Evolution of microcracks and energy of granite during shear test with PFC3D

-

摘要:

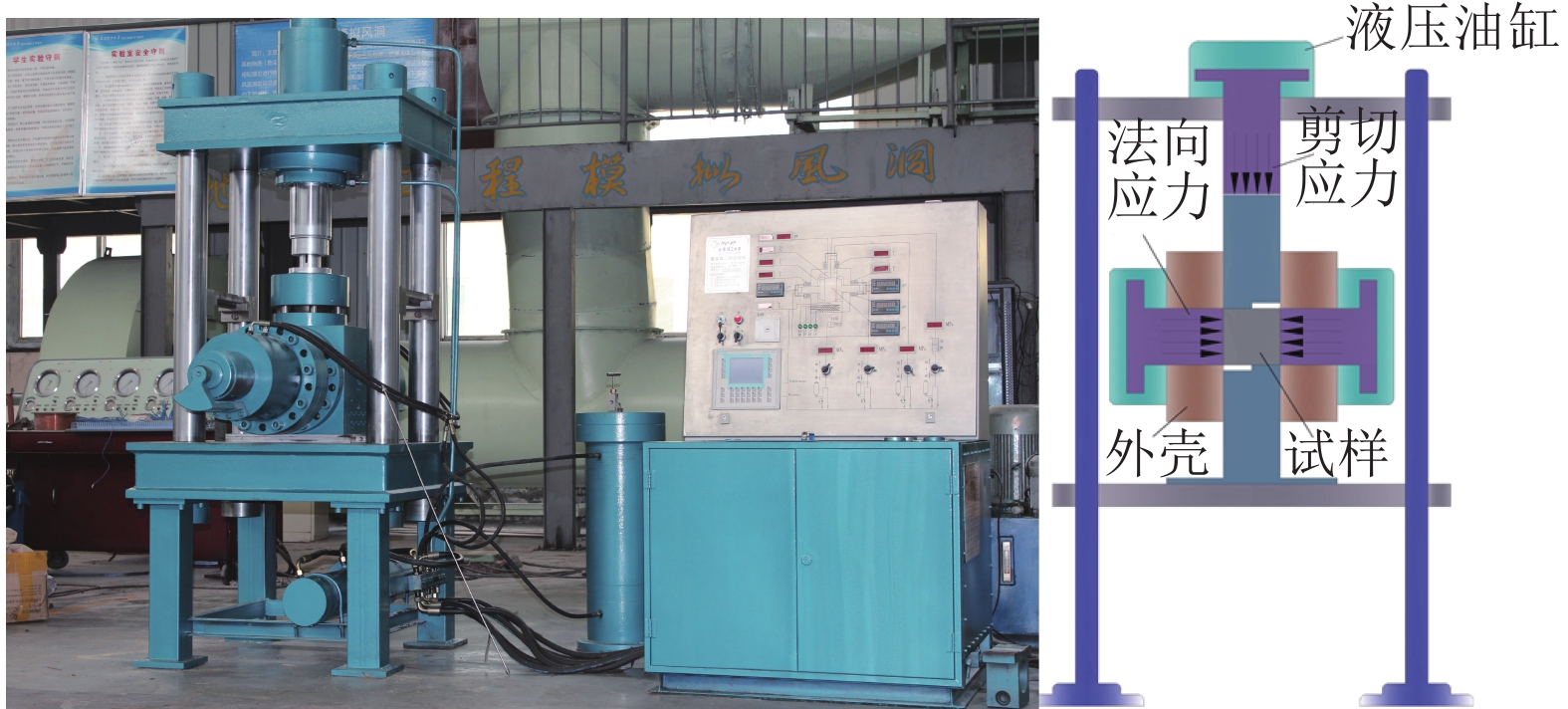

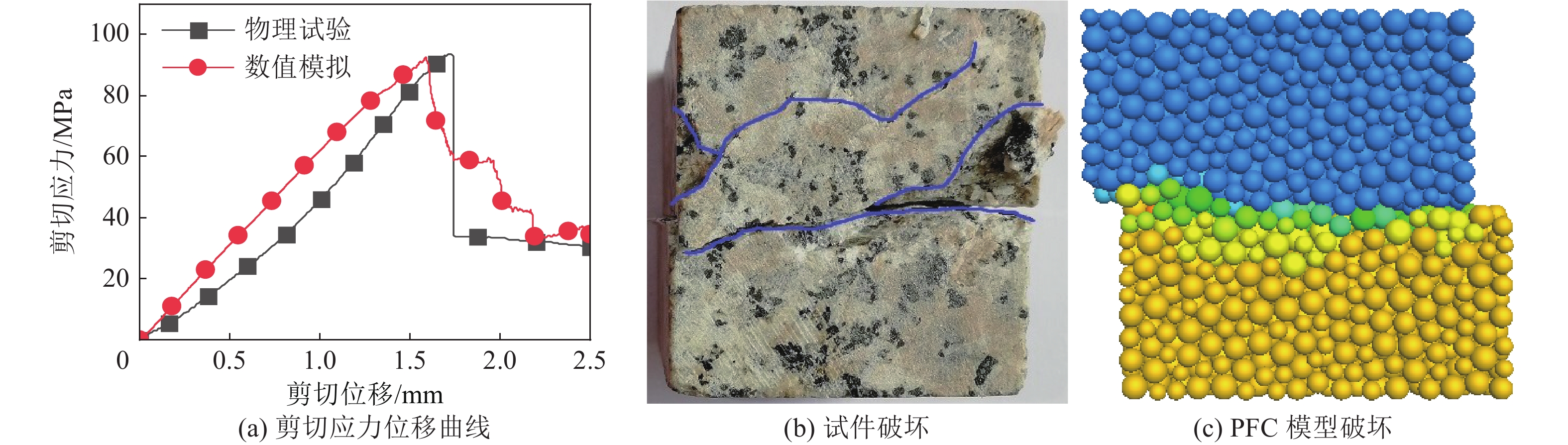

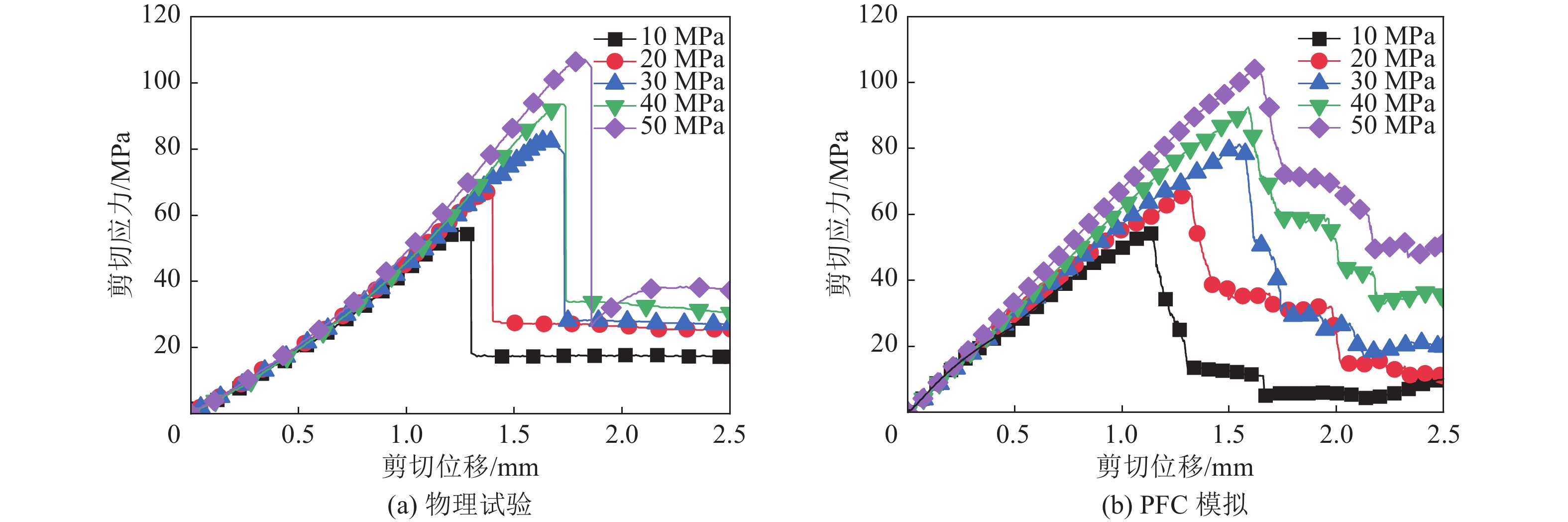

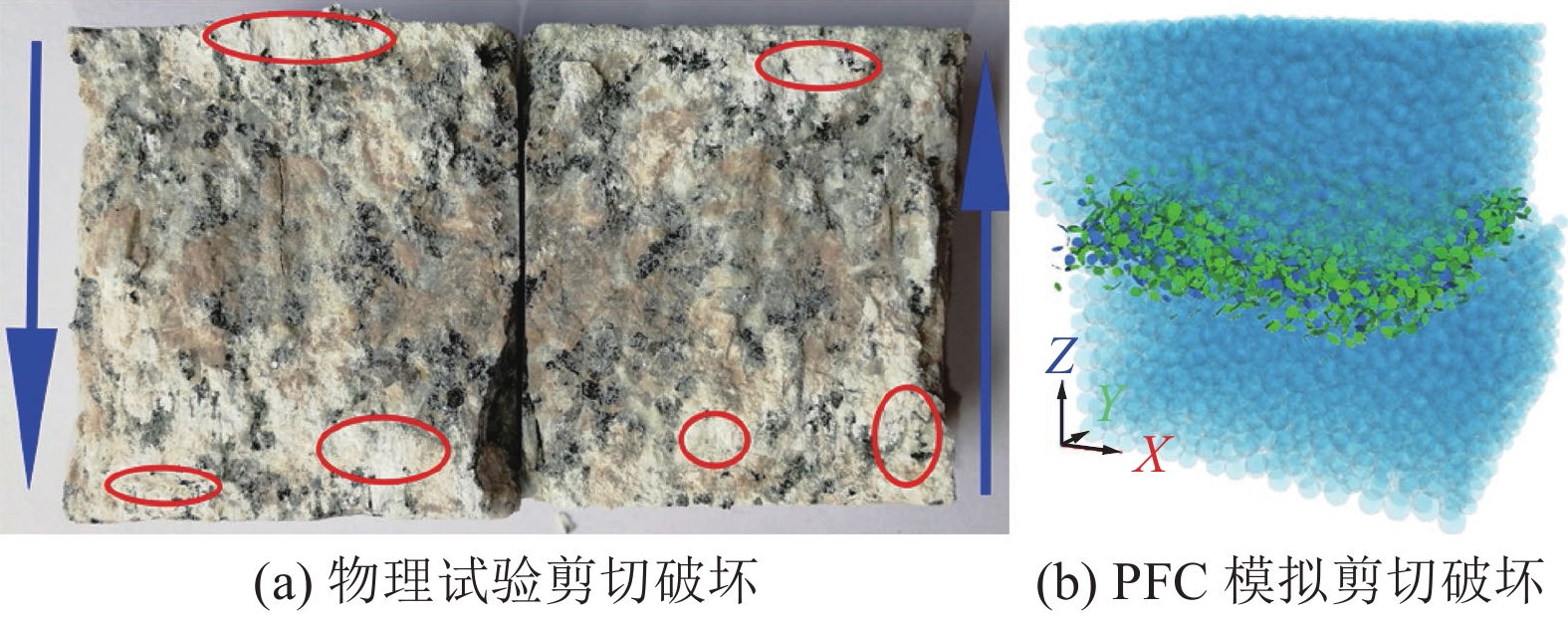

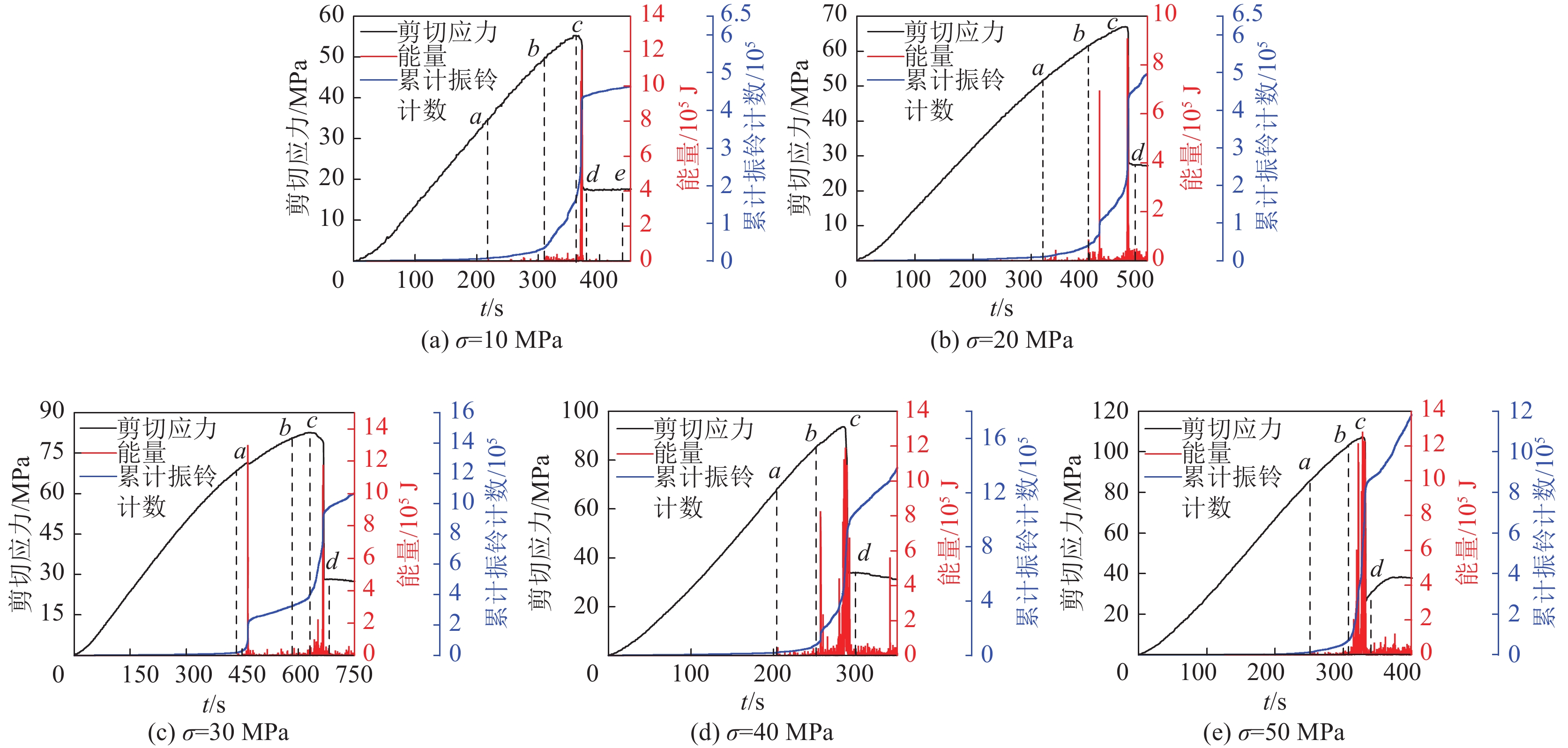

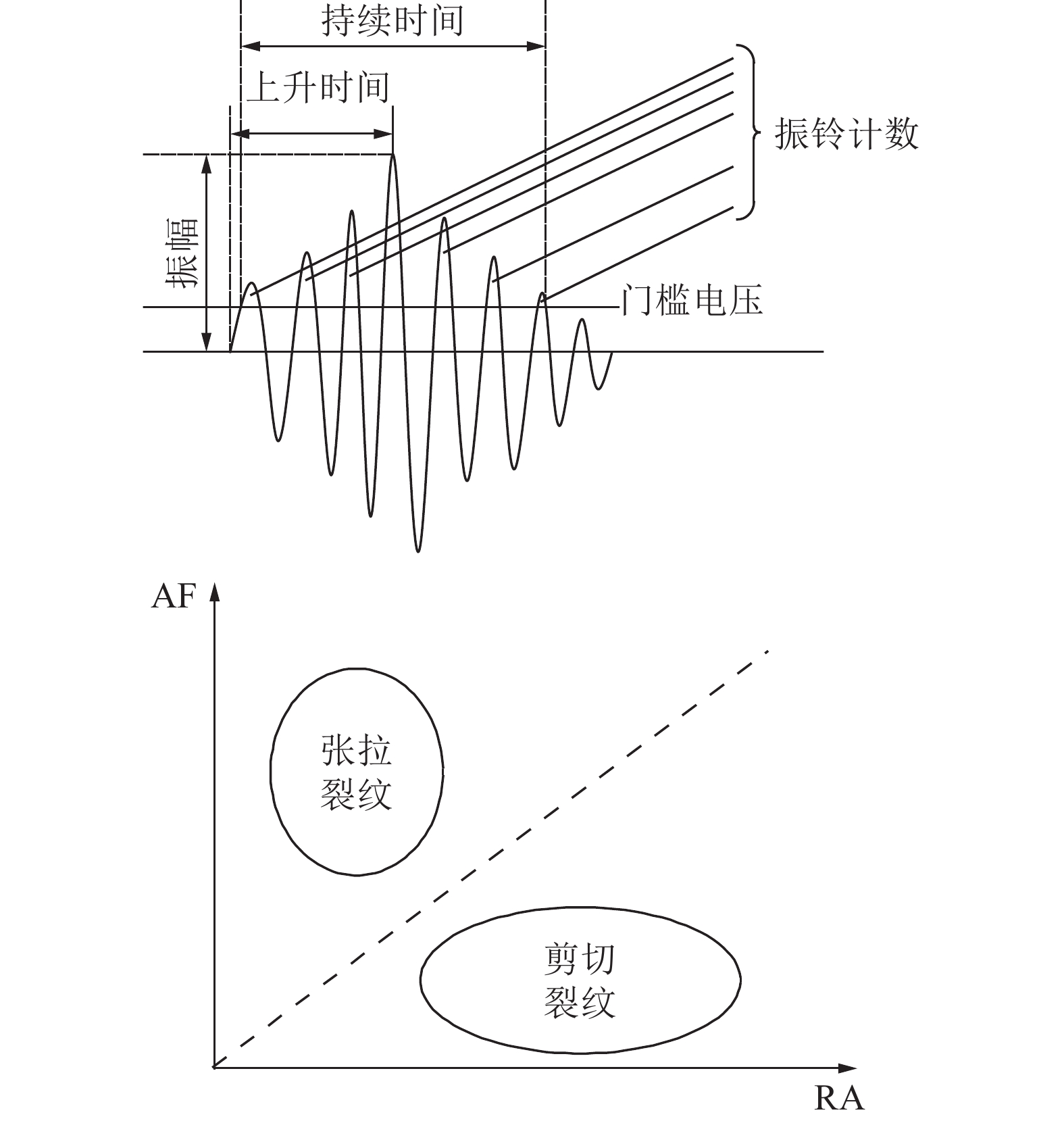

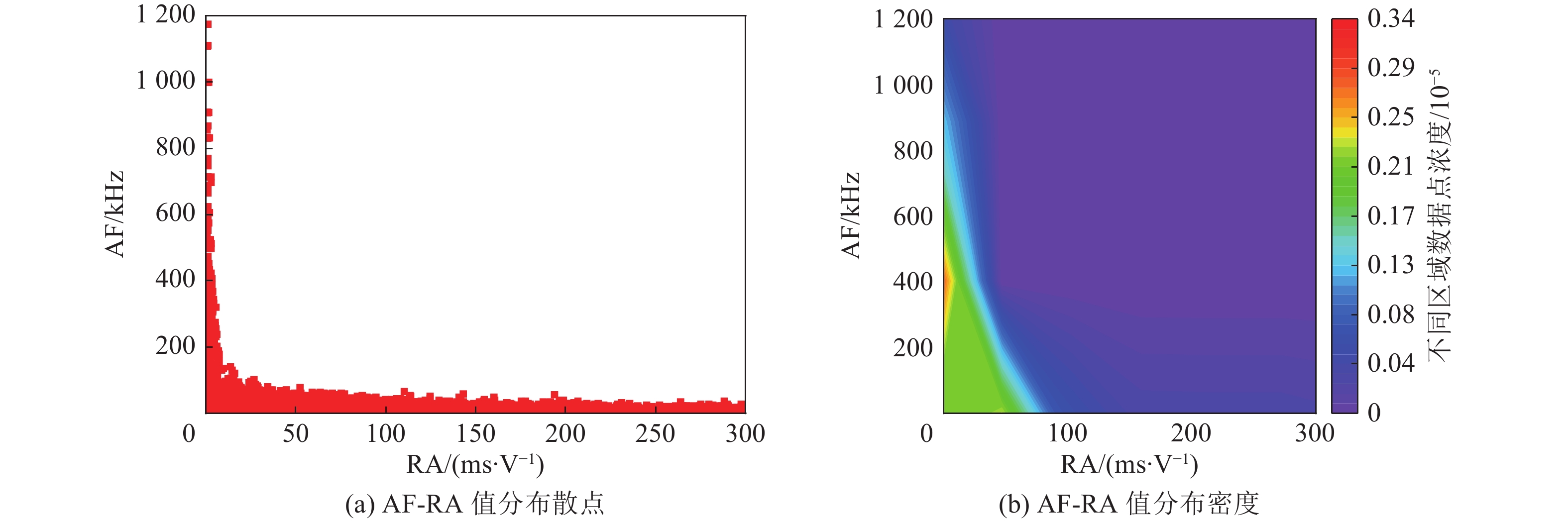

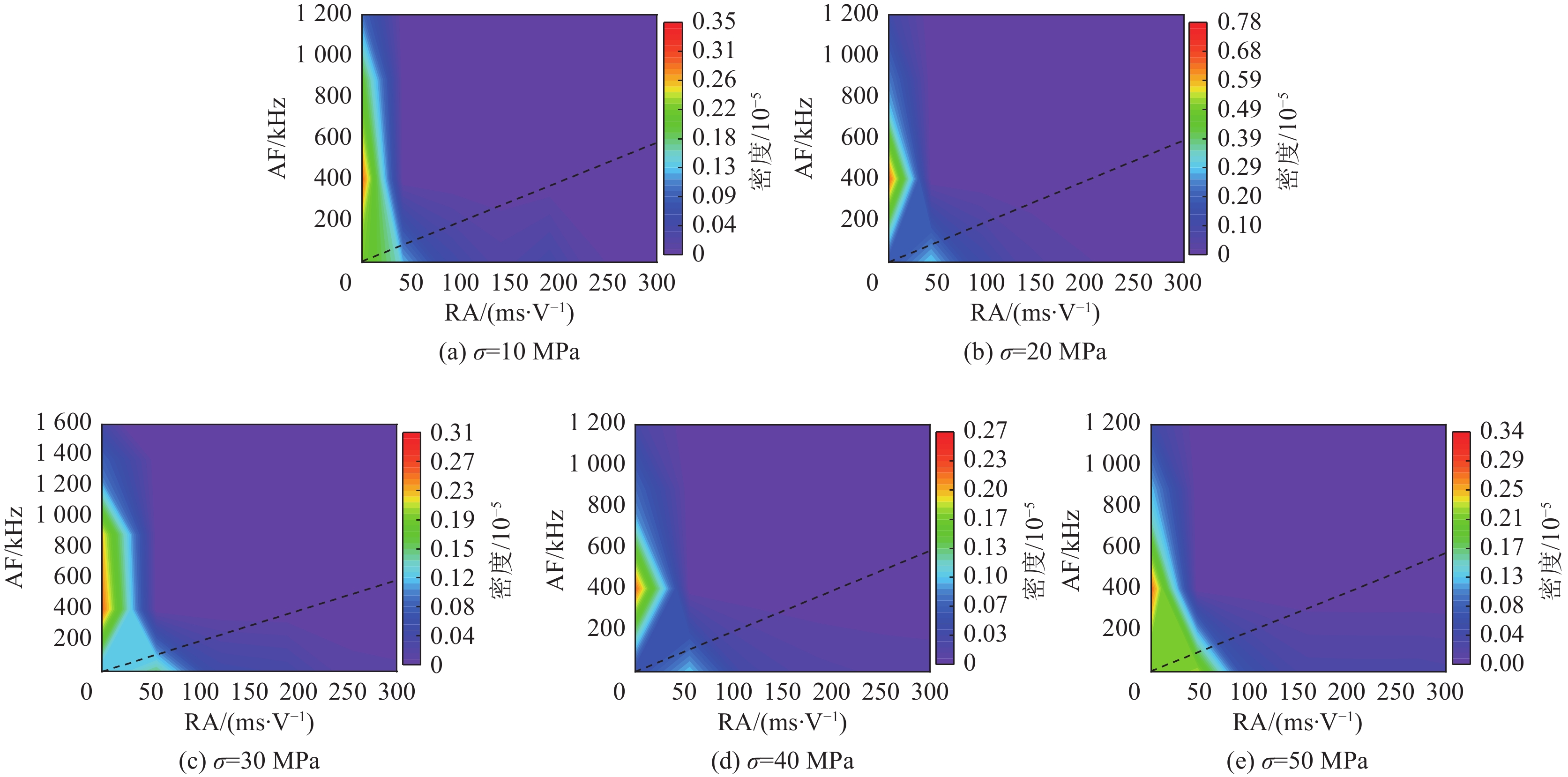

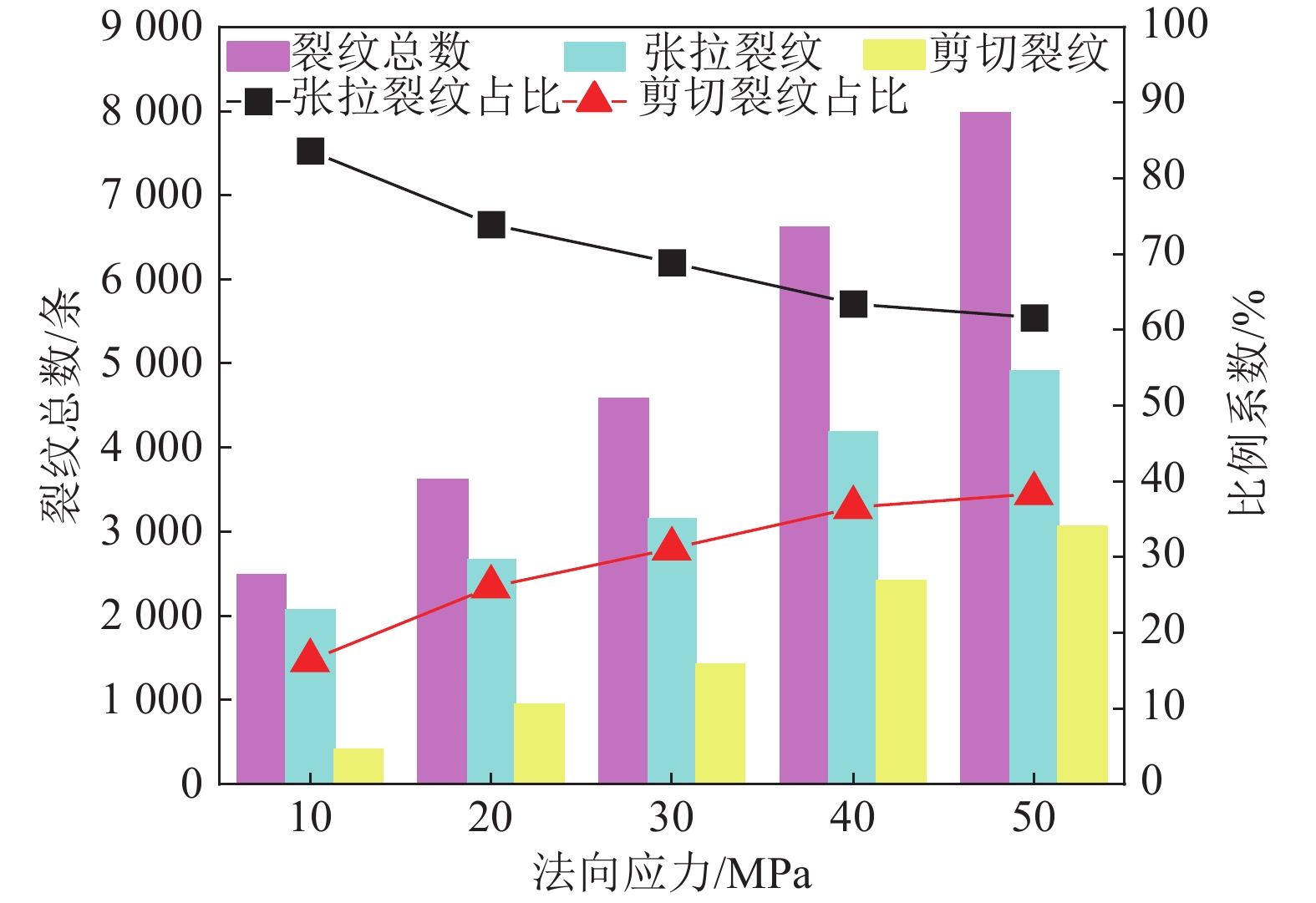

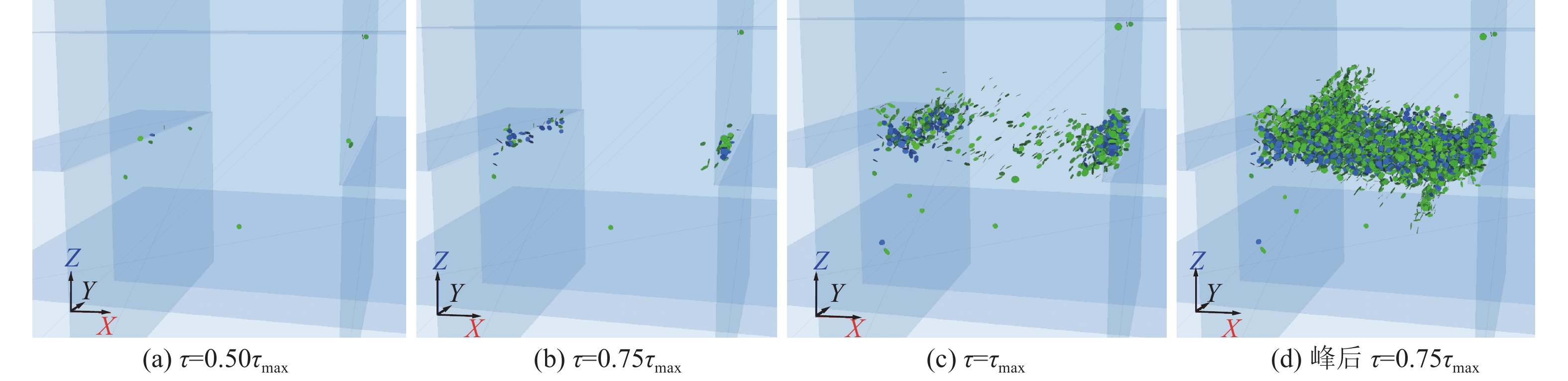

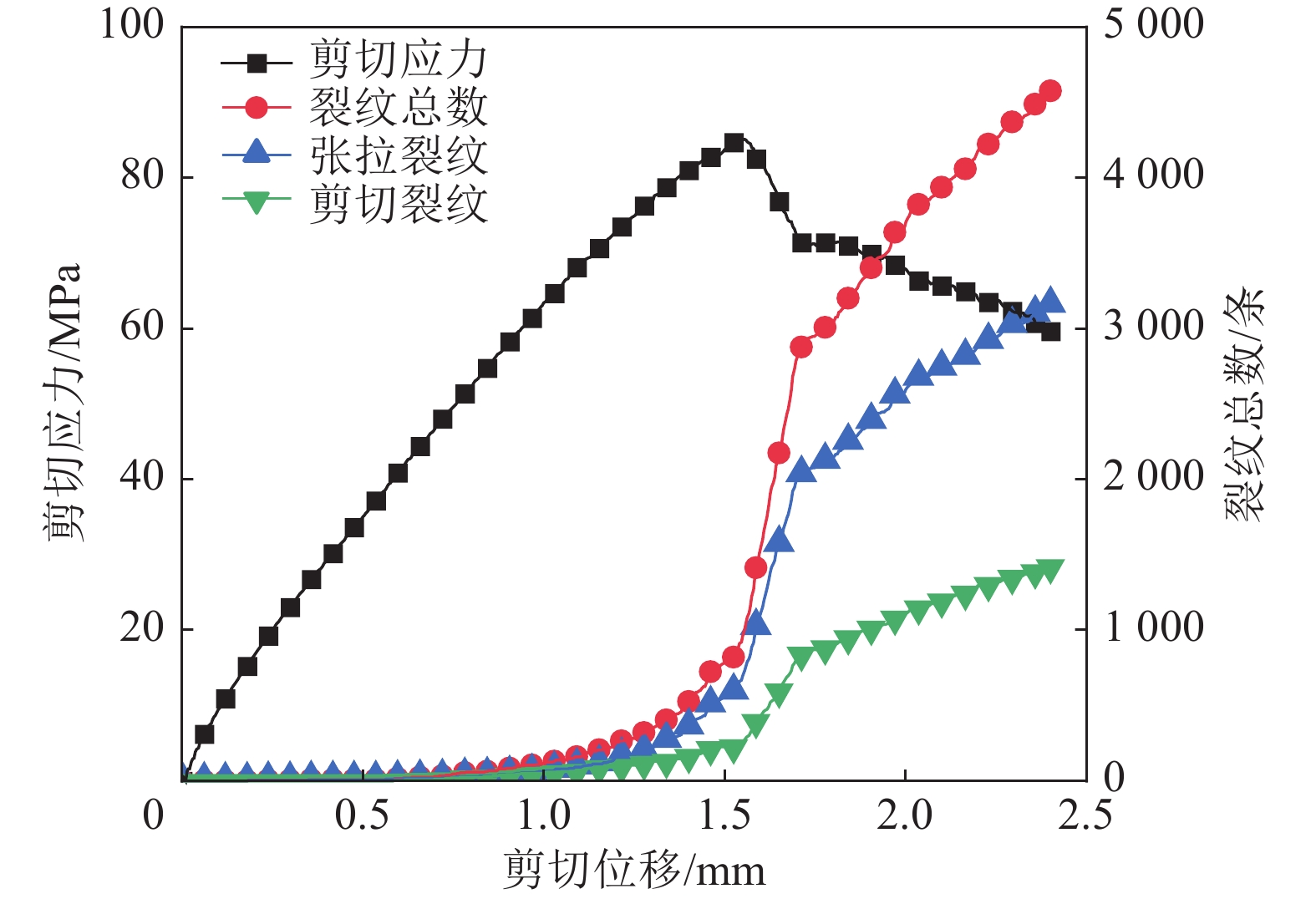

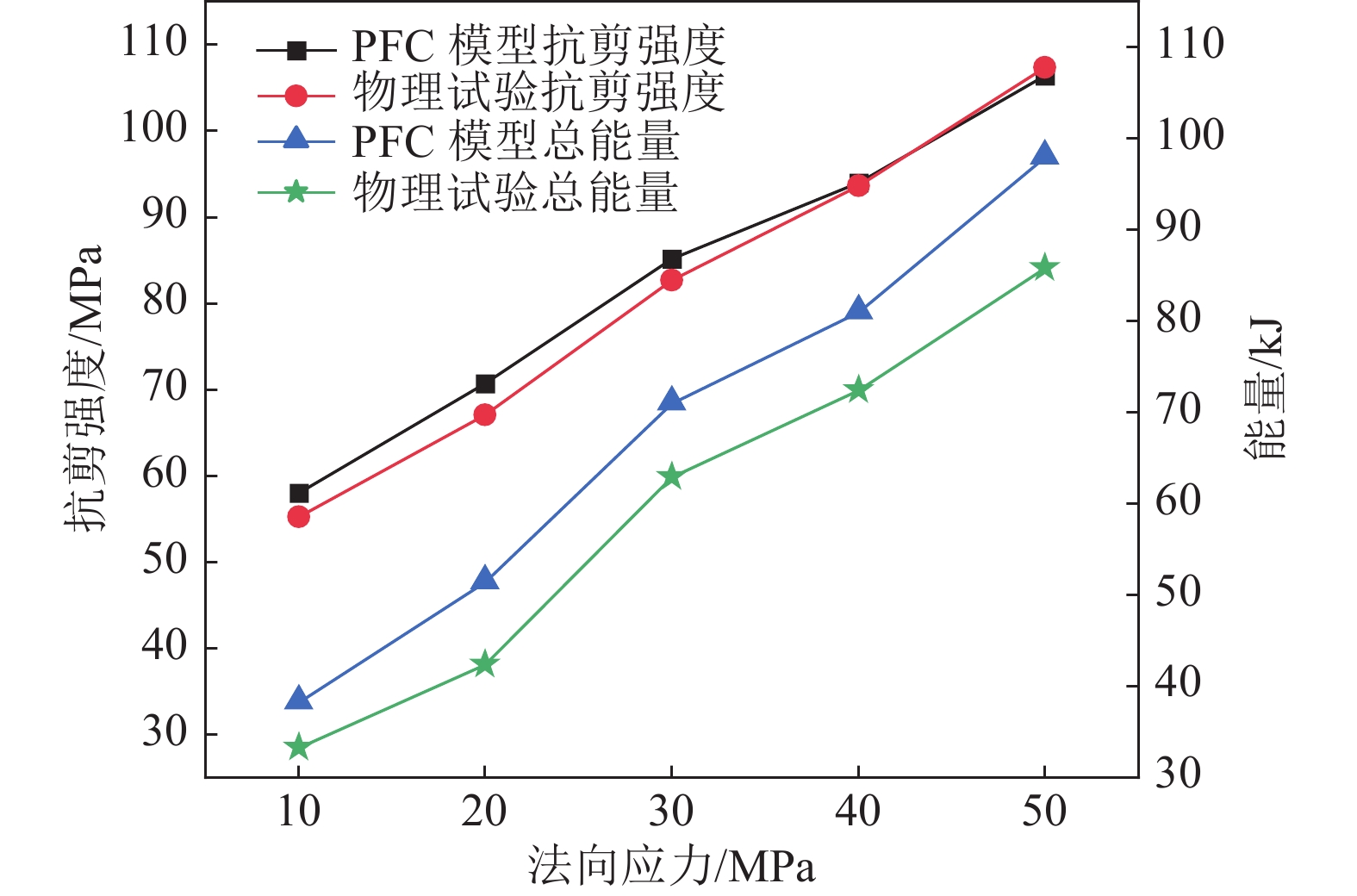

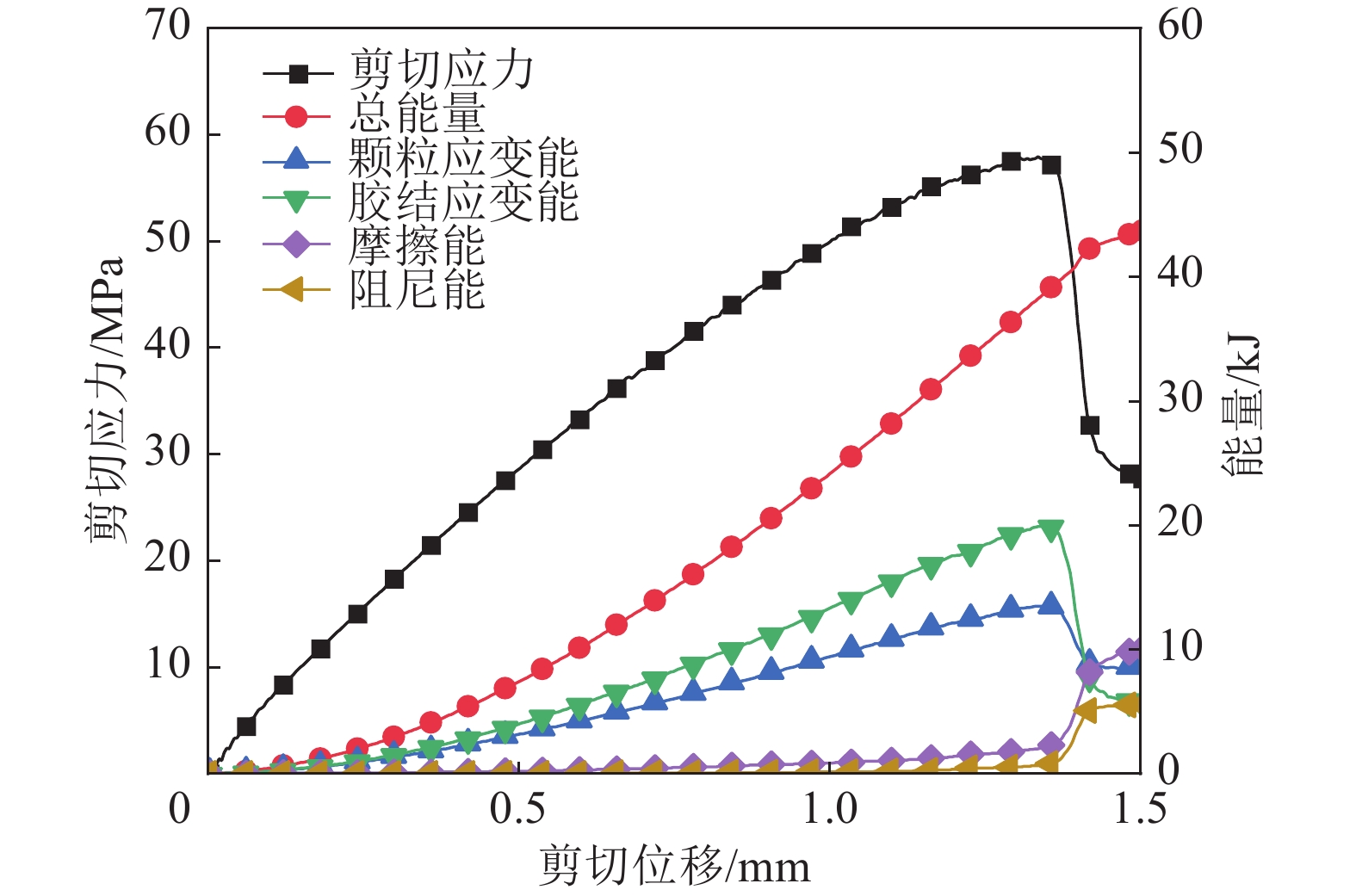

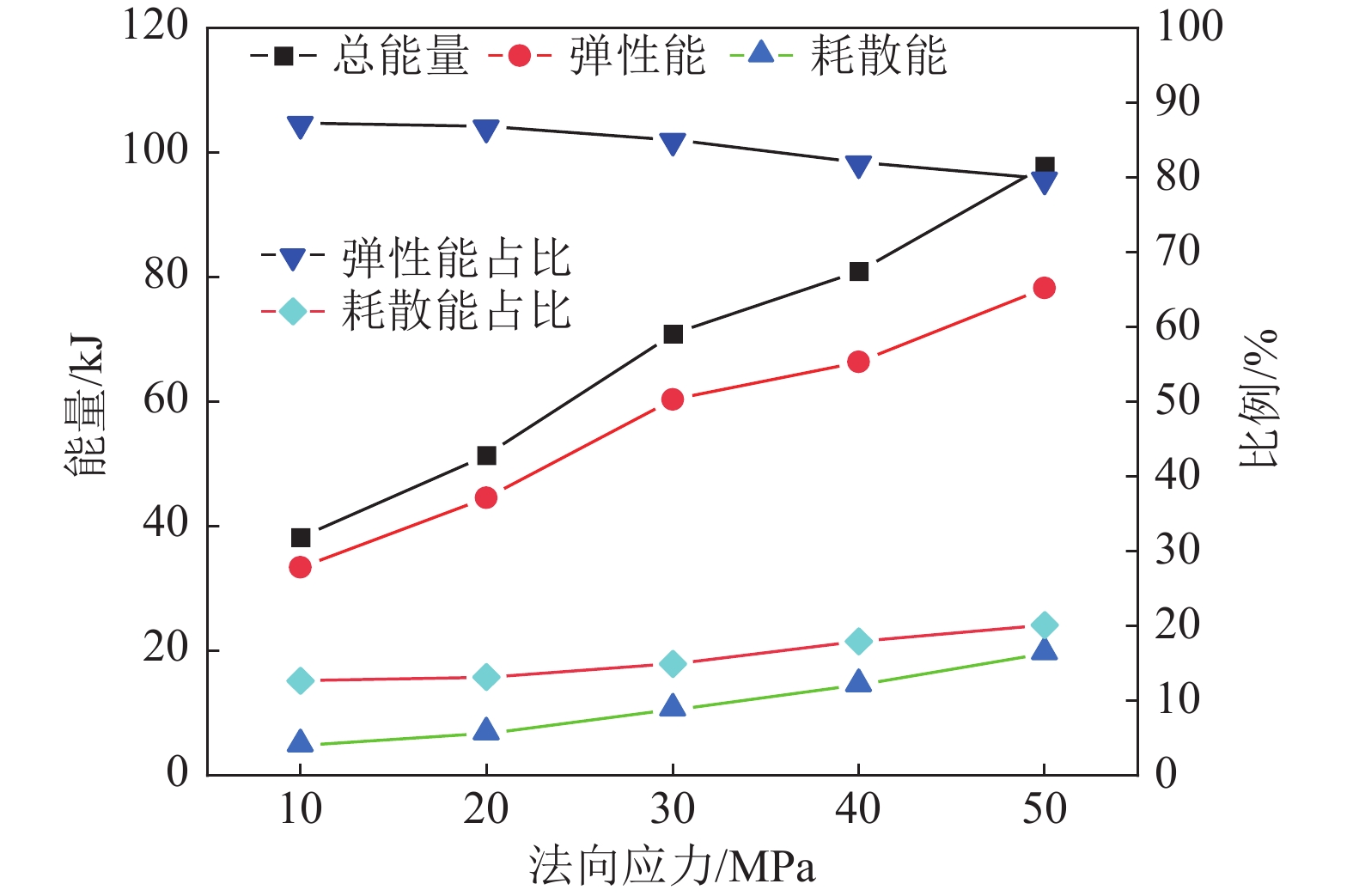

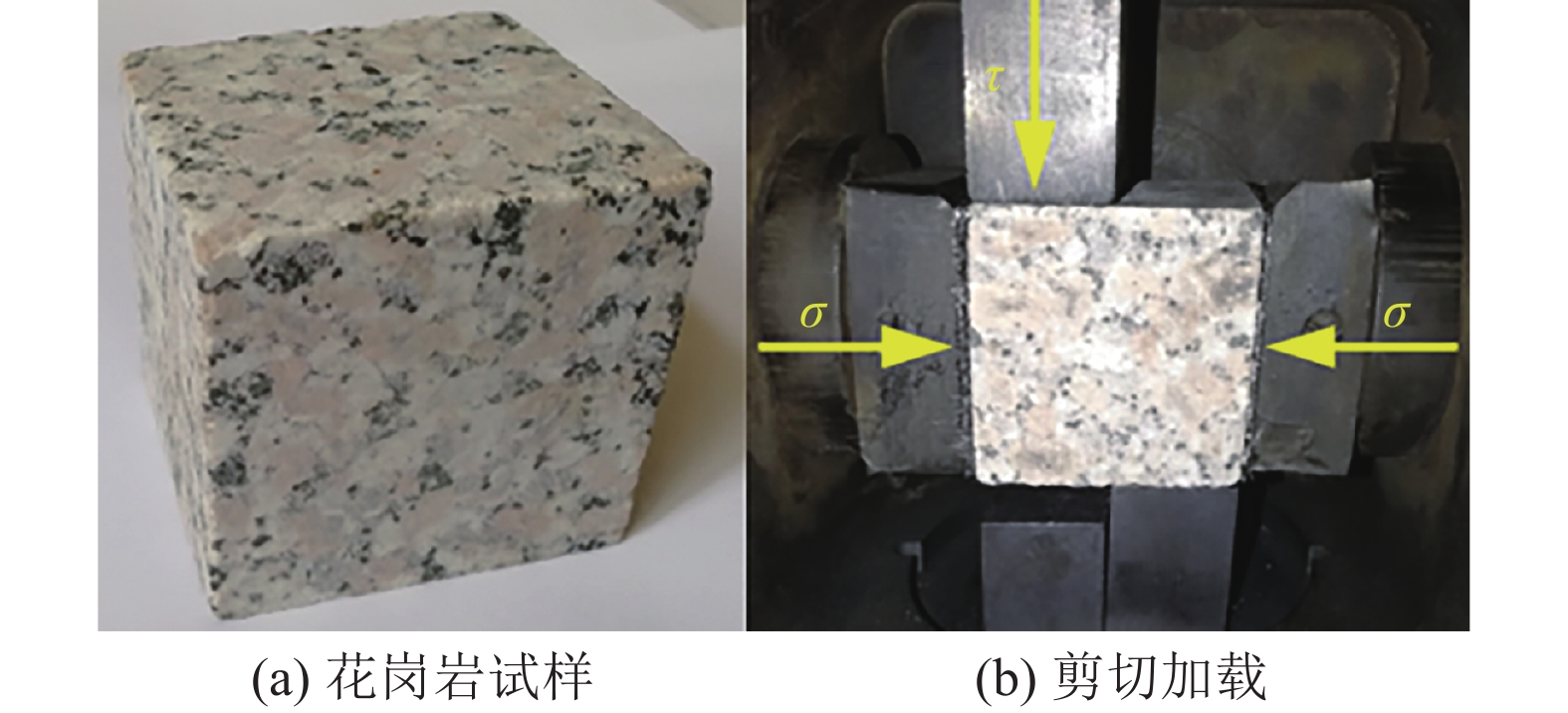

为了探究法向应力对岩石剪切过程中细观损伤演化的影响,开展了不同法向应力作用下的花岗岩直剪试验与PFC3D数值模拟试验,结合声发射信号监测及声发射信息特征值RA(上升时间与振幅的比值)与AF(声发射振铃计数与持续时间的比值)的分析,对花岗岩在不同法向应力作用下剪切变形过程中细观微裂纹及能量演化特征进行了研究,研究结果表明:基于平行黏结接触模型建立的PFC3D模型,不仅在宏观力学参数与破坏模式上与岩石物理试验相近,而且在岩石细观裂纹与能量演化规律上也与岩石物理试验基本一致;花岗岩剪切破坏过程中主要产生张拉裂纹,峰值应力点前产生的微裂纹只占裂纹总数的10%~30%,且法向应力越大,峰值应力点前岩石内部产生的微裂纹数量越少;花岗岩剪切变形过程中,声发射信号可以分为平静期、稳定期和加速期,法向应力越大,平静期越明显,即法向应力对岩石内部微裂纹的生成起抑制作用;随着法向应力的增大,花岗岩剪切破坏过程中,声发射累计振铃计数与岩石内部微裂纹总数均逐渐增大;随着法向应力的增大,花岗岩剪切破坏过程中产生的剪切裂纹数量及其占微裂纹总数的比例均逐渐增加;花岗岩剪切变形过程中外力做功转化为弹性能与耗散能,随着法向应力增大,岩石剪切破坏所需总能量逐渐增大,弹性能与耗散能近似线性增大,且其中耗散能所占的比例逐渐增大。

Abstract:In order to investigate the influence of normal stress on the internal meso-scale damage process during rock shearing, direct shearing experiments and PFC3D numerical simulation experiments of granite under different normal stresses were carried out, combined with acoustic emission signal monitoring and analysis of acoustic emission information characteristic values of RA (ratio of rise time to amplitude) and AF (ratio of acoustic emission ring count to duration). The results show that the PFC3D model based on the parallel adhesive contact model is not only similar to rock physics experiments in macroscopic mechanical parameters and failure modes, but also basically consistent with rock physics experiments in the evolution of meso-cracks and energy in rock. Tensile micro-cracks are mainly produced in the process of shear failure of granite, and the microcracks produced before the peak stress point only account for 10%−30% of the total number of cracks, and the larger the normal stress, the smaller the number of microcracks produced inside the rock before the peak stress point. In the process of granite shear deformation, the acoustic emission signal can be divided into calm period, stable period and accelerated period, the greater the normal stress, the more obvious the calm period, i.e. the normal stress inhibits the generation of microcracks inside the rock.With the increase of the normal stress, the cumulative acoustic emission ring count and the total number of microcracks inside the rock gradually increase in the process of granite shear damage. With the increase of normal stress, the number of shear cracks produced during the shear damage of granite and its proportion to the total number of microcracks gradually increased. The work done by the external force during the shear deformation of granite is converted into elastic energy and dissipation energy, with the increase of normal stress, the total energy required for rock shear failure gradually increases, and the elastic energy and dissipation energy increase approximately linearly, in which the proportion of dissipation energy gradually increases.

-

Keywords:

- rock mechanics /

- meso-cracks /

- granite /

- direct shear test /

- PFC3D simulation

-

-

表 1 校正后的PFC3D模型细观参数

Table 1 Mesoscopic parameters of PFC3D model

细观参数 释义 标定值 $ {R}_{{\mathrm{min}}} $ 最小颗粒半径/mm 0.1 $ {{R}}_{\mathrm{m}\mathrm{a}\mathrm{x}} $/$ {{R}}_{\mathrm{m}\mathrm{i}\mathrm{n}} $ 最大最小颗粒半径比 1.66 $ {E}_{{\mathrm{c}}} $ 颗粒接触模量/GPa 3.78 $ {{k}}^{\mathrm{*}} $ 颗粒刚度比 0.5 $ \mathrm{\mu } $ 颗粒摩擦因数 0.5 $ {\bar{E}}_{{\mathrm{c}}} $ 平行黏结模量/GPa 3.78 $ {\bar{{k}}}^{\mathrm{*}} $ 平行黏结刚度比 0.5 $ {\bar{\sigma }}_{{\mathrm{c}}} $ 平行黏结抗拉强度/MPa 72 $ \bar{c} $ 平行黏结黏聚力强度/MPa 108 $ \bar{{\varnothing }} $ 内摩擦角/(°) 40 表 2 PFC模拟与物理试验所得花岗岩剪切强度参数

Table 2 Shear strength parameters of granite obtained by PFC simulation and physical experiment

法向应力/MPa $ {\tau } $/MPa ${G} $/GPa 物理试验 PFC模拟 物理试验 PFC模拟 10 55.24 52.92 2.31 2.39 20 67.03 66.75 2.61 2.67 30 82.68 81.35 2.8 2.78 40 93.59 92.66 3.14 3.08 50 107.32 105.04 3.47 3.43 -

[1] 刘泉声,王中伟. 基于数字图像处理的岩石数值模拟研究进展[J]. 岩石力学与工程学报,2020,39(S2):3286−3296. LIU Quansheng,WANG Zhongwei. Research progress of rock numerical simulation based on digital image processing[J]. Journal of Rock Mechanics and Geotechnical Engineering,2020,39(S2):3286−3296.

[2] 冯增朝,沈永星. 基于表面位移的岩石失稳前兆识别研究[J]. 岩石力学与工程学报,2021,40(S2):3024−3032. FENG Zengchao,SHEN Yongxing. Rock instability precursor identification based on surface displacement[J]. Journal of Rock Mechanics and Engineering,2021,40(S2):3024−3032.

[3] 胡训健,卞 康,刘 建,等. 离散裂隙网络对岩石力学性质和声发射特性影响的颗粒流分析[J]. 岩土力学,2022,43(S1):542−552. HU Xunjian,BIAN Kang,LIU Jian,et al. Particle flow analysis of the effect of discrete fracture networks on the mechanical properties and acoustic emission characteristics of rocks[J]. Rock and Soil Mechanics,2022,43(S1):542−552.

[4] 李兆霖,周 伟,王连国,等. 含随机裂隙岩石真三轴破裂演化数值模拟[J]. 中国矿业大学学报,2023,52(1):43−51. LI Zhaolin,ZHOU Wei,WANG Lianguo,et al. Numerical simulation of true triaxial rupture evolution of rocks containing random fractures[J]. Journal of China University of Mining and Technology,2023,52(1):43−51.

[5] 石 崇,张 强,王盛年. 颗粒流(PFC5.0)数值模拟技术及应用[J]. 岩土力学,2018,39(S2):36. SHI Chong,ZHANG Qiang,WANG Shengnian. Numerical simulation technique and application of granular flow (PFC5.0)[J]. Rock and Soil Mechanics,2018,39(S2):36.

[6] 李 勇,蔡卫兵,朱维申,等. 单轴压缩条件下平行双裂隙演化机理的颗粒流分析[J]. 中南大学学报(自然科学版),2019,50(12):3035−3045. LI Yong,CAI Weibing,ZHU Weishen,et al. Particle flow analysis of the evolution mechanism of parallel double fractures under uniaxial compression conditions[J]. Journal of Central South University (Natural Science Edition),2019,50(12):3035−3045.

[7] 周 杰,汪永雄,周元辅. 基于颗粒流的砂岩三轴破裂演化宏–细观机理[J]. 煤炭学报,2017,42(S1):76−82. ZHOU Jie,WANG Yongxiong,ZHOU Yuanfu. Macro-fine view mechanism of sandstone triaxial fracture evolution based on granular flow[J]. Journal of China Coal Socity,2017,42(S1):76−82.

[8] 荣浩宇,李桂臣,梁东旭,等. 应力路径影响下高应力岩石力学特性颗粒流模拟[J]. 采矿与安全工程学报,2022,39(1):163−173. RONG Haoyu,LI Guichen,LIANG Dongxu,et al. Simulation of granular flow for mechanical properties of highly stressed rocks under the influence of stress paths[J]. Journal of Mining and Safety Engineering,2022,39(1):163−173.

[9] 沙 鹏,杨丹莲,邬一鑫,等. 花岗岩巴西劈裂渐进破坏特征与能量演化研究[J]. 工程地质学报,2021,29(5):1258−1266. SHA Peng,YANG Danlian,WU Yixin,et al. Study on the characteristics and energy evolution of progressive damage of granite splitting in Brazil[J]. Journal of Engineering Geology,2021,29(5):1258−1266.

[10] 黄 达,李 悦,岑夺丰,等. 压–拉应力状态下大理岩强度及破裂性质的微观晶粒影响[J]. 岩土力学,2020,41(S2):1−12. HUANG Da,LI Yue,CEN Duofeng,et al. Microscopic grain effects on strength and fracture properties of marble under compressive-tensile stress state[J]. Rock and Soil Mechanics,2020,41(S2):1−12.

[11] 杨圣奇,李 尧,黄彦华,等. 单孔圆盘劈裂试验宏细观力学特性颗粒流分析[J]. 中国矿业大学学报,2019,48(5):984−992. YANG Shengqi, LI Yao, HUANG Yanhua, et al. Particle flow analysis of macroscopic and microscopic mechanical properties of Brazilian disc containing a hole under splitting test[J]. Journal of China University of Mining and Technology,2019,48(5):984−992.

[12] 刘 婕,丛 宇,张黎明,等. 花岗岩真三轴加、卸载破坏的细观损伤机制研究[J]. 中南大学学报(自然科学版),2021,52(8):2677−2688. LIU Jie,CONG Yu,ZHANG Liming,et al. Study on the fine-scale damage mechanism of true triaxial loading and unloading damage of granite[J]. Journal of Central South University (Natural Science Edition),2021,52(8):2677−2688.

[13] 田文岭,杨圣奇,方 刚. 煤样三轴循环加卸载力学特征颗粒流模拟[J]. 煤炭学报,2016,41(3):603−610. TIAN Wenling,YANG Shengqi,FANG Gang. Simulation of particle flow characteristic of triaxial circulation plus unloading mechanics of coal samples[J]. Journal of China Coal Socity,2016,41(3):603−610.

[14] 张 杰,郭奇峰,蔡美峰,等. 循环扰动荷载作用下花岗岩中裂隙萌生扩展过程的颗粒流模拟[J]. 工程科学学报,2021,43(5):636−646. ZHANG Jie,GUO Qifeng,CAI Meifeng,et al. Granular flow simulation of fracture sprouting extension process in granite under cyclic disturbance loading[J]. Chinese Journal of Engineering,2021,43(5):636−646.

[15] 王伟超,朱高房. 盐岩破坏中能量特征应变率效应颗粒流分析[J]. 河南理工大学学报(自然科学版),2020,39(6):144−151. WANG Weichao,ZHU Gaofang. Analysis of energy characteristic strain rate effect granular flow in salt rock destruction[J]. Journal of Henan University of Science and Technology (Natural Science Edition),2020,39(6):144−151.

[16] 田文岭,徐 杰,杨圣奇,等. 高温后花岗岩损伤劣化机制晶粒模型数值研究[J]. 应用基础与工程科学学报,2024,32(3):888−899. TIAN Wenling,XU Jie,YANG Shengqi,et al. Numerical study on grain model of damage and deterioration mechanism of granite after high temperature[J]. Journal of Basic Science and Engineering,2024,32(3):888−899.

[17] 武世岩,黄彦华. 含弧形裂隙花岗岩裂纹扩展特征PFC模拟[J]. 中南大学学报(自然科学版),2023,54(1):169−182. WU Shiyan,HUANG Yanhua. PFC simulation of crack extension characteristics of granite containing arc fractures[J]. Journal of Central South University (Natural Science Edition),2023,54(1):169−182.

[18] 蒋明镜,陈 贺,张 宁,等. 含双裂隙岩石裂纹演化机理的离散元数值分析[J]. 岩土力学,2014,35(11):3259−3268,3288. JIANG Mingjing,CHEN He,ZHANG Ning,et al. Discrete element numerical analysis of the crack evolution mechanism in rocks containing double fractures[J]. Rock and Soil Mechanics,2014,35(11):3259−3268,3288.

[19] 张 涛,蔚立元,鞠明和,等. 基于PFC3D-GBM的晶体–单元体尺寸比对花岗岩动态拉伸特性影响分析[J]. 岩石力学与工程报,2022,41(3):468−478. ZHANG Tao,WEI Liyuan,JU Minghe,et al. Analysis of the effect of crystal-unit size ratio on dynamic tensile properties of granite based on PFC3D-GBM[J]. Journal of Rock Mechanics and Geotechnical Engineering,2022,41(3):468−478.

[20] 张 帆,王 亮,赵建建,等. 花岗岩张拉和压剪裂隙渗透率演化研究[J]. 岩土力学,2016,37(10):2803−2809. ZHANG Fan,WANG Liang,ZHAO Jianjian,et al. Study on the evolution of granite tension and compression-shear fracture permeability[J]. Rock and Soil Mechanics,2016,37(10):2803−2809.

[21] 陈鹏宇. PFC2D模拟裂隙岩石裂纹扩展特征的研究现状[J]. 工程地质学报,2018,26(2):528−539. CHEN Pengyu. Current status of research on PFC2D simulation of fracture rock crack extension characteristics[J]. Journal of Engineering Geology,2018,26(2):528−539.

[22] 赵云阁,黄麟淇,李夕兵. 岩石损伤强度及峰值强度前后阶段的声发射识别[J]. 岩土工程学报,2022,44(10):1908−1916. ZHAO Yunge,HUANG Linqi,LI Xibing. Acoustic emission identification of rock damage intensity and pre- and post-peak intensity stages[J]. Chinese Journal of Geotechnical Engineering,2022,44(10):1908−1916.

[23] 何满潮,赵 菲,杜 帅,等. 不同卸载速率下岩爆破坏特征试验分析[J]. 岩土力学,2014,35(10):2737−2747,2793. HE Manchao,ZHAO Fei,DU Shuai,et al. Experimental analysis of rockburst damage characteristics under different unloading rates[J]. Rock and Soil Mechanics,2014,35(10):2737−2747,2793.

[24] 甘一雄,吴顺川,任 义,等. 基于声发射上升时间/振幅与平均频率值的花岗岩劈裂破坏评价指标研究[J]. 岩土力学,2020,41(7):2324−2332. GAN Yixiong,WU Shunchuan,REN Yi,et al. Study on evaluation index of granite splitting damage based on acoustic emission rise time/amplitude and average frequency value[J]. Rock and Soil Mechanics,2020,41(7):2324−2332.

[25] 毛瑞彪. 声发射实时定位监测岩体压裂破裂演化方法与规律研究[D]. 太原:太原理工大学,2020:35−38. MAO Ruibiao. Research on the Law of Fracturing Evolution of Rock Mass by Real-Time Acoustic Emission Location Monitoring[D]. Taiyuan:Taiyuan University of Technology,2020:35−38.

[26] 张学朋,蒋宇静,王 刚,等. 基于颗粒离散元模型的不同加载速率下花岗岩数值试验研究[J]. 岩土力学,2016,37(9):2679−2686. [27] 黄彦华,杨圣奇,鞠 杨,等. 岩石巴西劈裂强度与裂纹扩展颗粒尺寸效应研究[J]. 中南大学学报(自然科学版),2016,47(4):1272−1281. HUANG Yanhua,YANG Shengqi,JU Yang,et al. Brazilian splitting strength of rock and particle size effect of crack propagation[J]. Journal of Central South University ( Natural Science Edition ),2016,47(4):1272−1281.

[28] 许尚杰,尹小涛,党发宁. 晶体及矿物颗粒大小对岩土材料力学性质的影响[J]. 岩土力学,2009,30(9):2581−2587. XU Shangjie,YIN Xiaotao,DANG Faning. Influence of crystal and mineral particle size on the mechanical properties of geotechnical materials[J]. Rock and Soil Mechanics,2009,30(9):2581−2587.

[29] 丛 宇,王在泉,郑颖人,等. 基于颗粒流原理的岩石类材料细观参数的试验研究[J]. 岩土工程学报,2015,37(6):1031−1040. CONG Yu,WANG Zaiquan,ZHENG Yingren,et al. Experimental study of fine-scale parameters of rock-like materials based on the principle of granular flow[J]. Chinese Journal of Geotechnical Engineering,2015,37(6):1031−1040.

[30] DU Kun,LI Xuefeng,TAO Ming,et al. Experimental study on acoustic emission (AE) characteristics and crack classification during rock fracture in several basic lab tests[J]. International Journal of Rock Mechanics and Mining Sciences,2020,133:104411.

[31] Federation of Construction Materials Industries. JCMS-III B5706. Monitoring method for active cracks in concrete by acoustic emission[S]. Japan:Federation of Construction Materials Industries,2003.

[32] OHNO K, OHTSU M. Crack classification in concrete based on acoustic emission[J]. Construction and Building Materials,2010,24(12):2339−2346.

[33] 张恒源,郭佳奇,孙飞跃,等. 不同试验条件和含水状态下花岗岩的声发射与破裂演化特征[J]. 高压物理学报,2022,36(6):77−91. ZHANG Hengyuan,GUO Jiaqi,SUN Feiyue,et al. Acoustic emission and fracture evolution characteristics of granites under different test conditions and water-bearing states[J]. Chinese Journal of High Pressure Physics,2022,36(6):77−91.

[34] LUO Song,GONG Fengqiang. Linear energy storage and dissipation laws of rocks under preset angle shear conditions[J]. Rock Mechanics and Rock Engineering,2020,53:3303−3323.

下载:

下载: