Mechanical properties and energy evolution mechanism of coal prone to ejection

-

摘要:

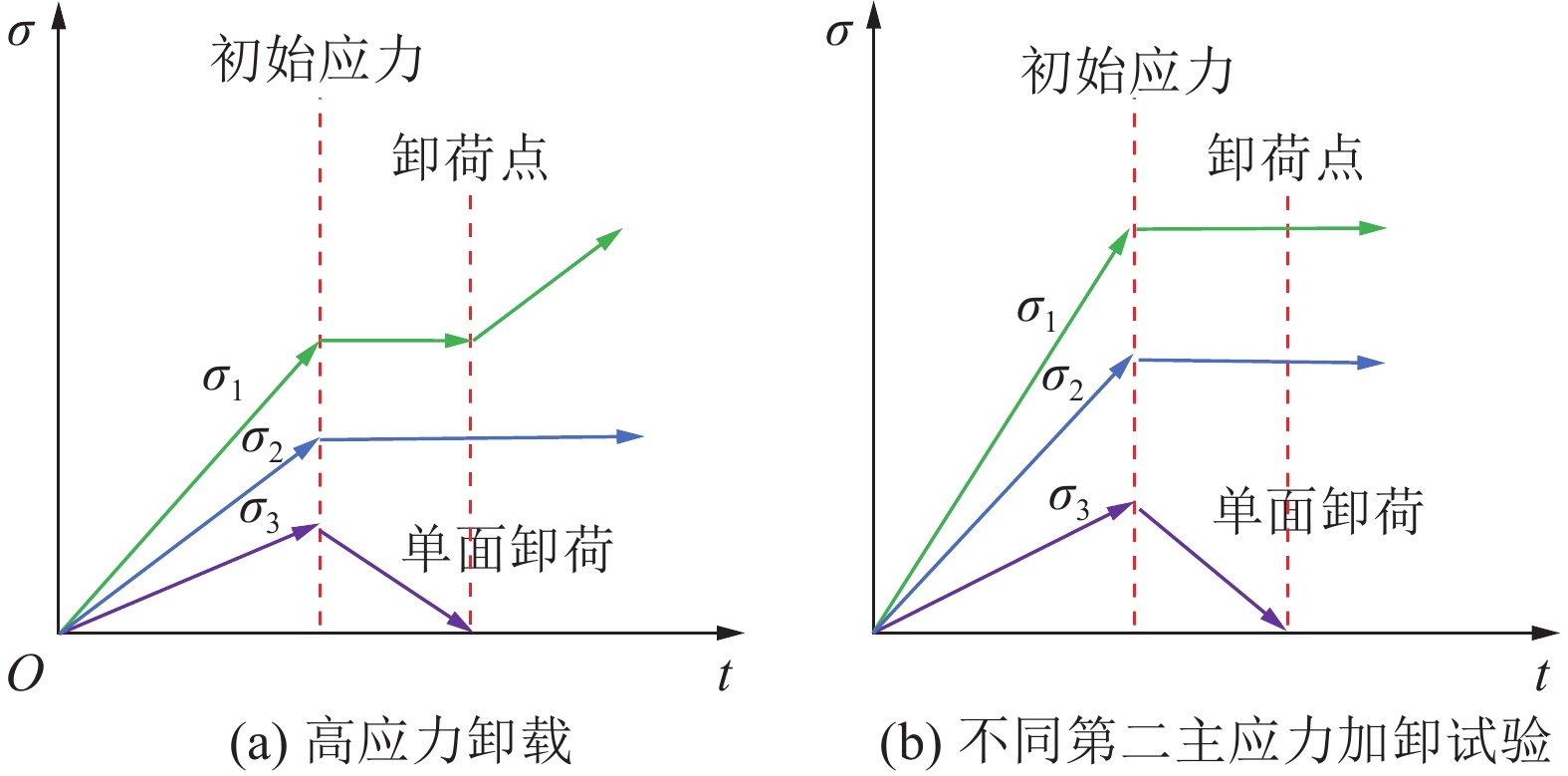

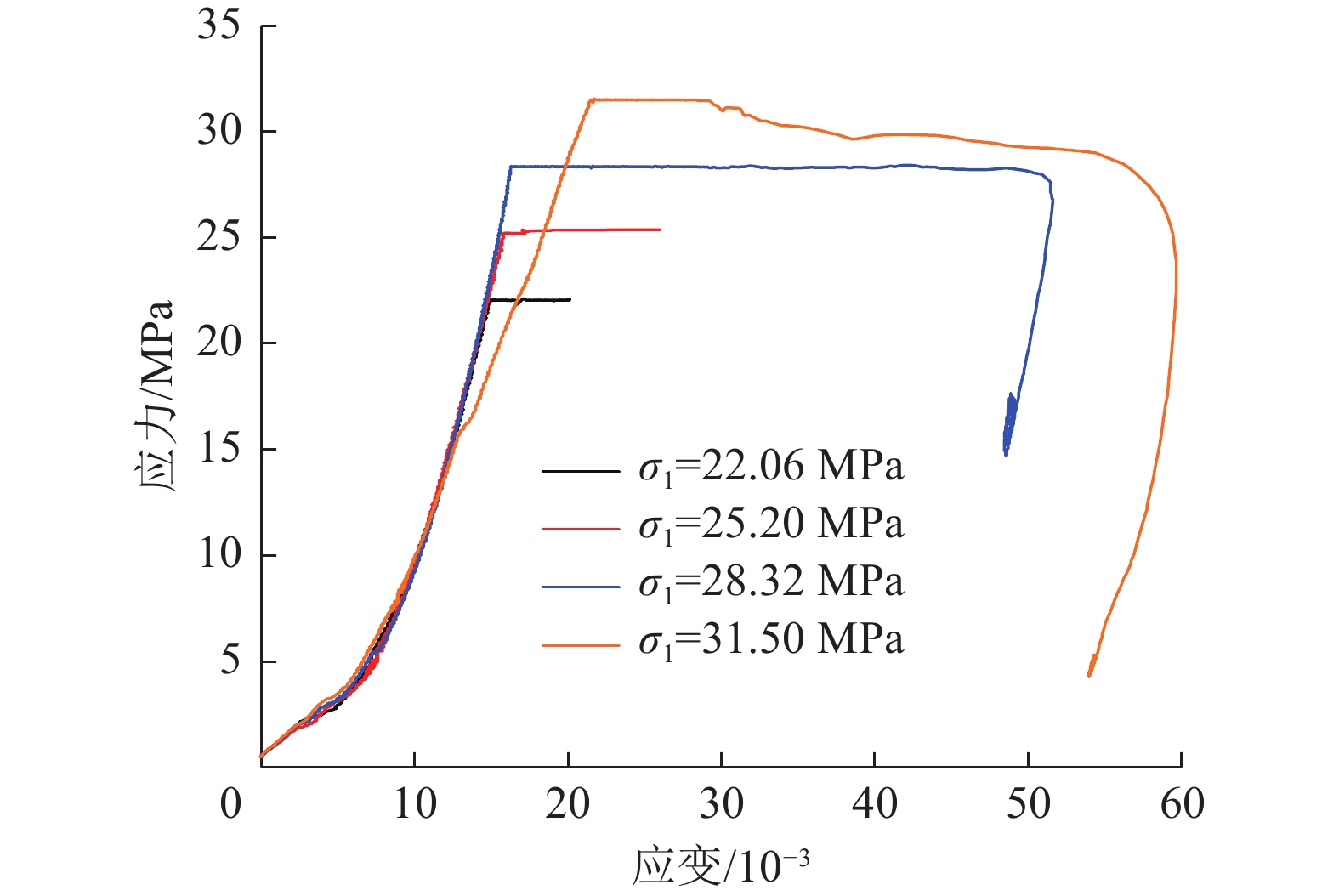

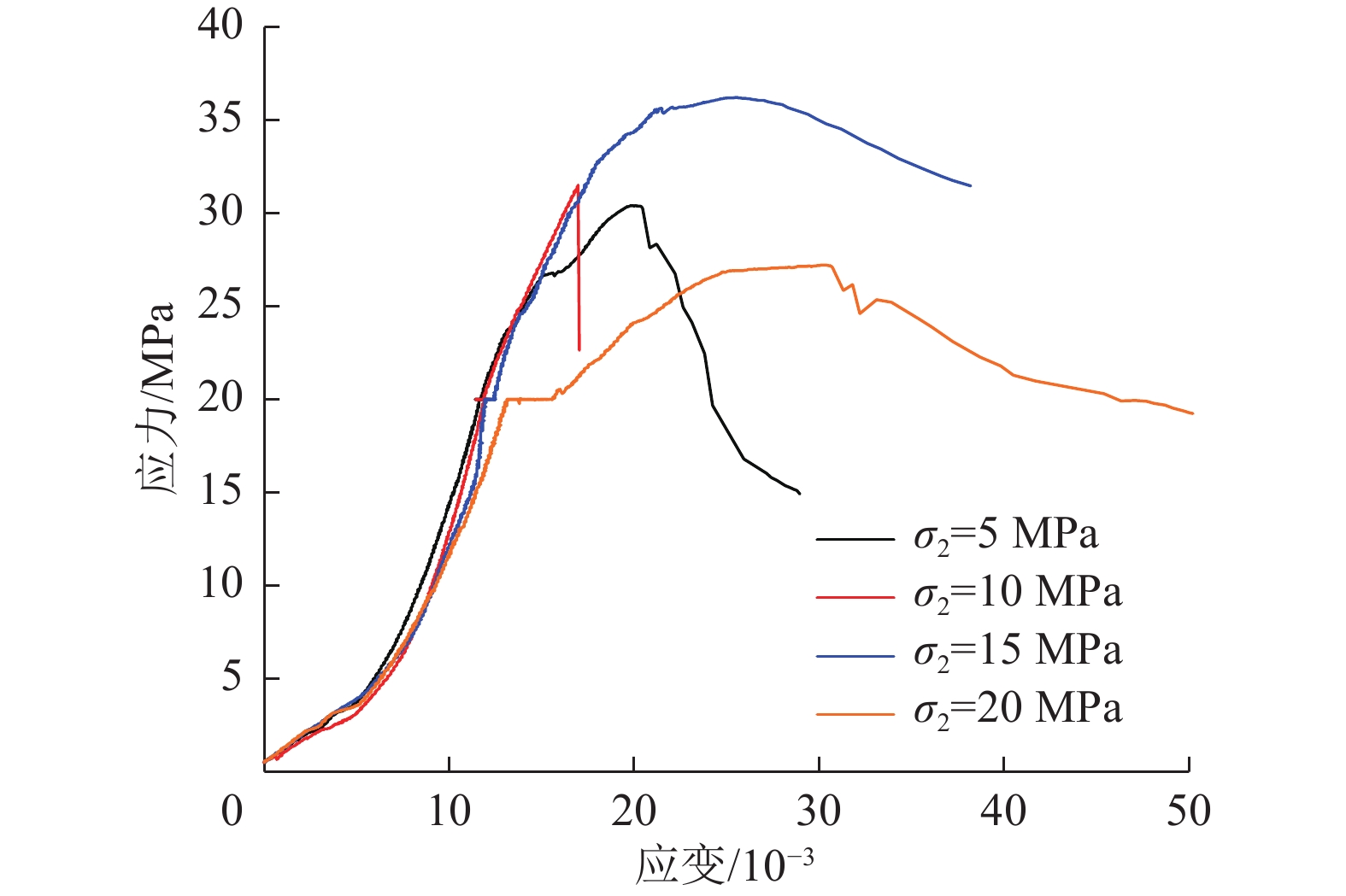

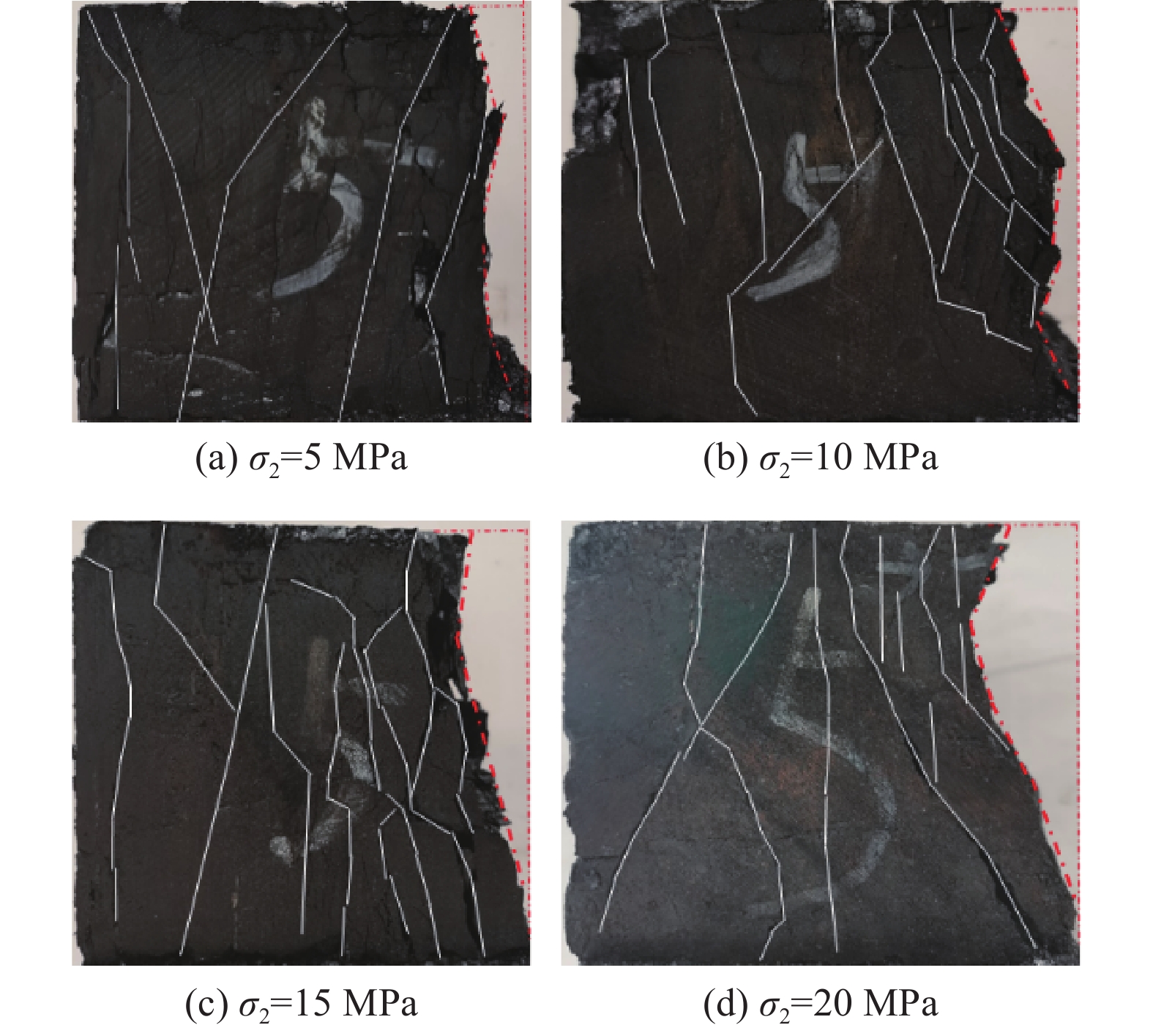

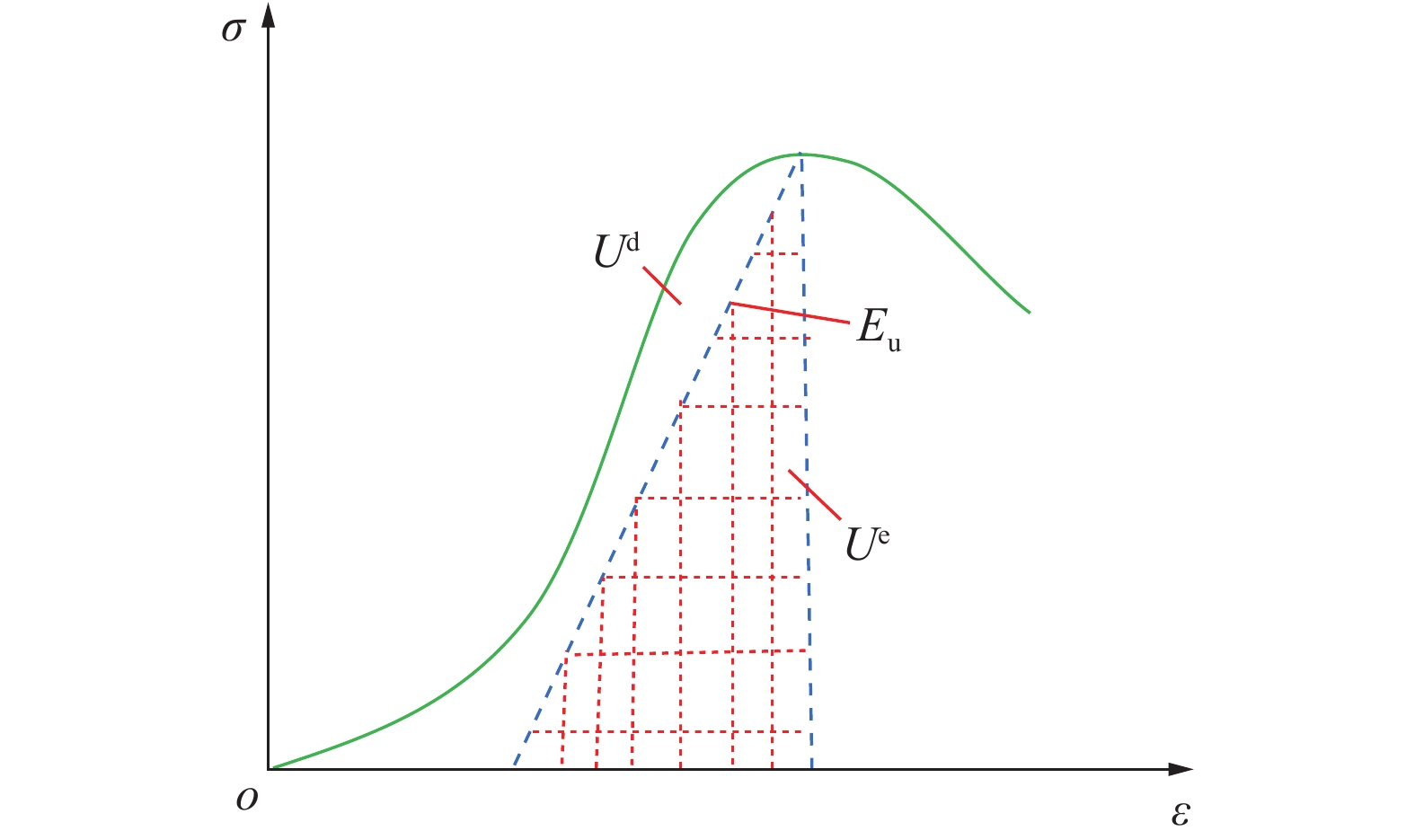

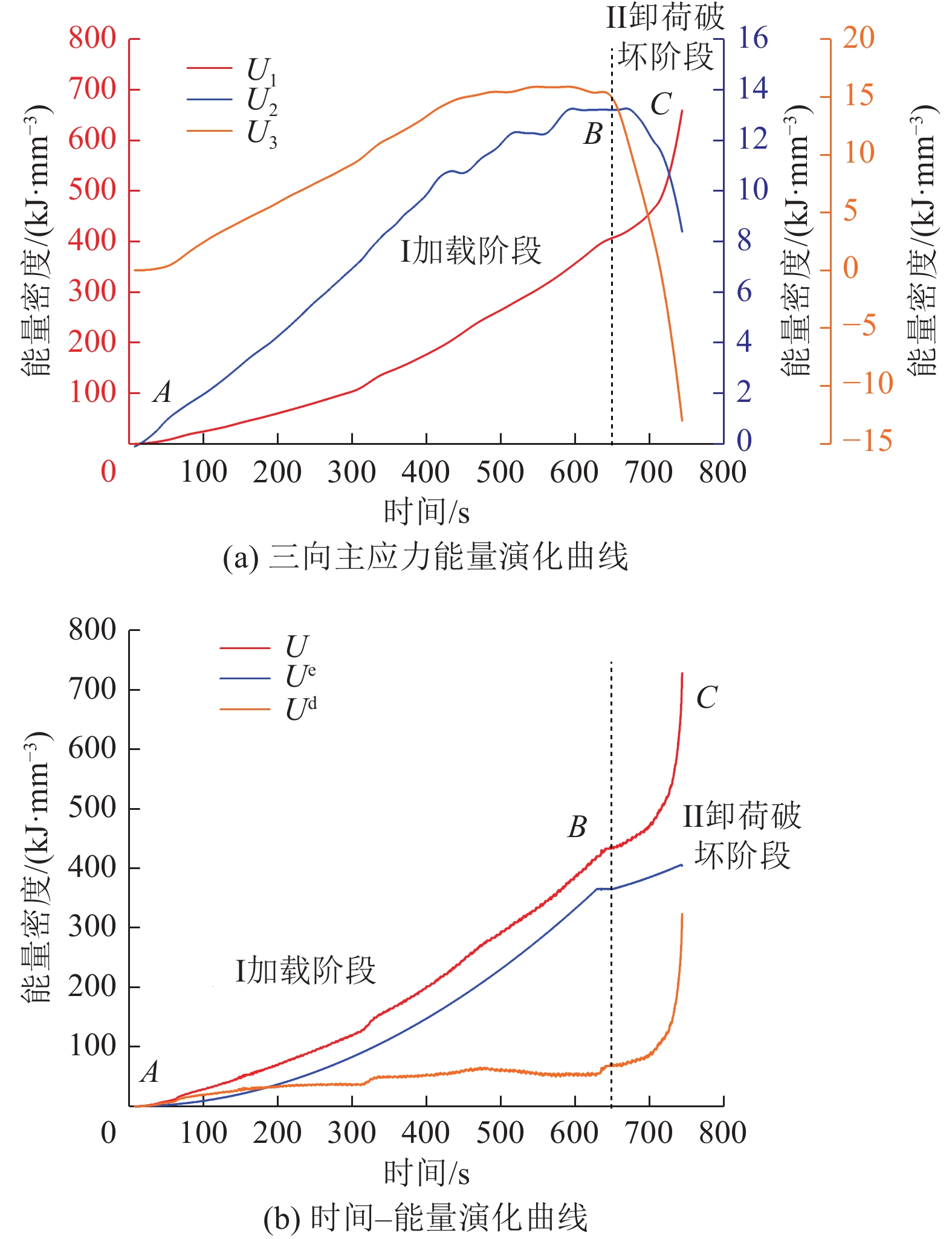

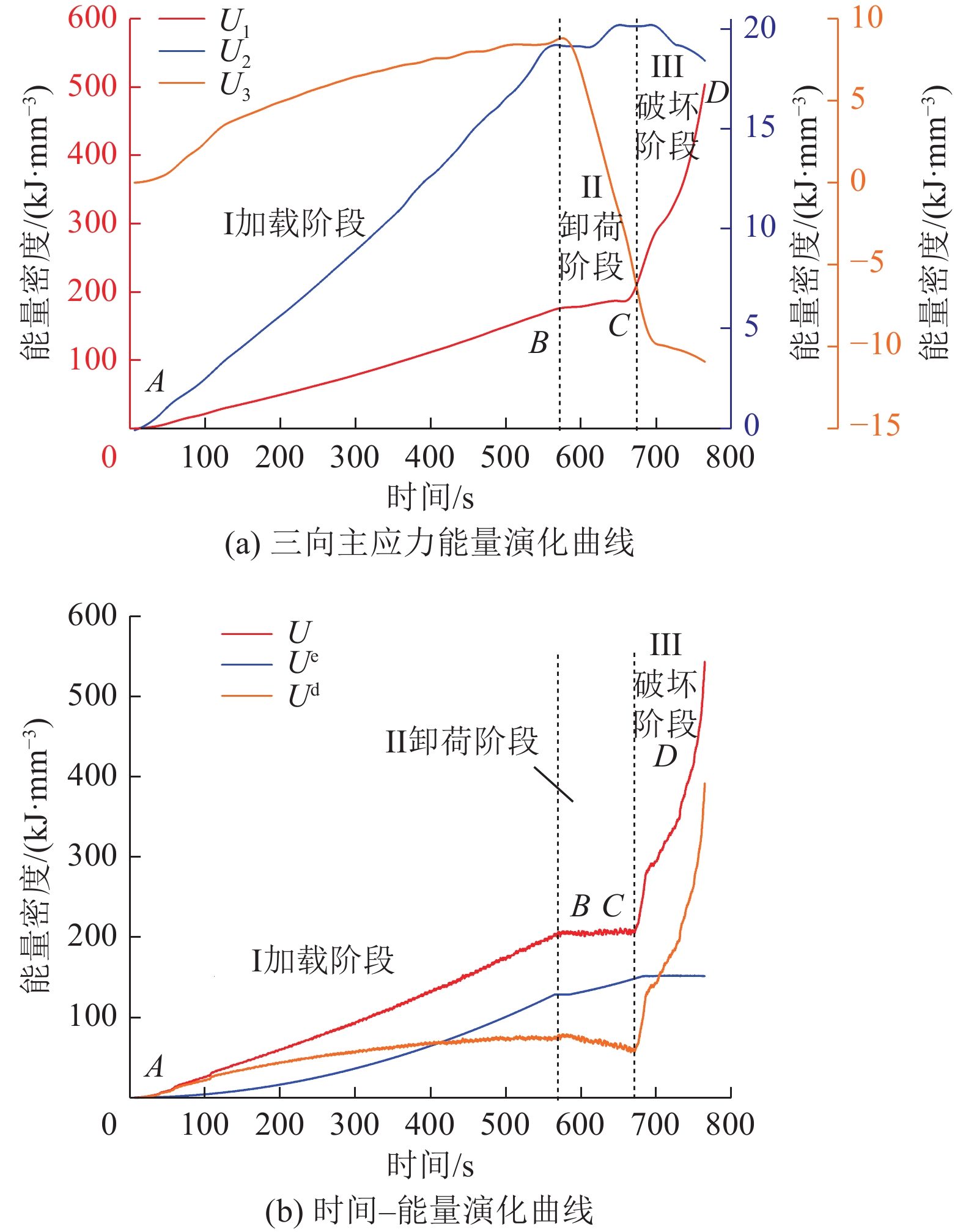

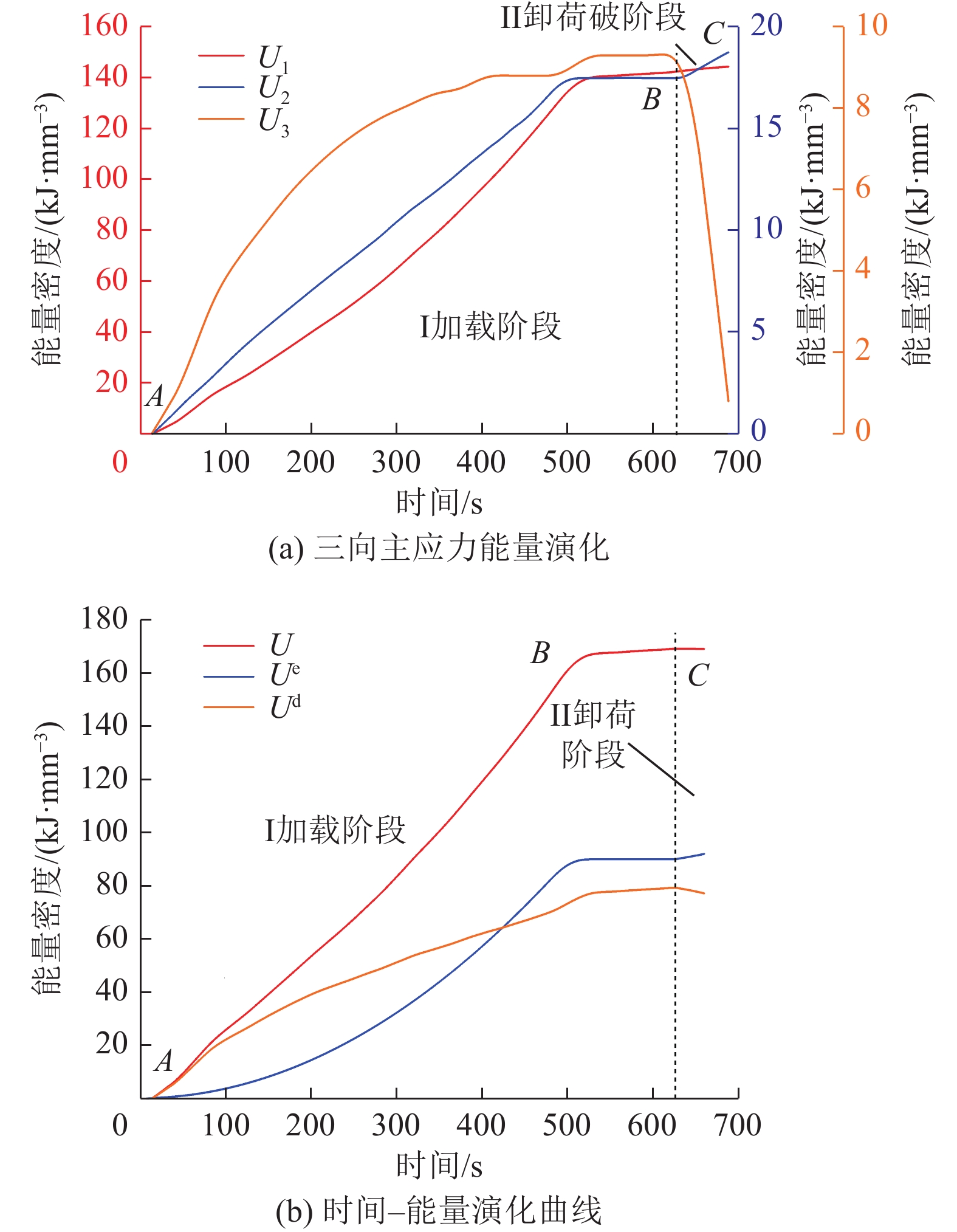

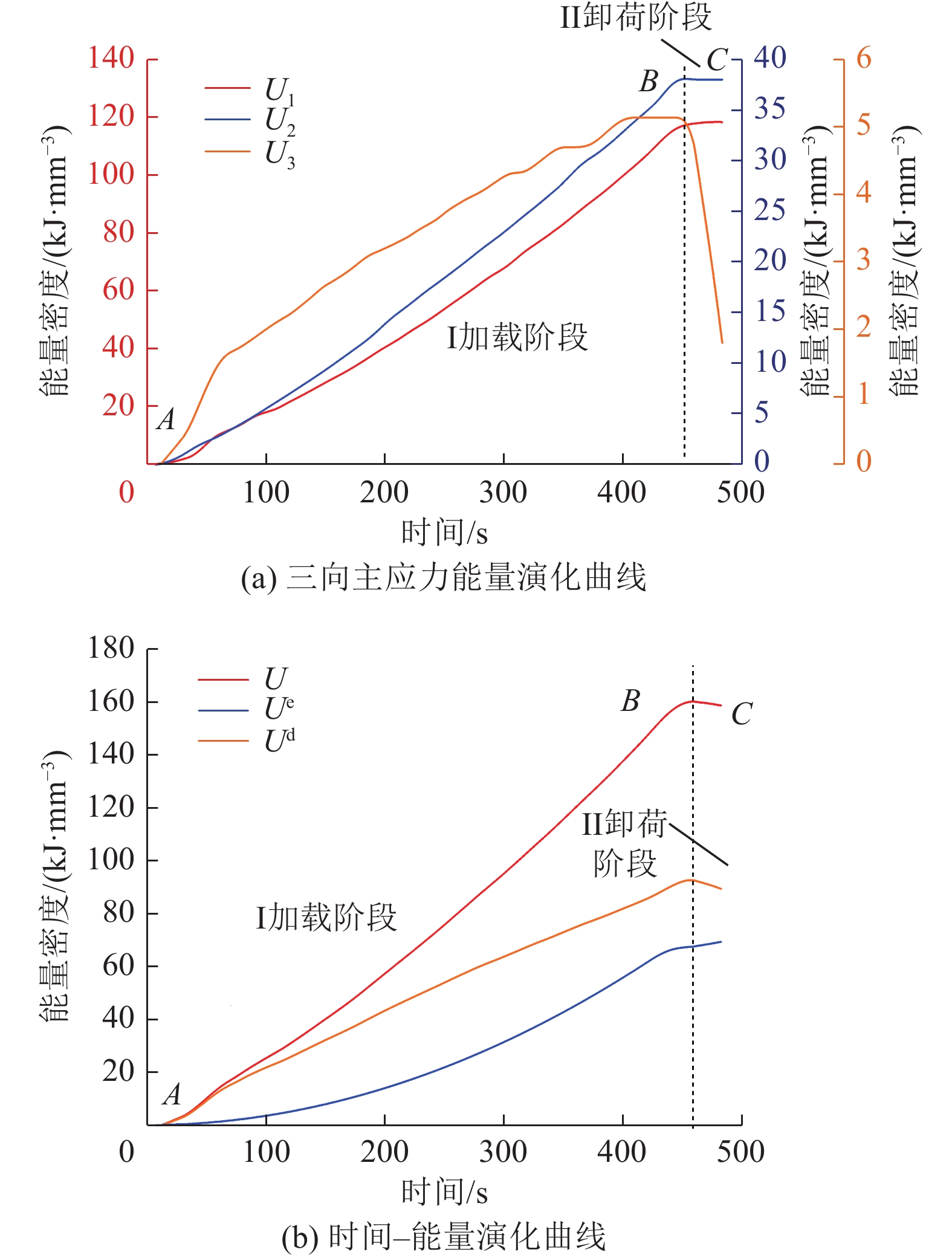

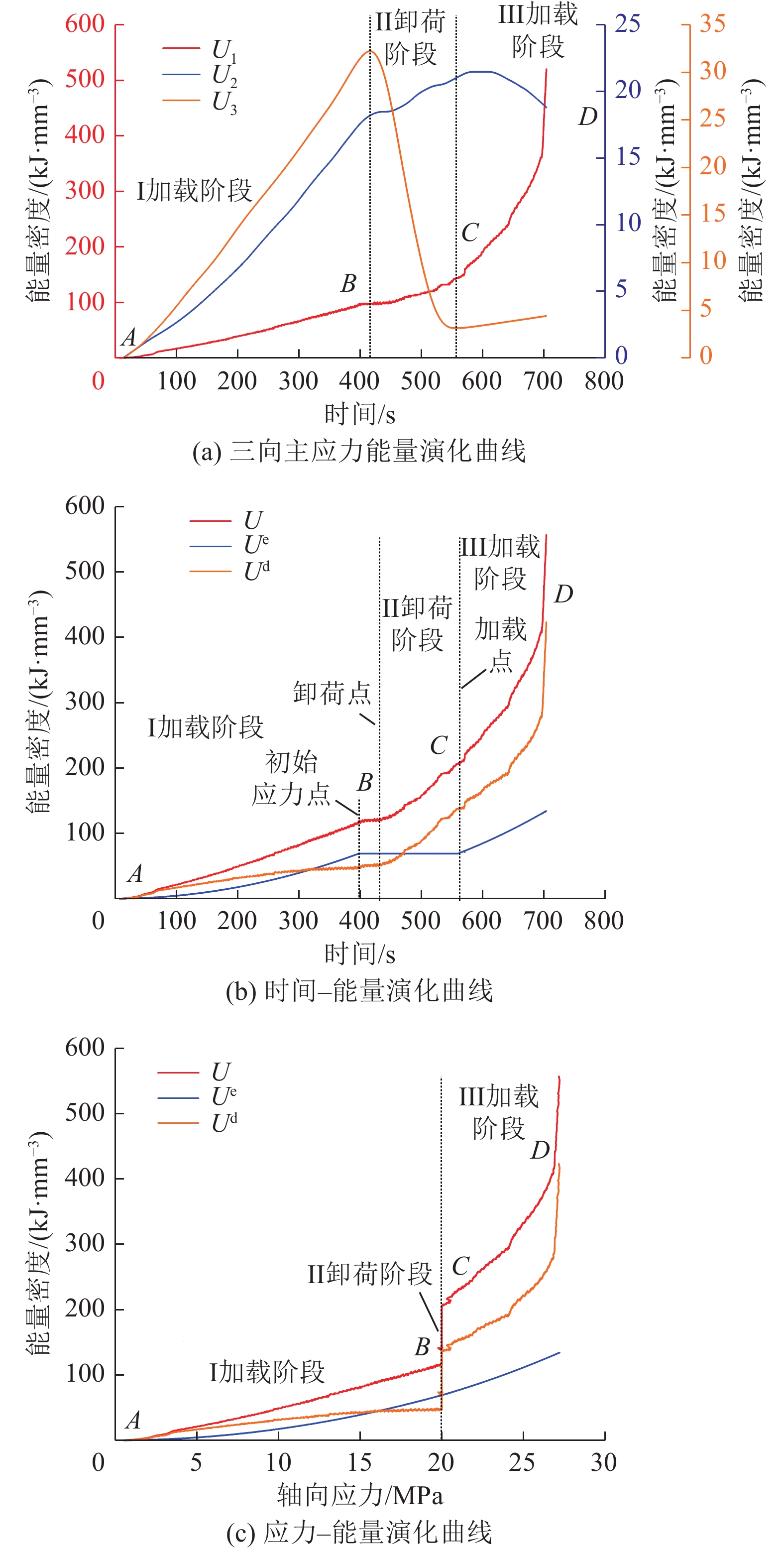

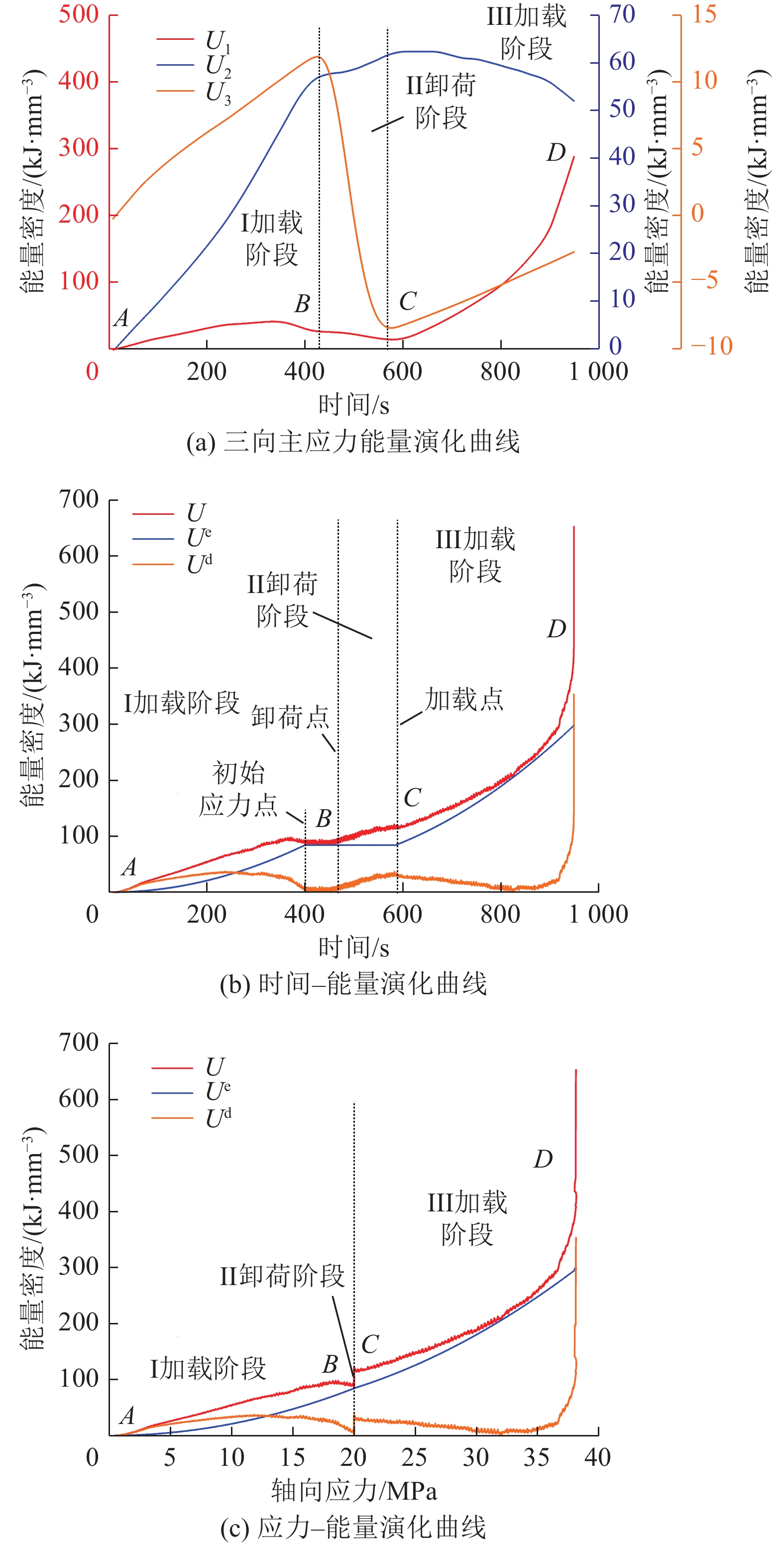

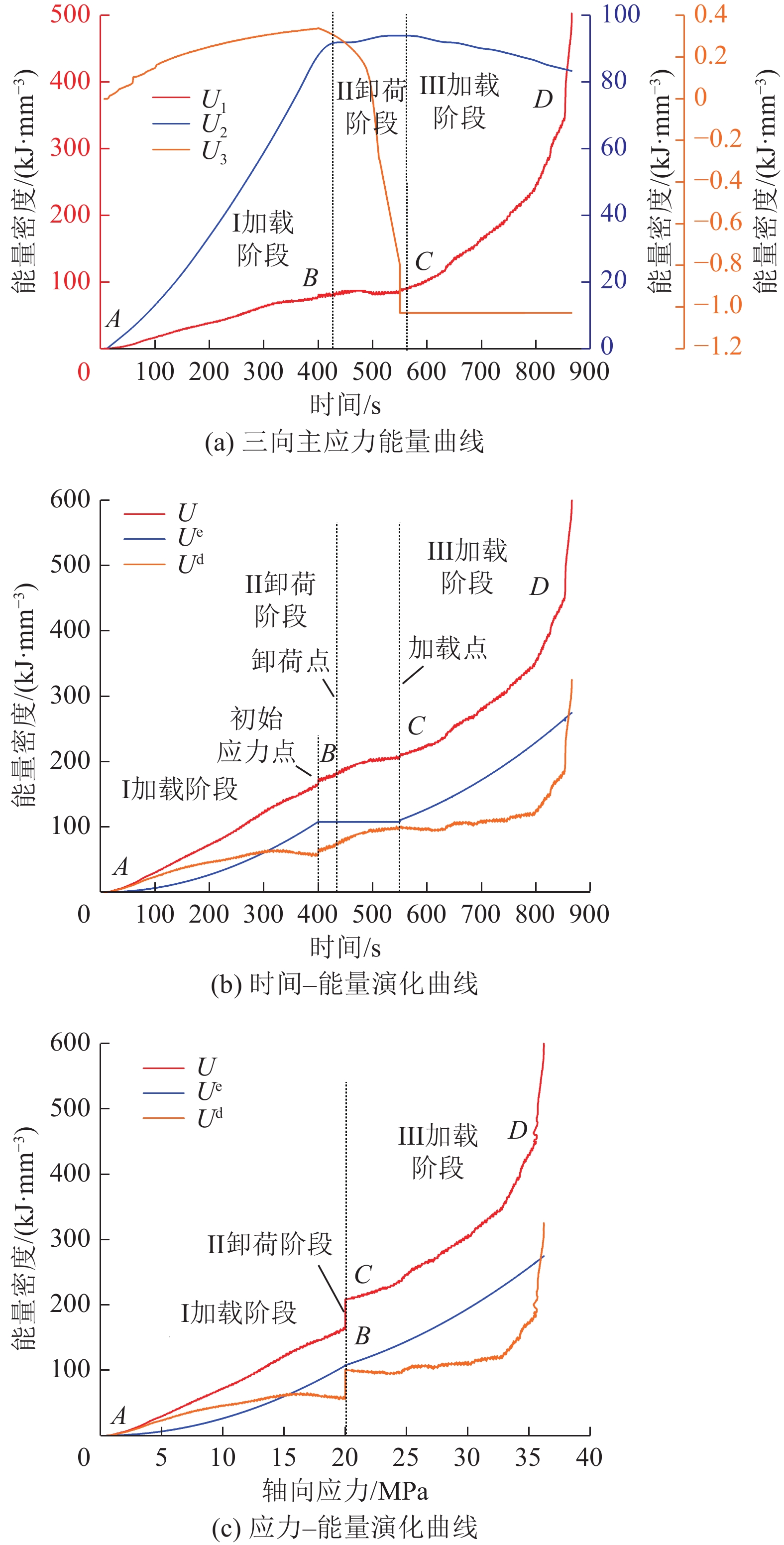

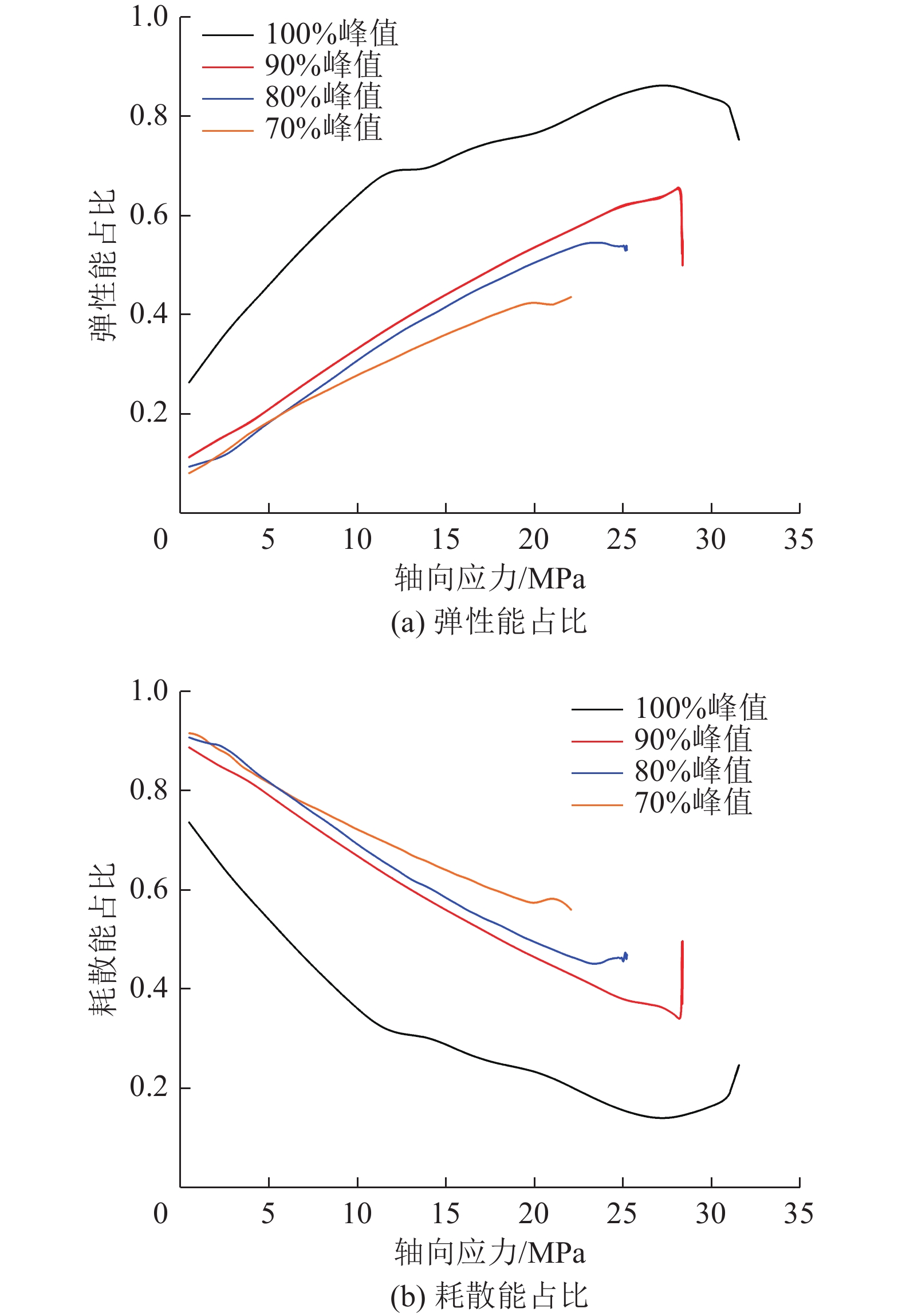

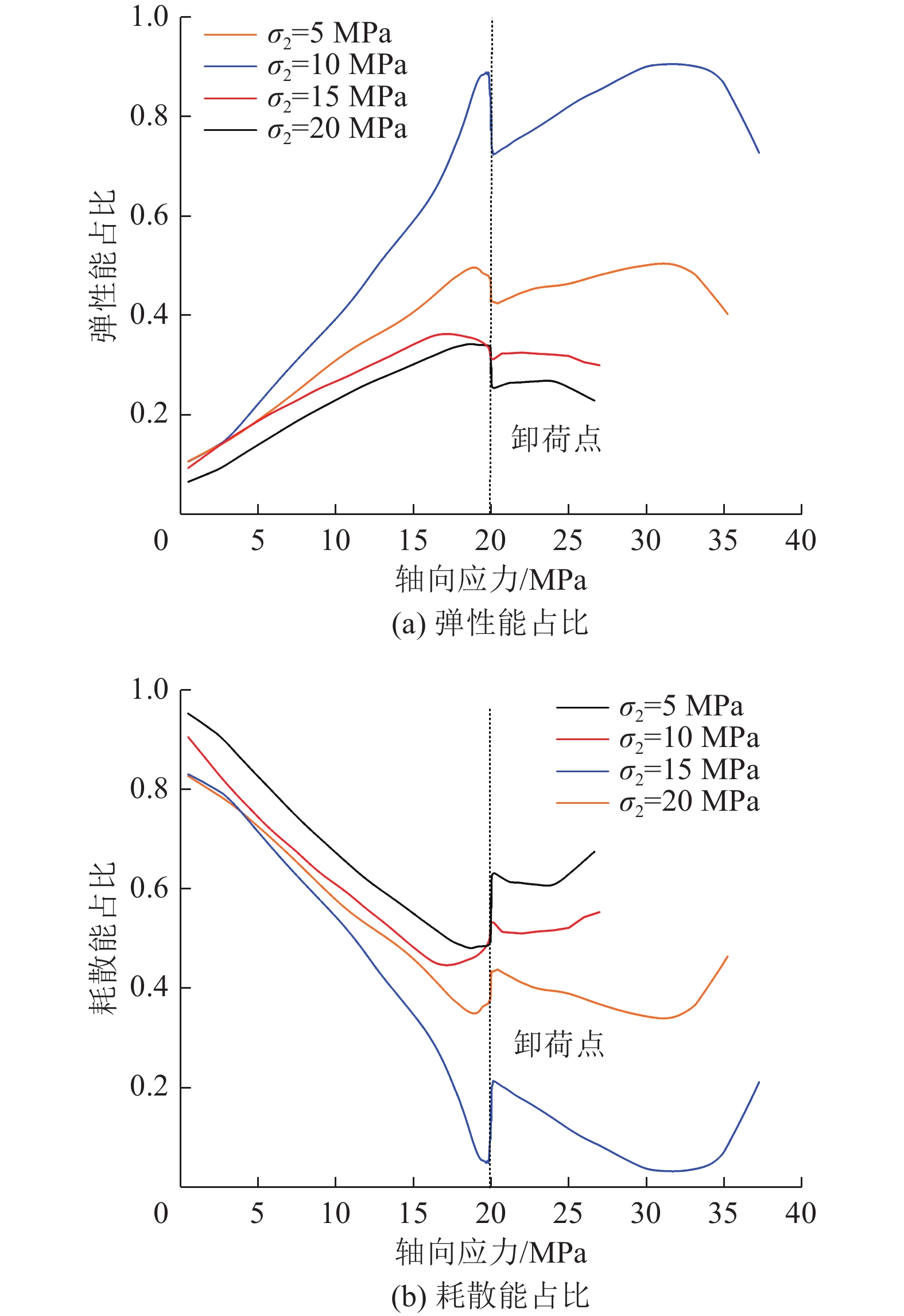

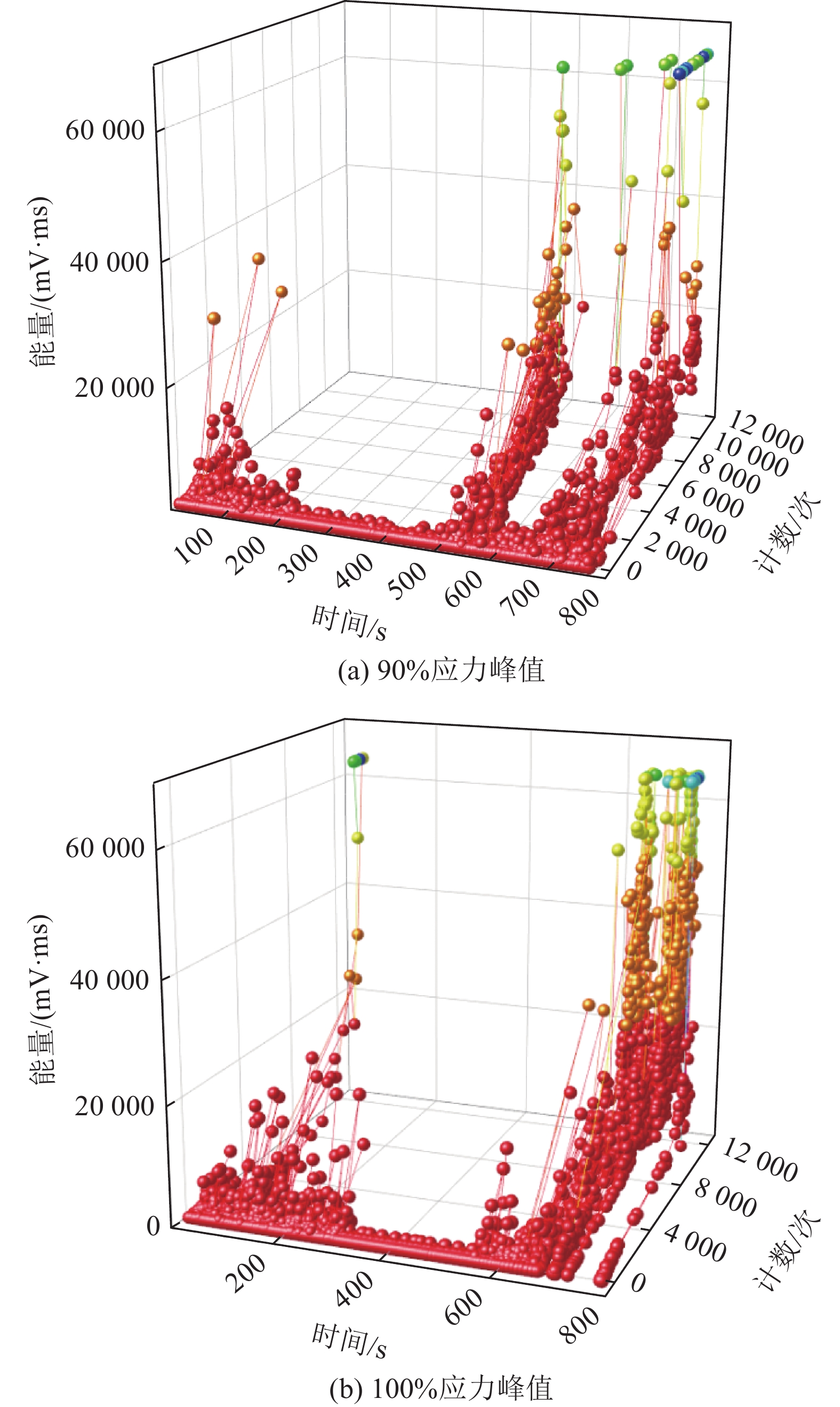

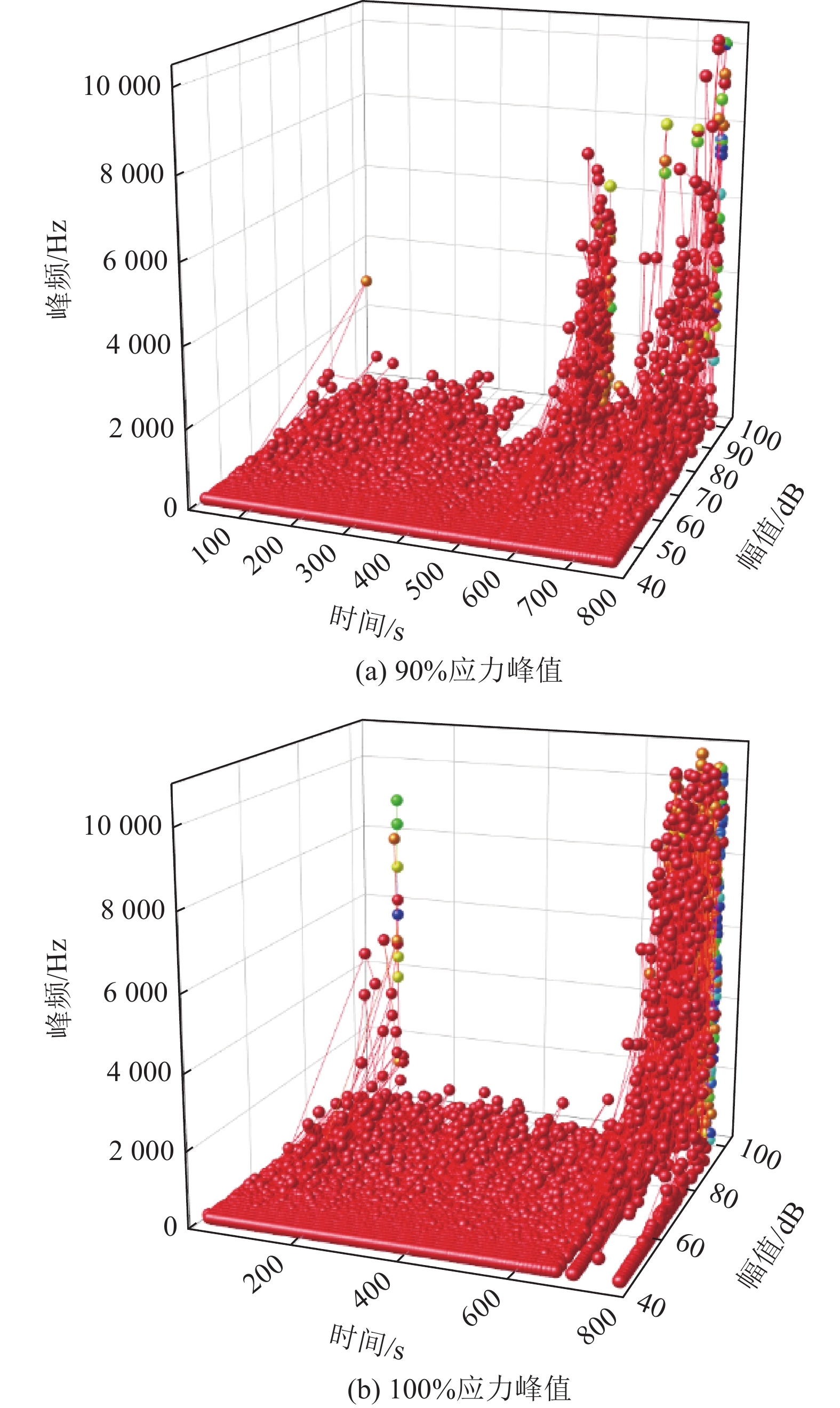

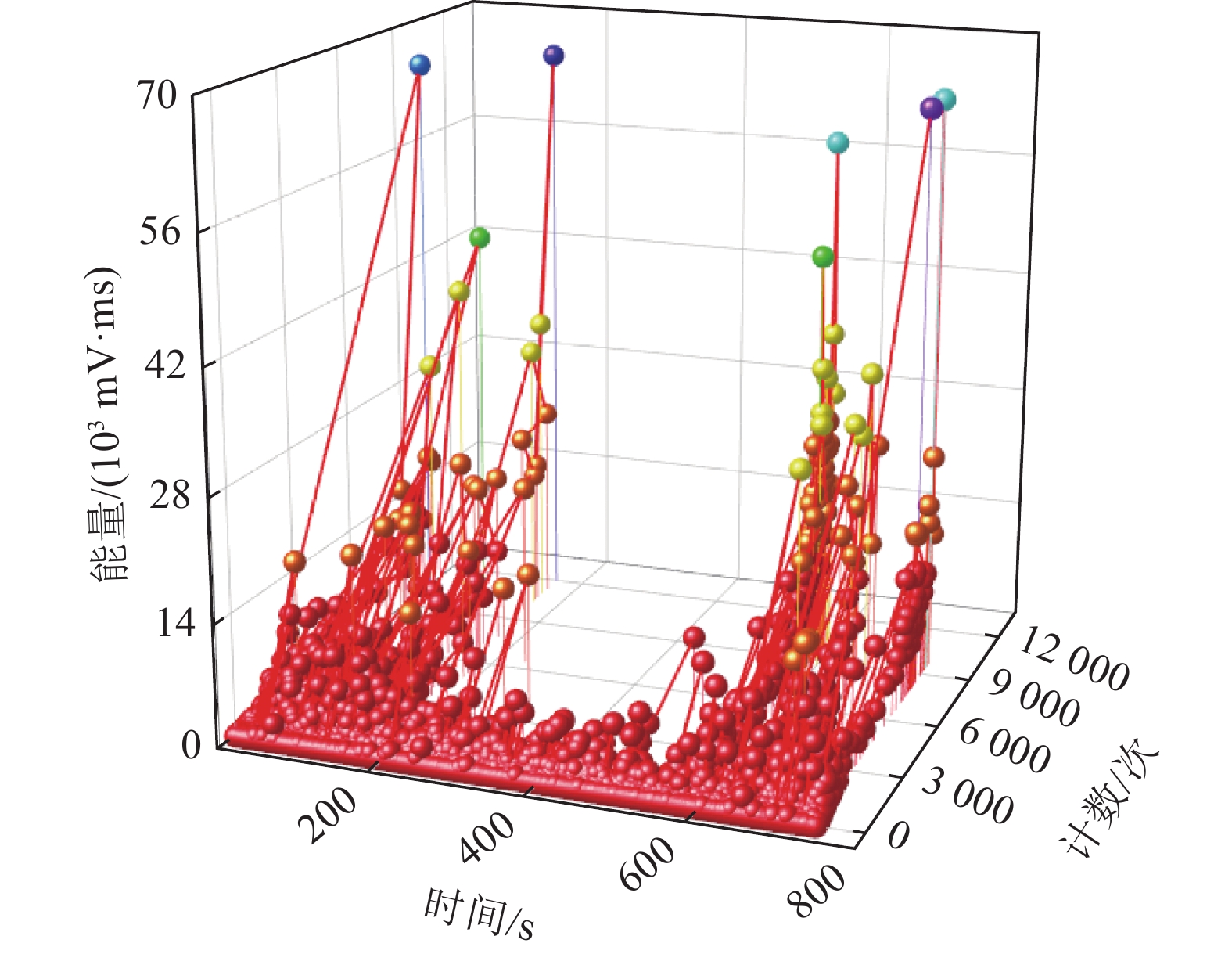

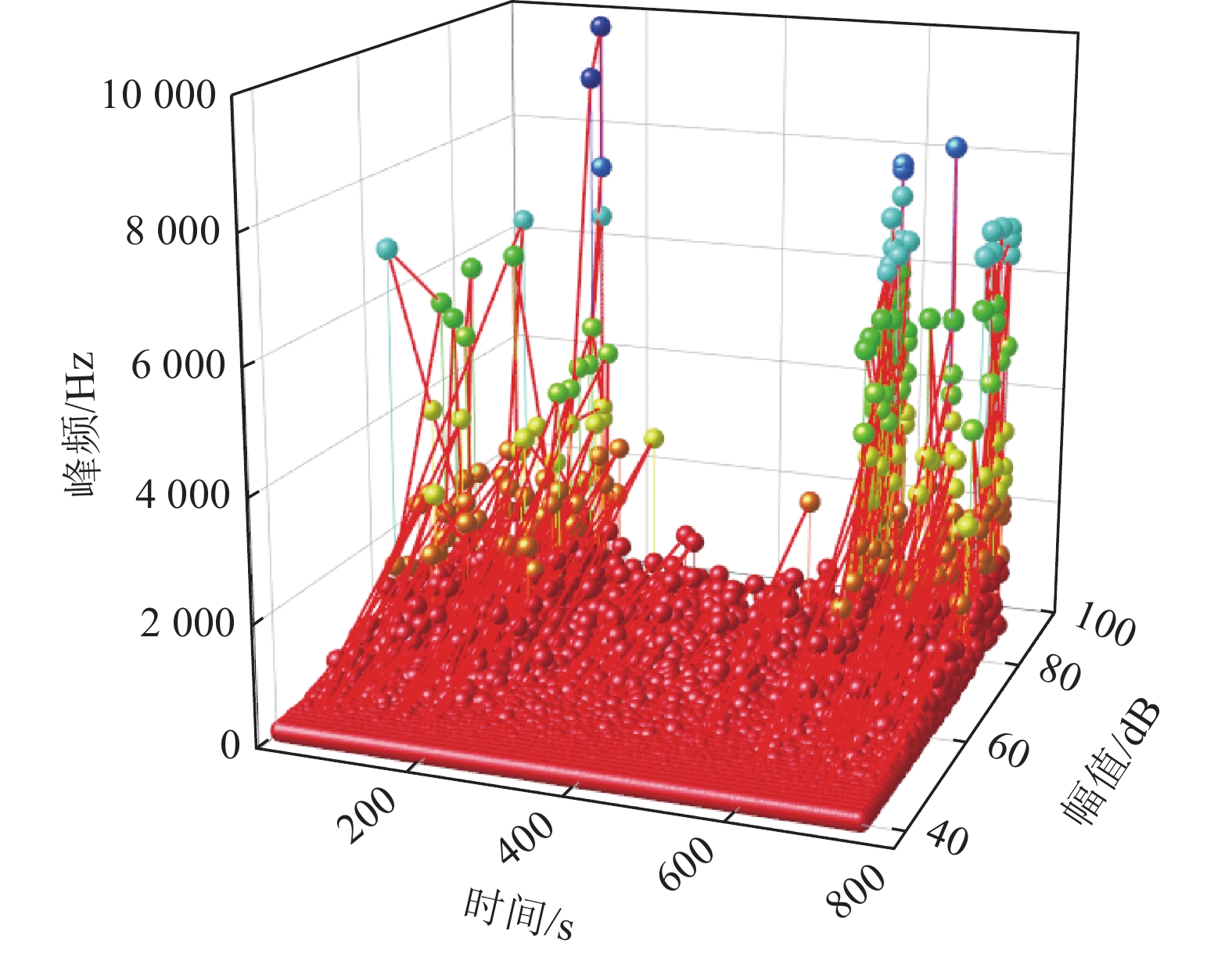

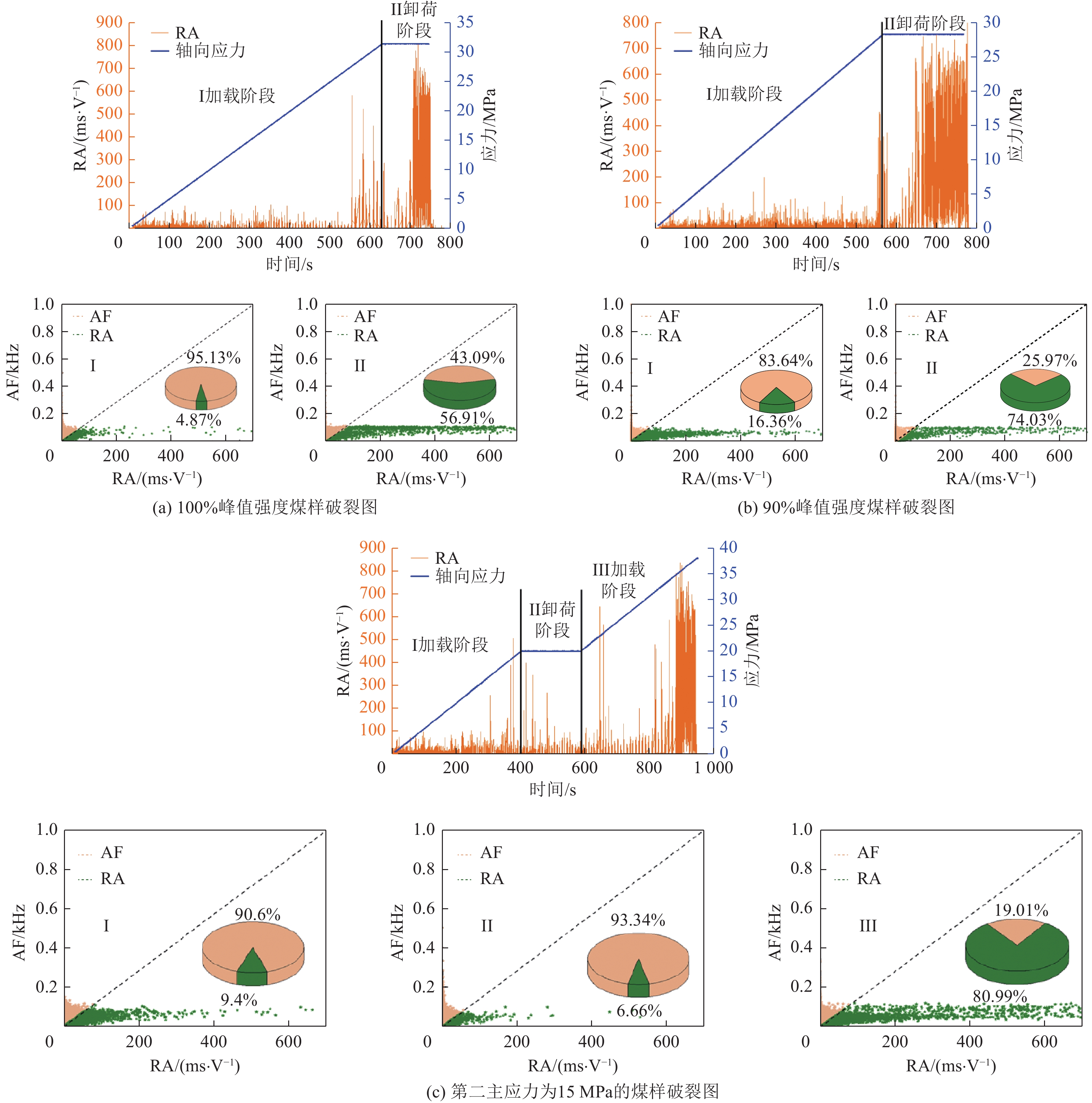

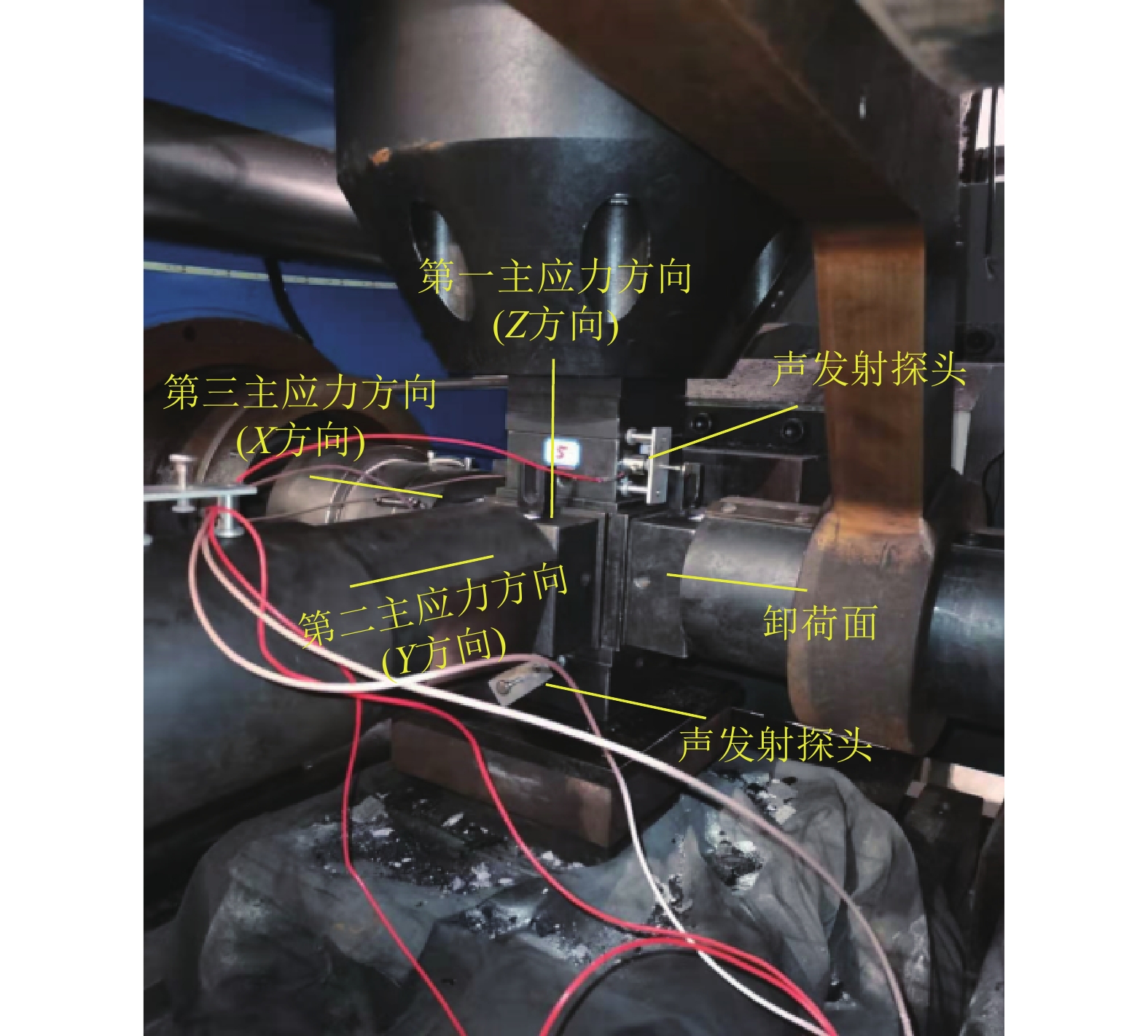

通过开展不同主应力条件下真三轴加卸载试验,研究不同加卸载路径下易弹射煤体的力学特性、破坏特征及能量演化规律,揭示开挖卸荷易弹射巷道围岩弹射机制。研究表明:易弹射煤样在高应力单面卸荷比加载破坏更剧烈,当轴压为峰值的90%时卸荷,易弹射煤样表面出现一条大剪切裂缝,轴向应变率高,其自身破坏程度大,弹射现象明显;当轴压为峰值的80%,70%时卸荷,煤样未发生整体宏观破坏,轴向应变率低,自身的破坏程度小,仅在临空面产生张拉裂纹,弹射现象不明显;随着第二主应力的增大,在一定范围内对易弹射煤样有补强的作用,易弹射煤样内部复合型裂纹先增加后减小,破坏形态由剪切破坏转变为张拉–剪切复合破坏,最后发展为劈裂破坏,弹射剧烈程度呈现出先增加后减小的现象;高应力卸荷破坏过程中,弹性能转化为耗散能瞬间释放,耗散能占比急剧增大,抛离母体的碎块携带能量弹射出去,临空面出现明显的交叉网格裂缝,弹射现象明显;高应力易弹射煤样卸荷后张拉–剪切裂纹迅速扩展贯通,发生张拉–剪切复合破坏,弹射现象显著;卸荷后,易弹射煤样出现张拉–剪切裂纹,RA急剧值增高,AF值持续降低,AE呈现高能、高计、高幅、高频特征。研究结果可为类似地下工程开挖围卸荷岩微冲击现象控制提供借鉴。

Abstract:In this paper, true triaxial loading and unloading tests under different principal stress conditions were conducted to study the mechanical properties, failure characteristics, and energy evolution laws of coal bodies that are prone to ejection under different loading and unloading paths, aiming to reveal the ejection mechanism of the surrounding rock of roadway that is prone to ejection after excavation and unloading. The results are as follows. Firstly, the damage of coal samples that are prone to ejection was more severe under high stress single-sided unloading than under loading; when the axial pressure is 90% of the peak value, a large shear crack appeared on the surface of the coal samples, the axial strain rate is high, its own damage degree is large, and the ejection phenomenon was obvious; when the axial pressure was 80% and 70% of the peak value, respectively, the coal samples did not undergo overall macroscopic damage, the axial strain rate is low, and the degree of damage is small, only generated tensile cracks on the free face, and the ejection phenomenon was not obvious. Secondly, the increase of the second principal stress had a reinforcing effect on coal samples that are prone to ejection within a certain range, the internal composite cracks of coal samples that are prone to ejection first increase and then decreased, and the failure mode changed from shear failure to tension-shear composite failure, and finally developed into splitting failure; the intensity of ejection first increased and then decreased. Thirdly, in the process of high stress unloading failure, elastic energy was converted into dissipated energy and released instantly, and the proportion of elastic energy increased sharply, causing the fragments being ejected from the mother body with energy; there were obvious cross mesh cracks in the free face, and the ejection phenomenon was obvious. Fourthly, for coal samples that are prone to ejection under high stress after unloading, the tension-shear cracks rapidly expanded and connected, resulting in tension-shear composite failure, and the ejection phenomenon was obvious; Fifth, tension-shear cracks appear in ejectable coal samples of after unloading, RA increased sharply and AF decreased continuously, AE showing the characteristics of high energy, high meter, high amplitude and high frequency. The study results can provide reference for the on trol of micro impact phenomena in unloading surrounding rock during excavation of similar underground engineering.

-

Keywords:

- coal ejection /

- principal stresses /

- unloading /

- energy /

- rock burst

-

-

表 1 初始应力值

Table 1 Initial stress value MPa

编号 $ {\sigma _{\text{1}}} $ $ {\sigma _{\text{2}}} $ $ {\sigma _{\text{3}}} $ TSX–1 20 10 5 TSX–2 100%$ {\sigma _{\mathrm{F}}} $ 10 5 TSX–3 90%$ {\sigma _{\mathrm{F}}} $ 10 5 TSX–4 80%$ {\sigma _{\mathrm{F}}} $ 10 5 TSX–5 70%$ {\sigma _{\mathrm{F}}} $ 10 5 TSX–6 20 5 5 TSX–7 20 15 5 TSX–8 20 20 5 表 2 高应力卸载力学参数

Table 2 High stress unloading mechanical parameters

试样编号 $ {\sigma _{\max }} $/MPa 弹性模量/GPa 应变率/s–1 TSX–2 31.5 1.30 0.052 TSX–3 28.35 2.32 0.045 TSX–4 25.2 2.56 0.026 TSX–5 22.06 2.56 0.020 表 3 不同第二主应力力学参数

Table 3 Mechanical parameters of different second principal stresses

试样编号 $ {\sigma _{\text{2}}} $/MPa $ {\sigma _{\max }} $/MPa E/GPa 破坏程度 TSX–6 5 30.4 1.88 剧烈 TSX–1 10 31.5 2.00 剧烈 TSX–7 15 38.1 2.94 非常剧烈 TSX–8 20 27.1 2.03 非常剧烈 表 4 高应力卸载下煤样能量值

Table 4 Energy value of coal sample under high stress unloading

kJ/m3 试样编号 $ U^{{\mathrm{e}}} $ $ U^{{\mathrm{d}}} $ $ U $ TSX–2 404.236 323.922 728.752 TSX–3 151.399 391.750 543.149 TSX–4 92.924 72.222 165.146 TSX–5 69.843 88.283 158.126 表 5 不同第2主应力加载能量值

Table 5 Different second principal stress loading energy values

kJ/m3 试样编号 $ {U^{\text{e}}} $ $ {U^{\text{d}}} $ $ U $ TSX–5 160.511 260.062 420.573 TSX–1 133.863 423.475 557.338 TSX–7 300.161 353.578 653.739 TSX–8 274.588 325.642 600.230 -

[1] 康红普,姜鹏飞,冯彦军,等. 煤矿巷道围岩卸压技术及应用[J]. 煤炭科学技术,2022,50(6):1−15. KANG Hongpu,JIANG Pengfei,FENG Yanjun,et al. Destressing technology for rock around coal mine roadways and its applications[J]. Coal Science and Technology,2022,50(6):1−15.

[2] 左建平,刘海雁,王军,等. 深部巷道主被动全空间协同控制技术及工程应用[J]. 煤炭科学技术,2023,51(7):255−267. doi: 10.13199/j.cnki.cst.2023-0360 ZUO Jianping,LIU Haiyan,WANG Jun,et al. Active and passive full-space collaborative control technology and engineering application in deep roadways[J]. Coal Science and Technology,2023,51(7):255−267. doi: 10.13199/j.cnki.cst.2023-0360

[3] 尤明庆,华安增. 岩石试样破坏过程的能量分析[J]. 岩石力学与工程学报,2002,21(6):778−781. YOU Mingqing,HUA Anzeng. Energy analysis of failure process of rock specimens[J]. Chinese Journal of Rock Mechanics and Engineering,2002,21(6):778−781.

[4] 齐庆新,李海涛,郑伟钰,等. 煤岩弹性变形能的表征物理模型及实测方法[J]. 煤炭科学技术,2022,50(1):70−77. QI Qingxin,LI Haitao,ZHENG Weiyu,et al. Physical model and measurement method for elastic deformation energy characterization of coal and rock[J]. Coal Science and Technology,2022,50(1):70−77.

[5] 苏承东,张振华. 大理岩三轴压缩的塑性变形与能量特征分析[J]. 岩石力学与工程学报,2008,27(2):273−280. doi: 10.3321/j.issn:1000-6915.2008.02.007 SU Chengdong,ZHANG Zhenhua. Analysis of plastic deformation and energy property of marble under pseudo-triaxial compression[J]. Chinese Journal of Rock Mechanics and Engineering,2008,27(2):273−280. doi: 10.3321/j.issn:1000-6915.2008.02.007

[6] 钱七虎. 岩爆、冲击地压的定义、机制、分类及其定量预测模型[J]. 岩土力学,2014,35(1):1−6. QIAN Qihu. Definition,mechanism,classification and quantitative forecast model for rockburst and pressure bump[J]. Rock and Soil Mechanics,2014,35(1):1−6.

[7] 司雪峰,宫凤强. 深部高应力圆形隧洞内部卸荷条件下岩爆模拟试验和强度弱化效应研究[J]. 岩石力学与工程学报,2021,40(2):276−289. SI Xuefeng,GONG Fengqiang. Rockburst simulation tests and strength-weakening effect of circular tunnels under deep high stresses and internal unloading conditions[J]. Chinese Journal of Rock Mechanics and Engineering,2021,40(2):276−289.

[8] SU G S,GAN W,ZHAI S. B,et al . Acoustic emission precursors of static and dynamic instability for coarse-grained hard rock[J]. Journal of Central South University,2020,27(10):2883−2898. doi: 10.1007/s11771-020-4516-6

[9] 宫凤强,潘俊锋,江权. 岩爆和冲击地压的差异解析及深部工程地质灾害关键机理问题[J]. 工程地质学报,2021,29(4):933−961. GONG Fengqiang,PAN Junfeng,JIANG Quan. The difference analysis of rock burst and coal burst and key mechanisms of deep engineering geological hazards[J]. Journal of Engineering Geoogy,2021,29(4):933−961.

[10] 朱建波,马斌文,谢和平,等. 煤矿矿震与冲击地压的区别与联系及矿震扰动诱冲初探[J]. 煤炭学报,2022,47(9):3396−3409. ZHU Jianbo,MA Binwen,XIE Heping,et al. Differences and connections between mining seismicity and coal bursts in coal mines and preliminary study on coal bursts induced by mining seismicity[J]. Journal of China Coal Society,2022,47(9):3396−3409.

[11] 宫凤强,赵英杰,王云亮,等. 煤的冲击倾向性研究进展及冲击地压“人–煤–环”三要素机理[J]. 煤炭学报,2022,47(5):1974−2010. GONG Fengqiang,ZHAO Yingjie,WANG Yunliang,et al. Resarch progress of coal bursting liability indices and coal burst “Human-Coal-Environment” three elements mechanism[J]. Journal of China Coal Society,2022,47(5):1974−2010.

[12] 顾金才,范俊奇,孔福利,等. 抛掷型岩爆机制与模拟试验技术[J]. 岩石力学与工程学报,2014,33(6):1081−1089. GU Jincai,FAN Junqi,KONG Fuli,et al. Mechanism of ejective rockburst and model testing technology[J]. Chinese Journal of Rock Mechanics and Engineering,2014,33(6):1081−1089.

[13] 何满潮,李杰宇,任富强,等. 不同层理倾角砂岩单向双面卸荷岩爆弹射速度实验研究[J]. 岩石力学与工程学报,2021,40(3):433−447. HE Manchao,LI Jieyu,REN Fuqiang,et al. Experimental investigation on rockburst ejection velocity of unidirectional double-face unloading of sandstone with different bedding angles[J]. Chinese Journal of Rock Mechanics and Engineering,2021,40(3):433−447.

[14] 苏国韶,蒋剑青,冯夏庭,等. 岩爆弹射破坏过程的试验研究[J]. 岩石力学与工程学报,2016,35(10):1990−1999. SU Guoshao,JIANG Jianqing,FENG Xiating,et al. Experimental study of ejection process in rockburst[J]. Chinese Journal of Rock Mechanics and Engineering,2016,35(10):1990−1999.

[15] 左宇军,李夕兵,张义平,等. 动–静组合加载诱发岩爆时岩块弹射速度的计算[J]. 中南大学学报(自然科学版),2006,37(4):815−819. doi: 10.3969/j.issn.1672-7207.2006.04.035 ZUO Yujun,LI Xibing,ZHANG Yiping,et al. Calculation of ejection velocity of rock in rockburst caused by static dynamic coupling loading[J]. Journal of Central South University(Science and Technology),2006,37(4):815−819. doi: 10.3969/j.issn.1672-7207.2006.04.035

[16] 宫伟力,汪虎,何满潮,等. 深部开采中岩爆岩块弹射速度的理论与实验[J]. 煤炭学报,2015,40(10):2269−2278. Gong Weili,Wang Hu,He Manchao,et al. Theoretical and experimental study on rock block ejection velocity for rock burst found in deep mining[J]. Journal of China Coal Society,2015,40(10):2269−2278.

[17] 苏国韶,胡李华,冯夏庭,等. 低频周期扰动荷载与静载联合作用下岩爆过程的真三轴试验研究[J]. 岩石力学与工程学报,2016,35(7):1309−1322. SU Guoshao,HU Lihua,FENG Xiating,et al. True triaxial experimental study of rockburst process under low frequency cyclic disturbance load combined with static load[J]. Chinese Journal of Rock Mechanics and Engineering,2016,35(7):1309−1322.

[18] 何满潮,任富强,宫伟力,等. 基于双目立体视觉技术的岩爆碎屑弹射速度理论修正模型[J]. 岩石力学与工程学报,2017,36(10):2341−2349. HE Manchao,REN Fuqiang,GONG Weili,et al. Modified model for ejection velocity of rock burst fragments based on binocular stereovision technology[J]. Chinese Journal of Rock Mechanics and Engineering,2017,36(10):2341−2349.

[19] AKDAG S,KARAKUS M,TAHERI A,et al. Effects of thermal damage on strain burst mechanism for brittle rocks under true-triaxial loading conditions[J]. Rock Mechanics and Rock Engineering,2018,51(6):1657−1682. doi: 10.1007/s00603-018-1415-3

[20] 赵恩来. 动静载与温度耦合作用下煤岩动力学特征及损伤机理研究[D]. 徐州:中国矿业大学,2022:126–127. ZHAO Enlai. Study on Dynamic Characteristics and Damage Mechanism of Coal and Rock under Coupling Action of Dynamic and Static Load and Temperature[D]. Xuzhou:China University of Mining and Technology,2022.

[21] 冯龙飞,王皓,王晓东,等. 煤冲击破坏的微破裂演化特征及前兆识别[J]. 岩石力学与工程学报,2022,41(7):1440−1452. FENG Longfei,WANG Hao,WANG Xiaodong,et al. Microfracture evolution characteristics and precursor identification of coal impact failure[J]. Chinese Journal of Rock Mechanics and Engineering,2022,41(7):1440−1452.

[22] 华安增. 地下工程周围岩体能量分析[J]. 岩石力学与工程学报,2003,22(7):1054−1059. HUA Anzeng. Energy analysis of surrounding rocks in underground engineering[J]. Chinese Journal of Rock Mechanics and Engineering,2003,22(7):1054−1059.

[23] 谢和平,鞠杨,黎立云. 基于能量耗散与释放原理的岩石强度与整体破坏准则[J]. 岩石力学与工程学报,2005,24(17):3003−3010. XIE Heping,JU Yang,LI Liyun. Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles[J]. Chinese Journal of Rock Mechanics and Engineering,2005,24(17):3003−3010.

[24] 孙振武,代进,杨春苗,等. 矿山井巷和采场冲击地压危险性的弹性能判据[J]. 煤炭学报,2007,32(8):794−798. SUN Zhenwu,DAI Jin,YANG Chunmiao,et al. Elastic energy criterion of rock burst in roadway and coalface of mine[J]. Jounal of China Coal Society,2007,32(8):794−798.

[25] 潘俊锋,宁宇,毛德兵,等. 煤矿开采冲击地压启动理论[J]. 岩石力学与工程学报,2012,31(3):586−596. PAN Junfeng,NING Yu,MAO Debing,et al. Theory of rockburst start-up during coal mining[J]. Chinese Journal of Rock Mechanics and Engineering,2012,31(3):586−596.

[26] 郭超. 煤岩能量特征与冲击地压强度关系研究[D]. 阜新:辽宁工程技术大学,2017:35–63. GUO Chao. Research on relationship between the energy characteristics of coal-rock mass and intensity of rockburst[D]. Fuxin Liaoning Technical University,2017:35–63.

[27] 徐婕. 煤矿深部砂岩卸荷特性及岩爆预测方法研究 [D]. 武汉:武汉大学,2016:27–42. XU Jie. Study on characteristics of deep-burred sandstone in the coal mine under loading and unloading conditions and rockburst prediction methods[D]. Wuhan:Wuhan University,2016:27–42.

[28] 徐鼎平,郭广涛,夏跃林,等. 高应力强卸荷下双江口花岗岩岩爆中间主应力效应宏细观试验研究[J]. 岩土力学,2021,42(9):1−12. XU Dingping,GUO Guangtao,XIA Yuelin,et al. Macro–meso experimental study on the intermediate principal stress effect on the rockburst of Shuangjiangkou granite under high stress and strong unloading[J]. Rock and Soil Mechanics,2021,42(9):1−12.

[29] 郭延华,姜福兴,张常光. 高地应力下圆形巷道临界冲击地压解析解[J]. 工程力学,2011,28(2):118−122. GUO Yanhua,JIANG Fuxing,ZHANG Changguang. Analytical solution for critical rockburst of a circular chamber subjected to high in-situ stress[J]. Engineering Mechanics,2011,28(2):118−122.

[30] 李文帅,王连国,陆银龙,等. 真三轴条件下砂岩强度、变形及破坏特征试验研究[J]. 采矿与安全工程学报,2019,36(1):191−197. LI Wenshuai,WANG Lianguo,LU Yinlong,et al. Experimental investigation on the strength,deformation and failure characteristics of sandstone under true triaxial compression[J]. Journal of Mining and Safety Engineering,2019,36(1):191−197.

[31] 向天兵,冯夏庭,陈炳瑞,等. 开挖与支护应力路径下硬岩破坏过程的真三轴与声发射试验研究[J]. 岩土力学,2008,29(S1):500−506. XIANG Tianbing,FENG Xiating,CHEN Bingrui,et al. True triaxial and acoustic emission experimental study of failure process of hard rock under excavating and supporting stress paths[J]. Rock and Soil Mechanics,2008,29(S1):500−506.

[32] 刘刚,肖福坤,秦涛. 小尺寸效应下岩石力学特性及声发射规律[J]. 岩石力学与工程学报,2018,37(S2):3905−3917. LIU Gang,XIAO Fukun,QIN Tao. Rock mechanics characteristics and acoustic emission rule under small-size effect[J]. Chinese Journal of Rock Mechanics and Engineering,2018,37(S2):3905−3917.

[33] 彭琦,张茹,谢和平,等. 基于AE时间序列的岩爆预测模型[J]. 岩土力学,2009,30(5):1436−1440. PENG Qi,ZHANG Ru,XIE Heping,et al. Prediction model for rockburst based on acoustic emission time series[J]. Rock and Soil Mechanics,2009,30(5):1436−1440.

[34] LI X B,FENG F,LI D Y,et al. Failure characteristics of granite infuenced by sample height-to-width ratios and intermediate principal stress under true-triaxial unloading conditions[J]. Rock Mechanics and Rock Engineering,2018,51(5):1321−1345. doi: 10.1007/s00603-018-1414-4

[35] MENG Q B,ZHANG M W,ZHANG Z Z,et al. Experimental research on rock energy evolution under uniaxial cyclic loading and unloading compression[J]. Geotechnical Testing Journal,2017,41(4):717−729.

[36] MENG Q B,ZHANG M W,HAN L J,et al. Effects of acoustic emission and energy evolution of rock specimens under the uniaxial cyclic loading and unloading compression[J]. Rock Mechanics and Rock Engineering,2016,49(10):3873−3886. doi: 10.1007/s00603-016-1077-y

[37] 何满潮,赵菲,杜帅,等. 不同卸载速率下岩爆破坏特征试验分析[J]. 岩土力学,2014,35(10):2737−2747,2793. HE Manchao,ZHAO Fei,DU Shuai,et al. Rockburst characteristics based on experimental tests under different unloading rates[J]. Rock and Soil Mechanics,2014,35(10):2737−2747,2793.

[38] 吴顺川,甘一雄,任义,等. 基于RA与AF值的声发射指标在隧道监测中的可行性[J]. 工程科学学报,2020,42(6):723−730. WU Shunchuan,GAN Yixiong,REN Yi,et al. Feasibility research of AE monitoring index in tunnel based on RA and AF[J]. Chinese Journal of Engineering,2020,42(6):723−730.

[39] 姜耀东,潘一山,姜福兴,等. 我国煤炭开采中的冲击地压机理和防治[J]. 煤炭学报,2014,39(2):205−213. JIANG Yaodong,PAN Yishan,JIANG Fuxing,et al. State of the art review on mechanism and prevention of coal bumps in China[J]. Journal of China Coal Society,2014,39(2):205−213.

[40] 齐庆新,潘一山,李海涛,等. 煤矿深部开采煤岩动力灾害防控理论基础与关键技术[J]. 煤炭学报,2020,45(5):1567−1584. QI Qingxin,PAN Yishan,LI Haitao,et al. Theoretical basis and key technology of prevention and control of coal-rock dynamic disasters in deep coal mining[J]. Journal of China Coal Society,2020,45(5):1567−1584.

[41] 许文松,赵光明,孟祥瑞,等. 大理岩真三轴单面卸荷条件下加卸载试验研究[J]. 西南交通大学学报,2019,54(3):526−534. doi: 10.3969/j.issn.0258-2724.20180542 XU Wensong,ZHAO Guangming,MENG Xiangrui,et al. Test study on true-triaxial loading and unloading for marble with unloaded single face[J]. Journal of Southwest Jiaotong University,2019,54(3):526−534. doi: 10.3969/j.issn.0258-2724.20180542

[42] 薛东杰,周宏伟,钟江城,等. 采动岩体能量释放及灾变机制研究[J]. 岩石力学与工程学报,2014,33(S2):3865−3872. XUE Dongjie,ZHOU Hongwei,ZHONG Jangcheng,et al. Mining-induced release of energy from rock and mechanism on catastrophic failure[J]. Chinese Journal of Rock Mechanics and Engineering,2014,33(S2):3865−3872.

下载:

下载: