Research on wind temperature prediction of tunneling working site based on PSO−SVR

-

摘要:

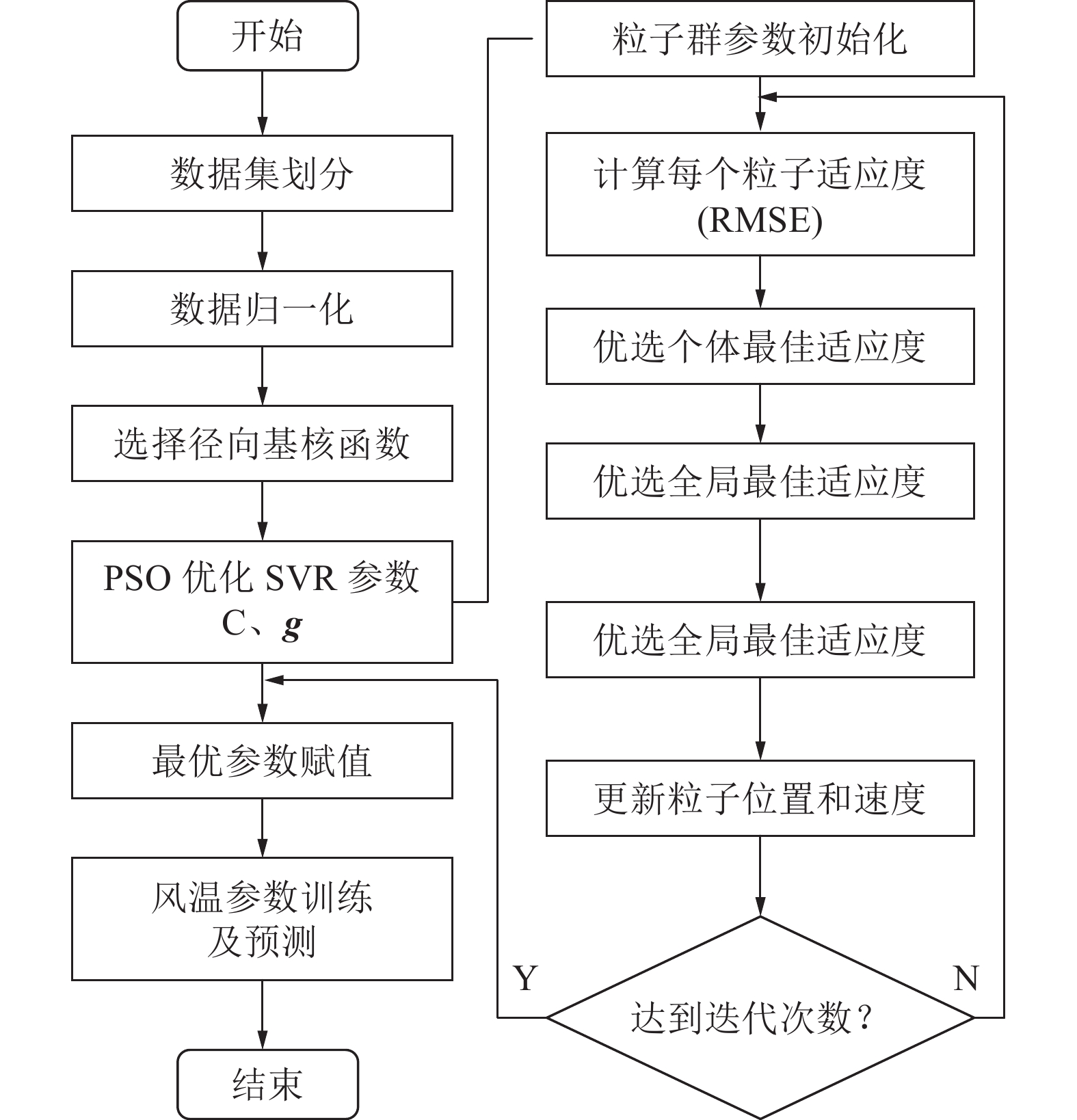

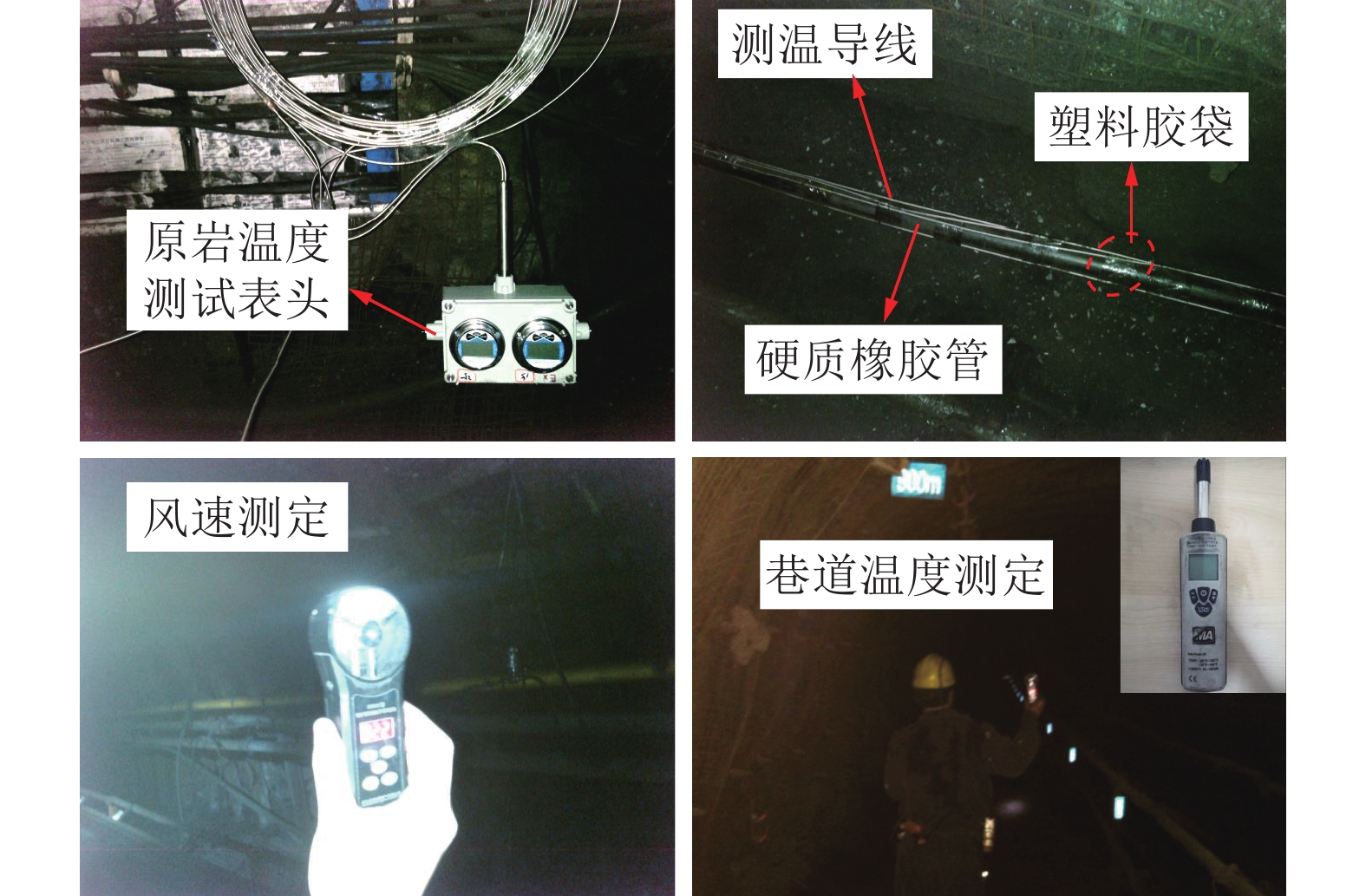

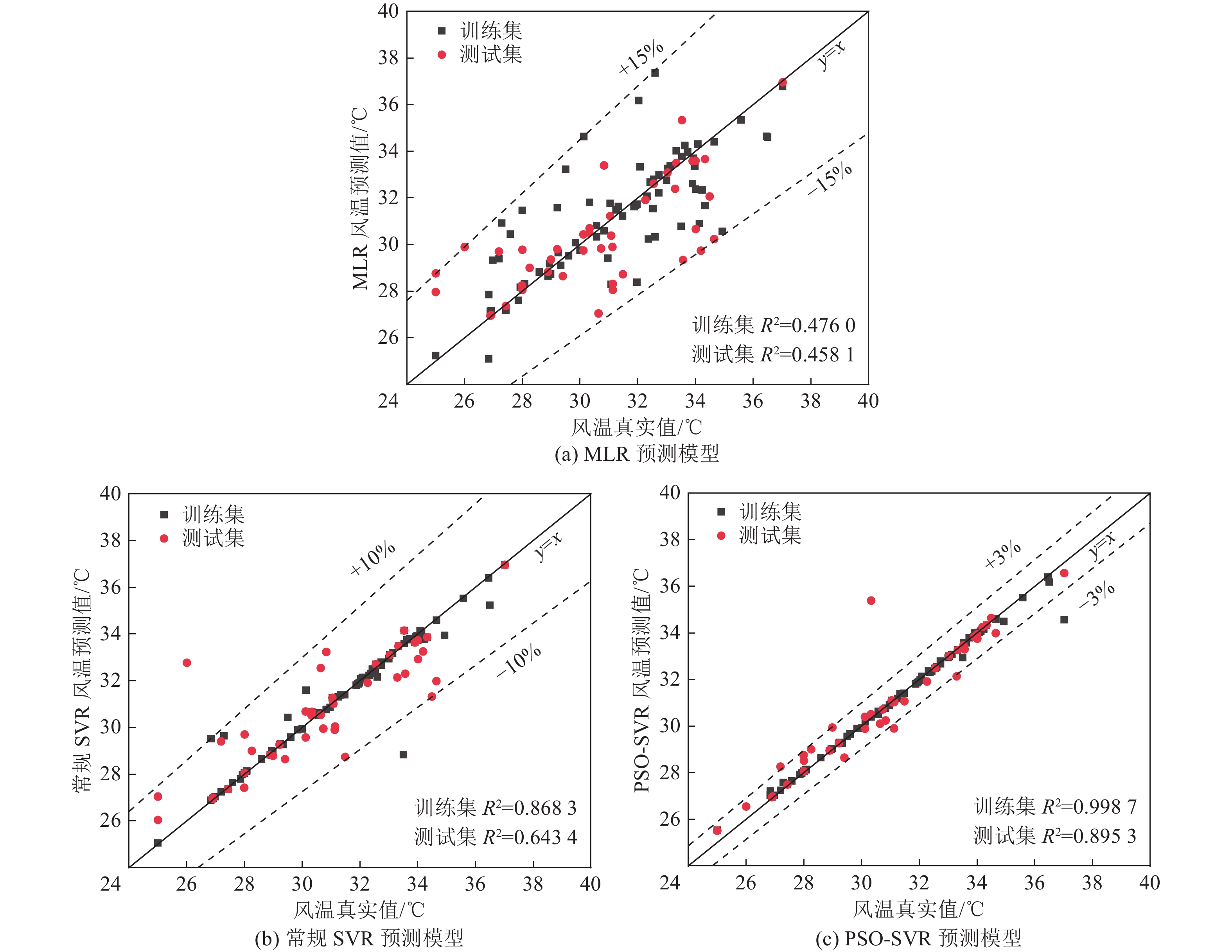

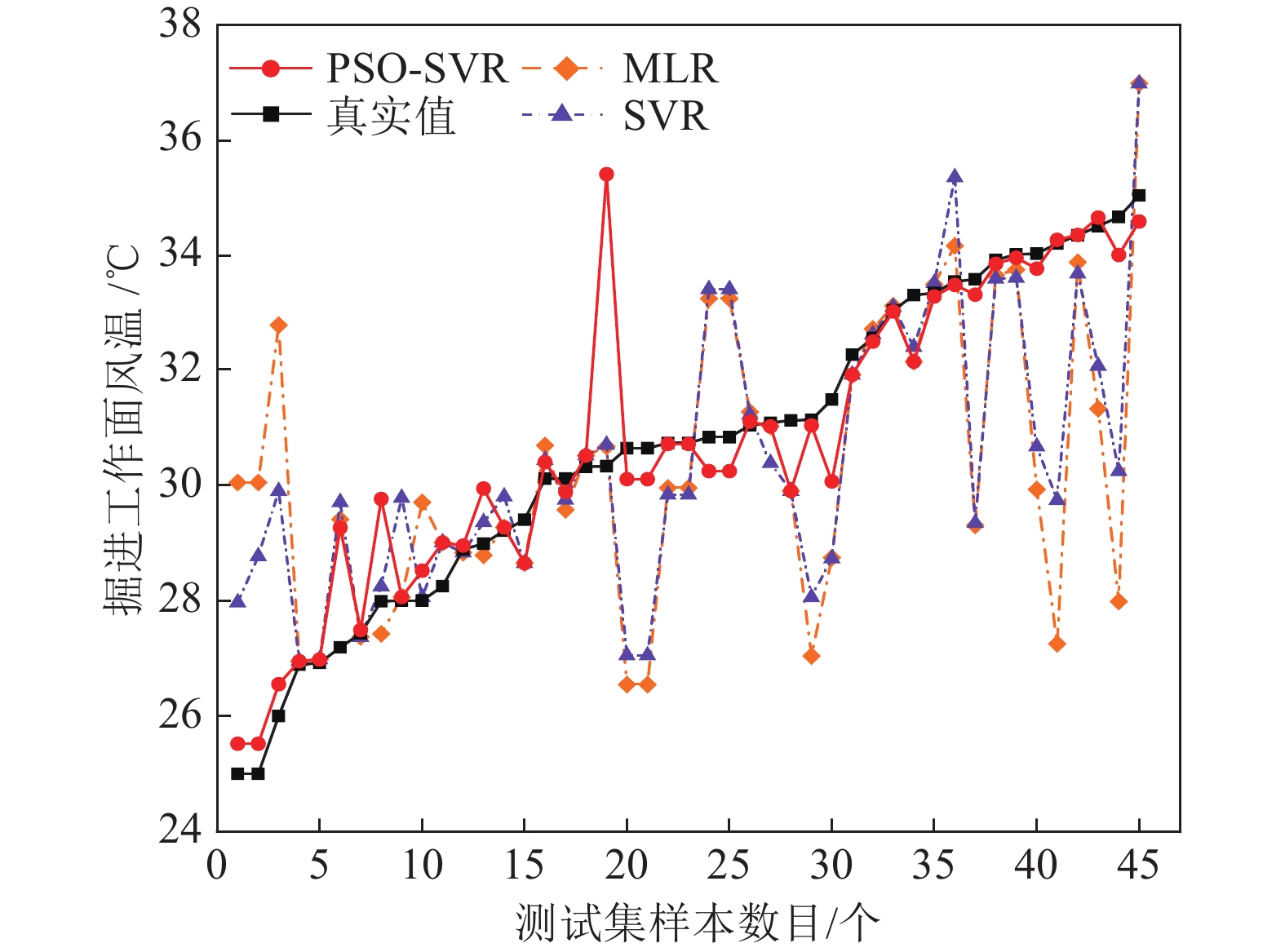

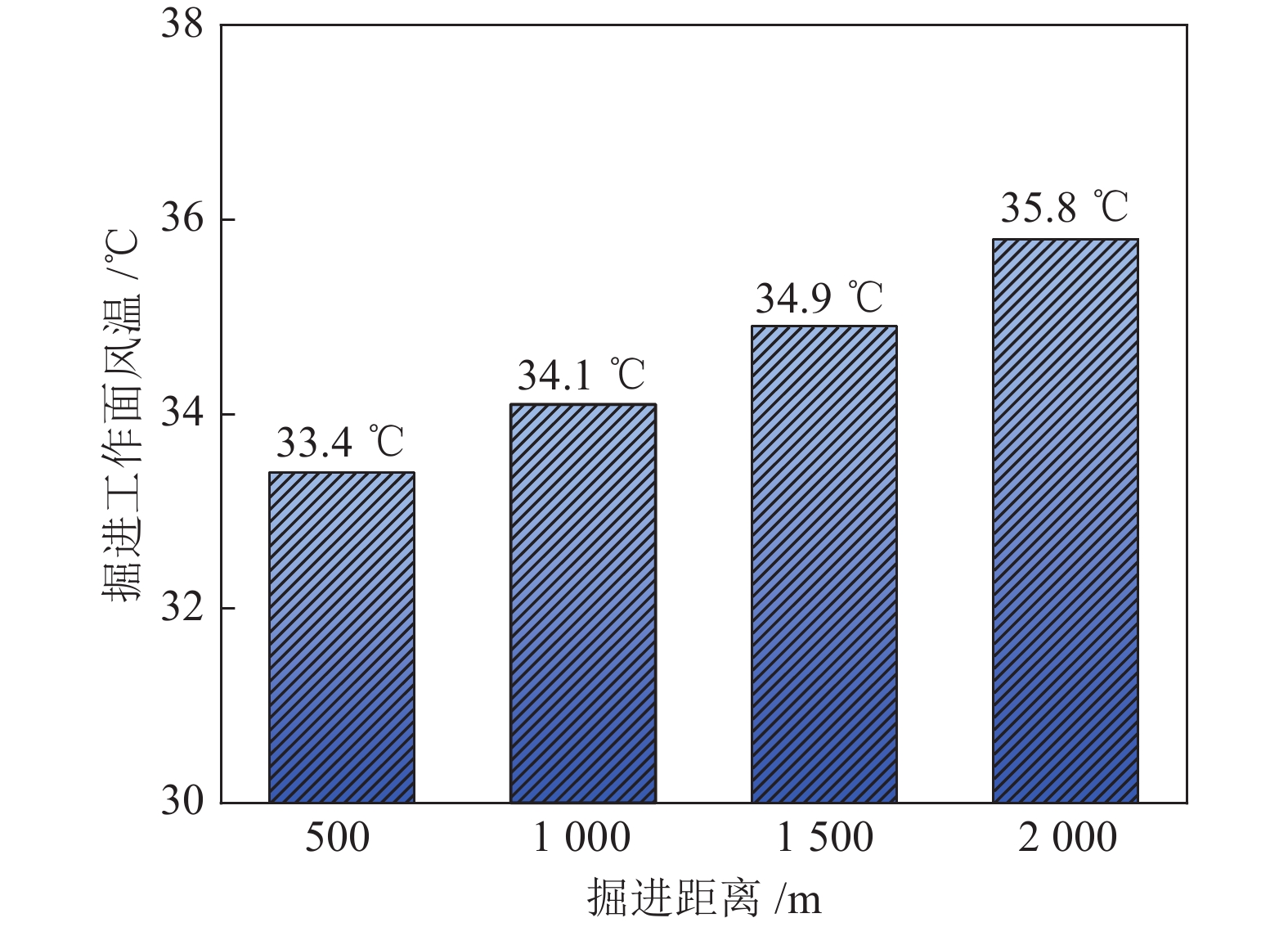

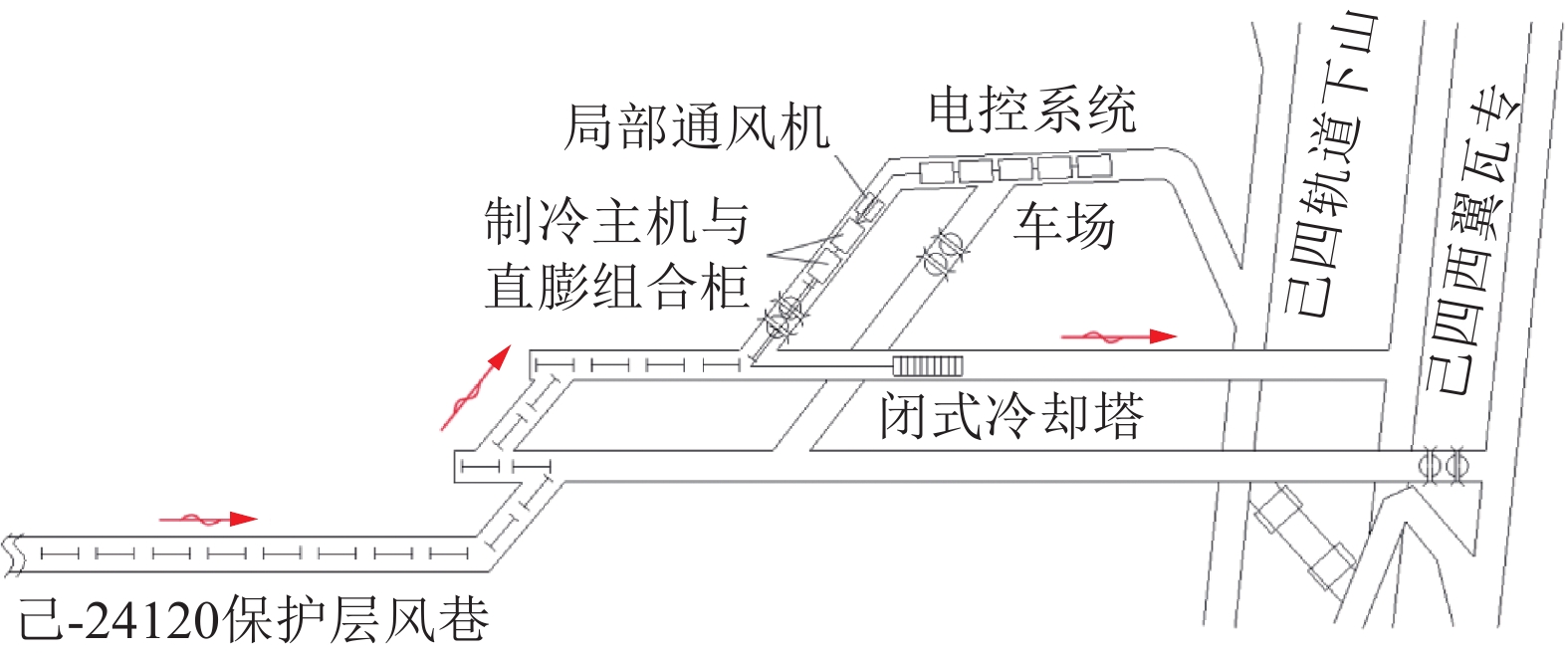

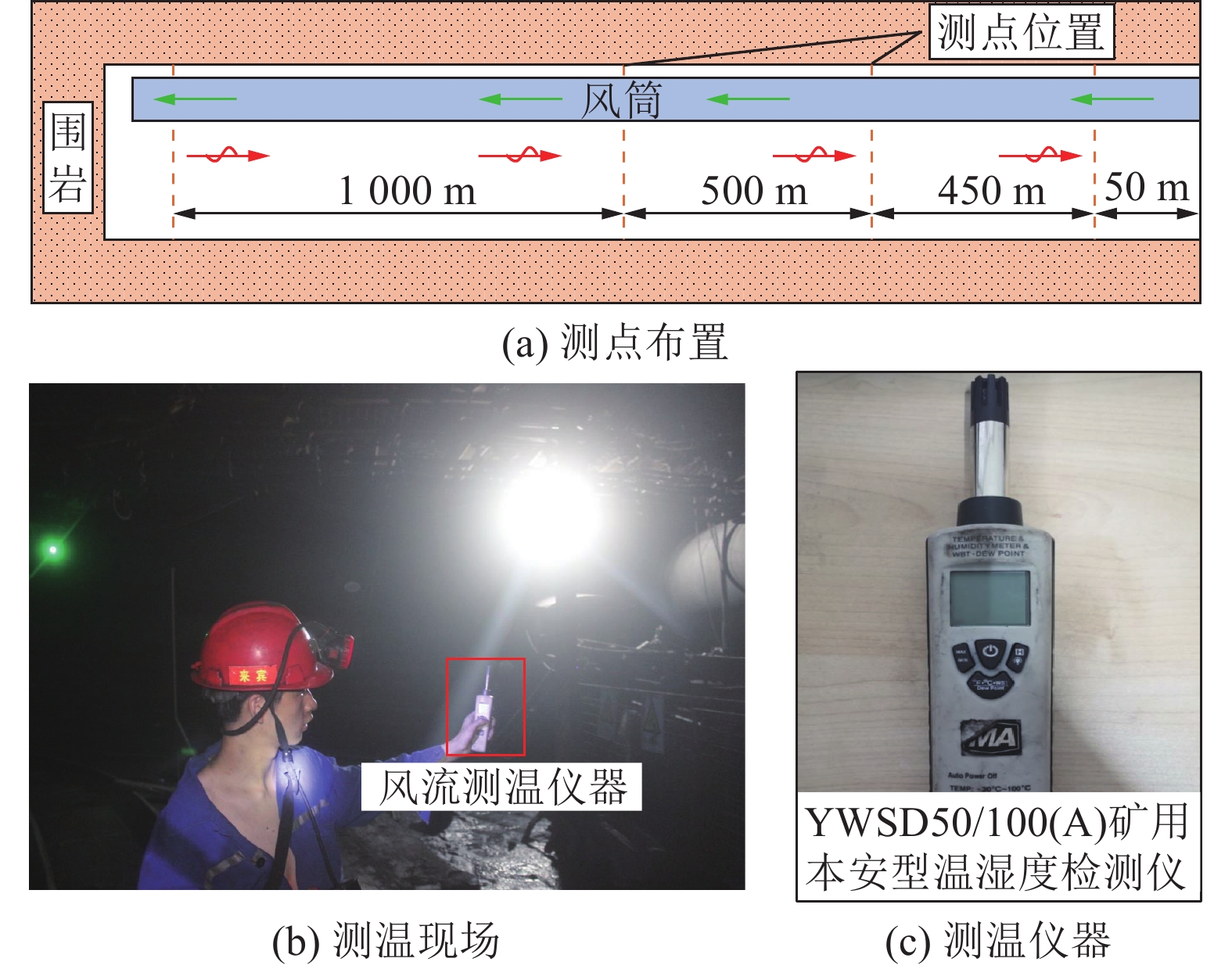

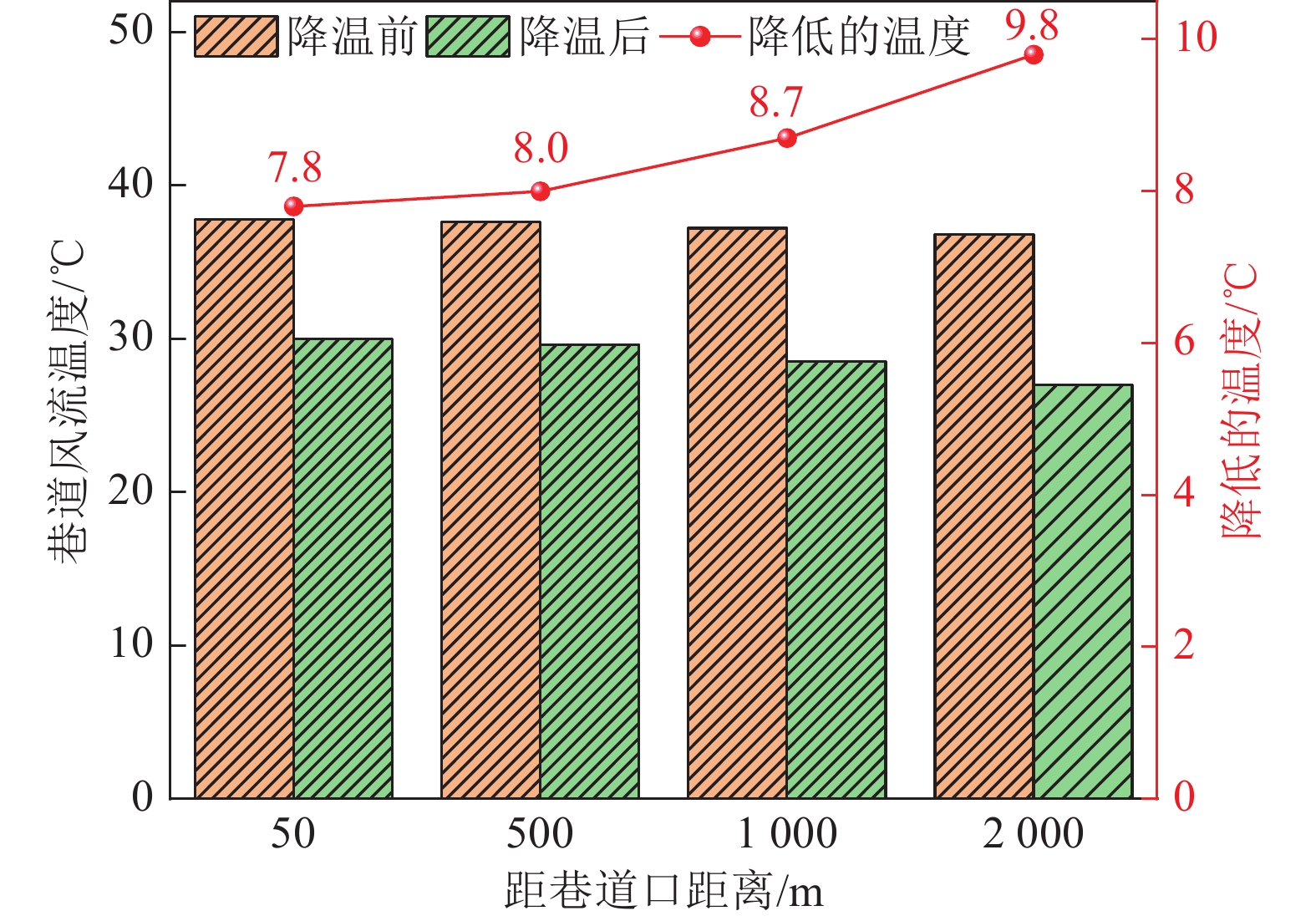

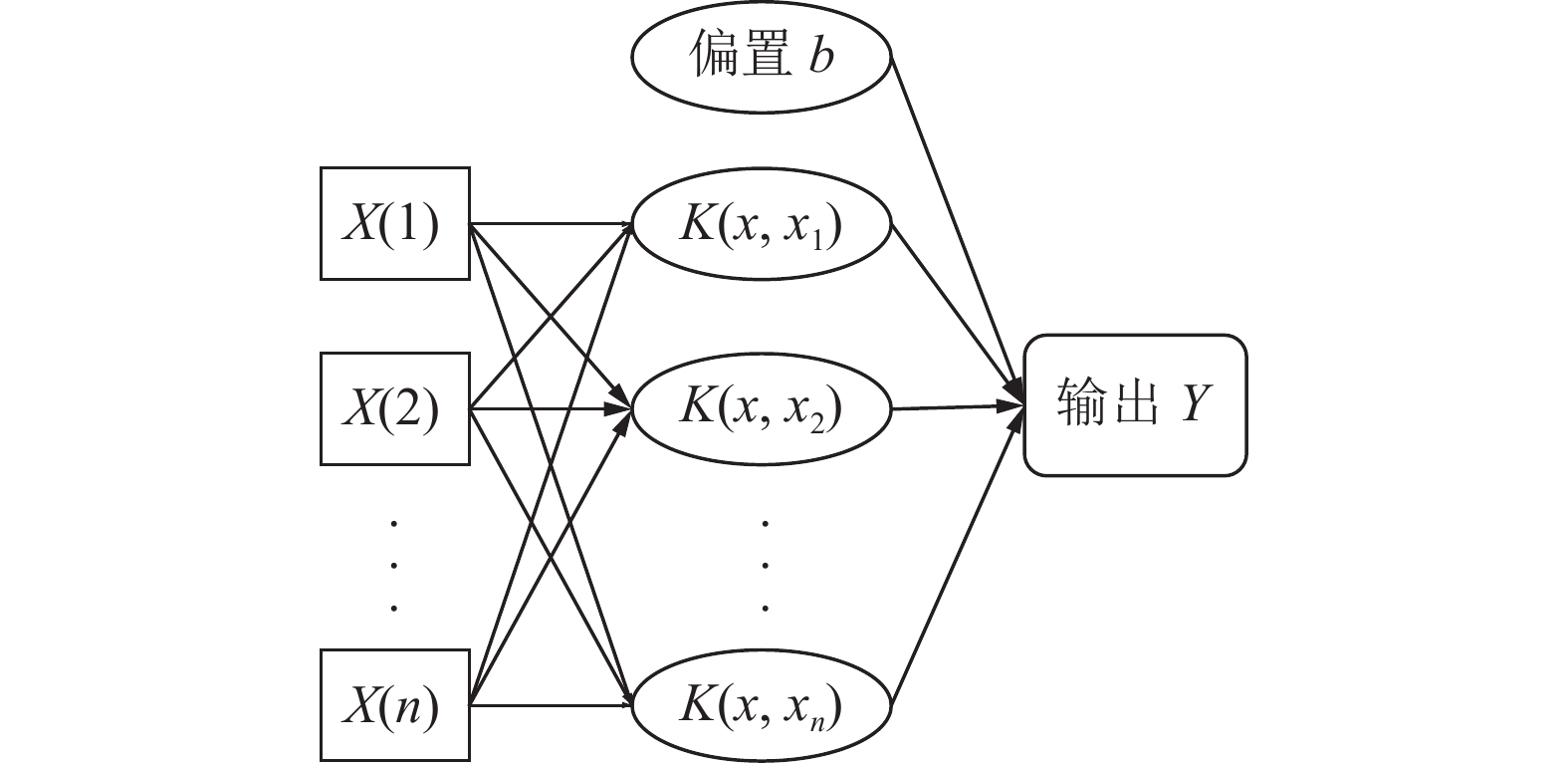

随着我国浅部煤炭资源的逐渐枯竭,矿井开采深度日益增大,热害问题也随之加剧。采掘作业空间是井下的主要热害场所,对其进行热害防治是矿井安全高效生产的重要基础。矿井热害治理的前提是明确其冷负荷,因此对采掘作业空间风温进行精准预测意义重大。建立了基于PSO-SVR(基于粒子群的支持向量回归)的掘进工作面风温预测模型,利用模型中的惩罚因子C和核函数参数g对模型进行了寻优。通过现场实测及文献调研,建立了掘进工作面风温预测训练样本集。通过与最小二乘法估计MLR模型和经“试错法”标定参数的常规SVR模型进行对比,分析了PSO-SVR算法的优势。将PSO-SVR算法模型应用于平煤十矿己-24120保护层风巷风温预测,并依据风温预测结果,指导了制冷机组的选型和降温方案设计。结果表明:PSO-SVR模型预测性能最优,模型绝对误差百分比仅为1.85%,较常规SVR模型减小了55.9%,可见PSO优化模型参数对于提高SVR拟合度、泛化性及预测精度具有重要作用。巷道每掘进100 m,工作面风流平均温升0.16 ℃,掘进至2 000 m时巷道迎头风温升至35.8 ℃。己-24120保护层风巷需冷量为1 083.28 kW,设计制冷机组总制冷量为1 085 kW。己-24120保护层风巷实施降温后,工作面平均温降8.6 ℃,降温效果显著,表明了PSO-SVR掘进工作面风温预测模型的可靠性和可行性。

Abstract:With the gradual depletion of shallow coal resources in China and the increasing depth of mine excavations, the thermal hazard has intensified significantly. The tunnelling working site is a primary underground thermal hazard and requires targeted thermal hazard mitigation to ensure safe and efficient mine production. The premise of mine the thermal hazard control is to clarify its cooling load so that the great significance is to predict the air temperature in the mining operation space accurately. The airflow temperature prediction model of the tunnelling working site based on PSO-SVR was established, and the model was optimized by using the penalty factor C and kernel function parameter g in the model. Through field measurement and literature research, the training sample set of airflow temperature prediction in the tunnelling working site is established. By comparing with the MLR model estimated by the least square method and the conventional SVR model calibrated by the “trial and error” method, the advantages of the PSO-SVR algorithm are analyzed. The PSO-SVR algorithm model was applied to predict airflow temperature in J-24120 protective airway of Pingmei No.10 Coal Mine. Based on the prediction results of air temperature, the selection of refrigeration units and the design of cooling schemes are guided. The results show that: The PSO-SVR model has the best prediction performance, and the absolute error percentage of the model is only 1.85 %, which is 55.9 % lower than that of the conventional SVR model. So PSO optimization model parameters play an important role in improving SVR fitting degree, generalization and prediction accuracy. For every 100 m of roadway excavation, the average temperature rise of head-on airflow is 0.16 °C. When the roadway is excavated to 2 000 m, the temperature of head-on airflow in the roadway rises to 35.8 °C. Ji-24120 protective airway cooling demand is 1 083.28 kW, and the total cooling capacity of the design refrigeration unit is 1085 kW. After the cooling of the Ji-24120 protective airway, the average head-on temperature drop is 8.6 °C, and the cooling effect is remarkable, which shows the reliability and feasibility of the PSO-SVR prediction model of airflow temperature in the tunnelling working site.

-

-

表 1 掘进工作面PSO−SVR风温预测部分样本数据

Table 1 Part of sample data of PSO−SVR wind temperature prediction in tunneling working site

序号 特征向量(影响因素) 真实值 巷道长度/ m 巷道埋深/ m 断面面积/ m2 原岩温度/ ℃ 风速/ (m·s−1) 掘进工作面风温/ ℃ 1 450 1 100 20.1 52.20 0.7 35.58 2 800 1 260 16.7 52.87 0.5 37.02 3 300 950 22.3 51.28 0.3 32.55 4 780 880 15.8 49.68 1.2 30.13 5 1530 650 16.2 44.38 0.6 28.07 6 1426 810 13.5 49.20 1.2 30.83 7 1562 860 21.0 48.87 0.4 31.47 $\vdots $ $\vdots $ $\vdots $ $\vdots $ $\vdots $ $\vdots $ $\vdots $ 63 1550 840 18.2 48.55 0.7 32.43 64 500 720 14.5 45.36 1.5 29.21 $\vdots $ $\vdots $ $\vdots $ $\vdots $ $\vdots $ $\vdots $ $\vdots $ 149 699 1066 15.1 41.38 1.42 28.25 150 792 700 14.6 40.00 0.44 28.89 表 2 掘进工作面风温预测模型参数

Table 2 Wind temperature prediction model parameters of digging face

预测模型 参数 数值 常规SVR 惩罚因子C 4 核函数参数g 1.1478 PSO−SVR 惩罚因子C 8.2687 核函数参数g 0.0842 学习因子c1,c2 1.5,1.7 粒子数pop 20 迭代数num 100 表 3 3种预测模型误差值汇总

Table 3 Summary of error values of three prediction models

评价指标 掘进工作面风温预测模型 MLR 常规SVR PSO−SVR MSE 7.08 4.19 1.09 MAE/℃ 1.70 1.44 0.56 MAPE/% 5.79 4.84 1.81 表 4 己-24120保护层风巷冷负荷计算结果

Table 4 Calculation results of cold load in wind tunnel of Ji-24120 protection layer

掘进距离/ m 500 1000 1500 2000 冷负荷/ kW 644.93 717.32 802.81 902.73 -

[1] 万志军,毕世科,张源,等. 煤-热共采的理论与技术框架[J]. 煤炭学报,2018,43(8):2099−2106. WAN Zhijun,BI Shike,ZHANG Yuan,et al. Framework of the theory and technology for simultaneous extraction of coal and geothermal resources[J]. Journal of China Coal Society,2018,43(8):2099−2106.

[2] 邓军,周佳敏,白祖锦,等. 瓦斯对煤低温氧化过程微观结构及热反应性的影响研究[J]. 煤炭科学技术,2023,51(1):304−312. DENG Jun,ZHOU Jiamin,BAI Zujin,et al. Effect of gas on microstructure and thermal reactivity of coal during low temperature oxidation[J]. Coal Science and Technology,2023,51(1):304−312.

[3] 秦波涛,蒋文婕,史全林,等. 矿井粉煤灰基防灭火技术研究进展[J]. 煤炭科学技术,2023,51(1):329−342. QIN Botao,JIANG Wenjie,SHI Quanlin,et al. Research progress on fly ash foundation technology to prevent and control spontaneous combustion of coal in mines[J]. Coal Science and Technology,2023,51(1):329−342.

[4] 吴星辉,蔡美峰,任奋华,等. 深部矿井高温巷道热交换降温技术探讨[J]. 中南大学学报(自然科学版),2021,52(3):890−900. WU Xinghui,CAI Meifeng,REN Fenhua,et al. Heat exchange cooling technology of high temperature roadway in deep mine[J]. Journal of Central South University (Science and Technology),2021,52(3):890−900.

[5] 张玉涛,杨杰,李亚清,等. 煤自燃特征温度与微观结构变化及关联性分析[J]. 煤炭科学技术,2023,51(4):80−87. ZHANG Yutao,YANG Jie,LI Yaqing,et al. Correlation analysis between characteristic temperature and microstructure of coal spontaneous combustion[J]. Coal Science and Technology,2023,51(4):80−87.

[6] ZHU S,CHENG J W,WANG Z,et al. Physical simulation experiment of factors affecting temperature field of heat adjustment circle in rock surrounding mine roadway[J]. Energy Sources,Part A:Recovery,Utilization,and Environmental Effects,2023,45(4):11278−11295.

[7] 张小康,何富连,马恒. 矿井通风系统环境温度实时计算与应用[J]. 煤炭学报,2012,37(5):863−867. ZHANG Xiaokang,HE Fulian,MA Heng. Real-time calculation and application of mine ventilation system environmental temperature[J]. Journal of China Coal Society,2012,37(5):863−867.

[8] 陈建勋,赵鹏宇,罗彦斌,等. 寒冷地区隧道传热特征及温度场演化规律现场试验[J]. 中国公路学报,2023,36(8):190−203. CHEN Jianxun,ZHAO Pengyu,LUO Yanbin,et al. Heat transfer characteristics and temperature field evolution laws:Field experiments of tunnel in cold areas under annual cycles[J]. China Journal of Highway and Transport,2023,36(8):190−203.

[9] 张源,万志军,周长冰,等. 巷道/隧道围岩非稳态导热模化试验方法[J]. 采矿与安全工程学报,2014,31(3):441−446. ZHANG Yuan,WAN Zhijun,ZHOU Changbing,et al. Modeling experimental method of unsteady heat conduction in surrounding rock of roadways or tunnels[J]. Journal of Mining & Safety Engineering,2014,31(3):441−446.

[10] 周航,张树光,路平平. 高温矿井巷道通风降温的界面热阻效应[J]. 应用基础与工程科学学报,2022,30(3):673−683. ZHOU Hang,ZHANG Shuguang,LU Pingping. Interfacial thermal resistance effect of ventilation cooling in high temperature mine roadway[J]. Journal of Basic Science and Engineering,2022,30(3):673−683.

[11] DANKO G,BAHRAMI D,STEWART C. Applications and verification of a computational energy dynamics model for mine climate simulations[J]. International Journal of Mining Science and Technology,2020,30(4):483−493. doi: 10.1016/j.ijmst.2020.03.019

[12] 秦跃平,王浩,郭开元,等. 巷道围岩温度场有限体积法模拟计算及实验分析[J]. 煤炭学报,2017,42(12):3166−3175. QIN Yueping,WANG Hao,GUO Kaiyuan,et al. Simulation of finite volume method and experimental analysis for temperature field of roadway surrounding rock[J]. Journal of China Coal Society,2017,42(12):3166−3175.

[13] ZHU S,WU S Y,CHENG J W,et al. An underground air-route temperature prediction model for ultra-deep coal mines[J]. Minerals,2015,5(3):527−545. doi: 10.3390/min5030508

[14] LIANG X J,WU J,RUAN K Y. Simulation modeling and temperature over-advance perception of mine hoist system based on digital twin technology[J]. Machines,2023,11(10):966. doi: 10.3390/machines11100966

[15] BASCOMPTA M,ROSSELL J M,SANMIQUEL L,et al. Temperature prediction model in the main ventilation system of an underground mine[J]. Applied Sciences,2020,10(20):7238. doi: 10.3390/app10207238

[16] 高佳南,吴奉亮,马砺,等. 矿井淋水井筒风温PSO−SVR预测方法[J]. 西安科技大学学报,2022,42(3):476−483. GAO Jianan,WU Fengliang,MA Li,et al. PSO−SVR prediction method of airflow temperature of shaft with water dropping in mine[J]. Journal of Xi’an University of Science and Technology,2022,42(3):476−483.

[17] 姬建虎,廖强,胡千庭,等. 热害矿井掘进工作面换热特性[J]. 煤炭学报,2014,39(4):692−698. JI Jianhu,LIAO Qiang,HU Qianting,et al. Heat transfer characteristics of driving face in heat harm mine[J]. Journal of China Coal Society,2014,39(4):692−698.

[18] 秦跃平,孟君,贾敬艳,等. 非稳态导热问题有限体积法[J]. 辽宁工程技术大学学报(自然科学版),2013,32(5):577−581. QIN Yueping,MENG Jun,JIA Jingyan,et al. Unsteady heat transfer problems with finite volume method[J]. Journal of Liaoning Technical University (Natural Science),2013,32(5):577−581.

[19] 张源. 高地温巷道围岩非稳态温度场及隔热降温机理研究[D]. 徐州:中国矿业大学,2013:6−15. ZHANG Yuan. Study on unsteady temperature field and thermal insulation and cooling mechanism of surrounding rock in high ground temperature roadway[D]. Xuzhou:China University of Mining and Technology,2013:6−15.

[20] 贾澎涛,林开义,郭风景. 基于PSO-SRU深度神经网络的煤自燃温度预测模型[J]. 工矿自动化,2022,48(4):105−113. JIA Pengtao,LIN Kaiyi,GUO Fengjing. A temperature prediction model for coal spontaneous combustion based on PSO-SRU deep artificial neural networks[J]. Journal of Mine Automation,2022,48(4):105−113.

[21] 吕鹏飞,邱林. 基于PSO-LSSVM的矿井冲击地压分级预测研究[J]. 矿业安全与环保,2021,48(1):120−125. LYU Pengfei,QIU Lin. Research on classification prediction of mine rock burst based on PSO-LSSVM[J]. Mining Safety & Environmental Protection,2021,48(1):120−125.

[22] 马砺,张雅婷,刘尚明,等. 高温矿井制冷降温管网解算及优化方法研究[J]. 煤炭科学技术,2024,52(2):150−158. MA Li,ZHANG Yating,LIU Shangming,et al. Research on calculation and optimization method of refrigeration and cooling pipe network in high temperature mine[J]. Coal Science and Technology,2024,52(2):150−158.

[23] MARCO A R D B,DURJOY B,SEYED A G. Techno-economic feasibility assessment of a diesel exhaust heat recovery system to preheat mine intake air in remote cold climate regions[J]. International Journal of Mining Science and Technology,2020,30(4):517−523.

[24] 孔松,吴建松,郭伟旗,等. 掘进工作面围岩温度场的无因次分析[J]. 辽宁工程技术大学学报(自然科学版),2016,35(6):576−580. KONG Song,WU Jiansong,GUO Weiqi,et al. Dimensionless analysis of the temperature field of surrounding rock in heading face[J]. Journal of Liaoning Technical University (Natural Science),2016,35(6):576−580.

[25] 乔红彦. 高地温隧道超长独头施工降温及热环境特征研究[J]. 地下空间与工程学报,2023,19(2):632−639. QIAO Hongyan. Research on cooling and thermal environment of super-long single-headed tunnel construction with high ground temperature[J]. Chinese Journal of Underground Space and Engineering,2023,19(2):632−639.

[26] SUN L L,ZHANG C,CHENG W M,et al. Effect of high-temperature environment of mine goaf on pore and fracture of coal[J]. Fuel,2022,325:124810. doi: 10.1016/j.fuel.2022.124810

[27] 王毅泽,董凯丽,张玉龙,等. CMC/ZrCit/GDL防灭火凝胶泡沫的制备及特性研究[J]. 煤炭科学技术,2023,51(6):122−129. WANG Yize,DONG Kaili,ZHANG Yulong,et al. Study on preparation and characteristics of CMC/ZrCit/GDL fire-fighting gel foam[J]. Coal Science and Technology,2023,51(6):122−129.

[28] 董孝通,边梦龙,王二雨. 掘进巷道热环境影响因素重要性分析[J]. 工矿自动化,2021,47(10):91−96. DONG Xiaotong,BIAN Menglong,WANG Eryu. Analysis on the importance of factors influencing the thermal environment of the excavation roadway[J]. Industry and Mine Automation,2021,47(10):91−96.

下载:

下载: