艺架号

Table 4 Shearer speed is 4 meters per minute support process frame number

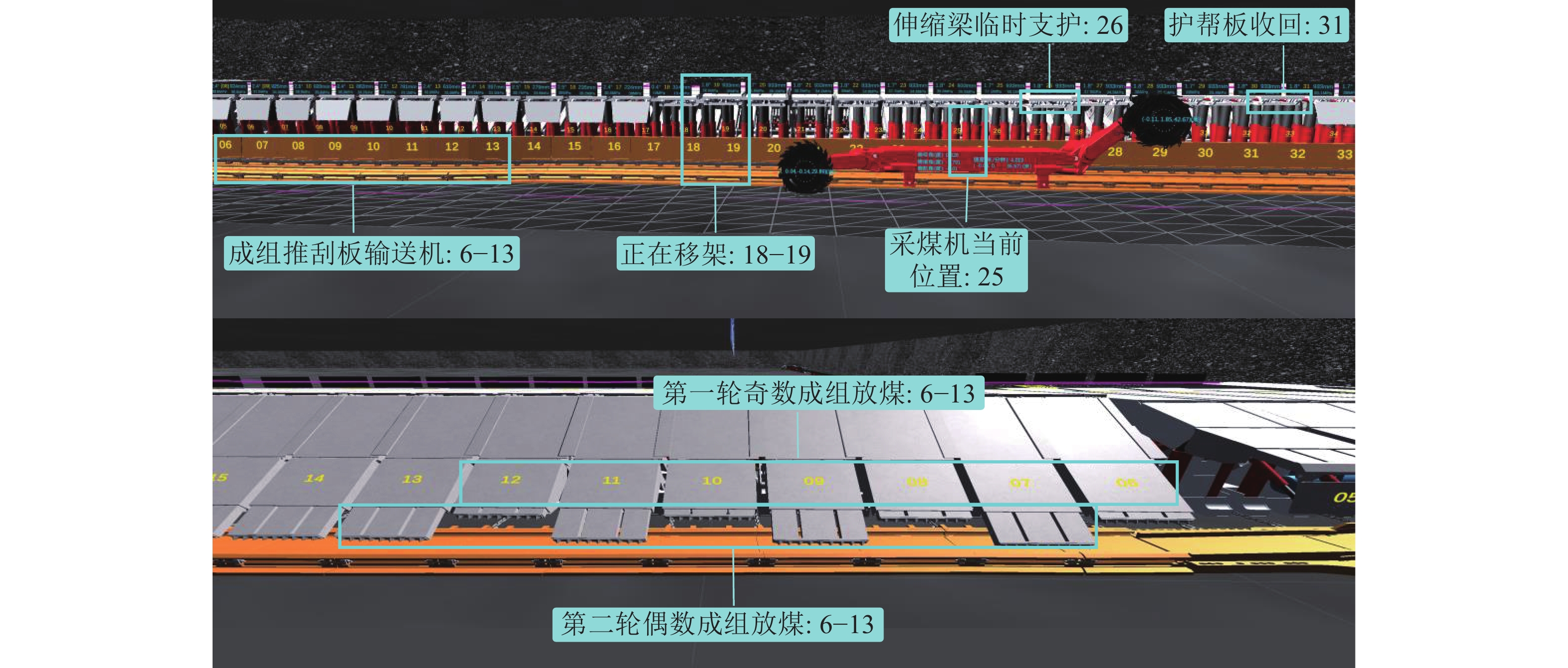

支架工艺架号 采煤机 收护

帮板临时

支护支架降

移升成组

推刮板输送机第一轮

放煤第二轮

放煤24 30 26 17—18 — — — 25 31 27 18—19 6—13 6,8,10,12 7,9,11,13 26 32 28 19—20 — — — 27 33 29 20—21 — — — 28 34 30 21—22 — — — 29 35 31 22—23 — — — 30 36 32 23—24 — — — 31 37 33 24—25 12—19 12,14,16,18 13,15,17,19 32 38 34 25—26 — — — ... ... ... ... ... ... ... 114 120 116 107—108 — — — 115 121 117 108—109 96-103 96,98,100,102 97,99,101,103 116 122 118 109—110 — — — 表 5 采煤机速度为$ 8\;{\mathrm{m}}/\min $支架工艺架号

Table 5 Shearer speed is 8 meters per minute support process frame number

支架工艺架号 采煤机 收护

帮板临时

支护支架降

移升成组

推刮板输送机第一轮

放煤第二轮

放煤24 30 26 16—18 — — — 25 31 27 17—19 6—13 6,8,10,12 7,9,11,13 26 32 28 18—20 — — — 27 33 29 19—21 — — — 28 34 30 20—22 — — — 29 35 31 21—23 — — — 30 36 32 22—24 — — — 31 37 33 23—25 12—19 12,14,16,18 13,15,17,19 32 38 34 24—26 — — — ... ... ... ... ... ... ... 114 120 116 106—108 — — — 115 121 117 107—109 96—103 96,98,100,102 97,99,101,103 116 122 118 109—110 — — — -

[1] 王国法. 煤矿智能化最新技术进展与问题探讨[J]. 煤炭科学技术,2022,50(1):1−27. WANG Guofa,New technological progress of coal mine intelli-gence and its problems[J]. Coal Science And Technology,2022,50(1):1−27.

[2] 王国法,杜毅博,徐亚军,等. 中国煤炭开采技术及装备50年发展与创新实践−纪念《煤炭科学技术》创刊50周年[J]. 煤炭科学技术,2023,51(1):1−18. WANG Guofa,DU Yibo,XU Yajun,et al. Development and innovation practice of China coal mining technology and equipment for 50 years: Commemorate the 50th anniversary of the publication of Coal Science and Technology[J]. Coal Science and Technology,2023,51(1):1−18.

[3] 王国法,庞义辉,任怀伟. 智慧矿山技术体系研究与发展路径[J]. 金属矿山,2022(5):1−9. WANG Guofa,PANG Yihui,HUAI Renwei. Research and development path of smart mine technology system[J]. Metal Mine,2022(5):1−9.

[4] Okol’nishnikov V V,Ordin A A,Rudometov S V,et al. Development of a digital model of mining face of coal mine[J]. Optoelectronics,Instrumentation and Data Processing,2022,57(6):659-667.

[5] 王自亭,黄佳强,张建军,等. 智能矿山建设实践[J]. 创新世界周刊,2023(3):63−67. WANG Ziting,HUANG Jiaqiang,ZHANG Jianjun,et al. Intellige-nt mine construction practice[J]. Innovation World Weekly,2023(3):63−67.

[6] 鞠建华,韩见,鞠方略. 中国智能矿山发展趋势与路径分析[J]. 中国矿业,2023,32(5):1−7. JU Jianhua,HAN Jian,JU Fanglue. Development trend and path analysis of intelligent mines in China[J]. Chine Mining Magazi-ne,2023,32(5):1−7.

[7] 陶飞,马昕,戚庆林,等. 数字孪生连接交互理论与关键技术[J]. 计算机集成制造系统,2023,29(1):1−10. TAO Fei,MA Xin,QI Qinglin,et al. Theory and key technologies of digital twin connection and interaction[J]. Computer Integra-ted Manufacturing Systems,2023,29(1):1−10.

[8] 谢嘉成,王学文,杨兆建. 基于数字孪生的综采工作面生产系统设计与运行模式[J]. 计算机集成制造系统,2019,25(6):1381−1391. XIE Jiacheng,WANG Xuewen,YANG Zhaojian. Design and ope-ration mode of production system of fully mechanized coal m-ining face based on digital twin theory[J]. Computer Integrated Manufacturing Systems,2019,25(6):1381−1391.

[9] 葛世荣,张帆,王世博,等. 数字孪生智采工作面技术架构研究[J]. 煤炭学报,2020,45(6):1925−1936. GE Shirong,ZHANG Fan,WANG Shibo. Digital twin for smart coal mining workface:Technological frame and construction[J]. Journal of China Coal Society,2020,45(6):1925−1936.

[10] 张帆,葛世荣,李闯. 智慧矿山数字孪生技术研究综述[J]. 煤炭科学技术,2020,48(7):168−176. ZHANG Fan,GE Shirong,LI Chuang. Research summary on dig-ital twin technology for smart mines[J]. Coal Science And Tec-hnology,2020,48(7):168−176.

[11] 雷晓荣,李明星,岳辉,等. 透明工作面数字孪生系统关键技术及实现[J]. 智能矿山,2022,3(7):50−56. LEI Xiaorong,LI Mingxing,YUE Hui,et al. Key technology and realization of digital twin system of transparent working face[J]. Journal of Intelligent Mine,2022,3(7):50−56.

[12] 刘清,张龙,李天越,等. 综采工作面“三机”数字孪生及协同建模方法[J]. 工矿自动化,2023,49(2):47−55. LIU Qing,ZHANG Long,LI Tianyue,et al. A three machine dig-ital twin and collaborative modeling method for fully mechanized working face[J]. Industry and Mine Automation,2023,49(2):47−55.

[13] 王学文,谢嘉成,郝尚清,等. 智能化综采工作面实时虚拟监测方法与关键技术[J]. 煤炭学报,2020,45(6):1984−1996. WANG Xuewen,XIE Jiachenng,HAO Shangqing,et al. Key tech-nologies of real-time virtual monitoring method for an intellig-ent fully mechanized coal-mining face[J]. Journal of China Coal Society,2020,45(6):1984−1996.

[14] HENGBO SHI,JIACHENG XIE,XUEWEN WANG,et al. An operation optimization method of a fully mechanized coal mining face based on semi-physical virtual simulation[J]. 国际煤炭科学技术学报(英文版),2020,7(1):147−163. [15] 李娟莉,李梦辉,谢嘉成,等. 分布式实时运行数据驱动的液压支架群虚拟监测关键技术[J]. 北京理工大学学报,2021,41(10):1023−1033. LI Juanli,LI Menghui,XIE Jiacheng,et al. Key technologies of virtual monitoring driven by distributed real-time running data for hydraulic support group[J]. Transactions of Beijing I-nstitute of Technology,2021,41(10):1023−1033.

[16] 李亚飞. 液压支架电液控制系统的设计与调试[J]. 机械管理开发,2020,35(12):227−228,252. LI Yafei. Research on the intelligent control system of suspension density in heavy medium sorting process of coal pre-paration plant[J]. Mechanical Management and Development,2020,35(12):227−228,252.

[17] 郭向阳,于亮亮,吴卫兵,等. 基于数字孪生的智慧煤矿安全管控平台研究[J]. 能源技术与管理,2022,47(4):134−136. [18] 苗丙,葛世荣,郭一楠,等. 煤矿数字孪生智采工作面系统构建[J]. 矿业科学学报,2022,7(2):143−153. MIAO Bing,GE Shirong,GUO Yinan,et al. Construction of digital twin system for intelligent mining in coal mines[J]. Journal of Mining Science and Technology,2022,7(2):143−153.

[19] 任怀伟,王国法,赵国瑞,等. 智慧煤矿信息逻辑模型及开采系统决策控制方法[J]. 煤炭学报,2019,44(9):2923−2935. HUAI Renwei,WANG Guofa,ZHAO Guorui,et al. Smart coal m-ine logic model and decision control method of mining syste-m[J]. Journal of China Coal Society,2019,44(9):2923−2935.

[20] 付翔,王然风,赵阳升. 液压支架群组跟机推进行为的智能决策模型[J]. 煤炭学报,2020,45(6):2065−2077. FU Xiang,WANG Ranfeng,ZHAO Yangsheng. Intelligent decision making model on the of hydraulic supports group advancing behavior to follow shearer[J]. Journal of China Coal Society,2020,45(6):2065−2077.

-

期刊类型引用(4)

1. 郑建伟,管增伦,鞠文君,张修峰,薛珊珊,王帅,李海涛,杨国强,李春元,王之禾. 三向应力下支护应力对圆形巷道围岩应力分布规律的影响. 采矿与岩层控制工程学报. 2024(03): 118-127 .  百度学术

百度学术

2. 赵文环,龙赣,李进华. 基于复变函数不同规格矩形巷道围岩应力分布规律解析. 矿产保护与利用. 2024(04): 111-123 .  百度学术

百度学术

3. 王红胜,张胜伟,李磊,李斌,黄义通,雒军利. 倾斜煤层矩形巷道围岩非对称破坏特征及控制技术研究. 煤炭工程. 2023(04): 119-123 .  百度学术

百度学术

4. 郑茂莹,王兴龙,李政伟. 煤矿巷道掘进围岩变形及稳定性分析. 山东煤炭科技. 2023(09): 65-68 .  百度学术

百度学术

其他类型引用(4)

下载:

下载: