Well wall water leakage control technology of vertical well drilling method in coal mines based on grouting of ground directional drilling

-

摘要:

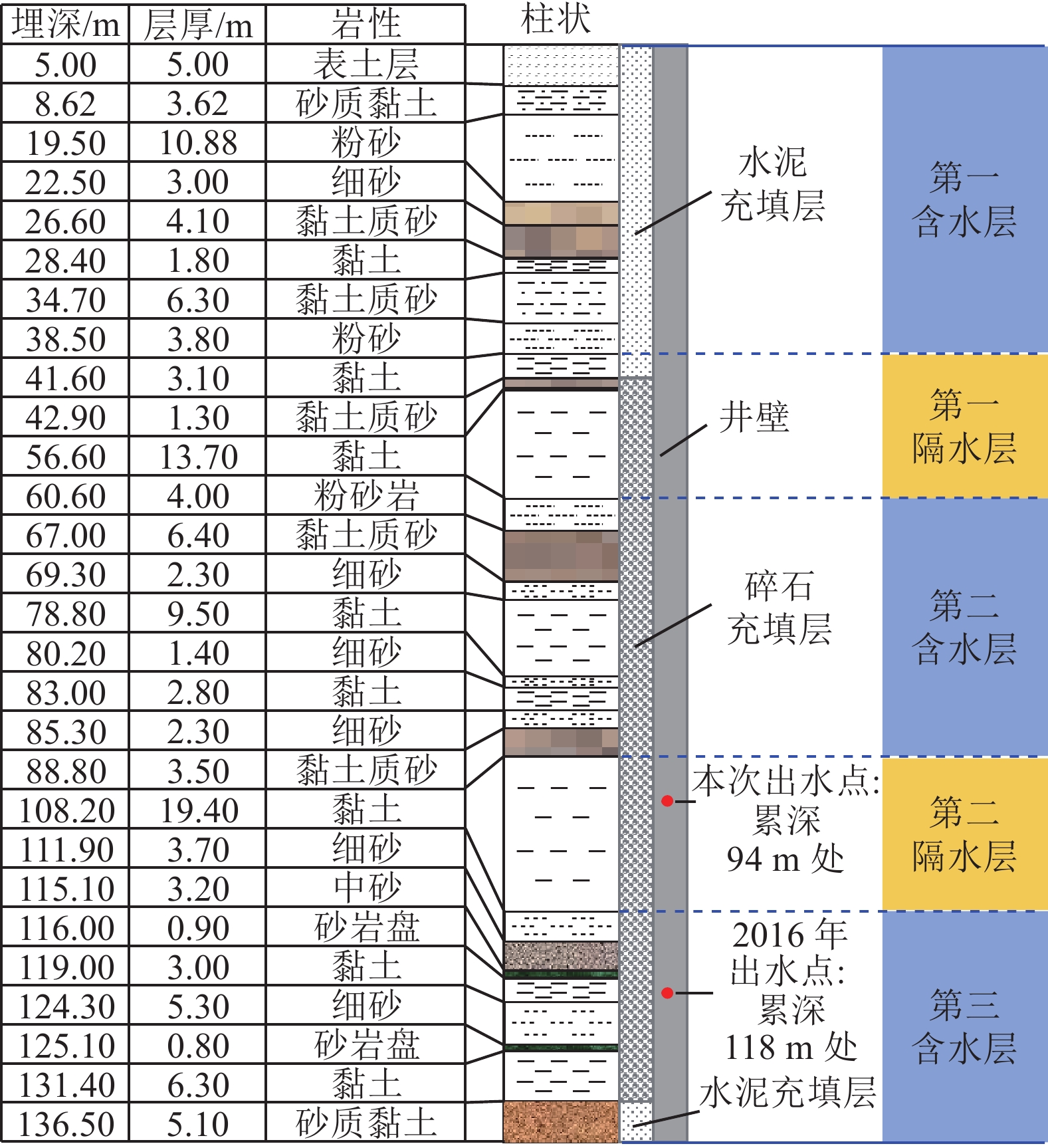

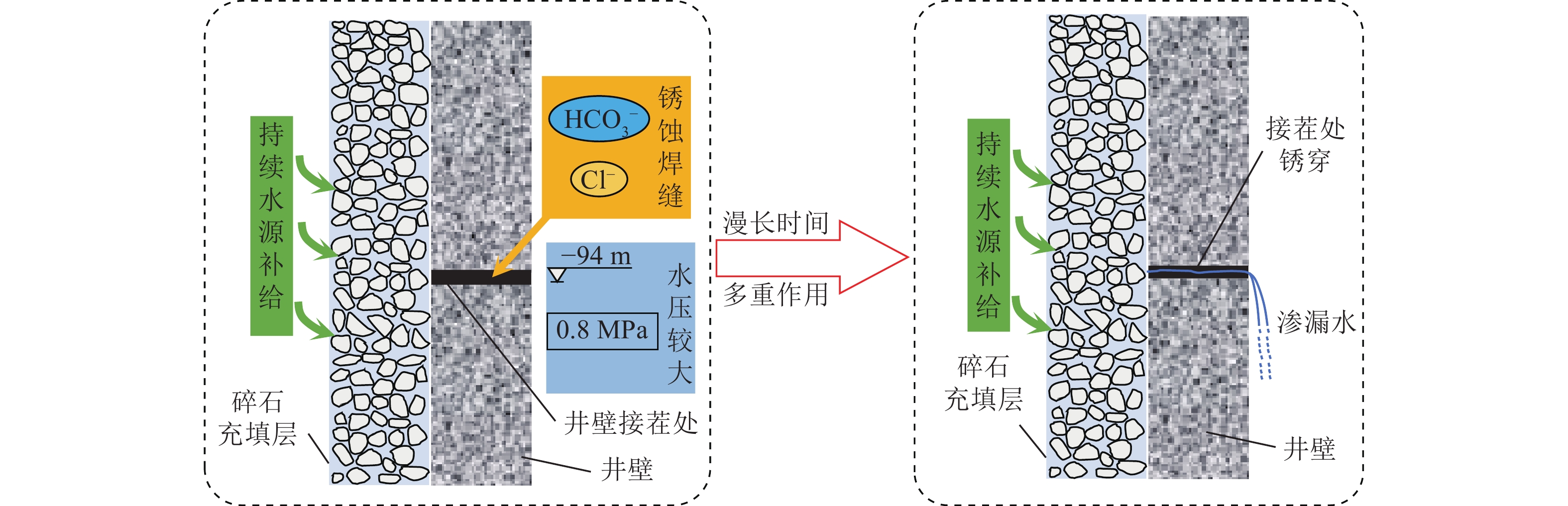

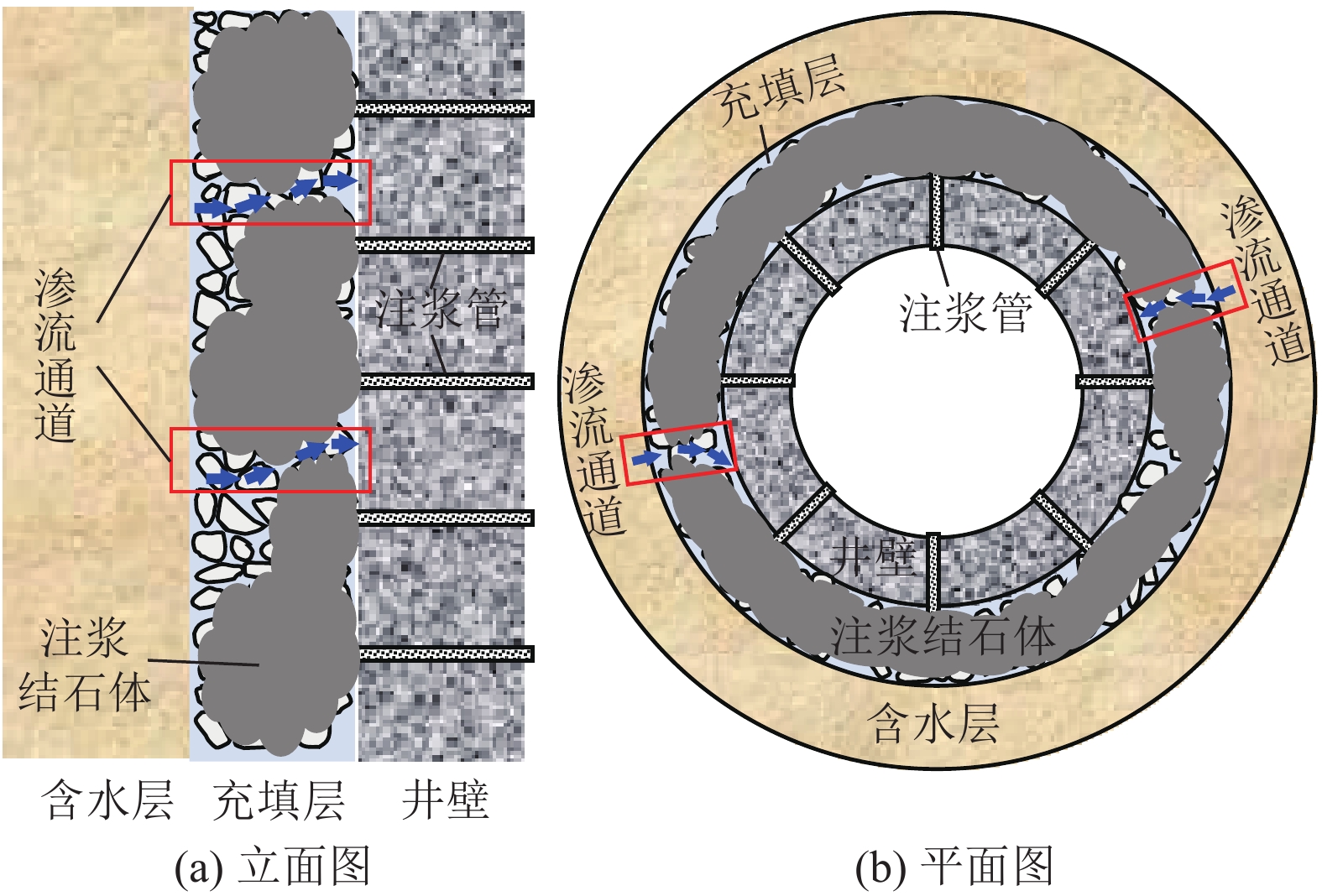

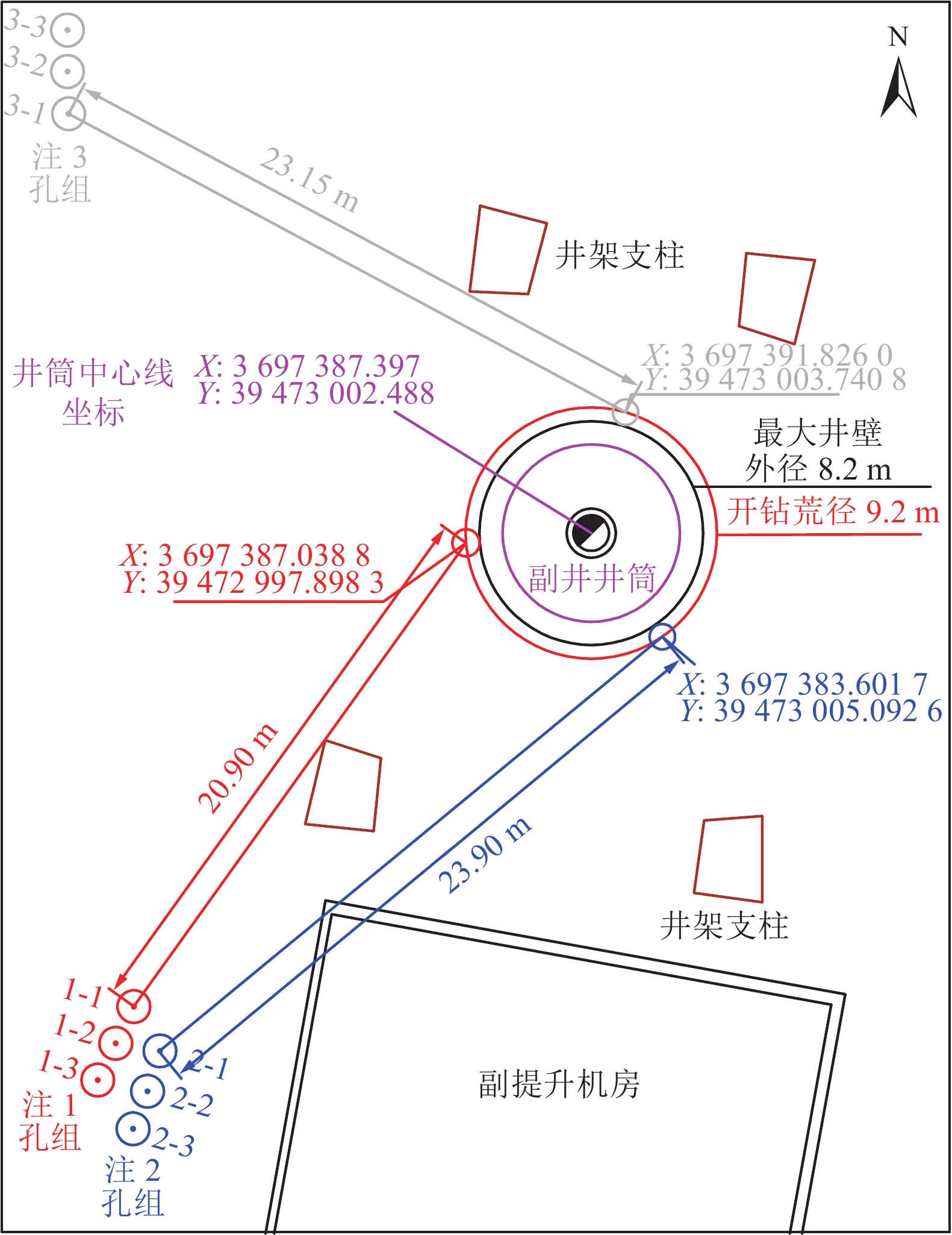

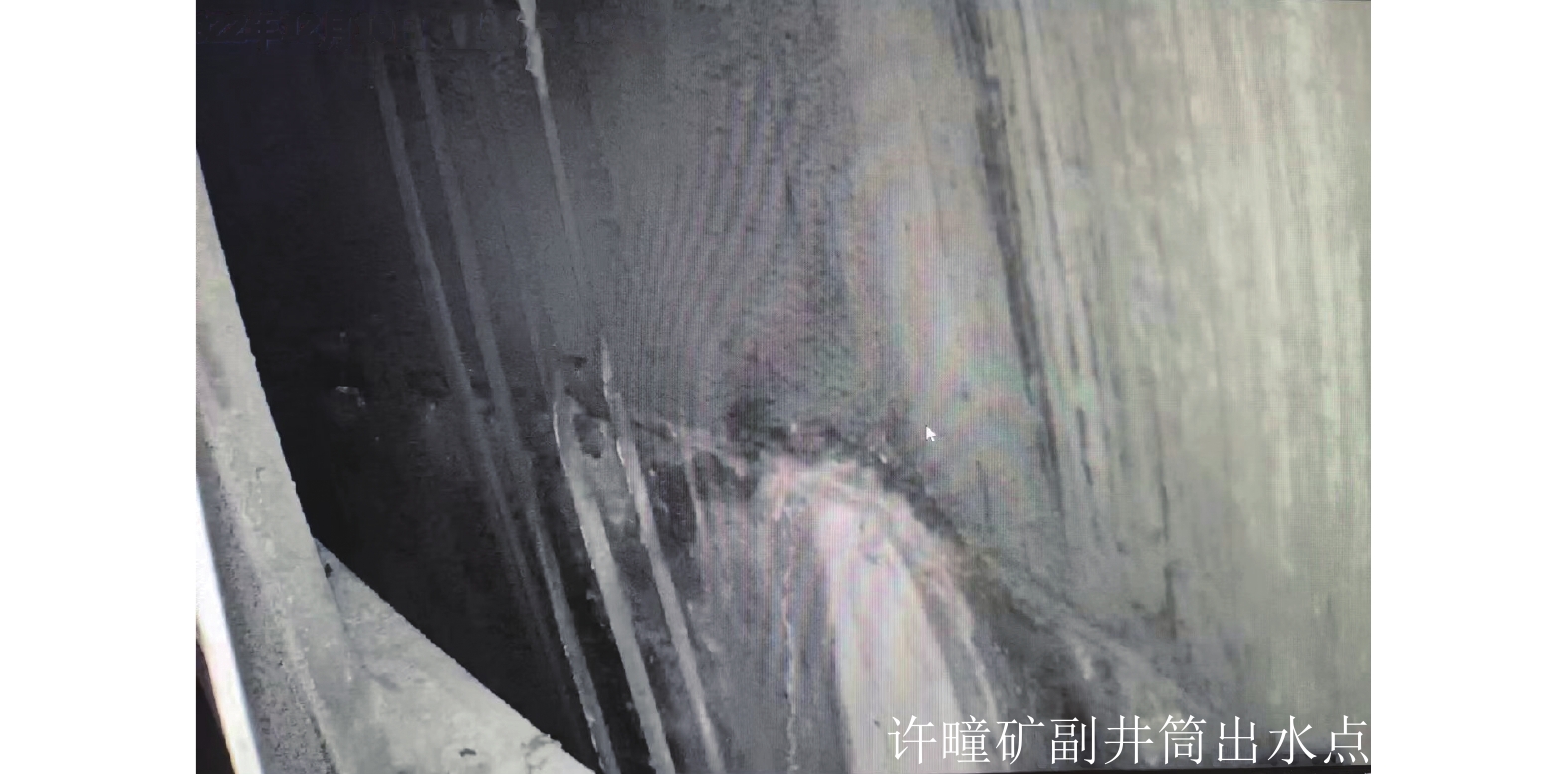

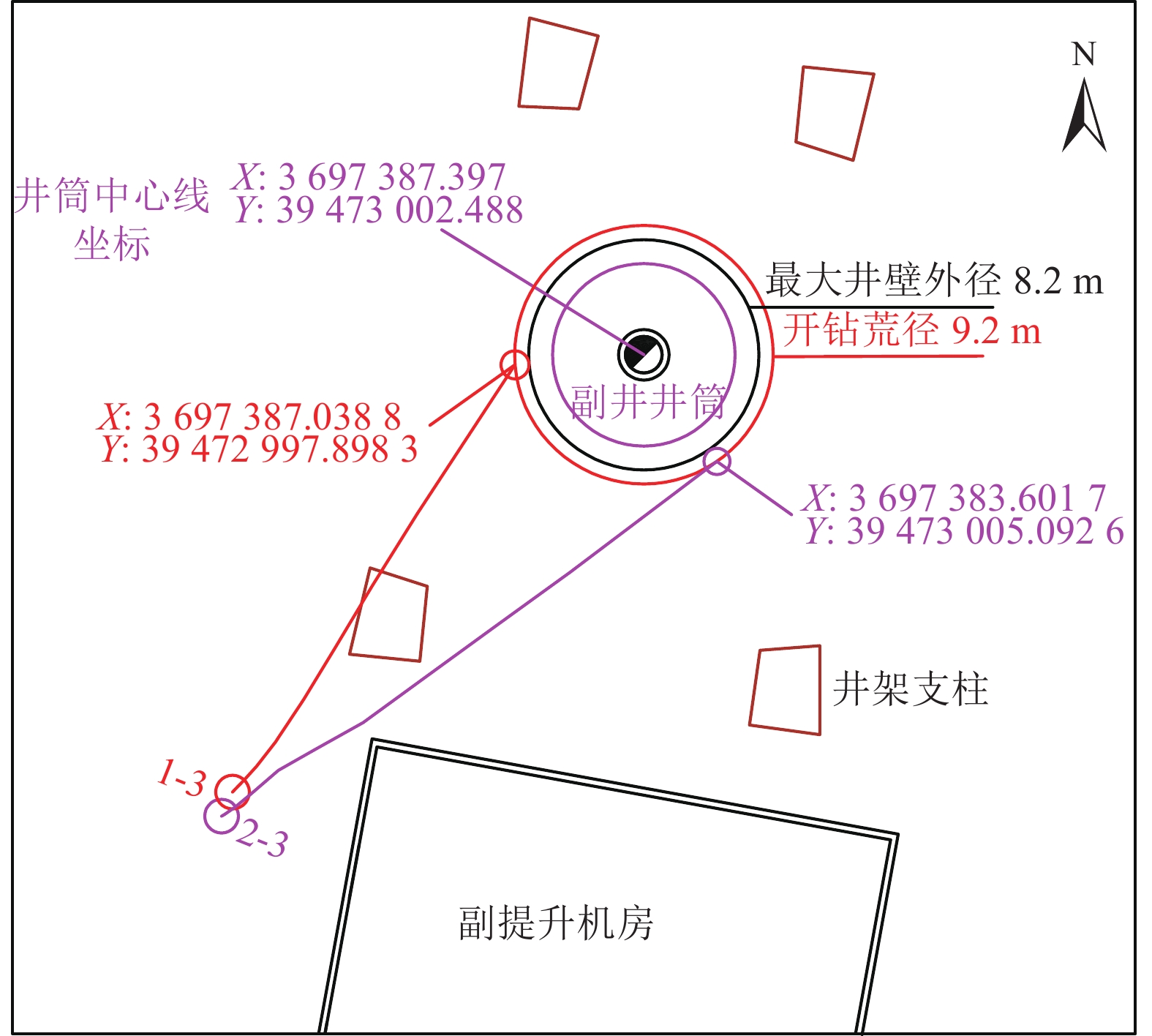

煤矿钻井井壁为单层结构,在深厚表土层段其渗漏水将严重威胁矿井安全生产,建井阶段井壁接茬部位若存在施工缺陷,则会导致地下水腐蚀锈穿接茬部位金属及焊缝,造成井壁渗漏水,若不及时治理,易引发突水溃砂而酿成淹井事故。为探寻一种行之有效的治理技术,以许疃煤矿副井井筒井壁渗漏水治理为工程背景,开展了煤矿钻井井壁渗漏水治理技术研究。首先,结合矿井水文地质特征等信息分析了钻井法单层井壁渗漏水致因,发现许疃煤矿副井井壁接茬处发生渗漏水的主要原因是地下水中的${\text{HCO}}_3^ - $、${\text{C}}{{\text{l}}^ - }$共同作用腐蚀锈穿井壁接茬部位后,含水层之间越流补给的高压地下水通过孔隙连通性良好的壁后碎石充填层流入井筒内;然后,对比分析了许疃煤矿副井井筒井壁渗漏水治理采用壁后注浆和地面钻孔注浆的可行性与安全性,发现在流砂层中对采用钻井法施工的钢筋混凝土单层井壁进行壁后注浆,安全风险较大,影响井筒正常提升,且存在再次发生渗漏水的风险,而采用地面定向钻孔注浆技术的注浆量大,壁后充填层碎石间孔隙可被水泥浆充分填充,改善井筒防渗和承载能力,且施工人员全程在地面操作,安全性好,不影响井筒正常提升;最后,提出了针对深厚表土层煤矿钻井井壁渗漏水治理的地面定向钻孔注浆技术并进行工程示范,2个钻孔共注入130.9 m3水泥浆,完全充填了94.00~131.40 m层段壁后充填层碎石间孔隙,顺利封堵了井下94 m处出水点,经现场长期观测,该段井壁未再渗漏水。研究结果表明,针对深厚表土层段煤矿钻井井壁渗漏水治理,采用地面定向钻孔注浆技术的治理效果良好,安全性高。研究成果可为深厚表土层煤矿钻井井壁渗漏水治理提供一定的参考。

Abstract:The coal mine drilling shaft wall is a single-layer structure, and water leakage in the deep alluvium will seriously threaten mine safety. If there are construction defects in the stubble part of the well wall at the construction stage, it will lead to groundwater corrosion and rust through the metal and the weld seam of the stubble part, resulting in water leakage from well wall, which, if not treated promptly, is prone to lead to a sudden water-sand inrush and flooding accidents. In order to explore an effective treatment technology, a research on the control technology of water leakage from the wall of coal mine drilling wells was carried out with the background of water leakage control of wall of sub-well of the Xutong Coal Mine. Firstly, the causes of water leakage from the single-layer well wall of the drilling method were analyzed with the information of hydrogeological characteristics of mine. It was found that the main reason of water leakage at the sub-well wall of Xutong Mine was that the high-pressure groundwater recharged from the aquifers flowed into the well through the gravel packing layer with great pore connectivity, after the corrosive effects of groundwater jointly penetrated the stubs of well walls. Then, the feasibility and safety of using post-wall grouting and ground drilling grouting for water leakage control in the wall of sub-well wall in Xutong Coal Mine were compared and analyzed. Post-wall grouting of reinforced concrete single-layer well walls constructed using the drilling method in fluvial sand layer was found to pose a high safety risk, affecting the normal lifting of wellbore and risking the reoccurrence of water leakage. Ground directional drilling grouting technology had a large grouting volume, and the pores in the gravel filling layer behind the wall can be fully filled by cement slurry, improving the leakage prevention and bearing capacity of the wellbore, and the construction personnel operated on the ground, which was safe and did not affect the normal lifting of the wellbore. Finally, the ground directional drilling grouting technology for water leakage control of coal mine wall in deep alluvium was proposed and demonstrated. A total of 130.9 m3 of cement slurry was injected into the two boreholes, which completely filled the pores space between the gravel of the filling layer behind the wall of the layer from 94.00-131.40 m, and successfully blocked the water outlet point at 94 m downhole. No further water leakage from this section of the well wall had been observed on site over a long period of time. The research results shown that, the ground directional drilling grouting technology had good control effect and high safety for the water leakage of coal mine drilling well wall in deep alluvium. The research results can provide a certain reference for the water leakage control of coal mine drilling well wall in deep alluvium.

-

Keywords:

- drilling wall /

- well wall stubble /

- water leakage /

- ground directional drilling /

- grouting

-

-

表 1 钻孔地面位置及落点位置坐标

Table 1 Coordinate of drilling ground position and landing point position

孔号 孔口位置 终孔落点 钻探工程量/m 孔口与终孔平面距离/m X/m Y/m X/m Y/m 垂深/m 注1-1 3697370.05 39472985.72 3697387.04 39472997.90 50.00 54.35 20.90 注1-2 3697368.71 39472985.06 3697387.04 39472997.90 77.00 81.27 22.38 注1-3 3697367.36 39472984.40 3697387.04 39472997.90 100.00 103.75 23.86 注2-1 3697368.43 39472986.68 3697383.60 39473005.09 50.00 55.71 23.90 注2-2 3697366.95 39472986.23 3697383.60 39473005.09 77.00 82.37 25.16 注2-3 3697365.58 39472985.69 3697383.60 39473005.09 100.00 104.61 26.48 注3-1 3697402.76 39472983.33 3697391.83 39473003.74 50.00 55.37 23.15 注3-2 3697404.31 39472983.29 3697391.83 39473003.74 77.00 81.88 23.96 注3-3 3697405.82 39472983.61 3697391.83 39473003.74 100.00 104.05 24.78 表 2 钻探工程量

Table 2 Drilling quantities

孔号 钻探深度/m 套管下入深度/m 一开

ø216 mm

孔径二开

ø152 mm

孔径终孔

孔深一开套管ø177.8 mm×8.05 mm 二开套管ø127 mm×6.5 mm 2-3 44.50 94.92 101.00 38.75 94.92 1-3 50.00 85.91 94.30 43.45 85.91 合计 — — 195.30 82.20 180.83 表 3 注浆工程量

Table 3 Grouting quantity

孔号 注浆量/

m3水泥用

量/t水灰质

量比相对密度/

(g·cm−3)停注原因 2-3 125.50 94 1.0 1.5 表头压力达0.5 MPa 1-3 5.40 4 1.0 1.5 表头压力达0.5 MPa 合计 130.90 98 — — — -

[1] ZHAO X D,ZHOU G Q,ZHAO G S,et al. Fracture controlling of vertical shaft lining using grouting into neighboring soil deposits:a case study[J]. Soils and Foundations,2017,57(5):882−891. doi: 10.1016/j.sandf.2017.08.018

[2] 岳宁,官云章,庞世界,等. 副斜井出水涌砂原因分析及抢险治理技术研究[J]. 煤炭工程,2018,50(12):73−75. YUE Ning,GUAN Yunzhang,PANG Shijie,et al. Causes analysis of sand and water inrush in an auxiliary inclined shaft and study on the emergency management technology[J]. Coal Engineering,2018,50(12):73−75.

[3] YU Q,YIN K X,MA J R,et al. Vertical shaft support improvement studies by strata grouting at aquifer zone[J]. Advances in Civil Engineering,2018,2018:5365987.

[4] 谢世平. 壁后引水注浆在井筒大涌水治理中的应用[J]. 采矿技术,2018,18(6):92−94. doi: 10.3969/j.issn.1671-2900.2018.06.030 XIE Shiping. Application of water diversion grouting behind the wall in the treatment of large water gushing in wellbore[J]. Mining Technology,2018,18(6):92−94. doi: 10.3969/j.issn.1671-2900.2018.06.030

[5] 仝洪昌,李国栋,闫昕岭. 立井井筒大段高、大涌水条件下的壁后注浆治水技术[J]. 建井技术,2008,29(3):7−9. TONG Hongchang,LI Guodong,YAN Xinling. Mine shaft back - grouting technology of water control in high sectional large water inrush in mine shaft[J]. Mine Construction Technology,2008,29(3):7−9.

[6] 张建,朱昌元. 深厚表土层井壁出水注浆加固技术研究[J]. 煤炭工程,2019,51(1):40−43. ZHANG Jian,ZHU Changyuan. Study on grouting reinforcement technology of shaft lining water gushing in deep and thick overburden[J]. Coal Engineering,2019,51(1):40−43.

[7] 惠金卫,马小卫,王言龙,等. 煤矿井筒井壁长跨度渗淋水壁后注浆治理措施[J]. 能源技术与管理,2022,47(5):18−21. HUI Jinwei,MA Xiaowei,WANG Yanlong,et al. Grouting treatment measures behind walls against long span leaching in coalmine shafts and walls[J]. Energy Technology and Management,2022,47(5):18−21.

[8] 张惠武,杨天亮,张建群. 深立井大突水淹井静水抛碴注浆堵水施工实践[J]. 中国矿山工程,2015,44(1):45−47. ZHANG Huiwu,YANG Tianliang,ZHANG Jianqun. Practice of blocking up water by dumping waste rocks and grouting in deep and flooded shaft[J]. China Mine Engineering,2015,44(1):45−47.

[9] 庞世界,钱自卫,蔡逢华,等. 井筒出水涌砂灾害机理及防治[J]. 建井技术,2019,40(3):41−44. PANG Shijie,QIAN Ziwei,CAI Fenghua,et al. Mechanism and prevention of water inflow and sand gushing in mine shaft[J]. Mine Construction Technology,2019,40(3):41−44.

[10] 姚直书,薛维培,陈廷学. 深厚冲积层钻井井壁渗漏水机理和注浆技术探讨[J]. 煤炭科学技术,2015,43(S1):1−4. YAO Zhishu,XUE Weipei,CHEN Tingxue. Discussion on mechanism of water leakage and grouting technology of drilling shaft lining in deep alluvium[J]. Coal Science and Technology,2015,43(S1):1−4.

[11] 刘孝孔,绪瑞华,赵艳鹏,等. 邻近厚松散层既有立井井筒地面注浆地层加固技术[J]. 煤炭科学技术,2022,50(7):127−134. LIU Xiaokong,XU Ruihua,ZHAO Yanpeng,et al. Ground grouting stratum reinforcement technology for thick loose layer adjacent to existing shaft[J]. Coal Science and Technology,2022,50(7):127−134.

[12] 吴昌文. 地面注浆封堵松散层段井筒涌水[J]. 煤田地质与勘探,1997,25(1):40−43. WU Changwen. Controlling the water inrush from loose layers in shaft by grouting from land surface[J]. Coal Geology & Exploration,1997,25(1):40−43.

[13] 张小青,杨维山,何艳录. 地面注浆堵水在鸣山矿井筒的应用[J]. 江西煤炭科技,2004(3):11−12. doi: 10.3969/j.issn.1006-2572.2004.03.006 ZHANG Xiaoqing,YANG Weishan,HE Yanlu. The application of face grouting to exclusion of water in MingShan Mine’s shafts[J]. Jiangxi Coal Science & Technology,2004(3):11−12. doi: 10.3969/j.issn.1006-2572.2004.03.006

[14] 田景对,李昌同. 地面注浆技术在治理井筒破裂中的应用[J]. 探矿工程(岩土钻掘工程),2003,30(2):29−31. TIAN Jingdui,LI Changtong. Application of ground grouting technique in treatment of broken on shaft face[J]. Exploration Engineering (Drilling & Tunneling),2003,30(2):29−31.

[15] 程桦,彭世龙,荣传新,等. 千米深井L型钻孔预注浆加固硐室围岩数值模拟及工程应用[J]. 岩土力学,2018,39(S2):274−284. CHENG Hua,PENG Shilong,RONG Chuanxin,et al. Numerical simulation and engineering application of grouting reinforcement for surrounding rocks of chamber in deep of 1 000 m by L-shaped boreholes[J]. Rock and Soil Mechanics,2018,39(S2):274−284.

[16] 荣传新,武汉,彭世龙,等. 千米深井L型钻孔地面预注浆岩体可注性研究[J]. 安徽理工大学学报(自然科学版),2018,38(1):1−7. RONG Chuanxin,WU Han,PENG Shilong,et al. Study on the grouting of rock mass in kilometer deep well by surface ground pre-grouting of L type drilling[J]. Journal of Anhui University of Science and Technology (Natural Science),2018,38(1):1−7.

[17] 袁辉,邓昀,蒲朝阳,等. 深井巷道围岩L型钻孔地面预注浆加固技术[J]. 煤炭科学技术,2014,42(7):10−13,17. YUAN Hui,DENG Jun,PU Chaoyang,et al. L type borehole ground grouting reinforcement technology of surrounding rock in deep mine roadway[J]. Coal Science and Technology,2014,42(7):10−13,17.

[18] 孔令健,姜春露,郑刘根,等. 淮北临涣矿采煤沉陷区不同水体水化学特征及其影响因素[J]. 湖泊科学,2017,29(5):1158−1167. doi: 10.18307/2017.0513 KONG Lingjian,JIANG Chunlu,ZHENG Liugen,et al. Characters of hydrochemistry and their influenced factors of different waters in the Linhuan coal mining subsidence area of Huaibei City[J]. Journal of Lake Sciences,2017,29(5):1158−1167. doi: 10.18307/2017.0513

[19] 罗通,李俊,赵成洲,等. 许疃矿深层煤系水水化学成分演变规律与水环境质量评价[J]. 安徽农学通报,2022,28(3):140−143,163. doi: 10.3969/j.issn.1007-7731.2022.03.043 LUO Tong,LI Jun,ZHAO Chengzhou,et al. Chemical composition evolution and water environment quality evaluation of deep coal water in Xutuan mine[J]. Anhui Agricultural Science Bulletin,2022,28(3):140−143,163. doi: 10.3969/j.issn.1007-7731.2022.03.043

[20] 许立铭,董泽华,范汉香. 油气田产出水中CO2和HCO3对碳钢腐蚀的影响[J]. 天然气工业,1996,16(4):57-60. XU Liming,DONG Zehua,FAN Hanxiang. Effects of CO2 and HCO3 in produced water of oil and gas fields on corrosion of carbon steel[J]. Natural Gas Industry,1996,16(4):57-60.

[21] 梁平,李晓刚,杜翠薇,等. Cl-对X80管线钢在NaHCO3溶液中腐蚀性能的影响[J]. 北京科技大学学报,2008,30(7):735−739. LIANG Ping,LI Xiaogang,DU Cuiwei,et al. Influence of chloride ions on the corrosion resistance of X80 pipeline steel in NaHCO3 solution[J]. Journal of University of Science and Technology Beijing,2008,30(7):735−739.

[22] 周建龙,李晓刚,杜翠薇,等. X80管线钢在NaHCO3溶液中的阳极电化学行为[J]. 金属学报,2010,46(2):251−256. ZHOU Jianlong,LI Xiaogang,DU Cuiwei,et al. Anodic electrochemical behavior of X80 pipeline steel in NaHCO3 solution[J]. Acta Metallurgica Sinica,2010,46(2):251−256.

-

期刊类型引用(13)

1. 李垂宇,侯俊领,黄童李,黄甫豪,王振亚. 预应力锚杆在拉拔试验过程中的力学分析. 低温建筑技术. 2025(01): 72-74 .  百度学术

百度学术

2. 刘泉声,刘滨,唐彬,康永水,卢海峰,朱元广,黄兴,潘玉丛,邓鹏海,孙磊,唐永志,卢兴利,张程远,余宏淦,李培涛,雷一鸣,贾浩男. 煤矿深部巷道碎胀大变形灾害控制及大变形灾变环境下TBM快速成巷技术. 煤炭学报. 2025(01): 224-244 .  百度学术

百度学术

3. 赵能,唐彬,张大欢,胡阳,王逸洋,谢凯. 基于黏聚力模型的螺纹钢锚杆拉拔数值模拟. 煤矿安全. 2024(02): 141-146 .  百度学术

百度学术

4. 赵能,陶文斌,沈仁为,胡阳,李宏亮,唐彬. 锚杆拉拔数值模拟试验研究. 福建建材. 2024(01): 10-13 .  百度学术

百度学术

5. 杨林,朱训国,夏洪春,杨帅. 拉压复合型锚杆锚固机理的数值及模型试验应用研究. 西安理工大学学报. 2024(01): 132-142 .  百度学术

百度学术

6. 段勇信,袁玉福,景小键. 松散软弱围岩巷道锚杆支护失效机理及协同支护研究. 内蒙古煤炭经济. 2024(05): 67-69 .  百度学术

百度学术

7. 袁维,王立言,裴子豪,孙瑞峰,王伟. 分级侧向膨胀型锚杆结构力学性能及锚固机理. 地下空间与工程学报. 2024(03): 868-876 .  百度学术

百度学术

8. 杜佳敏,何川,汪波,徐国文,陈旭,徐昆杰. 隧道斜向超前系统锚杆支护效果及承载规律. 隧道建设(中英文). 2024(08): 1617-1631 .  百度学术

百度学术

9. 郝英豪,韩昌良,刘计寒,杨厚强,白刚,宋凯,杨浩兴,魏民. 强采动巷道破碎顶板全长锚固案例分析. 煤炭技术. 2024(11): 6-11 .  百度学术

百度学术

10. 杜志刚,陶亚文,高富强,杜艳强. 玄武岩纤维筋的力学特性与破坏模式试验研究. 矿产勘查. 2023(02): 304-309 .  百度学术

百度学术

11. 王想君,李英明,赵光明,孟祥瑞,王艺,程详. 全长锚固锚杆支护软岩巷道围岩承载结构力学响应解析. 煤炭科学技术. 2023(10): 24-34 .  本站查看

本站查看

12. 石垚. 预应力锚杆支护应力场叠加效应试验研究. 能源与环保. 2023(11): 51-60 .  百度学术

百度学术

13. ZHU Zheng-de,SHU Xiao-yun,LI Zhe,TIAN Hong-ming,TIAN Yun. Stress analysis of full-length grouted bolt under shear deformation of anchor interface. Journal of Mountain Science. 2022(11): 3286-3301 .  必应学术

必应学术

其他类型引用(14)

下载:

下载: